A surface grinder will be useful for those craftsmen who work with wooden blanks and make furniture.

The homemade product is intended for sanding large surfaces made of wood or plywood: it can be a furniture board, a tabletop, etc.

In addition, you can use a homemade device for processing sheet metal blanks.

In this article we will tell you how to make a simple surface grinder from an angle grinder with your own hands.

What should such a machine be like?

To polish a car, low speeds are required - approximately 1000-2000 rpm. But drills have a power of up to 3000 rpm, and the well-known “grinder” has even higher power - up to 11,000 rpm. This is a rather risky frequency at which varnish and paint crack and burn hopelessly, completely deteriorating. That's why the speed must be adjusted.

You will have to hold the polishing machine for quite a long time, so it should be comfortable and light. In this regard, the winner is the “grinder”, in which the rotating working shaft serves at an angle of 900; it is convenient for the master to hold it. It’s not for nothing that store-bought polishing machines have a voluminous handle that allows you to change the grip. It also has a special lock that blocks the power button, which greatly simplifies the work.

To allow birds to immigrate to the United States, street lights in cities are dimmed.

Cake “Stripe” with butter cream and vanilla pudding: a no-bake dessert

Leo and 2 other zodiac signs, absolutely indifferent to any reproaches addressed to them

Making a grinder from a computer hard drive + (Video)

Any old hard drive can be converted into a miniature grinding machine. To do this you need to follow these steps:

- completely disassemble the hard drive and remove from the case everything that is located to the left of the magnetic disks;

- cut out a working circle from sandpaper, make a hole in the center of the circle for the spindle;

- stick several strips of double-sided tape onto the rotating disk of the hard drive and secure it with sandpaper;

- make a protective screen to protect the eyes from the possible ejection of the manufactured sanding disc;

- connect the finished design to the power supply from the computer and use it.

Of course, this design does not have high power, but it is quite possible to sharpen a small knife or scissors.

Drill

It is easy and quick to replace the polishing machine with an electric drill, but you will have to use it carefully. Buy a simple adapter to secure the plates. This option has disadvantages: at high speeds you can accidentally “boil” the paint and it is inconvenient to use. Holding a drill straight in front of you for several hours is, to put it mildly, inconvenient. If you immediately give exorbitant speed, the varnish and paint “boil”, and the polish scatters and foams.

How to choose a tape?

The sanding belt is one of the main components of a homemade sanding machine. The main indicator of the quality of a sanding belt is the size of the abrasive grains. They are responsible for the quality of material grinding. Belts can be coarse-grained, medium-grained or fine-grained. The abrasive grains themselves are artificial minerals with a high degree of hardness. Also, the tape material should not be too hard. Such tapes are often prone to breaks. You can also use rolls of regular sandpaper for a homemade sanding machine.

So, you can make a belt sander from an angle grinder without any problems and quite quickly with your own hands. And considering the cost of ready-made grinding machines, making them yourself is quite a relevant and reasonable solution.

To learn how to make a belt sander from an angle grinder, see the video below.

Bulgarian

Using the so-called “grinder” you can also polish a car, but the speed of this tool is too high. Take for modifications only models that have a speed control function. True, at low speeds the torque decreases sharply. If your grinder is small, then the polishing disc will constantly “freeze” or even stall.

Black is a mysterious color: how people dye their hair, depending on their personality type

Became brunettes: Lady Gaga and Margot Robbie are no longer blondes (photo)

Alexander Myasnikov decided to refute popular opinions about the dangers of tea and coffee

But it is comfortable to hold, just like a professional polishing machine. Some manage to mix a drill with an angle grinder gearbox.

To do this, cut off the anchor from the angle grinder, and use ordinary PVC plastic pipes as an adapter.

Some people make an adapter printed on a 3D printer to the desired size, but this is not for everyone.

All that remains is to put on the polishing sponge and get to work. This is the most perfect homemade “creation”, which, by the way, is relatively easy to make.

What is a grinder made of?

You can create your own belt sanding machine based on an industrial design, which involves moving the belt over the flat surface of the work table with the abrasive part outward. At the same time, the homemade device will differ from its branded counterpart in its larger size and stationary installation. For these works you will need an electric motor, for example, from a washing machine, a wooden or metal panel, chipboard, material for abrasive tape, glue.

Since a transmission in the form of a gearbox or belt drive significantly complicates the design of the tool in question, they try not to use it on homemade models. To do this, you can equip the device with an electric motor with a power of 2-3 kW with a rotor speed of 1500 rpm.

In this case, with a drive shaft radius of 10 cm, the belt will move at a speed of about 15 m/s. It should be taken into account that the design in question does not provide for adjustment of the belt rotation speed. However, it is possible to regulate the degree of tension due to the fact that the tension shaft, rotating on bearings to reduce friction, is mounted on a fixed axis, which can be shifted relative to the work table. The drive shaft is fixed to the electric motor shaft.

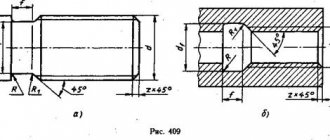

You can make a work table for such a grinding machine yourself from a wooden beam or sheet metal. It should be borne in mind that metal options allow you to process more complex objects. The dimensions of the working table of the tool in question are determined based on the dimensions of the belt and the distance between the axes of the shafts, as well as its purpose. Bevels should be made near the shafts in the work table in order to ensure smooth contact of the tape with it.

Drums can also be made by yourself. Chipboard can be used as the starting material for these elements. Squares with side lengths of 20 cm are cut out of the slab in such a quantity that their total thickness when superimposed on each other is about 25 cm. Then these blanks must be turned into disks with a diameter of 20 cm by processing on a lathe. You can process the cut fragments separately, but it is more convenient to grind them all at once, placing them on the axle and clamping them. It should be taken into account that the drums must have edges of a larger diameter in comparison with the central part to automatically hold the tape.

It is not a machine that polishes, but skillful hands!

The motorist needs to remember: having the most expensive and sophisticated polishing machine does not solve the repair issue. You still have to put your hands into it, whether with or without the machine. If you are physically developed and want to apply wax polish to your body, then just pick up a soft cloth and start working. This way you won’t waste time making accessories, and will reduce the risk of damaging your car to zero. True, you will have to work hard, but you will definitely be satisfied with the result.

Found a violation? Report content

Types of polishes

Even the most reliable paint coating sooner or later fades - because of this, chips and cracks appear on the surface of the car body. It is these that polishing destroys, returning your “iron horse” to its original appearance. Of course, to make the game worth the candle, you need to choose the right polish and paste:

Car body polishing products

- Abrasives. Polishing using these substances removes abrasions and scratches from the surface of the car. Remember that such products also destroy a small layer of varnish, so after polishing the car it needs to be restored. Of course, you should not overuse abrasive polishing - too frequent use of such products can destroy the paintwork of the car body;

- Non-abrasive substances. Using such products, protective polishing is carried out. In order for the car to look presentable, such a procedure must be carried out at least once a year;

- Silicone polishes. These substances fill the smallest cracks in the body and give the car a pleasant shine. They are often used in combination with abrasives to secure the polish.

Important points when constructing a pendulum machine

The type of tool under consideration belongs to the category of unsafe, therefore, when constructing the equipment, the following main points are taken into account:

The manufacture of the frame is the basis responsible for the reliability of the installation. It is impossible to save money on the manufacture of the frame, therefore only iron materials are used, the thickness of which is more than 2 mm. Frame - the design of this part can be different, but the most important thing is to ensure the mobility of the cutting tool. This is achieved through the introduction of various materials, but in any case, you need to think carefully about the quality of the hinge joint, because your life depends on it. It is better to spend more material, but make a high-quality and non-hazardous cutting machine. Tool fastening - the angle grinder is fixed specifically to the moving part. At the same time, the fixation must be as reliable and high quality as possible. When working with an angle grinder, “reverse impacts” may occur, which are unsafe because the machine may simply be damaged, and the master who does the manipulation will suffer as a result. Anticipate the improvement of the counterweight - this is a small but important element that allows the tool to return to its initial position when unnecessary

This will eliminate the possibility of damage to parts of the human body. A protective casing - it must be present, and it does not matter what design of the machine is invented, but using the device without a protective casing attached is strictly contraindicated. The presence of a ruler - this will increase the accuracy of the work performed, which is important when cutting such parts , like tiles, ceramics, and metal. A starter is also a kind of device that affects safety. The control button must be located in specific proximity to the master performing the work

This will allow you to quickly react at the right moment by turning off the power supply to the instrument.

In addition to the options when the machine has a moving part, there are also methods for producing cutting devices with the tool located at the bottom of the bed or workbench table top. But this option is only suitable for cases when sawing wood is planned. Below is an example of how to make a home sawmill from a grinder quickly and easily. Details on making home sawmills can be found in this article.

READ How to properly install a diamond blade on an angle grinder

Machine with shock absorbers

A reliable machine for a small grinder will be made from old car shock absorbers.

The principle of its operation is similar to the pendulum, but the design of the components is different, which allows you to adjust the reach of the cutting power tool along the guide. The manufacturing procedure is as follows:

For the machine you need to find two old, but working shock absorbers from a passenger car.

Shock absorbers have a weak point - the thin walls of the body. They cannot be a load-bearing structure, so brackets will need to be made. First, two identical plates are cut and holes are drilled in the center for a bolted connection. 8 half rings are cut out of a pipe whose diameter corresponds to the thickness of the shock absorber body. The blanks are welded against each other to the plates.

A rectangular frame frame is welded from a profile pipe. The pendulum stand is welded from two corners.

On the side shelves of both corners of the rack, it is unlikely that adjustment holes are drilled strictly opposite each other. Car shock absorbers are fixed in the bracket with bolts, after which the entire assembly is secured with a pin in one pair of holes on the rack.

The finished machine can be painted. Next, a clamp for the grinder is made. The console is made from a piece of angle, securing it with nuts on the shock absorber rods. One end of the return spring is attached to the rack jumper. Its other end is fixed with a clamp to the edge of the upper shock absorber.

The grinder clamp consists of two parts. It is bent from a steel strip, giving the shape of the body of a power tool.

The angle grinder, clamped in the two halves of the clamp, is screwed onto the console. You need to adjust the offset right away. To do this, a stud is provided along the axis of the shock absorbers with two nuts, secured to the bracket and to the console.

The machine is ready. All that remains is to sew up the frame of the bed with a steel sheet, make a slot for the disk and secure a stop for workpieces or planks.

A homemade machine made from a grinder is not inferior in its characteristics to a factory-made design.

Remodeling household power tools

Almost every owner has an angle grinder. It can be used for rough finishing - cleaning rust from metal and walls before plastering. Not suitable for delicate work, for example, bodywork - the speed is too high. One careless movement and there is a hole in the car. If you equip it with a voltage regulator, which is found on professional models, then delicate grinding will be possible for a household angle grinder.

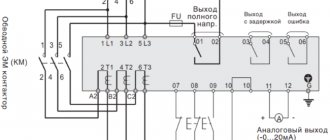

Anyone who has at least a little knowledge of radio engineering will assemble the device with their own hands. You will need running parts that can be easily purchased or soldered from old products. No explanation is needed for anyone who can read electrical diagrams.

Diagram of a homemade speed controller for an angle grinder.

The operating procedure is as follows:

- soldered using a printed circuit board or surface mounting;

- thyristors are installed on radiators;

- carry out testing with a 40–60 W light bulb (it should smoothly change brightness when turning the trimming resistor);

- After successful testing, the device is mounted under the tool housing.

The proposed circuit is simple; it is connected to the mains power supply of the angle grinder.

Materials and tools

In order to make a milling cutter based on a grinder, you will need the following tools and materials:

- The angle grinder is in working condition, the absence of any defects or malfunctions is mandatory;

- welding machine (if you are going to use metal);

- fasteners;

- screwdriver/screwdriver;

- electric drill;

- building level;

- ruler (tape measure) and pencil;

- square;

- a sheet of plywood or chipboard 1 cm thick or a sheet of metal approximately 3 mm thick;

- spanners;

- jigsaw or saws for working with wood/metal;

- metal corners or blocks of dense wood (5x5cm);

- punch;

- set of hex keys;

- file, coarse and fine-grained sandpaper.

Electrical equipment required to connect the engine to the network

In my case, it was planned to connect to a 220 V network, and therefore a capacitor was needed. According to the rules, to start a motor on a single-phase network, 10 microfarads per 100 W of power are required. I found 3.9 uF = 10% capacitors in the garage. Therefore, I took two barrels, in total it turned out to be almost 8 microfarads, which I connected in parallel.

A wire from a regular wall lamp with a switch was also used.

Capacitors connected in parallel, ready for connection