The correspondence between the length of a nail and its diameter is presented in the table.

| Rod diameter | Nail length | ||

| Nominal value | Maximum deviation | Nominal value | Maximum deviation |

| 4,5 | ±0,8 | 120,0 | ±4,0 |

| 4,0 | 120,0 | ||

| 100,0 | |||

| 90,0 | |||

State Standard 9870 of 1961 established the following basic technical requirements for final products in the form of slate nails:

- the material used to manufacture these products should be low-carbon, light-colored, thermally untreated steel wire that complies with the standards of GOST 3282-84;

- The zinc coating layer must be continuous, without thickening, cracking, or omissions that can be seen without the use of magnifying devices. It is allowed to have small longitudinal marks, marks from split dies, and also from clamps on the supporting surfaces of nail heads and on their rods coated with a layer of the Zn element.

- testing the quality of galvanizing is carried out by immersing nail heads twice for 1 minute in a solution of copper sulfate. As a result of this procedure, the integrity of the protective layer should be preserved;

- deviation of the coaxiality of the body of the nail head and its rod is allowed by no more than 1 mm;

- the sharpening angle is equal to or less than 40°.

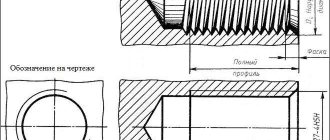

Screw nails drawing 7811-7070

Screw nails (their other name is twisted) are used for assembling critical wooden structures that are subject to increased requirements:

- by strength level;

- according to the degree of resistance to bending loads.

A special feature of these products is the incomplete screw.

The following fact is noteworthy. If we compare structures assembled with standard construction nails and with screw-type nails, the strength of the latter is (attention) four times higher! This phenomenon is explained by the peculiarity of the installation of screw nails: during the process of driving into the attached object and into the mounting base, these elements are rotated and screwed into both materials due to the turns of the thread. This ensures a more secure fastening.

Technical characteristics of screw nails made according to drawing 7811-7070 are presented in the table.

| Rod diameter (designation d) | Nail length (parameter L) | Cap height (designation h) | Cap diameter (parameter D) |

| 3,5 | 90,0; 90,0; 70,0; 65,0; 60,0;50,0 | 1,0 | 8,0 |

| 3,4 | 90,0; 80,0; 75,0; 70,0; 65,0; 60,0; 55,0; 50,0; 45,0; 40,0; 30,0 | 1,0 | 8,0 |

| 3,0 | 80,0; 70,0; 65,0; 60,0;50,0; 40,0; 35,0; 30,0; 25,0 | 0,8 | 7,0 |

| 2,8 | 70,0; 65,0; 60,0; 55,0; 50,0; 40,0;30,0 | 0,8 | 6,8 |

| 2,5 | 60,0; 55,0; 50,0; 45,0; 40,0; 30,0 | 0,7 | 6,3 |

Steel wire with a square cross-section is used as a raw material for the production of these products. Available with or without coating.

Using a gun to secure fasteners

The most common type of fastener is construction nails, which come in different types according to the degree of protection:

- black nails without a protective layer;

- galvanized, coated with a layer of zinc;

- copper-plated, protected from water and steam;

- brass plated, absolutely resistant to corrosion;

- chrome plated, characterized by optimal cost.

To increase productivity and speed of nailing, construction guns are used to help automate the installation process. In this case, it is necessary to select the correct mode of operation of the device and ensure full compliance with safety measures.

Screw nails drawing 7811-7335

Unlike the products of the previous version, the threads of screw nails made according to drawing 7811-7335 almost reach the head.

Fasteners of this type are used for:

- interior and exterior decoration of buildings;

- carrying out work related to the assembly of roofing structures;

- manufacturing:

- containers with increased strength characteristics;

- Euro pallets;

- large containers made of wood.

The table presents the values of the technical characteristics shown in the drawing.

| Rod diameter (parameter d) | Nail length (designation L) | Head height (parameter h) | Cap diameter (designation )D |

| 5,0 | 140,0 | 1,2 | 11,0 |

| 4,0 | 120,0; 110,0 | 1,0 | 8,0 |

| 3,4 | 90,0; 70,0; 60,0 | 7,0 | |

| 3,0 | 80,0; 70,0 | 0,8 | 6,5 |

| 2,5 | 60,0; 50,0 | 0,7 | 5,4 |

Thanks to screw nails made according to drawing 7811-7335, the structure assembled using them has:

- increased strength;

- resistance to bending external loads.

Advantages of using fasteners when carrying out various works

By looking at the proposed photos of nails, you can visually evaluate their characteristics and choose the best fastening option for independent use.

In addition, when choosing the necessary accessories for connecting different elements and constructing structures, it is necessary to take into account the advantages of their use:

- universal fastening of homogeneous or different materials in the process of carrying out all kinds of work;

- correctly selected nails for their intended purpose can withstand different types of loads during operation;

- a wide range of fasteners offered, suitable for performing various work processes and procedures;

- ease of use and ease of installation with the ability to use not only a hammer, but also other tools;

- long service life of the connected structures and the fasteners themselves, provided they are chosen correctly.

Finishing nails, made according to drawing 7811-7035

This fastening element is easy to distinguish from other similar hardware. Its head has an unusual shape for a nail, close to cylindrical.

It is used where it is necessary to provide the created structure with an attractive appearance. The finishing nail should be driven in at an angle to the surface in areas where the finishing elements adjoin one another, convenient for hiding the head.

The dimensional characteristics of nails of this type look like this:

- length – 80.0; 70.0; 60.0; 55.0; 50.0; 45.0; 40.0; 35.0; 30.0; 25.0; 20.0;

- rod diameter – 3.1; 3.0; 2.7; 2.5; 2.4; 2.2; 2.0; 1.8:1.6; 1.4.

Description and possibilities of using fasteners

The price of nails set by manufacturers and sellers depends on their economic purpose and intended use. Such fasteners belong to metal products, as one of the most common hardware used in different stages of household work to connect different elements together.

In appearance, nails are a simple structure consisting of a head and a leg, necessary for connecting materials.

The main features of the practical use of the fastening element remain strong fixation and ease of installation during use.

Using a hammer, the nail is simply driven into the body of the materials and holds them in a fixed position due to the physical force of natural friction.

Answers to the questions 'long nail'

| Bolt | Threaded nail 4 letters |

| Gvozdok | (decreased) nail 7 letters |

| Pin | Nail without a head 5 letters |

| Screw | Not yet a screw, but no longer a nail 5 letters |

| Screw | Nail with curves 5 letters |

| Dowel | Thick nail for concrete 6 letters |

| Button | Nail with wide head 6 letters |

| Pilaf | “Nail” of the Uzbek table 4 letters |

| Spenek | Small thorn, rod, nail 6 letters |

| Parade | Military holiday nail 5 letters |

End connection of boards

There is another definition for such a connection - build-up. It is characterized by the fact that all parts are fastened together at the end part, thereby increasing the length of the whole part. Depending on the type of fastening, these end connections can withstand high loads in compression, tension and bending. An ordinary whole board here is in many ways inferior to a board obtained by extension.

The end connection of parts that resist compression can have a different design. The main feature of this connection is that each block has both an overlay and a groove, which are most often made equal in thickness and length. You can make an extension with a straight half-tree overlay, or you can make an end connection with an oblique overlay.

Compression Resistant Extension with Straight Half-Wood Overlay

Compression Resistant Extension with Oblique Overlay

If you are not sure of the strength of the future connection, you can further complicate it with spikes or various joints. Naturally, this connection requires additional adhesive fastening or fastening with nails and screws.

The end connection of parts that resists tension at the core of its design contains a lining in the lock. First of all, you need to outline the overlay. Then make a groove on one part and a protrusion on the other. It is this lock that will allow both halves to avoid separation.

Just like a compression-resisting joint, this type of joint can have a straight overlay and a miter overlay.

Straight Resistant Straight Overlay Extensions

Tension Resistant Extensions with Oblique Overlay

For additional fastening, you can use glue, nails or screws.

An anti-bending end connection is based on either a beveled cap or a stepped joint.

Bend-resistant extension with oblique joint

Bend-resistant extension with stepped joint

A feature of the first type of connection, where an oblique joint is used, is that the end sides of both parts are cut at an acute angle. At the same time, when cutting out the ends, you must maintain the cutting angle with nanometer accuracy.

The second type of connection is characterized by the fact that there are small grooves and tenons on the end sides of the parts.

Both of the listed types of connections must have a straight surface of the linings. Overlays with an oblique surface are used quite rarely, although they are not inferior in strength to straight ones. For additional fastening, glue, screws or nails can be used to the same extent.

Additional fastening of large beams used in the construction of houses can be metal or wood. Both hollowed out and inserted tenons are used as wooden fastenings.

Metal fasteners can be in the form of clamps or wrapped with thick wire. Fastening with bolts is often found.

Notch / mortise connections

A notch, mortise or groove connection is called a corner or median connection, when the end of one part is attached to the layer and another part. It is based on a butt joint with an end cut made in the face. Used in frame (house frames) or box (cabinets) connections.

Types of jack/punch connections

The main types of notch joints are the t-notch in the dark/semi-dark (often this term is replaced by the term “flush/semi-dark”), which looks like a butt joint, but is stronger, the corner notch (corner connection) in the quarter and the corner notch in the dark/semi-dark. A corner notch into a rebate and a corner notch into a rebate with darkness/semi-darkness are made in the same way, but the rebate is made deeper - two-thirds of the material is selected.

Carrying out cutting

1. Mark a groove on the front side of the material. The distance between the two lines is equal to the thickness of the second part. Continue the lines to both edges.

2. Using a thickness gauge, mark the depth of the groove between the marking lines on the edges. The depth is usually made from one quarter to one third of the thickness of the part. Mark the waste portion of the material.

3. Use a C-shaped clamp to securely fasten the part. Saw the shoulders on the outgoing side of the marking lines to the required depth. If the groove is wide, make additional cuts in the waste to make it easier to remove the material with a chisel.

Saw close to the marking line on the waste side, making intermediate cuts with a wide groove.

4. Using a chisel on both sides, remove excess material and check that the bottom is even. You can use a primer to level the bottom.

Use a chisel to remove waste, working from both sides, and level the bottom of the groove.

5. Check the fit; if the part fits too tightly, it may need to be trimmed. Check for squareness.

6. The notch connection can be strengthened in one of the following ways or a combination of them:

- gluing and clamping until the glue sets;

- screwing with screws through the face of the outer part;

- nailing at an angle through the face of the outer part;

- Nailing obliquely across a corner.

The notch connection is quite strong