Transformer design

If you look at the transformer from the outside, it is an W-shaped device consisting of a metal core, a cardboard or plastic frame and a copper wire winding.

There are two windings. The core is several steel plates that are treated with a special varnish and connected to each other. The varnish is applied specifically to prevent tension from passing between the plates. In this way they fight the so-called eddy currents (Foucault currents). The thing is that Foucault currents will simply heat the core itself. And these are losses.

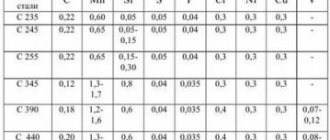

The composition of the core plates is also associated with losses. Transformer iron (as core steel is most often called by experts), if you look at it in cross-section, consists of large crystals, which, in turn, are isolated from each other by an oxide film.

Transformer assembly

The quality of the transformer largely depends on the correct assembly of the magnetic circuit. When assembling the W-shaped armor core, adjacent plates must be laid alternately in different directions. The plate pack should be stacked as tightly as possible. After assembly, it must be tightened tightly with screws. A loose transformer makes a lot of noise during operation. Particular attention should be paid to the tight fit of the W-shaped plates with the floor plates. The gap between them will lead to the core becoming open-circuited, and this implies the following:

- Increased no-load current;

- Decrease in efficiency;

- Increased magnetic scattering field.

When assembling a split strip core, you need to pay attention to the fit of the parts to each other, since during manufacturing they are adjusted by grinding. To reduce noise, the ends of the plate packages can be coated with a layer of varnish.

Read also: Attachment to the grinder chain saw

Note! Parts of the tape magnetic circuit require careful handling, since delaminated tapes are almost impossible to install in their original place. The plates of the collapsible core cannot be bent or subjected to impacts, as this will disrupt the structure of the metal and it will lose its properties. As a last resort, plates bent at a large radius must be carefully bent by hand and, when assembled, placed in the middle of the plate pack. With further screeding they will align.

Calculating a network transformer is not difficult. It is more important to determine the requirements for it. The accuracy of further calculations will depend on the correctness of the task. For a power transformer, the calculation can also be conveniently performed using an online calculator. The step-up transformer is calculated using the same method.

Transformer windings

These same coils of wire in a transformer are called windings. The windings mainly consist of varnished copper wire. Such a wire is in varnish insulation, therefore, the wire in the winding does not short-circuit with each other. A winding transformer wire looks something like this.

It can be of different diameters. It all depends on what load this or that transformer is designed for.

The simplest single-phase transformer can have two such windings.

The winding to which voltage is applied is called the primary winding. People also call it “primary”. The winding from which the voltage has already been removed is called secondary or “secondary”.

In order to find out where the primary winding is and where the secondary is, just look at the transformer nameplate.

I/P: 220M50Hz (RED-RED) - this tells us that the two red wires are the primary winding of the transformer, to which we supply a mains voltage of 220 Volts. Why do I think this is primary? I/P means InPut, which is translated as “input”.

O/P: 12V 0.4A (BLACK, BLACK) – secondary winding of the transformer with an output voltage of 12 Volts (OutPut). The maximum current that this transformer can supply to the load is 0.4 Ampere or 400 mA.

How the device works

A transformer is an electrical device designed to transmit energy without changing its shape and frequency. Using the phenomenon of electromagnetic induction in its work, the device is used to convert an alternating signal or create galvanic isolation. Each transformer is assembled from the following structural elements:

- core;

- windings;

- frame for winding arrangement;

- insulator;

- additional elements ensuring the rigidity of the device.

The principle of operation of any transformer device is based on the effect of the appearance of a magnetic field around a conductor with an electric current flowing through it. This field also occurs around magnets. Current is the directional flow of electrons or ions (charges). By taking a wire conductor and winding it around a coil and connecting a potential measuring device to its ends, you can observe a surge in the voltage amplitude when the coil is placed in a magnetic field. This suggests that when a magnetic field is applied to a coil with a wound conductor, an energy source or energy converter is obtained.

In a transformer design, such a coil is called primary or mains. It is designed to create a magnetic field. It is worth noting that such a field must necessarily change in direction and magnitude all the time, that is, be variable.

A classic transformer consists of two coils and a magnetic circuit connecting them. When an alternating signal is applied to the contacts of the primary coil, the resulting magnetic flux is transmitted through the magnetic circuit (core) to the second coil. Thus, the coils are connected by magnetic power lines. According to the rule of electromagnetic induction, when the magnetic field changes, an alternating electromotive force (EMF) is induced in the coil. Therefore, a self-induction emf occurs in the primary coil, and a mutual induction emf occurs in the secondary coil.

The number of turns on the windings determines the amplitude of the signal, and the diameter of the wire determines the greatest current strength. If the turns on the coils are equal, the input signal level will be equal to the output. In the case where the secondary coil has three times as many turns, the amplitude of the output signal will be three times greater than the input - and vice versa.

The heating of the entire device depends on the cross-section of the wire used in the transformer. It is possible to select the correct cross-section using special tables from reference books, but it is easier to use an online transformer calculator.

The ratio of the total magnetic flux to the flux of a single coil sets the strength of the magnetic coupling. To increase it, the windings of the coils are placed on a closed magnetic circuit. It is made from materials with good electromagnetic conductivity, for example, ferrite, alsifer, carbonyl iron. Thus, three circuits arise in the transformer: an electrical circuit - formed by the flow of current in the primary coil, an electromagnetic circuit - forming a magnetic flux, and a second electrical circuit - associated with the appearance of current in the secondary coil when a load is connected to it.

The correct operation of the transformer also depends on the frequency of the signal. The larger it is, the less losses occur during energy transfer. This means that the dimensions of the magnetic circuit depend on its value: the higher the frequency, the smaller the dimensions of the device. Pulse converters are built on this principle, the manufacture of which is associated with development difficulties, so a calculator is often used to calculate a transformer according to the core cross-section, which helps to get rid of manual calculation errors.

Purpose and functionality

So, what functions does a transformer perform?

- This is a reduction in voltage to the required parameters.

- With its help, the galvanic isolation of the network is reduced.

As for the second function, it is necessary to give explanations. Both windings (primary and secondary) of the current transformer are not directly connected to each other. This means that the resistance of the device, in fact, should be infinite. True, this is an ideal option. The connection of the windings occurs through the magnetic field created by the primary winding. This is such a complex functionality.

Calculation

There are several types of calculations used by professionals. For beginners, they are all quite complex, so we recommend the so-called simplified version. It is based on four formulas.

The transformer allows you to reduce the voltage to the required parameters.

Formula of the law of transformation

So, the transformation law is determined by the following formula:

U1/U2=n1/n2, where:

- U1 – voltage on the primary winding,

- U2 – on the secondary,

- n1 – number of turns on the primary winding,

- n2 – on the secondary.

How to measure wire diameter

If you have a micrometer lying around at home, you can use it to measure the diameter of the wire.

It is better to first heat the wire in a match flame and only then remove the weakened insulation with a scalpel. If this is not done, then part of the copper can be removed along with the insulation, which will reduce the accuracy of the measurement, especially for a thin wire.

If you don’t have a micrometer, you can use an ordinary ruler. You need to wind 100 turns of wire around the tip of a screwdriver or another suitable axis, compress the turns with your fingernail and attach the resulting set to a ruler. Dividing the result by 100, we get the diameter of the wire with insulation. You can find out the diameter of the copper wire from the table below.

Example.

I wound 100 turns of wire and got a set length of -39 mm.

39 / 100 = 0.39 mm

Using the table, I determine the diameter of the copper wire - 0.35 mm.

Winding Wire Data Table

| Diameter without insulation, mm | Copper cross section, mm² | Resistance 1m at 20ºС, Ohm | Permissible load at current density 2A/mm² | Diameter with insulation, mm | Weight 100m with insulation, g |

| 0,03 | 0,0007 | 24,704 | 0,0014 | 0,045 | 0,8 |

| 0,04 | 0,0013 | 13,92 | 0,0026 | 0,055 | 1,3 |

| 0,05 | 0,002 | 9,29 | 0,004 | 0,065 | 1,9 |

| 0,06 | 0,0028 | 6,44 | 0,0057 | 0,075 | 2,7 |

| 0,07 | 0,0039 | 4,73 | 0,0077 | 0,085 | 3,6 |

| 0,08 | 0,005 | 3,63 | 0,0101 | 0,095 | 4,7 |

| 0,09 | 0,0064 | 2,86 | 0,0127 | 0,105 | 5,9 |

| 0,1 | 0,0079 | 2,23 | 0,0157 | 0,12 | 7,3 |

| 0,11 | 0,0095 | 1,85 | 0,019 | 0,13 | 8,8 |

| 0,12 | 0,0113 | 1,55 | 0,0226 | 0,14 | 10,4 |

| 0,13 | 0,0133 | 1,32 | 0,0266 | 0,15 | 12,2 |

| 0,14 | 0,0154 | 1,14 | 0,0308 | 0,16 | 14,1 |

| 0,15 | 0,0177 | 0,99 | 0,0354 | 0,17 | 16,2 |

| 0,16 | 0,0201 | 0,873 | 0,0402 | 0,18 | 18,4 |

| 0,17 | 0,0227 | 0,773 | 0,0454 | 0,19 | 20,8 |

| 0,18 | 0,0255 | 0,688 | 0,051 | 0,2 | 23,3 |

| 0,19 | 0,0284 | 0,618 | 0,0568 | 0,21 | 25,9 |

| 0,2 | 0,0314 | 0,558 | 0,0628 | 0,225 | 28,7 |

| 0,21 | 0,0346 | 0,507 | 0,0692 | 0,235 | 31,6 |

| 0,23 | 0,0416 | 0,423 | 0,0832 | 0,255 | 37,8 |

| 0,25 | 0,0491 | 0,357 | 0,0982 | 0,275 | 44,6 |

| 0,27 | 0,0573 | 0,306 | 0,115 | 0,31 | 52,2 |

| 0,29 | 0,0661 | 0.2bb | 0,132 | 0,33 | 60,1 |

| 0,31 | 0,0755 | 0,233 | 0,151 | 0,35 | 68,9 |

| 0,33 | 0,0855 | 0,205 | 0,171 | 0,37 | 78 |

| 0,35 | 0,0962 | 0,182 | 0,192 | 0,39 | 87,6 |

| 0,38 | 0,1134 | 0,155 | 0,226 | 0,42 | 103 |

| 0,41 | 0,132 | 0,133 | 0,264 | 0,45 | 120 |

| 0,44 | 0,1521 | 0,115 | 0,304 | 0,49 | 138 |

| 0,47 | 0,1735 | 0,101 | 0,346 | 0,52 | 157 |

| 0,49 | 0,1885 | 0,0931 | 0,378 | 0,54 | 171 |

| 0,51 | 0,2043 | 0,0859 | 0,408 | 0,56 | 185 |

| 0,53 | 0,2206 | 0,0795 | 0,441 | 0,58 | 200 |

| 0,55 | 0,2376 | 0,0737 | 0,476 | 0,6 | 216 |

| 0,57 | 0,2552 | 0,0687 | 0,51 | 0,62 | 230 |

| 0,59 | 0,2734 | 0,0641 | 0,547 | 0,64 | 248 |

| 0,62 | 0,3019 | 0,058 | 0,604 | 0,67 | 273 |

| 0,64 | 0,3217 | 0,0545 | 0,644 | 0,69 | 291 |

| 0,67 | 0,3526 | 0,0497 | 0,705 | 0,72 | 319 |

| 0,69 | 0,3739 | 0,0469 | 0,748 | 0,74 | 338 |

| 0,72 | 0,4072 | 0,043 | 0,814 | 0,78 | 367 |

| 0,74 | 0,4301 | 0,0407 | 0,86 | 0,8 | 390 |

| 0,77 | 0,4657 | 0,0376 | 0,93 | 0,83 | 421 |

| 0,8 | 0,5027 | 0,0348 | 1,005 | 0,86 | 455 |

| 0,83 | 0,5411 | 0,0324 | 1,082 | 0,89 | 489 |

| 0.86 | 0,5809 | 0,0301 | 1,16 | 0,92 | 525 |

| 0,9 | 0,6362 | 0,0275 | 1,27 | 0,96 | 574 |

| 0,93 | 0,6793 | 0,0258 | 1,36 | 0,99 | 613 |

| 0,96 | 0,7238 | 0,0242 | 1,45 | 1,02 | 653 |

| 1 | 0,7854 | 0,0224 | 1,57 | 1,07 | 710 |

| 1,04 | 0,8495 | 0,0206 | 1,7 | 1,12 | 764 |

| 1,08 | 0,9161 | 0,0191 | 1,83 | 1,16 | 827 |

| 1,12 | 0,9852 | 0,0178 | 1,97 | 1,2 | 886 |

| 1,16 | 1,057 | 0,0166 | 2,114 | 1,24 | 953 |

| 1,2 | 1,131 | 0,0155 | 2,26 | 1,28 | 1020 |

| 1,25 | 1,227 | 0,0143 | 2,45 | 1,33 | 1110 |

| 1,3 | 1,327 | 0,0132 | 2,654 | 1,38 | 1190 |

| 1,35 | 1,431 | 0,0123 | 2,86 | 1,43 | 1290 |

| 1,4 | 1,539 | 0,0113 | 3,078 | 1,48 | 1390 |

| 1,45 | 1,651 | 0,0106 | 3,3 | 1,53 | 1490 |

| 1,5 | 1,767 | 0,0098 | 3,534 | 1,58 | 1590 |

| 1,56 | 1,911 | 0,0092 | 3,822 | 1,64 | 1720 |

| 1,62 | 2,061 | 0,0085 | 4,122 | 1,71 | 1850 |

| 1,68 | 2,217 | 0,0079 | 4,433 | 1,77 | 1990 |

| 1,74 | 2,378 | 0,0074 | 4,756 | 1,83 | 2140 |

| 1,81 | 2,573 | 0,0068 | 5,146 | 1,9 | 2310 |

| 1,88 | 2,777 | 0,0063 | 5,555 | 1,97 | 2490 |

| 1,95 | 2,987 | 0,0059 | 5,98 | 2,04 | 2680 |

| 2,02 | 3,205 | 0,0055 | 6,409 | 2,12 | 2890 |

| 2,1 | 3,464 | 0,0051 | 6,92 | 2,2 | 3110 |

| 2,26 | 4,012 | 0,0044 | 8,023 | 2,36 | 3620 |

| 2,44 | 4,676 | 0,0037 | 9,352 | 2,54 | 4220 |

Types of cores

Transformers differ from each other not only in their scope of application, technical characteristics and dimensions, but also in the type of magnetic circuit. A very important parameter affecting the magnitude of the magnetic field, in addition to the turns ratio, is the size of the core. The saturation ability depends on its value. The saturation effect occurs when, as the current in the coil increases, the magnitude of the magnetic flux remains unchanged, i.e., the power does not change. To prevent the saturation effect from occurring, you will need to correctly calculate the volume and cross-section of the core, the size of which determines the power of the transformer. Therefore, the greater the power of the transformer, the larger its core should be.

By design, the core is divided into three main types:

- core;

- armored;

- toroidal.

The core magnetic circuit is a U-shaped or W-shaped structure. It is assembled from rods pulled together by a yoke. To protect the coils from the influence of external electromagnetic forces, armored magnetic circuits are used. Their yoke is located on the outside and covers the rod with the coil. The toroidal type is made of metal strips. Due to their ring design, such cores are the most economically advantageous.

Knowing the shape of the core, it is easy to calculate the power of the transformer. It is found using a simple formula: P=(S/K)*(S/K), where:

- S is the cross-sectional area of the core.

- K is a constant coefficient equal to 1.33.

The area of the core depends on its type, its unit of measurement is a centimeter squared. The result obtained is measured in watts. But in practice, it is often necessary to calculate the core cross-section based on the required power of the transformer: Sc = 1.2√P, cm2. Based on the formulas, we can confirm the conclusion: that the greater the power of the product, the larger the core used.

Calculation programs

There are many programs that offer online calculation of the parameters of any transformer with an armored or rod core. One of these could be the service on the “skrutka” website. To determine the characteristics, you will need to indicate a number of the following data:

- input voltage - U1;

- output voltage - U2;

- plate width - a;

- stack thickness - b;

- network frequency - Hz;

- overall power - V*A;

- efficiency;

- magnetic inductance of the magnetic circuit - T;

- current density in the windings - A/mm sq.

The last 4 values are tabular, so you will need to use a reference book.

It is necessary to competently and responsibly calculate the parameters of the transformer, because the quality of the functioning of your power supply will depend on the quality of the work performed. You shouldn't always rely on programs; they may contain errors. Select one or more parameters and recalculate them manually using the previously given formulas. If you get approximately the same value, then the result can be considered correct.

Recommendations for assembly and winding

When assembling a transformer with your own hands, the core plates are assembled “over the roof”. The magnetic core is tightened with a clip or hairpin nuts. In order not to damage the insulation, the studs are covered with a dielectric. You need to tighten the hardware with force: if it is not enough, a hum will occur during operation of the device.

The conductors are wound onto the coil tightly and evenly, each subsequent row is insulated from the previous one with thin paper or Mylar film. The last row is wrapped with keeper tape or varnished cloth. If a tap is made during the winding process, the wire breaks, and a tap is soldered in place of the break. This place is carefully isolated. The ends of the windings are secured with threads that tie the wires to the surface of the core.

There is a trick: after the primary winding, you should not wind the entire secondary winding at once. Having wound 10-20 turns, you need to measure the voltage at its ends.

Based on the obtained value, you can imagine how many turns will be required to obtain the required amplitude of the output voltage, thereby controlling the resulting calculation when assembling the transformer.

Transformer calculation online

There is a transformer calculation formula that helps to calculate the power transformer. To make your life easier and avoid errors in calculations, you can use this program. It will allow you to design transformers for various voltages and powers very quickly and without problems. This is a very convenient calculator for radio amateurs and professionals. It will help not only calculate the transformer, but also help you study its structure and how everything works. This is the easiest and fastest way to calculate everything. To do this, you need to fill in all the information you know and press the button. It turns out that you need to press one button to calculate the transformer!

Advantages of an online calculator

As a result of calculating the transformer online, the output parameters are obtained in the form of power, current in amperes, number of turns and wire diameter in the primary and secondary windings.

There are formulas that allow you to quickly perform transformer calculations. However, they do not provide a complete guarantee against errors in calculations. To avoid such troubles, an online calculator program is used.

The results obtained make it possible to design transformers for various powers and voltages. Using the calculator, not only transformer calculations are carried out. There is an opportunity to study its structure and basic functions.

The requested data is inserted into the table and all that remains is to click the desired button.

Thanks to the online calculator, you do not need to carry out any independent calculations. The results obtained allow you to rewind the transformer yourself.

Most of the necessary calculations are carried out in accordance with the dimensions of the core. The calculator simplifies and speeds up all calculations as much as possible.

You can obtain the necessary explanations from the instructions and then strictly follow their instructions.

The design of transformer magnetic cores is represented by three main options - armored, rod and toroidal. Other modifications are much less common. To calculate each type, initial data is required in the form of frequency, input and output voltage, output current and dimensions of each magnetic circuit.

Typical parameter calculation

Quite often, radio amateurs use a simplified method when calculating a transformer. It allows you to perform calculations at home without using quantities that are difficult to know. But it’s easier to use an online calculator ready for calculating a transformer. In order to use such a calculator, you will need to know some data, namely:

- voltage of the primary and secondary windings;

- core dimensions;

- plate thickness.

After entering them, you will need to click the “Calculate” button or something similar in name and wait for the result.

Rod type magnetic core

If it is not possible to calculate on a calculator, performing such an operation yourself is not difficult and manually. To do this, you will need to determine the voltage at the output of the secondary winding U2 and the required power Po. The calculation proceeds as follows:

After the first stage is completed, proceed to the next stage of calculation. The number of turns in the primary winding is determined by the formula: K1 = 50*U1/S. And the number of turns of the secondary winding is determined by the expression K2= 55* U2/S, where:

- U1 - voltage of the primary winding, V.

- S—core area, cm².

- K1, K2 - number of turns in windings, pcs.

It remains to calculate the diameter of the wound wire. It is equal to D = 0.632*√ I, where:

- d — wire diameter, mm.

- I is the winding current of the calculated coil, A.

Calculation of a pulse transformer of a push-pull converter

The advantage of push-pull converters is their simplicity and the ability to increase power. In a properly designed push-pull converter, a constant current passes through the winding, so there is no strong core bias. This allows you to use a full magnetization reversal cycle and get maximum power. Since it is performed on a ferrite core, the calculation of the output voltage of the transformer is similar to a conventional toroidal one.

You can simplify the transformer calculation options by using special calculation calculators, which are offered by some online resources. One has only to enter the desired data, and the machine will provide the necessary parameters of the planned electromagnetic device.

Network transformer calculation

- If you have a certain transformer core from which you need to make a transformer, then you need to measure the core (as shown in the figure), and also measure the thickness of the plate or tape.

- The first step is to calculate the cross-sectional area of the core - Sc (cm²) and the cross-sectional area of the window - So (cm²).

- For a toroidal transformer:

- Sc= H * (D – d)/2

- S0= π * d2/ 4

For W and P-shaped core:

Let's determine the overall power of our core at a frequency of 50 Hz:

- η is the efficiency of the transformer,

- Sc is the cross-sectional area of the core, cm2,

- So is the cross-sectional area of the window, cm2,

- f is the operating frequency of the transformer, Hz,

- B—magnetic induction, T,

- j is the current density in the winding wire, A/mm2,

- Km is the filling factor of the core window with copper,

- Kc is the coefficient of filling of the core section with steel.

When calculating a transformer, it is necessary to take into account that the overall power of the transformer must be greater than the calculated electrical power of the secondary windings.

The initial initial data for the simplified calculation are:

- primary winding voltage U1

- secondary winding voltage U2

- secondary winding current l2

- power of the secondary winding P2 = I2 * U2 = Pout

- core cross-sectional area Sc

- window cross-sectional area So

- transformer operating frequency f = 50 Hz

The efficiency (η) of the transformer can be taken from the table, provided that Pout = I2 * U2 (where I2 is the current in the secondary winding, U2 is the voltage of the secondary winding), if there are several secondary windings in the transformer, which is considered Pout each and then they are added.

B - magnetic induction is selected from the table, depending on the design of the magnetic circuit and Pout.

j is the current density in the winding wire, also selected depending on the design of the magnetic circuit and Pout.

Km - fill factor of the core window with copper

Kc is the coefficient of filling of the core section with steel

Fill factors for plate cores are indicated in parentheses when the plates are insulated with varnish or phosphate film.

During the initial calculation, it is necessary to comply with the condition - Pgab ≥ Pout; if this condition is not met, then during the calculation, reduce the current or voltage of the secondary winding.

Once you have decided on the overall power of the transformer, you can begin to calculate the voltage of one turn:

- where Sc is the cross-sectional area of the core, f is the operating frequency (50 Hz), B is the magnetic induction selected from the table, depending on the design of the magnetic core and Pout.

- Now we determine the number of turns of the primary winding:

- w1=U1/u1

- where U1 is the voltage of the primary winding, u1 is the voltage of one turn.

- The number of turns of each of the secondary windings is found from a simple proportion:

- where w1 is the number of turns of the primary winding, U1 is the voltage of the primary winding, U2 is the voltage of the secondary winding.

- Let's determine the power consumed by the transformer from the network, taking into account losses:

- Р1 = Рout / η

- where η is the efficiency of the transformer.

- We determine the current value in the primary winding of the transformer:

- I1 = P1/U1

- We determine the diameters of the wires of the transformer windings:

- d = 0.632*√ I

- where d is the wire diameter, mm, I is the winding current, A (for the primary and secondary windings).

How to assemble a transformer: proven technologies

The work consists of two separate stages:

- core installation;

- winding the coil.

Their sequence varies depending on the design of the magnetic circuit.

How to wind windings with wire: 2 ways

There are two ways to mount a winding with a wire around the core:

- By winding the turns directly onto a non-detachable magnetic circuit insulated with tapes and laying them evenly by hand.

- By creating a coil with a winding and inserting split plates into it.

The first method is more labor-intensive. It is used for toroidal magnetic cores made of solid electrical steel strips.

The core iron is wrapped with strips of insulating material, for example, varnished cloth or paper, to smooth out the sharp corners on the torus profile.

Special winding machines have been created for industrial purposes.

For home use this is a costly method. Here the procedure is simpler: a long piece of thick wire is rolled up like a snake (about a meter) and, threading it through the inner window of the core, the turns are laid by hand.

It is more convenient to place a thin wire on a shuttle made of a board or thick wire and push it inside the hole.

Each layer of the winding is covered with a layer of insulation.

The second method is used for collapsible cores assembled by joining individual U- or W-shaped plates.

A frame is made of insulating material under the coil. They can be electrical cardboard, getinaks, fiberglass. One of the forms is shown below.

The core plates should fit freely into the internal cavity, and the wire should be wound outside the frame. Holes are made in the top cover on each side to allow the ends to come out.

You can wind the coils manually or make a simple winding machine, which greatly facilitates this work.

I show two homemade versions of its execution with photographs below.

This design can be easily assembled from planks, giving it the shape of an inverted bench. It is now convenient to make a revolution counter, that is, the number of turns, from an old calculator.

To do this, open its case and carefully solder the wiring to the contacts of the “Equal” button. Their second ends are connected to a reed switch, which is fixed to the stand of the winding machine near the axis of rotation. A small magnet is mounted against it on the rotating part.

Each revolution of the shaft is accompanied by the passage of a magnet next to the reed switch and the operation of the latter. Closing the contact is accompanied by the display of the next number on the display.

The turns of the winding must be laid in even rows, as they did in Soviet times, appreciating the quality of work, and each layer must be covered with insulating paper.

Some home-made workers practice bulk winding, creating a total mass without any additional insulation according to the principle: it works that way.

Indeed: it works, but not for a long time. At numerous bends, knots with additional mechanical forces are created. Dynamic loads from magnetic fluxes and heating of the wire weaken the insulation at these points.

It breaks through over time, creating an interturn short circuit. The transformer loses the necessary performance characteristics and fails.

Thin baking paper produced for the manufacture of culinary products is very suitable for insulating layers.

They simply cut strips out of it with a stationery knife along the width of the coil opening and lay each layer with them.

The thin wire requires very careful handling; it can break from a small accidental tug. If there are few turns wound, then it is better to replace it. But, it is quite acceptable to strip the insulation, twist and solder the twist, and then re-insulate it.

When space inside the coil is limited, the broken end and its continuation are taken outside the frame and a connection is made there. In this case, it makes sense to place it on an individual terminal: it can be used as a separate tap to relieve some of the voltage or for checks.

The power windings of transformers of chargers and welding machines may be subject to increased heating. Therefore, it is useful to enhance their insulation by impregnating liquid glass. This is a regular silicate glue used to glue paper.

However, this technology takes a long time to complete: each layer must be dried after impregnation. But it will work reliably and for a long time. Therefore, this is done only for the most critical devices.

Windings created using the bulk principle can be strengthened by impregnation with a special varnish with electrical insulating properties, for example, grade ML-92. Impregnation is applied periodically during work to several layers of wire and allowed to dry.

You should not use nitro varnish, adhesives, or epoxy putties. They can corrode the factory insulation layer and are not suitable for copper in terms of linear expansion coefficient when heated: additional mechanical loads will be created.

Impregnation of the turns after the final winding of the coil is useless: liquid varnish simply will not penetrate deep into the winding.

How to mount magnetic circuit plates: what to pay special attention to

First, I recommend picking up one plate and examining it. You will notice different color shades on the two opposite sides. This is due to the insulation of iron with varnish. It happens that it is applied only on one side.

The plates must be inserted so that the layers of varnish constantly alternate and do not match in color.

Features of core disassembly

Electrical steel is soft, and in the assembled core it is tightly compressed. Often wedges made of fiberglass are used for fastening, sealing the free space. During disassembly they should be pulled out or knocked out.

Only after this the first plate is removed. If it fits tightly and cannot be reached, then it is first separated with a thin knife blade, and then knocked out with a hammer and a metal flat bar. You can use the blade of a simple screwdriver.

Features of core assembly

The main plates are alternately inserted from below and above the coil until its internal space is completely filled. Then additional inserts are added to them and knocked down on a flat hard object with light blows of a hammer.

It is necessary to ensure a tight fit of all joints to prevent loss of magnetic flux as it flows through the core.

In most dismountable magnetic cores, their structure is tightened with mounting bolts or screws. They must be reliably isolated from the core plates.

For this purpose, it is enough to cut out flat washers from thick cardboard and wrap the screws themselves in strips of paper.

Even such simple insulation will prevent the loss of electricity due to the creation of eddy currents.

All fastening screws should be tightened well. During operation, the transformer housing is exposed to dynamic forces from the magnetic flux flowing through it.

A poorly compressed magnetic circuit will hum, produce increased noise, and transmit additional forces to the winding. This cannot be allowed. The core must be assembled very tightly.

Calculation of a three-phase transformer

Manufacturing a three-phase transformer and its precise calculation is a more complex process, since here the primary and secondary windings already consist of three coils. This is a type of power transformer, the magnetic circuit of which is most often made using the rod method. Here such concepts as phase and linear voltages already appear. Linear ones are measured between two phases, and phase ones between a phase and ground. If a three-phase transformer is designed for 0.4 kV, then the linear voltage will be 380V, and the phase voltage 220V. The windings can be connected in a star or triangle, which gives different values of currents and voltages.

The windings of a three-phase transformer are located on the rods in the same way as in a single-phase one, i.e., the low voltage LV windings are placed closer to the rod, and the higher voltage HV windings are located on the lower voltage windings.

High-voltage three-phase current transformers are calculated and manufactured exclusively in industrial conditions. By the way, any step-down transformer, when switched back on, acts as a voltage-increasing device.