To buy a new chain, or buy a new bar for a chainsaw, you need to tell the seller the size of your chain.

Even though many chainsaw owners have owned their saw for a long time, they still struggle with sizing correctly. Often, inexperienced sellers cannot properly select a chain and give the wrong size, which either leads to failure of the tire and sprocket, or you have to waste time returning the incorrectly selected chain.

Therefore, here are instructions for you on the correct selection of chains for chainsaws, please use them.

If you need to buy a new chain - what to look for

To choose a chain for your chainsaw, you need to know the pitch, shank thickness, length, cutting depth, type of links, as well as the type of sawing, material and sequence of teeth.

All these criteria have been discussed above. To avoid having to trust sellers, you need to understand each criterion and choose the right values for yourself. Saw accessories

You can learn from specialists how to choose the right saw set. At the same time, it is not necessary to look for them, since the material contains a video that tells in detail about the correct choice of chain. The choice is also influenced by price, which directly characterizes quality. The higher the price, the better the quality, but it doesn’t always make sense to purchase expensive devices. Saw sets are produced by various manufacturers, both branded (Shtil, Makita, Husqvarna) and little-known ones, including Chinese.

If you want to buy a good device that will serve you for at least 3 seasons, then it is better to buy expensive models. Cheap models are only worth using them on household units. After purchasing a new headset, you need.

Publications on the topic

Breather on a lawn mower, what is it and where is it located?

The chainsaw does not start - all the reasons and troubleshooting methods

How a chainsaw carburetor works (detailed description)

How to properly shorten a chain on chainsaws and features of the process

Tips and recommendations when choosing on Aliexpress

The Aliexpress marketplace offers a large assortment of saw chains from various manufacturers. These can be both popular brands and unknown manufacturers. Often, well-known companies such as Oregon or Husqvarna do not sell their products on this site. Therefore, the purchased product turns out to be a fake.

On Aliexpress, saw chains from unknown brands are inexpensive. It’s true that they don’t work for long. As a rule, they have to be sharpened very soon. Therefore, if you plan to use a chainsaw frequently, purchase a saw chain from an authorized dealer. In case of rare use for trimming small branches and twigs, you can use the products purchased on this site.

Partner

Partner recommends using only original chains when replacing this part. All chains from this manufacturer have a 3/8' pitch and a special low link profile. This shape increases smoothness when cutting thick wood, making it easier to control the process. Partner chainsaws belong to the household class; accordingly, the number of teeth in them does not exceed 62 pieces.

When choosing a new chain, remember that you are choosing not only speed and smooth operation, you are choosing the safety of yourself and others, so you should not buy a low-quality and unsuitable product.

How to choose

The selection issue is relevant for inexperienced users. Professionals know almost everything about the headset and know how to choose what they need. For this reason, our advice will be aimed specifically at amateurs, and not at pros. So let's get started.

In order to choose correctly you need:

- Know the characteristics of the chainsaw, namely the pitch and length of the bar. When choosing, you should not rely on the name and model of the chainsaw, because... One chainsaw can be equipped with tires of different lengths and seat widths.

- Decide in advance on the volume and type of work for which you plan to use it. If you cut across, we choose chisel ones; if we cut along, we choose chipper ones.

Important! You will have to sharpen it for a longitudinal cut (10 0) yourself or at a service center. A headset sharpened for longitudinal cuts is rarely found on sale

Separately, it is necessary to mention the choice of the Shtil headset. If you are planning to buy a chain from this manufacturer (they are considered the highest quality today), then to make your choice it is better to use a special search form, which can be found on the company’s website.

By entering the chainsaw data into the search form, the program will automatically select and offer you suitable options. The service is convenient, but has one big drawback: selection is carried out only according to Shtil chainsaw models. In order to select a chain for saws of other brands, you will have to arm yourself with a catalog.

How to choose the best option

Every owner of a chainsaw, no matter how carefully he worked with the tool, was faced with the need to replace the sawing device. Popular models differ in the configuration and thickness of the links, pitch, average price and other characteristics.

The chain and guide bar belong to the category of replaceable equipment, so when purchasing budget options, you can replace these elements with more wear-resistant and durable ones. Changing the headset to a longer one will help improve efficiency, but this will only work if you have sufficient engine power and the rotation element. To avoid mistakes when choosing, it is worth getting advice from specialized experts.

Correspondence between engine power and the distance between the cutting teeth of the chainsaw chain

Based on data obtained experimentally, it is recommended to select a chainsaw by considering the ratio of drive power and the distance between the cutting edges. It is known that the higher the pitch, the more force must be applied to rotate the drive sprocket and the greater must be the maximum torque developed by a gasoline engine.

To select the correct tool configuration, it is necessary to use the minimum power data for each of the three typical chain pitches.

Critical power indicators of gasoline engines rotating the drive:

Chain pitch value.

- step 0.325” – power of at least 1.8 hp. (1.47 kW);

- 3/8” pitch – power of at least 3 hp. (2.21 kW);

- pitch 0.404” – power of at least 4.5 hp. (3.31 kW).

If the power of the driving motor is less than the specified values, then during the cutting process the following phenomena are possible: jamming of the chain in the tree, a decrease in the rotation speed of the drive, leading to overheating of the motor, increased cutting time and increased operating costs for fuel.

The use of powerful motors with a small pitch chain is not advisable, as this will also increase the time for dissolution and increase fuel costs. However, this combination is allowed if there is a need to perform precise work with wood.

The indicated minimum values of the drive characteristics indicate the ability of the equipment to operate reliably, but do not indicate the time of its continuous use in a professional environment. Rather, these values are given as recommendations for occasional work or for operating conditions where the tool is used for long periods of time. For long-term use of the equipment, which involves professional mode, the following technical data are required:

- step 0.325” – power 2.5 hp (1.84 kW);

- 3/8” pitch – 4 hp power. (2.94 kW);

- pitch 0.404” – power 6 hp. (4.41 kW).

And if, for example, it will be used occasionally or for summer cottage work, then such a choice is inappropriate.

Bicycle chain device

Any bicycle chain (except Half-Link) consists of several elements, namely:

- Outer link plate.

- Inner plate.

- Video clip.

- Bushing (glass).

- Pin.

- Full chain link.

- Gap for side bending.

1 link consists of 2 half-links. They are connected to each other using a pin placed in the “glass”. A roller is put on it. The roller is necessary to hold the bicycle sprockets on the teeth (where the chain is put on). The length of one full link is 1 inch, which translates to 25.4 millimeters. The length of the entire chain is determined by how many links there are in it.

For a 12 speed adult bike, a 126 link chain is typically used. There are many variations, the number of links varies from 110 to 126 pieces. Mountain bikes (MTB) use 106 or 108 chainstays.

If after purchase it turns out that the chain is too long, it can be shortened. This is done by disconnecting the lock (if there is one) and knocking out the pin. After that, everything is connected back together and installed on the bike. This way you can adjust a chain that is too long to fit your bike.

Saw chain lubrication system

The reliability and efficiency of the latter directly depends on the quality of lubrication of the chain and chain saw bar. In order to ensure normal operation of the tool, manufacturers supply it with an oil pump, which supplies oil to the cutting system through special holes. The chain itself is responsible for the uniform distribution of oil - its shanks, passing through the sprocket, capture the lubricant, which, as a result of the movement of the headset, spreads over it and the saw bar. Often, to increase the efficiency of lubrication, special channels are made in the drive links using a milling cutter or drill, and additional recesses are made in the connecting links.

The chain saw's lubrication system works to reduce the destructive effect of friction and, of course, heating. This significantly increases the service life of both the chain set and the tool as a whole. Therefore, the user must control the lubrication process. If, when the chain accelerates, there is no oil trace on the cutting line, this means that the saw is overheating, and the chain itself can quickly become dull, or even burst.

In order to increase the lubrication effect, global manufacturers produce saw oils on an organic basis. They cost a little more, but provide a quarter of the consumption, and when released into the environment, they self-decompose within a few hours.

How does the need to sharpen a chain manifest itself?

If the working teeth have lost their sharpness or are worn unevenly in height, working with such a chainsaw turns from pleasure into torture.

Typical signs that a chain needs to be sharpened are:

- decreased productivity;

- increase in noise and vibration during cutting;

- frequent reverse shocks when inserting the saw into an existing cut;

- formation of small chips compared to ordinary chips;

- the smell of smoldering wood.

If these signs appear, you should stop work and sharpen the chain. This can be done in two ways.

The manual sharpening method does not require complete removal of the chain from the bar; it is enough to loosen it. A special mandrel is installed on the link to be sharpened, which sets the sharpening angles of the working surfaces of the teeth. Using a round and flat file moving along the guides, the teeth are sharpened. Next, the mandrel is loosened and moved to the next link, repeating the operation.

Attention: sharpening can only be done with the engine stopped. If a power saw is used, it must be disconnected from the mains.

The accuracy of sharpening in this way greatly depends on the qualifications and accumulated experience of the worker. Its advantage is the low cost of the sharpening kit and the ability to straighten teeth directly on the workplace.

The second method requires expensive equipment comparable in cost to the chainsaw itself. Such a machine will pay for itself if you need to sharpen a large number of chains every day. The undoubted advantages of the method are

- high productivity of mechanized or automated installations;

- stability of sharpening angles from link to link;

- the ability to set the sharpening height according to the most ground tooth.

The latter feature allows you to automatically adjust the height of the teeth. This significantly increases the service life of the chain, since the load is evenly distributed between all links.

Another way to save both time and money is to send the chain to a service center for sharpening. It is convenient if you have a spare chain.

Thickness of link components (tails)

The main part of the load falls on this element of the chainsaw. To measure the thickness of the connecting elements of the chain included in the tire, use a caliper.

Let's list the standard indicators:

- 1.1-1.3 mm - more often found in products for infrequent home use and gentle operation. This tail thickness is suitable for light loads.

- 1.5mm is the most common option found in household saws, but is not suitable for heavy-duty applications.

- 1.6-2.0 mm is an option for complex work. This width of tails is found in professional saws, the elements of which are made of special steel.

Which tooth shape is best?

The cutting teeth of chainsaw sets also differ in the shape of their profile. The key selection factor here is the nature of the work to be done:

- For domestic use, when maximum practicality and ease of maintenance are required, a chain with chipper profile teeth, characterized by a round, crescent shape, is more suitable. When using such a chain, you get increased cutting performance, relative ease of sharpening, which does not require scrupulous attention to angles. At the same time, working with a chipper chain creates an increased load on the tool and somewhat reduces the quality of work.

- For professional use, equipment with a chisel profile is intended, which in appearance resembles the number 7. The cutting accuracy here will be higher, but such chains are much more difficult to maintain. When sharpening, you need to accurately maintain the coal, and when working, avoid getting in contact with dirt, which will quickly dull the cutting edges.

So, if the main thing for you is performance, and quality is not so critical, you should choose equipment with a chipper profile. If professionalism and quality of work are a priority, then a chain with chisel teeth will suit you.

Drive Link Shank Thickness

Along with the pitch and number of links that determine the length, there is such a parameter as the thickness of the chain. It is also very important because the bus-net pair correspondence must be strictly correlated. If the shank is too thick, it will jam in the groove of the tire or will not fit there at all. A chain that is too thin will vibrate freely in the groove. This will increase the risk of slipping and injury. Trying to compensate for vibrations, an inexperienced user will overtighten the chain, which will lead to accelerated wear of the saw set.

The easiest way to measure the shank is with a caliper. However, this should be done only on a chain that has not worked much - very worn copies are worn out and ground down, and the value may be taken incorrectly. It’s better to go online and read the specifications or consult a store.

The thickness of the leading link has also been standardized for a long time and is represented by the following values

| Width, mm | Width, inches | Marking | Application area |

| 1,1 | 0,043 | 1 | Compact solutions, mini-saws, one-handed options with low-power motors |

| 1,3 | 0,050 | 3 | Most household and some semi-professional units, designed for tire lengths up to 40 cm and engine power up to 2.5 horsepower |

| 1,5 | 0,0578 | 5 | Some household and most professional saws with an increased power engine and a bar length of 38 - 50 cm |

| 1,6 | 0,063 | 6 | Professional tools for various purposes and power |

| 2,0 | 0,080 | Heavy, powerful saws exclusively for felling trees |

Tire classification

Manufacturers produce products that differ in size. The main parameter of a saw chain is considered to be the number of links. The length of the product depends on this indicator. In addition, the systems have a specific step. Its indicator is the distance between links connected in series, divided in half. Let's look more specifically at each parameter.

Step by step

It is customary to distinguish the following classes:

- 0.25 (1/4"). It's called a "small step". These designs are installed on one-handed chain saws with low power, but high accuracy and the ability to use in hard-to-reach places.

- 0.325 (3/8"). The most common models. The lion's share of products are equipped with this type of headset.

- 0.404 (3/4"). Powerful tools with high productivity are equipped, such as harvesting equipment, felling systems, and so on.

Shank thickness

The parameter must match the groove of the bar. This increases the reliability of the fit and prevents it from falling off during operation. In this case, the movement will be smooth, without excessive vibration and sudden movements. Branded products are produced with the following values:

| Parameters (mm) | Purpose |

| 1,1 | Small chains for mini saws. |

| 1,3 | Used for household and semi-professional chainsaws. |

| 1,5 | More powerful tools are available. |

| 1,6 | Designed for professional saws. |

| 2,0 | Industrial saws are equipped. |

Cutting depth, profile height, engine capacity

What should you pay special attention to when choosing a product? Precisely on this data. The height of the cutting edge varies, and therefore a distinction is made between low-profile and high-profile designs. The latter are distinguished by excellent performance, the former by an increased support area of the cutting link, which has a positive effect on operational safety.

Cutting depth affects productivity. The larger it is, the stronger the vibration. To balance the performance of products with large pitches, they are equipped with cutting teeth with a shallow depth. The most popular gaps are 0.025" and 0.03". Designs with a value of 0.07” have found their use in felling timber on an industrial scale.

Engine size plays an important role when choosing the optimal unit. If you install a saw chain on a tool with significant power, then increased loads will soon damage it and you will have to buy a new one. Therefore, before purchasing a new headset, it is necessary to review the technical characteristics of the saw.

Material

The rating of quality products is always topped by representatives made from wear-resistant material. According to buyers, this is an important aspect when making a final decision, along with design features and functionality. Household and professional units use high-quality designs at a significant price and with a long service life. Which company is better depends on the preferences of the master. In specialized retail outlets you can see devices for cutting concrete. They are equipped with a wear-resistant diamond chain, which belongs to the category of emergency rescue products. They are not intended for gardening equipment.

The main selection criterion is not the brand and how much it costs, but the wear resistance of the carbide structure and its maintainability. There will be no need to constantly replace the product, provided that there is special equipment for sharpening it, which will significantly extend its service life. The carbide construction is used for sawing hard wood or light building materials.

If you use the device to work with aerated concrete or foam concrete blocks, then even the best models with additional functions will last two or three times less than the established period.

Cross and longitudinal cutting

If the sharpening angle of the links is 25 - 35 degrees, then they are used for transverse cutting of wood. This is the main range of manufactured goods, both Russian and foreign. Products for longitudinal sawing are quite rare. You can eliminate the deficiency by changing the sharpening angle yourself at home, making it standard from 5 to 15 degrees. In this case, the tire is operated without changing the structural elements. If difficulties arise, you can use step-by-step instructions.

When to sharpen

If the teeth are dull, the work will progress slowly. There will be increased vibration, reverse shocks as the headset enters the cut, too many small chips and a distinct smell of burnt wood.

If the tool comes with an installed manual sharpening device, a flat or cylindrical file, then there is no need to remove the element from the tire. Sharpening will occur automatically. If necessary, higher-quality sharpening can be performed in a specialized workshop, in which the action takes place on a stationary sharpening machine. Restoring the teeth's functionality is carried out quickly and efficiently, with a guarantee of the same angle. User reviews boil down to the need to resort to a professional sharpening method.

Lubrication

The tool will function reliably and efficiently if there is timely lubrication. For this purpose, an oil pump is provided, thanks to which oil is supplied to the cutting system through special holes. The oil is evenly distributed thanks to the shanks.

The lubricant is intended, first of all, to reduce friction and overheating of the unit, which allows to increase its operational life and maintain performance at the proper level. The lubrication process must be controlled. It is worth paying attention to the presence of an oil trace on the cutting line. Its absence indicates that the device is overheated, which can lead to dullness or complete failure.

To avoid negative consequences, manufacturers of rated products use an organic base when producing oils. Such new products are more expensive than their analogues, but at the same time the consumption of lubricant is significantly reduced, automatically increasing the service life.

Recoil and vibration

Regardless of the quality of the product, significant vibration and recoil occur under high loads. With light loads, such inconveniences cannot be avoided either, but their power and intensity can be reduced. To reduce vibration you should use:

- shock-absorbing protrusions on connectors and shanks;

- beveled cut stop;

- beveled or high heel of the incisor.

These actions can be carried out with your own hands, without the involvement of outside help. These design features will help minimize the risk of injury due to tool kickback.

Recommendations for extending service life

The approximate service life of a branded tire is equal to the total service life of 3 high-quality saw chains; the drive sprocket varies depending on its condition. Experts recommend using a set of several circuits.

The main factors for early tire failure:

- excessive chain tension or discrepancy between its pitch and the characteristics of the drive sprocket crown, which initiates the rapid development of the groove and shanks;

- applying significant force when sawing hard or frozen wood;

- the tire heats up and wears out intensively due to lack of lubricant supply, due to a malfunction or incorrect adjustment of the standard oil pump;

- saving money on the use of low-quality chain oil or oil surrogates such as waste.

Forced consumption of the saw set resource occurs when soil or sand gets into it, or when a new chain operates on a worn drive sprocket.

Additionally: Chainsaw MAKITA EA3202S40B, owner reviews

Design features of the chain

There are also several features of the chains. There are round and square teeth. The former are able to cut more often, but their efficiency is lower. But it is possible to get an even cut, which is important when performing construction work. Sharpening is rarely required.

The order of the links

A square tooth has a larger working surface area. It can cut wood at right angles faster. The cut is not very neat, and there will be a lot of sawdust. With square teeth, sharpening will have to be done more often.

Reference ! Teeth are considered dull if their size has decreased by 20%. It is necessary to work with the middle part of the headset to ensure an even load on the entire chain.

Do not over-tension the chain. Then it may break, and the load on the tool’s engine will also increase. This negatively affects its wear resistance. However, it should not hang too much, otherwise it will fall off. It is necessary to determine the correct tension. To do this, simply tighten the chain in the center of the top of the tire. One link should be located above the edge, and the other two should barely touch it. Over time, the chain stretches. When it is not possible to achieve optimal tension, it is replaced.

How to choose a chain for an electric saw

These are the main nuances that you need to know about when choosing a chain for an electric saw or chainsaw. There is no difference since they are required for both tools. Only one runs on fuel, and the other runs on electricity. When choosing a chain, you need to take into account the operating features. If it will be used a couple of times a year, you can buy an inexpensive Chinese one. But for periodic use, it is better to overpay a little and purchase a product made from a high-quality alloy. This will save money in the long run.

Each manufacturer has a wide range of products. You need to take this into account in order to buy a chain not only of the required characteristics, but also of the class. Professional models have increased strength, requiring rare sharpening. But their price is higher. Chains are supplied in coils or in a box.

Preparatory work

In the package version of making a knife from a chain, the product is suitable for various mechanisms: a motorcycle, a car, a bicycle or a chainsaw. Having decided on the manufacturing method, you need to prepare the tools and materials:

- an anvil, two hammers - large and small;

- oven or forge;

- vices, angle grinders with discs for various purposes;

- tetraboric acid (borax);

- Hydraulic Press;

- grinding machine;

- welding machine, steel chain;

- high carbon steel plate;

- motor oil and a container of water;

- drill, wooden block, epoxy glue;

- masking tape, sandpaper of different grains;

- Handle impregnation made from natural oils.

Knife from a chain. Tools and materials are professional in nature. From the very beginning it was stated that this was a job for experienced craftsmen. Beginners should not try this material. You need to start experimenting with simple preparations.

Instructions for making a knife from a chain

A distinctive feature of the batch forging process is the work with several metal plates. Having everything you need, you need to start the initial forging of the blade:

- Using a cutting wheel on an angle grinder, cut the chain into several pieces of equal length. Having folded them into a single form, using welding, we “grab” them to obtain a solid workpiece.

- A rod is welded to the resulting rectangle for ease of holding. Having warmed up the oven, place the workpiece in it and heat it to 1100-1200 °C.

- Once the metal has reached a bright red hue, remove it and sprinkle it generously with borax. This will allow you to more reliably fasten the pieces of the chain together and get rid of voids in the links. Place in the oven for further heating.

- We take it out again, sprinkle it with borax and quickly move to the press. With its help, we gradually compress the workpiece from all sides. We monitor the temperature; when the part has cooled down, go back into the oven. The process performed by the press will help get rid of voids in the workpiece and forge weld it into a monolith.

- After making sure that the welding is sufficient, use a large hammer to flatten the workpiece into one plate. Cool the product in air, cut off the rod using an angle grinder. And with the same tool we halve the plate.

- Between the resulting halves we lay carbon steel, sprinkling the layers with brown. We carefully “grab” it with welding and return the rod to its place. Place in the oven and heat until bright red. Having taken out the plates, we forge them with a large hammer. The plates must be welded together using the forging method.

Knives from a chainsaw chain.

Saw chain parameters

Chains for chainsaws are usually divided according to the following parameters:

- The pitch or distance between adjacent three rivets.

- Landing link width.

- Number of links.

- Type of cutting teeth.

The headset parameters combine various combinations, which determine the final results, quality and cutting speed.

For example, a headset may have the following parameters: pitch 3/8, length 52 links, groove width 1.3 mm, chipper type of cutting tooth. An experienced specialist, having assessed the data, will say that it is designed for longitudinal cutting and has average performance and returns. Chains of this type can be installed on household chainsaws, because... they are more versatile.

Let's figure out why he makes such conclusions.

And the last thing that gives reason to classify the headset as a middle performance class is the width of the mounting groove. There are mainly three width options: 1.1 mm, 1.3 and 1.5.

The width of the groove is directly proportional to the width of the cut and depends on the size of the tooth. The wider the groove, the wider the cut and vice versa. Chains with a minimum width are characterized by low kickback and cutting speed. Basically, these are installed on gasoline pole saws and low-power chain saws.

The headset with a 1.3 mm seat can be installed on both household and semi-professional and professional chainsaws; the chain pitch can be different.

The 1.5 mm width was previously only used on chains for professional use. Recently, due to the fact that the market has been flooded with powerful and affordable Chinese-made chainsaws, such chains have begun to be used on them.

Width 1.6 mm and 2 mm. used exclusively on professional and industrial saws.

What are there

Any saw chain for a chainsaw has three types of links:

| Varieties | Description |

| Connecting | Connects leading and cutting elements. |

| Presenters | People call them “shanks”. Thanks to the drive sprocket, rotation is transmitted to the structure from the engine, which ensures its precise position on the tire. |

| Cutting | Quite a complex device. It consists of a cut depth limiter and a cutting element where there is a contour cutting angle. |

The main one is considered to be the cutting link. They are made right- and left-handed. Incisors are divided into two types:

- Chisel. They are distinguished by high productivity and excellent cutting speed. The configuration provides a smaller contact area with the wood, which helps reduce surface resistance. The main disadvantage is excessive sensitivity to abrasives, as well as difficulty in sharpening.

- Chipper. It features an increased contact area, which reduces cutting efficiency. The main advantage is ease of maintenance. The main area of use is cutting contaminated wood.

Types of chains for chainsaws

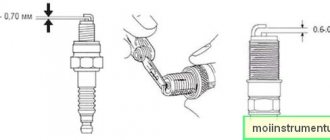

Those who have dealt with sawing wood know that it can be sawed either along the grain or across it. Based on this, different types of chains for chainsaws are produced: for transverse or longitudinal cutting of wood. In both cases, the difference in material resistance will be significantly different. For longitudinal sawing, the teeth are sharpened at an angle from 5 to 15°. Cross cutting requires sharpening the tool at an angle of 25-35°. The figure below shows how the tooth sharpening angle is determined.

Chains for longitudinal sawing are used extremely rarely, because it is much easier to unravel the workpiece on a circular saw. Due to low demand, manufacturers of this tool do not particularly improve it, and it is quite difficult to find a chain for rip sawing on sale. Most chainsaw buyers choose a tool with a cross-cut type, and it is the most popular among both professionals and home craftsmen. But, before choosing a chain for a chainsaw, you should study the main parameters that affect the performance and quality of the tool.

How to eliminate the risks of buying a counterfeit chain

Some unscrupulous manufacturers and sellers try to pass off their crafts as high-quality products from well-known brands.

They counterfeit both the chain itself and the branded packaging. Externally, the instrument looks exactly the same, but since counterfeiters skimp on materials, it will not last long.

The packaging is usually made of loose cardboard, and the printing is often smudged and unclear. If you take several of these packages, they will all have the same serial number.

Experienced experts advise not to play roulette, trying to recognize a fake on your own. It is better to buy chains in branded service centers or in trusted construction stores that value their reputation and do not deal with counterfeiters.

Varieties and main differences

A chain with a guide bar is replaceable equipment, which means, for example, when deciding which chain for a budget-class Stihl chainsaw is better, you can also consider carved elements of a different class. In other words, owners of budget gasoline chainsaws can choose a durable saw kit for their tool that is more wear-resistant.

When trying to figure out which chains are best for a chainsaw, you can rely on reviews from owners of different power units. You can do it differently by turning to specialists for professional advice. It is possible to make the right choice, focusing on the rating and characteristics of the replacement equipment. To select the ideal components that do not reduce the performance of the tool and cause its malfunctions, take into account a number of criteria, according to which the carved element differs:

- the quality of the material from which the chain is made;

- chain length;

- chain pitch;

- thickness of the replacement headset;

- groove features;

- features of the links (there are two types in total).

In a number of characteristics, branded and budget chains differ significantly. Nevertheless, some operators of fairly powerful budget gasoline saws manage to combine the unit with a perfect saw set produced by the companies Oregon, Husqvarna, Shtil. If you believe unofficial data, recently the Hammer and Power Sharp models have taken leading positions in consumer demand ratings for such products.

The higher the price range, the greater the likelihood that a branded chain will compensate for the technical imperfections of the tool by improving work results even when performing complex sawing work, due to an increased repair life, and due to the stability of a number of operational characteristics.

The best manufacturers in terms of quality and reliability

Having analyzed the technical parameters, the level of chain reliability, as well as taking into account the opinions of experts and user reviews, we have compiled a rating of the best manufacturers of saw chains for chainsaws that are represented on the domestic market.

Oregon Cutting Systems

The Oregon brand was founded in the USA in 1949. Since its founding, the company has been producing saw accessories for various types of gasoline and electric saws. Having its own design department and continuous quality control allowed the company to take a leading position in the global sawing equipment market. Oregon products are distinguished by good balance, sharp cutting edges and durability.

The disadvantage of the product is the large number of fakes. Therefore, it is better to purchase saw chains from trusted suppliers and official dealers.

We also recommend reading an interesting article about Oregon chains.

Stihl

Founded in 1929, the Stihl concern was engaged in the production of chain saws and consumables for them. Our own design bureau constantly improves our products. All components used for the production of saw chains undergo a full production cycle, from smelting blanks to sharpening and assembly. The company's products are characterized by high reliability and performance.

The disadvantages of saw chains include low popularity in the domestic market and a large number of counterfeits. In Russia, chains from this company are sold both separately and with the chainsaws themselves, for example Shtil MS 180.

We also recommend reading an interesting article about Stihl chains.

Husqvarna

The Swedish company Husqvarna was founded in 1689 and was engaged in the production of firearms. It produced its first saw in 1959 and has been manufacturing its own tools and components ever since. Saw chains manufactured at the company's factories are distinguished by good tensile strength, excellent balance, ease of maintenance and high performance.

The disadvantages include the high cost of saw chains and the presence of counterfeits on the market. Therefore, it is better to buy them from an official dealer.

The list lacks such companies as Echo, Partner, Champion, etc. There are none because in Russia they are in less demand and, moreover, their quality is worse.

We also recommend reading an interesting article about Husqvarna chains.

Preparing a fuel mixture for a chain saw.

Since the majority of chain saws available to consumers are equipped with two-stroke engines that do not provide separate lubrication of rubbing parts, it is very important to prepare the correct fuel mixture during break-in. It is prepared from gasoline and two-stroke engine oil in a certain proportion recommended by the chainsaw manufacturer

What gasoline should I use for the fuel mixture?

The basis is gasoline with an octane rating of at least 90. For Russia, Belarus, Kazakhstan and other CIS countries, the optimal fuel option is AI-92. Avoid using questionable fuels, as well as using any additives that increase the octane number. Over time, additives lose their properties, and gasoline becomes of low quality.

Using fuel with a low octane number when running in and operating a chainsaw causes uneven engine operation and knocking. At the same time, there is an increase in engine temperature and an increase in the load on the main bearings. Imaginary savings most often lead to failure of the cylinder-piston group, requiring significant funds to restore it.

New chainsaw owners often have a question about what kind of gasoline to pour into the tool tank: leaded or unleaded? Leaded fuel is used to start an engine without a catalyst. If your saw has a catalyst (green gas tank cap), then use unleaded fuel.

What oil should I use in the fuel mixture, and in what proportions?

Two-stroke engine oil is used both for break-in and for continuous operation of the chainsaw. If you don’t want to take risks and experiment, then purchase the lubricant recommended by the tool manufacturers. As a rule, large companies produce fuel and lubricants for them to order. This allows the manufacturer of chain saws and other gas-powered tools to guarantee proper starting and trouble-free operation of their products.

Since branded oils for chainsaws Husqvarna, Stihl, Partner, Oregon, Jonsered are bottled from the same barrel, you can break in the tool with any of the following

In this case, it is very important to take into account the recommendations both in the instructions for oils and the recommendations of chain saw manufacturers. When using branded fuels and lubricants, when preparing the fuel mixture, follow the operating instructions for the gas-powered tool

| Recommended proportions of fuels and lubricants when preparing fuel | |||

| Break-in chainsaw | Proportion | Gasoline, (liters) | Oil, (liters) |

| Husqvarna up to 1.5 kW | 1:40 | 1 | 0,025 |

| Husqvarna over 1.5 kW | 1:50 | 1 | 0,020 |

| Stihl up to 1.5 kW | 1:40 | 1 | 0,025 |

| Stihl over 1.5 kW | 1:50 | 1 | 0,020 |

| Partner | 1:40 | 1 | 0,025 |

| Partner | 1:33 | 1 | 0,030 |

If branded oils are not available, you can break in a new chainsaw using third-party lubricants of the JASOFB or ISOEGB class. According to the instructions, the ratio of components is taken at the rate of 1:33. At the same time, the tool manufacturer does not recommend using four-stroke motor oils or two-stroke motor oils for water-cooled outboard engines, labeled as TCW.

The fuel mixture for a chainsaw to be run in should be prepared in a clean container intended for storing fuel and lubricants.

- Pour half the required gasoline into the container;

- Add required amount of oil;

- Gently mix the ingredients;

- Pour in the remaining gasoline and stir.

Roller drive chains

Roller drive chains are designed for power mechanical transmissions of various machines and mechanisms. Of all the drive chains, they are most widespread. There are three main standards regulating the parameters of drive roller chains - GOST 13568-97, adopted in Russia; ISO/R 606, a British standard adopted in European countries, and ANSI B29.1M, adopted in the USA. Chains of this type can be made collapsible, with straight and curved plate contours, as well as with various types of anti-corrosion coatings. The dimensions of roller chains are identical to those of American and British standards.

go to the Technical Support section

Regulatory documents: GOST 13568-97 Roller and bushing drive chains. International standards: ISO/R 606, ANSI B29.1M.