Why resistance occurs

Electrons, colliding with charged atoms (ions) that make up the crystal lattice of the conductor, lose speed. The mass of an atom significantly exceeds the mass of an electron, so their collision leads to a loss of speed (“braking”) and a change in the direction of motion of the electron. This creates resistance to the flow (increase) of current. This means that resistance is a physical quantity.

Collisions of electrons with atoms.

What is it measured in?

According to the international system of units, the value is measured in ohms multiplied by a meter. In some cases, the unit used is ohm multiplied by millimeter squared divided by meter. This is a designation for a conductor having a meter length and a square millimeter cross-sectional area.

Unit

Formula how to find

According to the provision from any textbook on electrodynamics, the resistivity of the conductor material formula is equal to the proportion of the total resistance of the conductor per cross-sectional area, divided by the conductor length. It is important to understand that the final indicator will be influenced by temperature and the degree of material purity. For example, if you add a little manganese to copper, the overall indicator will be increased several times.

Main calculation formula

Interestingly, there is a formula for inhomogeneous isotropic material. To do this, you need to know the electric field strength with the electric current density. To find it, you need to divide the first quantity by the other. In this case, the result is not a constant, but a scalar quantity.

Ohm's law in differential form

There is another, more difficult to understand formula for an inhomogeneous anisotropic material. Depends on the tensor coordinate.

It is important to note that the relationship between resistance and conductivity is also expressed by formulas. There are rules for finding isotropic and anisotropic materials through tensor components. They are shown in the diagram below.

Relationship with conductivity expressed in physical relations

Selecting the wire cross-section based on the number of consumers

What I also wanted to say is that it is better to use several independent power lines for each room in a room or apartment. Thus, you will not use a wire with a cross-section of 10 mm 2 for the entire apartment, routed to all rooms, from which there are taps.

Such a wire will come to the input machine, and then from it, in accordance with the power of the consumed load, selected wire sections will be routed for each of the rooms.

Typical electrical wiring diagram for an apartment or house with an electric stove (indicating the cable cross-section for electrical appliances)

What does it depend on

Resistance depends on temperature. It increases when the thermometer rises. This is explained by physicists in such a way that as the temperature increases, atomic vibrations in the crystalline conductor lattice increase. This prevents free electrons from moving around.

Note! As for semiconductors and dielectrics, the value decreases due to the fact that the structure of the concentration of charging carriers increases.

Temperature dependence as the main property of conductive resistance

Calculation of wire cross-section

Let's start not with a table, but with a calculation. That is, each person, without having the Internet at hand, where the PUE with tables is freely available, can independently determine the cable cross-section by current. To do this you will need a caliper and a formula.

If we consider the cross-section of the cable, it is a circle with a certain diameter. There is a formula for the area of a circle: S = 3.14*D²/4, where 3.14 is the Archimedean number, “D” is the diameter of the measured core. The formula can be simplified: S=0.785*D².

If the wire consists of several cores, then the diameter of each is measured, the area is calculated, then all the indicators are summed up. How to calculate the cross-section of a cable if each core consists of several thin wires?

The process becomes a little more complicated, but not much. To do this, you will have to count the number of wires in one core, measure the diameter of one wire, calculate its area using the described formula and multiply this figure by the number of wires. This will be the cross section of one core. Now you need to multiply this value by the number of cores.

If you don’t want to count the wires and measure their sizes, you just need to measure the diameter of one core, consisting of several wires. You must take measurements carefully so as not to crush the core. Please note that this diameter is not exact because there is space between the wires.

Relation between current and cross section

To understand how an electrical cable works, you need to remember a regular water pipe. The larger its diameter, the more water will pass through it. It's the same with wires.

The larger their area, the greater the current that will pass through them, the greater the load such a wire can withstand. In this case, the cable will not overheat, which is the most important requirement of fire safety rules.

Therefore, the cross-section - current connection is the main criterion that is used in the selection of electrical wires in the wiring. Therefore, you need to first figure out how many household appliances and what total power will be connected to each loop.

| Wire core cross-section, mm2 | Copper conductors | Aluminum conductors | ||

| Current, A | Power, W | Current, A | Power, W | |

| 0.5 | 6 | 1300 | ||

| 0.75 | 10 | 2200 | ||

| 1 | 14 | 3100 | ||

| 1.5 | 15 | 3300 | 10 | 2200 |

| 2 | 19 | 4200 | 14 | 3100 |

| 2.5 | 21 | 4600 | 16 | 3500 |

| 4 | 27 | 5900 | 21 | 4600 |

| 6 | 34 | 7500 | 26 | 5700 |

| 10 | 50 | 11000 | 38 | 8400 |

| 16 | 80 | 17600 | 55 | 12100 |

| 25 | 100 | 22000 | 65 | 14300 |

For example, the kitchen must have a refrigerator, microwave, coffee grinder and coffee maker, an electric kettle and sometimes a dishwasher. That is, all these devices can be turned on simultaneously at the same time. Therefore, the total power of the room is used in the calculations.

You can find out the power consumption of each device from the product passport or on the tag.

- For example, let's designate some of them:

- Kettle – 1-2 kW.

- Microwave and meat grinder 1.5-2.2 kW.

- Coffee grinder and coffee maker – 0.5-1.5 kW.

- Refrigerator 0.8 kW.

Having found out the power that will act on the wiring, you can select its cross-section from the table. We will not consider all the indicators in this table; we will show those that prevail in everyday life.

What do resistivity numbers mean?

In order to be able to compare the resistivity of different materials, from products such as copper and aluminum to other metals and substances including bismuth, brass and even semiconductors, it is necessary to use a standard measurement.

The unit of resistivity in the International System of Units (SI) is Ohm m.

The SI unit of resistivity is equal to the resistivity of a substance such that a homogeneous conductor 1 m long with a cross-sectional area of 1 m2, made from this substance, has a resistance of 1 ohm. Accordingly, the resistivity of an arbitrary substance, expressed in SI units, is numerically equal to the resistance of a section of an electrical circuit made of a given substance with a length of 1 m and a cross-sectional area of 1 m2

Resistivity table for common conductors

The table below shows resistivity values for various materials, particularly metals used for electrical conductivity.

Resistivity indicators are given for such “popular” materials as copper, aluminum, nichrome, steel, lead, gold and others.

MaterialResistivity, ρ, at 20 °C (Ohm m)Source

| Brass | ~0.6 – 0.9 x 10-7 | |

| Silver | 1.59×10−8 | [3][4] |

| Copper | 1.68×10−8 | [5][6] |

| Burnt copper | 1.72×10−8 | [7] |

| Gold | 2.44×10−8 | [3] |

| Aluminum | 2.65×10−8 | [3] |

| Calcium | 3.36×10−8 | |

| Tungsten | 5.60×10−8 | [3] |

| Zinc | 5.90×10−8 | |

| Cobalt | 6.24×10−8 | |

| Nickel | 6.99×10−8 | |

| Ruthenium | 7.10×10−8 | |

| Lithium | 9.28×10−8 | |

| Iron | 9.70×10−8 | [3] |

| Platinum | 1.06×10−7 | [3] |

| Tin | 1.09×10−7 | |

| Tantalum | 1.3×10−7 | |

| Gallium | 1.40×10−7 | |

| Niobium | 1.40×10−7 | [8] |

| Carbon steel (1010) | 1.43×10−7 | [9] |

| Lead | 2.20×10−7 | [2][3] |

| Galinstan | 2.89×10−7 | [10] |

| Titanium | 4.20×10−7 | |

| Electrical steel | 4.60×10−7 | [11] |

| Manganin (alloy) | 4.82×10−7 | [2] |

| Constantan (alloy) | 4.90×10−7 | [2] |

| Stainless steel | 6.90×10−7 | |

| Mercury | 9.80×10−7 | [2] |

| Manganese | 1.44×10−6 | |

| Nichrome (alloy) | 1.10×10−6 | [2][3] |

| Carbon (amorphous) | 5×10−4 — 8×10−4 | [3] |

| Carbon (graphite) parallel-basal plane | 2.5×10−6 — 5.0×10−6 | |

| Carbon (graphite) perpendicular-basal plane | 3×10−3 | |

| Gallium arsenide | 10−3 to 108 | |

| Germanium | 4.6×10−1 | [3][4] |

| Sea water | 2.1×10−1 | |

| Swimming pool water | 3.3×10−1 — 4.0×10−1 | |

| Drinking water | 2×101 — 2×103 | |

| Silicon | 2.3×103 | [2][3] |

| Wood (wet) | 103 — 104 | |

| Deionized water | 1.8×105 | |

| Glass | 1011 — 1015 | [3][4] |

| Carbon (diamond) | 1012 | |

| Hard rubber | 1013 | [3] |

| Air | 109 — 1015 | |

| Wood (dry) | 1014 — 1016 | |

| Sulfur | 1015 | [3] |

| Fused quartz | 7.5×1017 | [3] |

| PAT | 1021 | |

| Teflon | 1023 — 1025 |

It can be seen that the resistivity of copper and the resistivity of brass are both low, and considering their cost relative to silver and gold, they become cost-effective materials to use for many wires. Copper's resistivity and ease of use have led to it being widely used as a conductor material on printed circuit boards.

Occasionally, aluminum and especially copper are used due to their low resistivity. Most wires used for interconnection today are made of copper because it provides low resistivity at an affordable cost.

The resistivity of gold is also important because gold is used in some critical applications despite its cost. Gold plating is often found on high quality low current connectors where it provides the lowest contact resistance. The gold coating is very thin, but even so it is able to provide the required characteristics of the connectors.

Silver has a very low level of resistivity, but is not widely used due to its cost and because it tarnishes, which can result in higher contact resistance.

However, it is used in some radio transmitter coils where silver's low electrical resistivity reduces losses. When used for such purposes, silver was usually applied only to the existing copper wire. Coating the wire with silver allowed for significant cost savings compared to solid silver wire without significantly compromising performance.

It will be interesting➡ Total resistance

Other materials in the electrical resistivity table may not have such obvious uses. Tantalum appears in the table because it is used in capacitors—nickel and palladium are used in the end connections of many surface mount components such as capacitors.

Quartz finds its main application as a piezoelectric resonant element. Quartz crystals are used as frequency-determining elements in many oscillators, where the high Q value allows for very frequency-stable circuits. They are similarly used in high efficiency filters. Quartz has a very high level of resistivity and is not a good conductor of electricity, meaning it is classified as a dielectric.

Comments:

Stanislav

Unfortunately, even now developers do not hesitate to use aluminum cables. I saw in one new building an incoming aluminum cable from the meter to the consumer. At the same time, the construction company showed documents that, according to the rules, this is allowed...

Yurievich

Stanislav, the fact of the matter is that, according to pre-revolutionary rules, in some cases this is actually allowed, but people who invest money in these apartments even before construction expect that at least in this they will not be deceived, but aluminum is input is a very common practice.

Michael

And for me, one master connected aluminum with copper in a junction box with twists. The apartment almost burned down. And most importantly, at first everything works as it should, and only six months later it begins to spark, hiss and melt...

Oleg

In low-voltage and low-current networks, wiring made of copper, oxygen-free copper, silver or gold makes sense. And your networks have 220 V. Don’t fool around and don’t litter our people’s heads with garbage. They are already very weak. 16 sq. section - you have to be a complete fool to invent this nonsense. In power shields, the risers are laid thinner. Factories have produced and will continue to produce aluminum wires, regardless of your stupid articles.

Anton

Regarding the fragility of aluminum wire: I hung a chandelier in an old house built by captured Germans in the first years after the war - the soft aluminum wires bent so easily that it seemed as if under their own weight. This is the aluminum wire of the post-war years. And now in wires and cables it’s not aluminum, but duralumin; if you bend it, it even cracks, sometimes cracking at the bend.

irakli

moemu domu 46 let i aluminumevaia provodka rabotaet dosixpor bez problem 2.5mm a ne 16

Sergey

And my apartment burned down from overheated oxidized aluminum contacts. House 74 years old, Moscow. Luckily no one was hurt. Now only copper and arc-flash circuit breakers.

Sergey

Poor boy! Did he read this nonsense or memorize it?

Leave a comment Cancel reply

Similar posts

Hidden wiring in a wooden house - advantages and disadvantages, as well as features of installation Features and some secrets of installing open wiring in a wooden house with your own hands Replacing electrical wiring in an apartment, list of necessary tools and materials Correct connection of phase-zero-ground wires.

Concept of electrical resistance of a conductor

The classical definition explains electric current by the movement of “free” (valence) electrons. It is provided by the electric field created by the source. Movement in the metal is hampered not only by the normal components of the crystal lattice, but also by defective areas, impurities, and inhomogeneous areas. During collisions with obstacles, due to the transition of momentum into thermal energy, the temperature increases.

A good example is heating water with a boiler.

In gases, electrolytes and other materials the physics of the phenomenon is somewhat different. Linear relationships are observed in metals and other conductors. The basic relationships are expressed by the well-known formula of Ohm's law:

R (electrical resistance) = U (voltage) / I (current).

For convenience, the inverse quantity, conductivity (G = 1/R), is often used. It denotes the ability of a certain material to pass current with certain losses.

To simplify, the example of a water pipe is sometimes used. A moving fluid is an analogue of a current. Pressure is the equivalent of voltage. By decreasing (increasing) the cross section or position of the locking device, the conditions of movement are determined. In a similar way, the basic parameters of electrical circuits are changed using resistance (R).

For your information. The amount of liquid passing per unit time through the control section of the pipe is the equivalent of electrical power.

Temperature dependence ρ(T)

For most materials, numerous experiments have been carried out to measure resistivity values. Data for most conductors can be found in reference tables.

Specific resistance of metals and alloys, Ohm*mm2/m

(at T = 20C)

| Silver | 0,016 | Bronze (alloy) | 0,1 |

| Copper | 0,017 | Tin | 0,12 |

| Gold | 0,024 | Steel (alloy) | 0,12 |

| Aluminum | 0,028 | Lead | 0,21 |

| Iridium | 0,047 | Nickelin (alloy) | 0,42 |

| Molybdenum | 0,054 | Manganin (alloy) | 0,45 |

| Tungsten | 0,055 | Constantan (alloy) | 0,48 |

| Zinc | 0,06 | Titanium | 0,58 |

| Brass (alloy) | 0,071 | Mercury | 0,958 |

| Nickel | 0,087 | Nichrome (alloy) | 1,1 |

| Platinum | 0,1 | Bismuth | 1,2 |

Most often, the values of ρ are given at normal, that is, room temperature 20C. But it turned out that with increasing temperature, the resistivity increases linearly in accordance with the formula:

$ ρ(T) = ρ0 * (1 + α*T)$ (6),

where: ρ is the resistivity of the conductor at a temperature of 0C, α is the temperature coefficient of resistivity, which also has its own individual meaning for each substance. From formula (6) it follows that the coefficient α has dimension or .

In accordance with the Joule-Lenz law, when an electric current flows, heat is released, which means the temperature of the conductor increases. In addition, depending on the area of application, electrical devices can operate at both low (minus) and high temperatures. For accurate calculations of electrical circuits, it is necessary to take into account the dependence ρ(T). The value of α for a specific material can be found in reference literature.

Cable cross-section

The cable cross-section is the cut area of the current-carrying core. If the cut of the core is round (as in most cases) and consists of one wire, then the area/section is determined by the formula for the area of a circle. If there are many wires in the core, then the cross-section will be the sum of the cross-sections of all the wires in this core.

The cross-sectional values are standardized in all countries, and the standards of the former CIS and Europe in this part completely coincide. In our country, the document that regulates this issue is the “Rules for the Construction of Electrical Installations” or briefly - PUE.

The cable cross-section is selected based on the loads using special tables called “Permissible current loads on the cable.” If you have no desire to understand these tables, then it is enough for you to know that it is advisable to use a copper cable with a cross-section of 1.5-2.5 mm² for sockets, and 1.0-1.5 mm² for lighting.

To introduce one phase into an ordinary 2-3 room apartment, 6.0 mm² is quite enough. All the same, your 40-80 m² will not fit larger equipment, even taking into account the electric stove.

Many electricians, in order to “estimate” the required cross-section, believe that 1mm² of copper wire can pass 10A of electric current through itself: accordingly, 2.5 mm² of copper can pass 25A, and 4.0 mm² - 40A, etc. If you analyze the cable cross-section selection table a little, you will see that this method is only suitable for estimation and only for cables with a cross-section no higher than 6.0 mm².

Below is an abbreviated table for selecting cable cross-sections up to 35 mm² depending on current loads. For your convenience, the total power of electrical equipment is given there for 1-phase (220V) and 3-phase (380V) consumption.

When laying the cable in a pipe (i.e. in any closed spaces), the possible current loads on the cable should be less than when laying it openly. This is due to the fact that the cable heats up during operation, and heat transfer in a wall or in the ground is much lower than in open space.

When the load is called in kW, we are talking about the total load. Those. for a single-phase consumer, the load will be indicated for one phase, and for a three-phase consumer - in total for all three. When the load value is named in amperes (A), we are always talking about the load on one core (or phase).

Load table for cable cross-section:

| Cable cross-section, mm² | Laid open | Installed in a pipe | ||||||||||

| copper | aluminum | copper | aluminum | |||||||||

| current, A | power, kWt | current, A | power, kWt | current, A | power, kWt | current, A | power, kWt | |||||

| 220V | 380V | 220V | 380V | 220V | 380V | 220V | 380V | |||||

| 0.5 | 11 | 2.4 | ||||||||||

| 0.75 | 15 | 3.3 | ||||||||||

| 1 | 17 | 3.7 | 6.4 | 14 | 3 | 5.3 | ||||||

| 1.5 | 23 | 5 | 8.7 | 15 | 3.3 | 5.7 | ||||||

| 2.5 | 30 | 6.6 | 11 | 24 | 5.2 | 9.1 | 21 | 4.6 | 7.9 | 16 | 3.5 | 6 |

| 4 | 41 | 9 | 15 | 32 | 7 | 12 | 27 | 5.9 | 10 | 21 | 4.6 | 7.9 |

| 6 | 50 | 11 | 19 | 39 | 8.5 | 14 | 34 | 7.4 | 12 | 26 | 5.7 | 9.8 |

| 10 | 80 | 17 | 30 | 60 | 13 | 22 | 50 | 11 | 19 | 38 | 8.3 | 14 |

| 16 | 100 | 22 | 38 | 75 | 16 | 28 | 80 | 17 | 30 | 55 | 12 | 20 |

| 25 | 140 | 30 | 53 | 105 | 23 | 39 | 100 | 22 | 38 | 65 | 14 | 24 |

| 35 | 170 | 37 | 64 | 130 | 28 | 49 | 135 | 29 | 51 | 75 | 16 | 28 |

To independently calculate the required cable cross-section, for example, for entry into a house, you can use a cable calculator or select the required cross-section from the table.

This table applies to cables and wires with rubber and plastic insulation. These are such widespread brands as: PVS, GDP, VPP, PPV, APPV, VVG. AVVG and a number of others. Paper-insulated cables have their own table, and non-insulated wires and buses have their own.

When calculating the cable cross-section, the specialist must also take into account the methods of laying the cable: in trays, in bundles, etc.

- In addition, the values from the tables on permissible current loads must be adjusted by the following reduction factors:

- correction factor corresponding to the cable cross-section and its location in the block;

- correction factor for ambient temperature;

- correction factor for cables laid in the ground;

- correction factor for different numbers of operating cables laid nearby.

Electrical resistivity

Further research made it possible to establish a connection between the value of electrical resistance and its basic geometric dimensions. It turned out that the resistance of the conductor is directly proportional to the length of the conductor L and inversely proportional to the cross-sectional area of the conductor S.

This functional relationship is well described by the following formula:

$ R = ρ *{ Lover S} $ (4)

The constant value ρ for each substance was called resistivity. The value of this parameter depends on the density of the substance, its crystal structure, atomic structure and other internal characteristics of the substance. From formula (4) you can obtain a formula for calculating resistivity if experimental values for R, L and S are available:

$ ρ = R*{ Sover L } $ (5)

For most known substances, measurements were made and entered into reference tables of electrical resistance of conductors.

Specific resistance of metals, Ohm*mm2/m

(at T = 20C)

| Silver | 0,016 | Bronze (alloy) | 0,1 |

| Copper | 0,017 | Tin | 0,12 |

| Gold | 0,024 | Steel (alloy) | 0,12 |

| Aluminum | 0,028 | Lead | 0,21 |

| Iridium | 0,047 | Nickelin (alloy) | 0,42 |

| Molybdenum | 0,054 | Manganin (alloy) | 0,45 |

| Tungsten | 0,055 | Constantan (alloy) | 0,48 |

| Zinc | 0,06 | Titanium | 0,58 |

| Brass (alloy) | 0,071 | Mercury | 0,958 |

| Nickel | 0,087 | Nichrome (alloy) | 1,1 |

| Platinum | 0,1 | Bismuth | 1,2 |

It was experimentally discovered that as the temperature decreases, the resistance of metals decreases. When approaching the temperature of absolute zero, which is -273C, the resistance of some metals tends to zero. This phenomenon is called superconductivity. Atoms and molecules seem to “froze”, stop any movement and offer no resistance to the flow of electrons.

Iron as a conductor in electrical engineering

Iron is the most common metal in nature and technology (after hydrogen, which is also a metal). It is the cheapest and has excellent strength characteristics, therefore it is used everywhere as the basis for the strength of various structures.

In electrical engineering, iron is used as a conductor in the form of flexible steel wires where physical strength and flexibility are needed, and the required resistance can be achieved through the appropriate cross-section.

Having a table of resistivities of various metals and alloys, you can calculate the cross-sections of wires made from different conductors.

As an example, let's try to find the electrically equivalent cross-section of conductors made of different materials: copper, tungsten, nickel and iron wire. Let's take aluminum wire with a cross-section of 2.5 mm as the initial one.

We need that over a length of 1 m the resistance of the wire made of all these metals is equal to the resistance of the original one. The resistance of aluminum per 1 m length and 2.5 mm section will be equal to

, where R is the resistance, ρ is the resistivity of the metal from the table, S is the cross-sectional area, L is the length.

Substituting the original values, we get the resistance of a meter-long piece of aluminum wire in ohms.

After this, let us solve the formula for S

, we will substitute the values from the table and obtain the cross-sectional areas for different metals.

So,

Since the resistivity in the table is measured on a wire 1 m long, in microohms per 1 mm2 section, then we got it in microohms. To get it in ohms, you need to multiply the value by 10-6. But we don’t necessarily need to get the number ohm with 6 zeros after the decimal point, since we still find the final result in mm2.

- Copper

- Tungsten

- Nikelin

- Iron

It will be interesting➡ Useful power

As you can see, the resistance of the iron is quite high, the wire is thick.

But there are materials for which it is even greater, for example, nickel or constantan.

Conductivity of copper and aluminum table

When an electrical circuit is closed, at the terminals of which there is a potential difference, an electric current occurs.

Free electrons, under the influence of electric field forces, move along the conductor. In their movement, electrons collide with the atoms of the conductor and give them a supply of their kinetic energy. The speed of electron movement continuously changes: when electrons collide with atoms, molecules and other electrons, it decreases, then under the influence of an electric field it increases and decreases again during a new collision. As a result, a uniform flow of electrons is established in the conductor at a speed of several fractions of a centimeter per second.

Consequently, electrons passing through a conductor always encounter resistance to their movement from its side. When electric current passes through a conductor, the latter heats up.

Electrical resistance

The electrical resistance of a conductor, which is denoted by the Latin letter r, is the property of a body or medium to convert electrical energy into thermal energy when an electric current passes through it.

In the diagrams, electrical resistance is indicated as shown in Figure 1, a.

| Figure 1. Symbol for electrical resistance |

Variable electrical resistance that serves to change the current in a circuit is called rheostat . In the diagrams, rheostats are designated as shown in Figure 1, b.

In general, a rheostat is made of a wire of one resistance or another, wound on an insulating base.

The slider or rheostat lever is placed in a certain position, as a result of which the required resistance is introduced into the circuit.

A long conductor with a small cross-section creates a large resistance to current. Short conductors with a large cross-section offer little resistance to current.

If you take two conductors from different materials, but the same length and cross-section, then the conductors will conduct current differently. This shows that the resistance of a conductor depends on the material of the conductor itself.

The temperature of the conductor also affects its resistance. As temperature increases, the resistance of metals increases, and the resistance of liquids and coal decreases. Only some special metal alloys (manganin, constantan, nickel and others) hardly change their resistance with increasing temperature.

So, we see that the electrical resistance of a conductor depends on: 1) the length of the conductor, 2) the cross-section of the conductor, 3) the material of the conductor, 4) the temperature of the conductor.

The unit of resistance is one ohm. Om is often represented by the Greek capital letter Ω (omega). Therefore, instead of writing “The resistance of the conductor is 15 ohms,” you can simply write: r = 15 Ω. 1,000 Ohms is called 1 kiloohm (1kOhm, or 1kΩ), 1,000,000 Ohms is called 1 megaohm (1mOhm, or 1MΩ).

When comparing the resistance of conductors from different materials, it is necessary to take a certain length and cross-section for each sample. Then we will be able to judge which material conducts electric current better or worse.

1. Conductor resistance

Electrical resistivity

The resistance in ohms of a conductor 1 m long, with a cross-section of 1 mm² is called resistivity and is denoted by the Greek letter ρ (rho).

Table 1 shows the resistivities of some conductors.

Table 1

Resistivities of various conductors

| Conductor material | Specific resistance ρ in |

| Silver Copper Aluminum Tungsten Iron LeadNickelin (alloy of copper, nickel and zinc) Manganin (alloy of copper, nickel and manganese) Constantan (alloy of copper, nickel and aluminum) MercuryNichrome (alloy of nickel, chromium, iron and manganese) | 0,016 0,0175 0,03 0,05 0,13 0,2 0,42 0,43 0,5 0,941,1 |

The table shows that an iron wire with a length of 1 m and a cross-section of 1 mm² has a resistance of 0.13 Ohm. To get 1 Ohm of resistance you need to take 7.7 m of such wire. Silver has the lowest resistivity.

1 Ohm of resistance can be obtained by taking 62.5 m of silver wire with a cross section of 1 mm². Silver is the best conductor, but the cost of silver excludes the possibility of its mass use. After silver in the table comes copper: 1 m of copper wire with a cross section of 1 mm² has a resistance of 0.0175 Ohm.

To get a resistance of 1 ohm, you need to take 57 m of such wire.

Chemically pure copper, obtained by refining, has found widespread use in electrical engineering for the manufacture of wires, cables, windings of electrical machines and devices. Aluminum and iron are also widely used as conductors.

The conductor resistance can be determined by the formula:

where r is the conductor resistance in ohms; ρ – conductor resistivity; l – conductor length in m; S – conductor cross-section in mm².

Example 1. Determine the resistance of 200 m of iron wire with a cross section of 5 mm².

Example 2. Calculate the resistance of 2 km of aluminum wire with a cross section of 2.5 mm².

From the resistance formula you can easily determine the length, resistivity and cross-section of the conductor.

Example 3. For a radio receiver, it is necessary to wind a 30 Ohm resistor from nickel wire with a cross section of 0.21 mm². Determine the required wire length.

Example 4. Determine the cross-section of 20 m of nichrome wire if its resistance is 25 Ohms.

Example 5. A wire with a cross section of 0.5 mm² and a length of 40 m has a resistance of 16 Ohms. Determine the wire material.

The material of the conductor characterizes its resistivity.

Based on the resistivity table, we find that lead has this resistance.

It was stated above that the resistance of conductors depends on temperature. Let's do the following experiment. Let's wind several meters of thin metal wire in the form of a spiral and connect this spiral to the battery circuit.

To measure current, we connect an ammeter to the circuit. When the coil is heated in the burner flame, you will notice that the ammeter readings will decrease.

This shows that the resistance of a metal wire increases with heating.

For some metals, when heated by 100°, the resistance increases by 40–50%. There are alloys that change their resistance slightly with heating.

Some special alloys show virtually no change in resistance when temperature changes.

The resistance of metal conductors increases with increasing temperature, while the resistance of electrolytes (liquid conductors), coal and some solids, on the contrary, decreases.

The ability of metals to change their resistance with changes in temperature is used to construct resistance thermometers. This thermometer is a platinum wire wound on a mica frame. By placing a thermometer, for example, in a furnace and measuring the resistance of the platinum wire before and after heating, the temperature in the furnace can be determined.

The change in the resistance of a conductor when it is heated, per 1 ohm of initial resistance and per 1° temperature, is called

the temperature coefficient of resistance and is denoted by the letter α.

If at temperature t0 the resistance of the conductor is equal to r0, and at temperature t is equal to rt, then the temperature coefficient of resistance

Note. Calculation using this formula can only be done in a certain temperature range (up to approximately 200°C).

We present the values of the temperature coefficient of resistance α for some metals (Table 2).

table 2

Temperature coefficient values for some metals

| Metal | α | Metal | α |

| Silver Copper Iron TungstenPlatinum | 0,0035 0,0040 0,0066 0,00450,0032 | Mercury Nikelin Constantan Nichrome Manganin | 0,0090 0,0003 0,000005 0,000160,00005 |

From the formula for the temperature coefficient of resistance we determine rt:

rt = r0 [1 ± α (t – t0)].

Example 6. Determine the resistance of an iron wire heated to 200°C, if its resistance at 0°C was 100 Ohms.

rt = r0 [1 ± α (t – t0)] = 100 (1 + 0.0066 × 200) = 232 Ohm.

Example 7. A resistance thermometer made of platinum wire in a room with a temperature of 15°C had a resistance of 20 ohms. The thermometer was placed in the oven and after some time its resistance was measured. It turned out to be equal to 29.6 Ohms. Determine the temperature in the oven.

Electrical conductivity

So far, we have considered the resistance of a conductor as the obstacle that the conductor provides to the electric current. But still, current flows through the conductor. Therefore, in addition to resistance (obstacle), the conductor also has the ability to conduct electric current, that is, conductivity.

The more resistance a conductor has, the less conductivity it has, the worse it conducts electric current, and, conversely, the lower the resistance of a conductor, the more conductivity it has, the easier it is for current to pass through the conductor. Therefore, the resistance and conductivity of a conductor are reciprocal quantities.

From mathematics we know that the reciprocal of 5 is 1/5 and, conversely, the reciprocal of 1/7 is 7. Therefore, if the resistance of a conductor is denoted by the letter r, then the conductivity is defined as 1/r. Conductivity is usually symbolized by the letter g.

Electrical conductivity is measured in (1/Ohm) or in siemens.

Example 8. The conductor resistance is 20 ohms. Determine its conductivity.

If r = 20 Ohm, then

Example 9. The conductivity of the conductor is 0.1 (1/Ohm). Determine its resistance

If g = 0.1 (1/Ohm), then r = 1 / 0.1 = 10 (Ohm)

Selecting the cross-section of wire, cable (copper, aluminum) based on power. Calculation of cross-section based on diameter (video)

The use of useful work of electric current is already something commonplace, irreplaceable and self-evident. Indeed, only two centuries have passed since the first currents were obtained from the first battery by the great scientist Alessandro Volta, back in 1800.

Why do metals have the lowest resistivities?

From the table above it can be seen that metals have the lowest resistivity values: silver, copper, gold, aluminum, etc. This property of metals is associated with a high concentration of free electrons, “not tied” to a specific atom, but wandering in the space of the crystal lattice. Voltage applied to the ends of a conductor creates an electric field that acts on the electrons, causing them to move in concert in the same direction.

Rice. 2. Electric current in metals, free electrons.

Silver has the lowest ρ value - 0.016 Ohm*mm2/m. But for widespread, mass use in power supply networks and equipment, this metal is not used due to its too high price. Silver is used to create the most critical contacts in special electrical devices. The following table shows the resistivity values of metals and alloys, commonly used metals in electrical engineering:

Table

Specific resistances of metals, Ohm*mm2/m

(at T = 200C)

| Silver | 0,016 | Bronze (alloy) | 0,1 |

| Copper | 0,017 | Tin | 0,12 |

| Gold | 0,024 | Steel (alloy) | 0,12 |

| Aluminum | 0,028 | Lead | 0,21 |

| Iridium | 0,047 | Nickelin (alloy) | 0,42 |

| Molybdenum | 0,054 | Manganin (alloy) | 0,45 |

| Tungsten | 0,055 | Constantan (alloy) | 0,48 |

| Zinc | 0,06 | Titanium | 0,58 |

| Brass (alloy) | 0,071 | Mercury | 0,958 |

| Nickel | 0,087 | Nichrome (alloy) | 1,1 |

| Platinum | 0,1 | Bismuth | 1,2 |

The most popular in electrical engineering are copper and aluminum. Copper and copper alloys are used to make cable products and shunts - parts that limit large currents through measuring instruments.

Advantages

This metal is lightweight. This advantage is particularly noticeable in situations where large amounts of aluminum cable need to be used. Thus, the lightness of this metal makes aluminum cable a favorite when laying power lines. It's worth noting that aluminum is a very common metal and costs less than copper. Actually, these two factors became the reason for the use of aluminum wiring in housing construction in the USSR.

Another feature that can be considered as an advantage is corrosion resistance. Although there are some nuances here. The fact is that the surface of aluminum upon contact with air immediately (almost instantly) oxidizes. A film forms on top, which subsequently protects the rest of the wire from oxidation. The downside is the poor ability of the film to conduct current. As a result, problems arise in the passage of current at the cable junctions.

Effect of temperature on resistivity

In reference books, the values of ρ of metals are given at room temperature 200C. But experiments have shown that the dependence ρ(T) is linear and is described by the formula:

$ ρ(T) = ρ0 * (1 + α*T)$ (3),

where: ρ0 is the resistivity of the conductor at a temperature of 00C, α is the temperature coefficient of resistance, which is also individual for each substance. Values of α obtained experimentally can be found in reference books. Below are α values for some metals:

- Silver - 0.0035;

- Copper - 0.004;

- Aluminum - 0.004;

- Iron - 0.0066;

- Platinum - 0.0032;

- Tungsten - 0.0045.

Thus, as the temperature increases, the resistance of metals increases. This is explained by the fact that with increasing temperature, the number of defects in the crystal lattice increases due to more intense thermal vibrations of the ions, which inhibit the electron current.

Temperature dependence of resistivity of metals.

As the metal temperature approaches absolute zero, the resistivity drops sharply to zero. This phenomenon is called superconductivity, and materials that exhibit this ability are called superconductors. This effect was discovered in 1911 by the Dutch physicist Kamerlingh Onnes. In his experiment, the resistivity of mercury decreased to zero at 4.10K.

Properties of resistive materials

The resistivity of a metal depends on temperature. Their values are usually given for room temperature (20°C). The change in resistivity as a result of a change in temperature is characterized by a temperature coefficient.

For example, thermistors (thermistors) use this property to measure temperature. On the other hand, in precision electronics, this is a rather undesirable effect. Metal film resistors have excellent temperature stability properties. This is achieved not only due to the low resistivity of the material, but also due to the mechanical design of the resistor itself.

Many different materials and alloys are used in the manufacture of resistors. Nichrome (an alloy of nickel and chromium), due to its high resistivity and resistance to oxidation at high temperatures, is often used as a material for making wirewound resistors. Its disadvantage is that it cannot be soldered. Constantan, another popular material, is easy to solder and has a lower temperature coefficient.

Rolled and low-grade material

Electrical aluminum obtained during foundry production is accepted separately. Usually these are components for machine tools, automobile, and aircraft components. Piston scrap contains silicon. Rental points in Moscow accept electrical aluminum with nickel if the component content is no more than 2.8%.

Low grade electrical aluminum - crushed, shavings. The material is sorted by alloy type. A separate class is multi-grade shavings.

Features of supplied aluminum

Electrical aluminum, stripped of insulation, is highly valued at rental points in Moscow. If there are transformers, they must be removed from the bus. The veins are cleaned mechanically, since firing leads to melting and the appearance of streaks on the metal. No paper allowed.

The most valuable aluminum is shiny and clean. The presence of oil is a reason for a decrease in cost due to clogging. If there is a steel core inside, cutting is necessary. Products with traces of oxidation and paint are not accepted. Before delivery, it is necessary to remove the wire grid, damaged parts, and elements containing impurities.

Sources and examples of scrap metal

Electrical aluminum is widely used. These are thin or thick wires and cables used in wiring in homes and large communication networks. In new systems, aluminum parts are less common than durable copper, but in old systems they are widespread. Since many people are replacing wiring with copper, the amount of electrical aluminum that can be recycled is large.

Important and useful

Individuals, enterprises, and large companies can donate electrical aluminum in Moscow

This is not only financially beneficial, but also important for the environment. Recycling and recycling of metal alloys helps protect the environment, maintain the balance of the planet, and protect people from the dangers associated with metal oxidation

Recycled aluminum is used in production processes, which saves costs and conserves resources.

◄ Back to news

High conductivity materials

The most widespread materials of high conductivity include copper and aluminum (Superconducting materials, which have a typical resistance 10-20 times lower than ordinary conductive materials (metals), are discussed in the section Superconductivity).

Copper

The advantages of copper, which ensure its widespread use as a conductor material, are as follows:

- low resistivity;

- sufficiently high mechanical strength;

- corrosion resistance is satisfactory in most applications;

- good workability: copper is rolled into sheets, strips and drawn into wire, the thickness of which can be increased to thousandths of a millimeter;

- relative ease of soldering and welding.

Copper is most often obtained by processing sulfide ores. After a series of ore smelting and roasting with intense blasting, copper intended for electrical purposes must undergo a process of electrolytic purification.

Copper grades M1 and M0 are most often used as conductor material. M1 grade copper contains 99.9% Cu, and in the total amount of impurities (0.1%) oxygen should be no more than 0.08%. The presence of oxygen in copper worsens its mechanical properties. The best mechanical properties are found in M0 grade copper, which contains no more than 0.05% impurities, including no more than 0.02% oxygen.

Copper is a relatively expensive and scarce material, so it is increasingly being replaced by other metals, especially aluminum.

In some cases, alloys of copper with tin, silicon, phosphorus, beryllium, chromium, magnesium, and cadmium are used. Such alloys, called bronzes, with the correct composition, have significantly higher mechanical properties than pure copper.

Aluminum

Aluminum is the second most important conductor material after copper. This is the most important representative of the so-called light metals: the density of cast aluminum is about 2.6, and rolled aluminum is 2.7 Mg/m3. Thus, aluminum is approximately 3.5 times lighter than copper. The temperature coefficient of expansion, specific heat capacity and heat of fusion of aluminum are greater than those of copper. Due to the high values of specific heat capacity and heat of fusion, heating aluminum to the melting point and transferring it to a molten state requires more heat than heating and melting the same amount of copper, although the melting point of aluminum is lower than that of copper.

Aluminum has lower properties compared to copper - both mechanical and electrical. With the same cross-section and length, the electrical resistance of an aluminum wire is 1.63 times greater than that of a copper wire. It is very important that aluminum is less scarce than copper.

For electrical purposes, aluminum containing no more than 0.5% impurities, grade A1, is used. Even purer AB00 grade aluminum (no more than 0.03% impurities) is used for the manufacture of aluminum foil, electrodes and housings of electrolytic capacitors. Aluminum of the highest purity AB0000 has an impurity content of no more than 0.004%. Additives of Ni, Si, Zn or Fe at a content of 0.5% reduce the γ of annealed aluminum by no more than 2-3%. A more noticeable effect is exerted by Cu, Ag and Mg impurities, which, at the same mass content, reduce γ aluminum by 5-10%. Ti and Mn greatly reduce the electrical conductivity of aluminum.

Aluminum oxidizes very actively and becomes covered with a thin oxide film with high electrical resistance. This film protects the metal from further corrosion.

It will be interesting➡ What is an autotransformer?

Aluminum alloys have increased mechanical strength. An example of such an alloy is Aldrey, containing 0.3-0.5% Mg, 0.4-0.7% Si and 0.2-0.3% Fe. In aldrey, the Mg2Si compound is formed, which imparts high mechanical properties to the alloy.

Iron and steel

Iron (steel), as the cheapest and most accessible metal, which also has high mechanical strength, is of great interest for use as a conductor material. However, even pure iron has a significantly higher resistivity compared to copper and aluminum; ρ steel, i.e. iron mixed with carbon and other elements is even higher. Ordinary steel has low corrosion resistance: even at normal temperatures, especially in conditions of high humidity, it quickly rusts; As the temperature rises, the corrosion rate increases sharply. Therefore, the surface of steel wires must be protected by a layer of more resistant material. Zinc coating is usually used for this purpose.

In some cases, to reduce the consumption of non-ferrous metals, the so-called bimetal is used. It is steel coated on the outside with a layer of copper, with both metals connected to each other firmly and continuously.

Sodium

Sodium metal is a very promising conductor material. Sodium can be obtained by electrolysis of molten sodium chloride NaCl in virtually unlimited quantities. From a comparison of the properties of sodium with the properties of other conductor metals, it is clear that the resistivity of sodium is approximately 2.8 times greater than ρ of copper and 1.7 times greater than ρ of aluminum, but due to the extremely low density of sodium (its density is almost 9 times less than the density of copper), a wire made of sodium for a given conductivity per unit length should be significantly lighter than a wire made of any other metal. However, sodium is extremely active chemically (it oxidizes intensely in air and reacts violently with water), which is why the sodium wire must be protected with a sealing sheath. The sheath must give the wire the necessary mechanical strength, since sodium is very soft and has a low tensile strength during deformation.

Conductivity of copper and aluminum table - Metalworker's Handbook

After reading this article, you will learn about the following questions:

We actively use electricity in every area of our lives. Of course, having electricity in the house is one of the main requirements for our existence. This electricity is supplied through wires. Moreover, they approach both the house or apartment itself and pass through all the rooms of our house. Various types of wiring are used to transmit electrical current.

The most popular is aluminum wiring. Actually, we will focus on such wiring in this article. First, I would like to note that aluminum wiring cannot boast of excellent performance characteristics. In other words, it cannot be called the most suitable or the most ideal. However, it is found in almost every home.

And this fact is due to the characteristics of aluminum itself.

Advantages

This metal is lightweight. This advantage is particularly noticeable in situations where large amounts of aluminum cable need to be used.

Thus, the lightness of this metal makes aluminum cable a favorite when laying power lines. It's worth noting that aluminum is a very common metal and costs less than copper.

Actually, these two factors became the reason for the use of aluminum wiring in housing construction in the USSR.

Another feature that can be considered as an advantage is corrosion resistance. Although there are some nuances here. The fact is that the surface of aluminum upon contact with air immediately (almost instantly) oxidizes.

A film forms on top, which subsequently protects the rest of the wire from oxidation. The downside is the poor ability of the film to conduct current.

As a result, problems arise in the passage of current at the cable junctions.

Flaws

Aluminum wiring is characterized by high electrical resistivity. This resistance is equal to 0.0271 Ohm x sq.mm/m. Taking this fact into account, the latest editions of the PUE note that in an apartment or house you can only use aluminum wiring whose cross-section exceeds 16 square meters. millimeters.

Ultimately, it turns out that to ensure the required level of throughput, you need to use a cable with a large cross-section. In other words, you need to install wiring that is thick. If we compare copper wiring, it has an electrical resistivity that is equal to 0.0175 Ohm x sq. mm/m.

This wiring is more efficient and for use in the home you can use copper cable with a smaller cross-section.

As noted above, aluminum is capable of oxidizing and the film formed during this process has poor conductivity. There is one more nuance here: this film is formed from the top of the wire.

As a result, there is a slight decrease in its cross-section, and as a result, the resistance increases.

Since the film on aluminum wiring has a high resistance, the transition resistance increases at the junction of individual parts of the wire. As a result, it manifests itself in heating of the wiring in such places.

In situations where the load on aluminum wiring increases, it begins to heat up. If the wire has a sufficient cross-section, then there is nothing to worry about.

However, if the wiring is not designed for such a load or is used beyond its normal service life, then this will necessarily lead to its heating.

The last fact can be called very bad for connection points. The fact is that when aluminum is heated, its shape and ductility change. Of course, the wire expands. After the load has disappeared and the cable has cooled, it takes on its usual shape. However, after repeated repetition of such processes, the contact between the ends of the electrical wires weakens.

Aluminum is also highly brittle. It increases greatly after it overheats. As for the service life, for aluminum wiring it is 25 years. After this, you need to install a different type of wiring.

Rules for using aluminum wiring

As you can see, wiring made of aluminum cannot be called the most optimal option for use in the home. However, it can be used if certain requirements are met:

- The cross section must be at least 16 square meters. millimeters.

- To connect the individual parts, clamp contacts must be used. In this case, you should use a special lubricant, which will prevent oxidation of the contacts and maintain a low level of contact resistance.

Helpful Hint: The connection can also be made in another way. It involves welding aluminum electrical wires in junction boxes. This method requires more costs and more time. Therefore, many electricians try to avoid it. With this in mind, anyone who installs aluminum wiring in their home should supervise the work of electricians.

Comparison with copper wiring

Comparison table between aluminum and copper in wiring

Note that it will be much simpler and safer to use copper wiring. We indicated above that copper wiring is characterized by lower resistivity. In other words, a copper cable with the same cross-section as an aluminum one can carry more current. In addition, copper electrical wire:

- is more resistant to physical impacts (it does not break after several bends);

- has a long shelf life;

- does not lose its conductive properties during oxidation.

A notable fact is that aluminum and copper oxidize. However, the films that are formed have different properties. First of all, this concerns current conductivity.

As we have already noted, the oxidation film of aluminum wiring has poor conductivity. A similar film on copper wiring has high current conductivity.

Electrical wires made of aluminum oxidize much faster than copper wires.

Copper oxidizes at room temperature, but the film that appears on the surface of the copper is very weak and easy to destroy. To do this, just twist the two cables tightly.

Strong oxidation of copper begins when the temperature rises above 70 degrees Celsius. We can conclude that copper cable is of higher quality and, most importantly, safer.

The reason for the popularity of aluminum lies in its cheapness.

Why can't you twist aluminum and copper cables?

Of course, if you are planning to rewire your home and are unable to install all the electrical wires made of copper, you can combine these two types of wiring.

In other words, you can use aluminum cables to supply current to lighting fixtures and copper wires to supply current to outlets or powerful electrical appliances.

At the same time, in some places it will be necessary to connect copper and aluminum wiring.

It should be noted from the outset that direct contact between copper and aluminum is, at a minimum, not recommended. This means that it is impossible to twist electrical wires made of two metals.

Why? The reason lies in their physical properties. These two metals have different conductivities and, as a result, the junctions between them will heat up.

This is also facilitated by the presence of oxidizing films.

If we talk about the oxidation film on copper wiring, then it can conduct current and therefore does not greatly affect heating. But the same film on an aluminum electrical wire has a strong resistance and, accordingly, passes less current.

This fact increases the heating. As the cables heat up, they expand. Since copper is a harder metal than aluminum, copper electrical wire leads to some deformation of the aluminum wire.

As a result, when cooling occurs, the connection itself looks slightly different.

After heating and cooling several times, the connection becomes loose, leading to problems such as overheating, sparking, and burning. The appearance of a galvanic couple also occurs. However, it only appears when moisture gets into the connection.

Otherwise, this pair will not form. A galvanic couple appears because at the junction of such wires, which we call copper and aluminum, dissociation of the oxides of the electrical wires begins. This process involves the breakdown of the oxide into charged ions.

What is the resistance of copper wire

In metals, a current is formed when an electric field appears. It “forces” electrons to move in an orderly manner, in one direction. Electrons from the distant orbits of an atom, weakly held by the nucleus, form a current.

Copper wires

As negative particles pass through the crystal lattice of copper molecules, they collide with atoms and other electrons. There is an obstacle or resistance to the directional movement of particles.

To evaluate the resistance to current, the value of “electrical resistance” or “electrical impedance” was introduced. It is designated by the letter “R” or “r”. Resistance is calculated using Georg Ohm's formula: R=, where U is the potential difference or voltage acting on a section of the circuit, I is the current strength.

Concept of resistance

Important! The higher the impedance value of a metal, the less current passes through it, and it is copper conductors that are so widespread in electrical engineering due to this property.

Based on Ohm's formula, the magnitude of the current is affected by the applied voltage at a constant R. But the resistance of copper wires varies depending on their physical characteristics and operating conditions.

Electrical conductivity and current carriers

The electrical conductivity of all substances is associated with the presence of current carriers (charge carriers) in them - mobile charged particles (electrons, ions) or quasiparticles (for example, holes in a semiconductor) capable of moving in a given substance over a long distance; in a simplified way, we can say what is meant that such a particle or quasiparticle should be able to travel an arbitrarily large, at least macroscopic, distance in a given substance, although in some particular cases carriers can change, being born and destroyed (generally speaking, sometimes, perhaps, through a very short distance), and carry current, replacing each other.

Since the current density is determined for one type of carrier by the formula:

j→=qnv→cp.,{\displaystyle {\vec {j}}=qn{\vec {v}}_{cp.},} where q{\displaystyle q} is the charge of one carrier, n{\displaystyle n} is the concentration of carriers, v→cp.{\displaystyle {\vec {v}}_{cp.}} is the average speed of their movement,

or j→=∑iqiniv→icp.{\displaystyle {\vec {j}}=\sum _{i}q_{i}n_{i}{\vec {v}}_{icp.}} for more than one type of carrier, numbered by the index i,{\displaystyle i,} taking a value from 1 to the number of types of carriers, each of which can have its own charge (possibly different in magnitude and sign), its own concentration, its own average speed of movement (summation in this formula is implied for all available types of carriers), then, given that the (steady-state) average speed of each type of particle when moving in a specific substance (medium) is proportional to the applied electric field (in the case when the movement is caused precisely by this field, which is what we are here we are considering):

v→cp.=μE→,{\displaystyle {\vec {v}}_{cp.}=\mu {\vec {E}},} where μ{\displaystyle \mu } is a proportionality coefficient called mobility and depending on the type of current carrier in a given specific environment.

It follows that the expression for electrical conductivity is valid:

σ=qnμ,{\displaystyle \sigma =qn\mu ,}

or:

σ=∑iqiniμi{\displaystyle \sigma =\sum _{i}q_{i}n_{i}\mu _{i}} - for more than one type of media.

What affects the resistance of a copper wire

The electrical impedance of a copper cable depends on several factors:

- Specific resistance;

- Wire cross-sectional area;

- Wire lengths;

- External temperature.

The last point can be neglected in conditions of domestic use of the cable. A noticeable change in impedance occurs at temperatures above 100°C.

Resistance dependence

Resistivity in the SI system is denoted by the letter ρ. It is defined as the resistance value of a conductor having a cross-section of 1 m2 and a length of 1 m, measured in Ohm ∙ m2. This dimension is inconvenient in electrical calculations, so the unit of measurement Ohm ∙ mm2 is often used.

Important! This parameter is a characteristic of the substance - copper. It does not depend on the shape or cross-sectional area. The purity of the copper, the presence of impurities, the method of making the wire, and the temperature of the conductor are factors that affect the resistivity.

The dependence of the parameter on temperature is described by the following formula: ρt= ρ20[1+ α(t−20°C)]. Here ρ20 is the resistivity of copper at 20°C, α is an empirically found coefficient, from 0°C to 100°C for copper it has a value equal to 0.004 °C-1, t is the temperature of the conductor.

Below is a table of ρ values for different metals at a temperature of 20°C.

Resistivity table

According to the table, copper has a low resistivity, lower only for silver. This ensures good conductivity of the metal.

The thicker the wire, the lower its resistance. The dependence of R of the conductor on the cross-section is called “inversely proportional”.

Important! As the cross-sectional area of the cable increases, it is easier for electrons to pass through the crystal lattice. Therefore, with increasing load and increasing current density, the cross-sectional area should be increased.

An increase in the length of a copper cable entails an increase in its resistance. Impedance is directly proportional to the length of the wire. The longer the conductor, the more atoms there are in the path of free electrons.

conclusions

The last element that affects the resistance of copper is the temperature of the environment. The higher it is, the greater the amplitude of movement of the atoms of the crystal lattice. Thus, they create an additional obstacle for electrons participating in directed movement.

Important! If you lower the temperature to absolute zero, which has a value of 0° K or -273°C, then the opposite effect will be observed - the phenomenon of superconductivity. In this state, the substance has zero resistance.

Temperature correlation

Cable selection

It is best to make internal wiring using copper wires. Although aluminum ones are not inferior to them. But there is one nuance here, which is associated with the correct connection of sections in the distribution box. As practice shows, connections often fail due to oxidation of the aluminum wire.

Another question is which wire to choose: single-core or stranded? Single-core has better current conductivity, so it is recommended for use in household electrical wiring. Multicore has high flexibility, which allows it to be bent in one place several times without compromising quality.

Single or stranded

When installing electrical wiring, wires and cables of the PVS, VVGng, PPV, APPV brands are usually used. This list contains both flexible cables and monocore cables.

Here we would like to tell you one thing. If your wiring will not move, that is, it is not an extension cord, or a bend point that constantly changes its position, then it is preferable to use a monocore.

You will ask why? It's simple! No matter how well the conductors are laid in the protective insulating braid, air containing oxygen will still get under it. Oxidation of the copper surface occurs.

As a result, if there are many conductors, then the oxidation area is much larger, which means the current-carrying cross-section “melts” much more. Yes, this is a long process, but we don’t think that you are going to change the wiring often. The more she works, the better.

This oxidation effect will be especially pronounced at the edges of the cable cut, in rooms with temperature changes and high humidity. So we strongly recommend that you use monocore! The cross-section of a monocore cable or wire will change slightly over time, and this is so important for our further calculations.

Copper or aluminum

In the USSR, most residential buildings were equipped with aluminum wiring; this was a kind of norm, standard, and even dogma. No, this does not mean at all that the country was poor and there was a shortage of copper. Even in some cases it's the other way around.

But apparently the designers of electrical networks decided that they could save a lot economically if they used aluminum rather than copper. Indeed, the pace of construction was enormous; just remember the Khrushchev buildings, in which half of the country still lives, which means the effect of such savings was significant. There is no doubt about this.

However, today the realities are different, and aluminum wiring is not used in new residential premises, only copper. This is based on the rules of the PUE, clause 7.1.34 “Cables and wires with copper conductors should be used in buildings...”.

So, we strongly do not recommend that you experiment and try aluminum. Its disadvantages are obvious. Aluminum strands cannot be soldered and are also very difficult to weld; as a result, the contacts in the junction boxes may break over time. Aluminum is very fragile, two or three bends and the wire falls off.

There will be constant problems connecting it to sockets and switches. Again, if we talk about conducted power, then a copper wire with the same cross-section for aluminum is 2.5 mm2. allows a continuous current of 19A, and for copper 25A. Here the difference is more than 1 kW.

So let’s repeat it again - only copper! Further, we will proceed from the fact that we are calculating the cross-section for a copper wire, but in the tables we will also give values for aluminum. You never know.

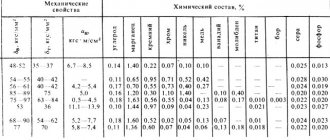

Comparison of conductivity of different types of steel

The characteristics of steel depend on its composition and temperature:

- For carbon alloys, the resistance is quite low: it is 0.13-0.2 μOhm/m. The higher the temperature, the greater the value;

- Low-alloy alloys have a higher resistance - 0.2-0.43 μOhm/m;

- High-alloy steels have high resistance - 0.3-0.86 μOhm/m;

- Due to the high chromium content, the resistance of chromium stainless alloys is 0.5-0.6 μOhm/m;

- Chromium-nickel austenitic steels are stainless and, thanks to nickel, have a high resistance of 0.7-0.9 μOhm/m.

Copper ranks second in terms of electrical conductivity: it perfectly passes electric current and is widely used in the manufacture of wires. Aluminum is also used no less often: it is weaker than copper, but cheaper and lighter.

Conductivity - Aluminum

The electrical conductivity of aluminum depends on the impurity content in it.

The electrical conductivity of aluminum is 62 - 65% of the electrical conductivity of copper. When exposed to air, aluminum is coated with a thin but durable film of oxide, protecting it from corrosion. Mercury salts, alkalis, hydrochloric acid and some of its salts strongly corrode it.

The electrical conductivity of aluminum decreases with the addition of various metals (especially manganese and titanium). Alloys of the hard alloy type have the lowest electrical conductivity in the quenched state and the highest in the annealed state. The cutting machinability of pure aluminum is poor.

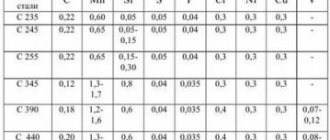

| Chemical composition of aluminum. |

The electrical conductivity of aluminum depends on the degree of purity of the metal and decreases with increasing impurity content.

The electrical conductivity of aluminum, used instead of copper for wires, is 65% of the electrical conductivity of copper.

The electrical conductivity of aluminum is highly dependent on impurities and little on mechanical and heat treatment. The purer the aluminum composition, the higher its electrical conductivity and better resistance to chemical influences. Machining, rolling and annealing significantly affect the mechanical strength of aluminum. Cold working increases its hardness, elasticity and tensile strength.

The electrical conductivity of aluminum is 60% of the electrical conductivity of copper, and the density is 3 2 times less than that of copper. Thus, the mass of aluminum wire with equal electrical conductivity is approximately 2 times less. However, the mechanical properties of aluminum, such as strength and fluidity, are significantly lower than those of copper.

The electrical conductivity of aluminum depends on the degree of purity of the metal and decreases with increasing impurity content.

The electrical conductivity of aluminum is 60% of the electrical conductivity of copper.

The electrical conductivity of aluminum is greatly influenced by its purity.

Various impurities affect the electrical conductivity of aluminum, but to varying degrees. The impurities of chromium, vanadium and manganese most strongly reduce electrical conductivity. To a small extent, the electrical conductivity of aluminum depends on the degree of its deformation and the heat treatment regime. The negative effect of deformation on electrical conductivity is eliminated by annealing.

| Microstructure of a wire made of ordinary copper after annealing for 30 minutes in a hydrogen environment at 850 C.| Microstructure of oxygen-free copper wire after annealing for 30 minutes in hydrogen at 850 C. |

Si impurities sharply reduce the electrical conductivity of aluminum, since they form an Al-Si solid solution with aluminum. Iron does not form a solid solution with aluminum, so its effect on the electrical conductivity of the wire is small.

Since vanadium impurities reduce the electrical conductivity of aluminum, contamination of aluminum hydroxide with sodium vanadate is unacceptable. Rinsing the aluminum hydroxide with hot water will usually remove the sodium vanadate fairly completely. With a relatively high V2O5 content in bauxite, special measures must be taken to remove sodium vanadate from the cycle. To do this, part of the circulating solution is cooled to 25 - 30 C. During cooling, vanadium sludge, which is a mixture of soda, phosphate and sodium vanadate, falls out of the solution. Vanadium sludge is a source of vanadium.

Active resistance of wires, cables and lines

Due to the fact that alternating current flows unevenly, under the same conditions, alternating and direct current R will be different. As already mentioned, steel electrical wires have a better active R compared to conductors made of non-ferrous metals, which have the same R at any current strength.

On the contrary, the active R of steel electrical cables always depends on the electric current, so DC conductivity is never used in this case. The active R of an electrical cable is determined using the formula: R=l/y*s.

Advantages and disadvantages of aluminum wiring

The widespread use of aluminum wiring was practiced in old buildings. The main criterion in those days was easy availability and low cost of metal. The possibility of a lack of cable cross-section was not considered in those days due to the lack of electrical household appliances in the apartments of average citizens.

Types of SIP cable for connecting a cottage Source yandex.net

Positive factors

The low weight of aluminum wire makes it popular when installing high-voltage power lines. This condition has already been stated earlier, so let’s consider a number of other aspects:

- Relatively low price of metal and products made from it. This factor plays a role when laying long lines. For example, to fully electrify a country house, more than 1,000 m of wire may be needed.

- Resistance to chemical oxidation. This condition is relevant given that the cores are hidden by plastic insulation.

- Durability of areas without insulation. As mentioned earlier, a protective film is formed on the surface of aluminum, which prevents the occurrence of oxidative processes.

High-voltage line with a voltage of 35 kV Source cdn.pixabay.com

The essence of the phenomenon

This is a value characteristic of a conductor having a length of 1 meter and a cross-sectional area of 1 square meter/millimeter. It is denoted by the Greek letter ρ. Different materials have different resistivities. At the same time, the resistance of the conductor will change in direct proportion to the length and in inverse proportion to the cross-sectional area. That is, the longer the conductor, the higher it is, but the greater the thickness, the lower it is.

Length

Previous

MiscellaneousWhat is active power?