Hello dear reader! Andrey Noak is in touch with you. In this material I will tell you how you can make a circular sawmill at home to solve wood sawing problems. A do-it-yourself circular sawmill is a set of measures according to which you will directly assemble the equipment at home according to circuit diagrams, drawings and assembly instructions. In order to form beams or boards from logs, a disk corner installation is used.

Before starting work, you need to study the principle of operation of the installation, read and become familiar with the equipment that will be used. Create a step-by-step operations plan. Never rush. Study everything carefully. This will save you from injuries and injuries.

Making a machine from a grinder

You need to approach the creation of a large sawmill gradually. This is due to special safety precautions when working with saws.

The most basic type of machine is a sawmill made from a grinder. It can be assembled with your own hands in literally a few hours if you have a ready-made saw blade. Of course, it is difficult to call it a sawmill in the broad sense of the word, however, for the first time it is quite suitable for gaining experience. A good grinder has a power of about 2 kW and a rotation speed of up to 3 - 5 thousand rpm. With this device, boards with a thickness of no more than 50 mm are cut and used as an additional circular saw in carpentry shops.

To make this sawmill you need: the grinder itself, a 250 mm circular saw, a small table with a tabletop and a sheet of iron 1 - 1.5 mm thick. The protective cover is removed from the angle grinder.

The tabletop is covered with thin tin for better sliding of lumber. Then a slot is made in the center of the table for the saw blade. This gap should be 3–4 cm in length and 1.5–2 cm in width larger than the disk. This is necessary for saw adjustments and self-removal of sawdust. The saw blade is secured to the grinder with standard nuts. This tool is then securely fixed to the bottom of the tabletop with clamps and bolts. In this case, the saw part of the blade itself should protrude from the top of the table by about 10 cm.

The sawmill is almost ready for work. You just need to install and strengthen the ruler along the sawing using clamps or bolts as in the photo. It is needed to support the board during dissolution. It is also used to regulate the width of lumber production.

The height of the saw blade can be adjusted by raising or lowering the tabletop. To do this, one edge is secured to hinges, and the other to high adjusting bolts. Then with such a machine you can cut grooves and quarters on boards, which is often necessary in the production of joinery.

Manufacturing recommendations

To make a homemade sawmill work more efficiently, you should pay attention to some recommendations:

- The structure must be stable and strong, since you have to work with logs of different weights and sizes;

- Equipment assembly work must be carried out directly at the site where it is planned to be located. This is due to the massiveness and heavy weight of the structure;

- It is necessary to constantly monitor the operation of the equipment and adjust the settings, since the design is done by hand, without the use of precise programs and computerization;

- Homemade sawmills are “scattered” with shavings, so you need to either build additional structures or clean up after the work is completed;

- A wide band cut affects the generation of a large amount of waste;

- To ensure efficient operation of the mobile cart, it is necessary to use gaskets and plates, and the gaskets must be 0.5 mm thicker than the channel;

- The electric motor can be easily replaced with a gasoline engine. This option will be simpler, because you can use a chainsaw, or rather its engine. The chainsaw blade will serve as a tape. How to make a gasoline band sawmill, see the video;

- All fastening elements must be securely fixed to ensure safe operation of the entire structure;

- To ensure efficient operation, the saw must be sharpened and the teeth set apart.

Sawmill made from a hand-held circular saw

The fastest way to make a sawmill is to use a standard hand-held circular saw, which can be purchased at any hardware or hardware store. It is fixed in the same way as a grinder at the bottom of the table top, a slot is made for the disk and a ruler for the stop. The machine is ready for use.

This device has one advantage over a grinder machine. The standard model of a hand-held circular saw provides an inclination of the cutting tool from 0 to 70 degrees, which allows you to make cuts at different angles. This is necessary when making, for example, triangular skirting boards or shaped slats. In the production of wooden window frames, a special angle saw (angle saw) is often needed, for which hand-held circular saws are precisely suited.

Large homemade device

For such a powerful unit, a reliable frame is made of channels and angles. The following will be mounted on it: an electric motor with a power of 3–5 kW, a movable subframe and an adjustment system for the operation of the machine. The sawmill also includes a carriage, guide rails and devices for holding the logs from moving.

If in circular saws the operator needs to feed lumber to the saw, then here it is the other way around. The log is secured to the base in front of the frame, and the sawing unit itself is pushed towards the workpiece along the rails. When moving parts are installed and adjusted correctly, operation occurs smoothly and without effort on the part of the operator. This machine is capable of cutting workpieces horizontally and vertically. The rotation of the engine with the saw is carried out by the worker.

When moving forward, the blade makes a horizontal cut. After passing, the operator turns the engine 90 degrees, the saw becomes vertical. A backward movement is made while simultaneously cutting the log. After which the subframe with the engine is lowered using an adjusting screw to the specified size. And then a new cycle of work is repeated. It only takes about 2 - 3 minutes to move forward and backward.

Of course, you can make a sawmill that will cut both horizontally and vertically at once. But for this you need two electric motors of the same power and rotation speed. At the same time, the design of the unit will become significantly and unjustifiably complicated, which is unprofitable at home.

Read also: How to charge a Krona battery at home

A homemade corner circular sawmill can cut from 5 to 8 cubic meters of wood in one working day. It is used to make:

- preparations of linear lumber;

- multilayer timber for house construction;

- radial and edged lumber for carpentry;

- parquet board;

- They make individual cutting of logs for special purposes.

The corner disc sawmill has a number of advantages over a band saw of the same type. Namely:

- the smallest amount of sawing waste;

- high reliability;

- eliminates waviness of the board surface. With band sawmills this happens when the saw band is poorly tensioned;

- high quality of circumcision;

- sawing takes place in one installation.

Large woodworking enterprises use the Finnish Kara disc sawmill. It is a two-saw system with a moving belt for feeding wood. Capable of dissolving logs up to 80 – 90 cm thick. Capacity up to 20 cubic meters per hour. It has a complex control system. Maintenance staff 2 people. The disadvantage is the high price not only of the sawmill itself, but also of the saw blade, which costs about 20 thousand rubles. For sawing hard wood, such as oak or larch, discs with stellite tips are used. These saws are several times more expensive than simple ones.

Homemade production of such machines is not carried out due to their complexity and the high cost of individual components.

In private households, a do-it-yourself circular sawmill makes it possible to produce timber and boards from logs of medium and large sections. With the growth of the expected volume of production, the requirements for accuracy, thoroughness in assembly work, and the quality of the materials used increase.

Operating principle

Before making the structure yourself, it is necessary to study the operation and features of the configuration of a miniature circular sawmill. It is often used for processing medium and large logs. As a result, timber and boards are formed.

The main element of the design is the power unit, which ensures the rotation of the sawing discs. In addition, to ensure automation of work, the following components are required:

- supply line It can be automatic and motionless. Often the latter solution is preferred because it is more economical to do it yourself;

- cutting unit . May include one or more cutting blades. It can also be transverse and horizontal;

- control block . It is located on top of the cutting unit. Using this device, the master has the opportunity to adjust engine speed, start and deactivate equipment.

The corner sawmill is used for radial and tangential sawing of workpieces. The design features of such an installation allow the entire log to be used extremely efficiently.

Design selection

The design of a circular sawmill is being developed for specific needs. Productivity, log width, even cut along the entire length of the workpiece require certain technical solutions in the assembled equipment. When feeding manually, the plane wave of the resulting board increases. The size of the saw blade and the limits of its displacement relative to the stop pad will determine the maximum size of the wood for sawing.

Main nodes

The components of the future machine must first be correctly positioned on the drawing. The device of any homemade disk sawmill includes:

- frame. Unites all components into a functional whole. At the same time, the distance between parts must allow for safe DIY work, maintenance, cooling, and waste disposal. The main qualities are stability, rigidity;

- engine. The electric three-phase version is selected according to power and number of revolutions. Operating voltage 380 V. If there is no connection to the network, install a gasoline engine with a step-up gearbox;

- cutting unit. Placed horizontally, vertically. Consists of one disk or two (corner). A single saw can be fixed in one specified position or rotated 90° to eliminate reverse idling (cutting an angle);

- supply line. A simple homemade product is limited to a fixed table with manual feed. This type is used for small DIY work with small workpieces. A massive log is fed under the knife on a carriage;

- Remote Control. Performs on/off operations, available control switches (revolutions, feed, indication). It is carried out to a place on the frame that is convenient for work and control of the process.

Despite the fact that manufacturing takes place at home, safety precautions must be observed - cover the rotating parts with a casing, and install a protective sheet of metal on the operator’s side to prevent the disc from flying apart. Woodworking circular sawmills are classified as high-risk equipment.

Two disks

The design of a circular sawmill with two simultaneously operating cutting tools allows the processing productivity to be increased. They are located at right angles to each other. Such homemade devices are more difficult to manufacture.

Each disk is equipped with its own motor and drive. The rotation frequency is selected to be the same.

The horizontal movement of the angular pairs of the disk with the drive mechanism occurs on a movable carriage. Guides are placed under it. To adjust the relative position of circular saws with your own hands, each pair is equipped with adjustment devices.

Drawing and material

Depending on the design, drawings of a circular sawmill of varying complexity are drawn up. In custom development, certain requirements must be taken into account.

- Using log feed on a carriage, the width of the platform is taken equal to the width of the guide rails. This will ensure stability under load. The rail is taken P50, the rollers are selected accordingly;

- on the platform, provide clamps for a tree trunk, convenient, reliable fixation of various sizes of workpieces;

- It is advisable not to combine an electric motor and a saw on a rigid drive. It should be protected by a belt (chain) drive. This will improve the air cooling of the windings and remove them from the zone of intense wood dust formation. Before creating a drawing with your own hands, you need to measure the dimensions of the engine; with the same characteristics, the manufacturer gives its size according to the overall dimensions;

- calculate the working area for a saw Ø 500 – 700 mm;

- The frame, depending on the dimensions of the installation, should be welded or dismountable (moving to a new place of work). Channel No. 4, No. 6 are placed in the main harness. Additional stiffening elements are made from steel corners and pipes (if necessary).

Read also: Connection diagram for an ammeter in a charger

Assembly order

The DIY installation process is divided into 3 stages. After each, the dimensions, tolerances, and stroke limits of the moving parts are checked against the working drawing.

- Support frame frame. Welded (bolted) joints are made. They check the quality, diagonals, location of seats, stability.

- Feeding part. In the case of a fixed table, the level is set to a horizontal plane. The coincidence of the longitudinal axis with the supporting frame is recorded. For a moving platform, first place the rails at the same level coaxially with each other and the base. Load the trolley with a check for smooth running and no chafing of the wheel flanges. A small homemade circular sawmill can have a light trolley on bearings and rollers. For them, a guide track is made from a corner for passage forward and backward. On larger models, the principle of moving a carriage with a disk above a log fixedly fixed on the table is used.

Household disc sawmill Astrogan 2

- Cutting organ. The first to be installed is the sawmill shaft with the saw. The support bearing assembly is mounted on the subframe, the axis of rotation and the presence of runout are checked. Then the engine is hung on the mounting slots. The fastening bolt should not be located at the edge of the groove. If a V-belt/chain drive is used, then with repeated revolutions it becomes loose and subsequent tensioning is necessary. When replacing with a new product, the motor is again fed closer to the shaft. Continuous adjustment can be made with spacer bolts on each side. A heavily tensioned belt or chain will overheat when the equipment is in use for long periods of time.

When assembling a corner sawmill with your own hands with a block of disks on a movable carriage, the design distances are controlled along the entire length of the stroke. An unexpected change in saw angles during sawing will lead to damage to raw materials and an accident.

Individual approach

Where a high-capacity sawmill is not required, a mini-machine with a sliding feed on a stationary plate is designed.

As the weight and length of the workpiece increases, the table is equipped with freely rotating rollers to facilitate manual pressure.

A universal solution would be a rotary (90°) gearbox for a circular saw. In some cases, the owner prefers to install end clamps to rotate the workpiece around the longitudinal axis.

Moving the tree or saw is a crucial issue in the design of a sawmill.

If you find an error, please select a piece of text and press Ctrl+Enter.

Making a circular sawmill with your own hands can significantly reduce the cost of equipping a small woodworking workshop.

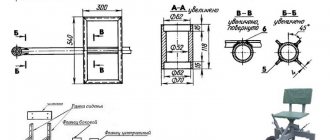

Scheme of a homemade sawmill.

Purpose of the unit

Wood is one of the most common and sought-after building materials. The most popular method of wood processing is sawing the material using saws of various designs. Very often, circular saws are used as sawing equipment. This design allows you to quickly and efficiently produce edged and unedged lumber from ordinary round timber; you can also easily produce timber, boards or slats in accordance with given dimensions.

Disc units can be used to carry out sequential processing of wood after cutting using a band saw and for the production of primary lumber.

Such equipment has a high level of productivity, as it has the ability to carry out longitudinal and end processing, as well as division.

A circular sawmill is an indispensable piece of equipment for the construction of wooden houses; its use allows you to speed up and simplify construction work.

The use of this equipment is especially effective when longitudinally sawing large timber. This procedure only takes a few minutes.

DIY band sawmill drawings

Dear visitors of the site “ Samodelkin Friend”, from the presented material you will learn how to make your own band sawmill yourself. Every craftsman dreams of having his own sawmill on his farm, because its presence will reduce the cost of lumber tenfold. Using this machine, you can cut the logs into boards and bars yourself; it is also an excellent option for those who are building , that is, the boards can be produced directly at the construction site of the future house. It is also possible to open your own private sawmill and cut boards for money and replenish the family treasury with additional income. In general, the machine is very good from all sides, and its independent assembly will again cost much less than a factory analogue, because many spare parts can be used second-hand and available to the car enthusiast, for example: wheels from a passenger car, hubs, bearings, bolts and other things that you can get in the garage)

The design of a band sawmill consists of 1. a rail track 2. a frame with a power unit 3. a blade 4 adjustment and tension mechanisms 5. a carriage 6. a flat surface (preferably a foundation slab)

Installation design

A circular sawmill is a hardware machine that performs longitudinal sawing of wood. The operation of the equipment is ensured by using an electric motor of appropriate power as a power drive. The main elements of the sawmill are:

- two electric motors;

- circular saws;

- rail guides;

- carriages.

The elementary design of the installation is a table on which a shaft with a disk is mounted, the cutting part of the latter rotates above the plane of the table.

Sawing installation of a sawmill.

This homemade circular sawmill is most often used in domestic use. The industrial installation has a more complex structure and is equipped with circular saws, which have the ability to change the cutting angle during operation.

The main working element of the installation is a circular saw, which is mounted on the spindle shaft of the installation or on the shaft of the electric motor. Depending on the design, such installations can be single- or multi-saw. In a multi-saw unit, separate electric motors are used to drive the working tool, which may not match each other in power.

Read also: How to measure cable cross-section with a caliper

The frame of the installation is mounted from durable pipes, which are held together by welding. The design of the equipment uses rails as guides on which metal carriages are installed to move the saw unit.

How does a sawmill work?

The principle of operation of a band sawmill is very easy to explain using the example of spools of thread.

The whole design resembles the rotation of two spools, between which a thread is stretched. This thread plays the role of a saw, and the distance between the coils is the maximum size of the log.

What a band sawmill allows you to do:

The band sawmill works as follows: the log is fixed on the platform and remains motionless, the mobile cart begins its movement and cuts the tree, the saw is in a horizontal position.

In order to ultimately get a board of the desired size, it is necessary to initially set the parameters by the operator. The saw acts as a saw blade, which must be well tensioned.

How a homemade sawmill works, see the video.

Before work, you need to prepare the equipment: to do this, sharpen the saw and set the teeth.

Operating principle of the device

The installation can operate both indoors and outdoors. The use of the unit allows you to obtain a smooth cutting surface. If a corner sawmill is used in the process, then sawing of the forest can be carried out in two planes simultaneously: both along and across the longitudinal axis of the log. This is achieved due to the fact that the working elements are located in two perpendicular planes. This type of installation can work with any wood.

Drawing of a sawmill with dimensions.

If a double-disc sawmill is used for sawing, then it is possible to saw logs whose diameter exceeds 70 mm in two perpendicular planes. The cutting width can be no more than 1 mm.

Transverse and longitudinal sawing of logs on such installations can be carried out simultaneously in both directions when moving along rails that guide the portal with saws installed on it. The portal and carriages move using a drive equipped with an electric motor. The speed of movement of the unit is adjusted in steps by using a chain transmission.

Installation does not require installation on a special platform or foundation. The main thing is that all electrical components of the structure must have reliable protection from precipitation. When setting up equipment, an electronic ruler is often used, which allows you to easily adjust cutting parameters automatically.

Main types of sawmills

There are the following types of sawmills:

- Frame. It is a structure with flat saw blades mounted on a frame. Frame sawmills are most often installed in large woodworking shops. This device is distinguished by its high power and robust design. The frame sawmill does not require additional maintenance. Its disadvantage is the large thickness of the cut, which increases the amount of chips produced.

- Tape. Processing of workpieces is carried out using a saw band, regulated by stabilizing rollers. The cutting element makes only translational movements obtained from the rollers. Band sawmills are used in small woodworking shops.

- Disk. It is one of the most common types of manual sawmills. It is equipped with a disc with teeth. Each tooth cuts a small part of the log. To improve productivity, these machines are equipped with several cutting discs.

- Chain. Sawing of logs is carried out using a chain saw mounted on a frame with a metal profile. The chain sawmill is lightweight and small in size. Therefore, this mini-machine is most often used in domestic conditions.

When choosing a sawmill, it is necessary to determine the volume of workpieces processed and the operating conditions of the equipment. You also need to take into account the technical characteristics and materials from which the cutting elements are made. One of the main selection criteria is the strength of the structure. The woodworking machine must be able to support the weight of the logs being processed.

Making a homemade sawmill

Before manufacturing the installation, detailed drawings of all components included in the design of the unit should be drawn. The simplest installation option is a single-disc sawmill. The scheme of such a design includes the following elements:

- moving carriage;

- two electric drives.

One of the electric drives ensures the movement of the portal along the guides, and the second drive serves to move the circular saw.

Sawmill assembly diagram.

This design is called horizontal. The device carriage is made of metal; it should easily move on rollers along the installation guides.

Making equipment with your own hands begins with preparing tools and materials for construction, these are:

- construction trestles;

- boards;

- metal plates;

- elements;

- electric motors;

- a set of tools and accessories for assembling the unit.

To manufacture the unit, you first need to assemble the frame of the device. For this purpose, construction trestles are combined using boards. The length of the boards used depends on the size of the material that is supposed to be processed on a homemade machine.

After making the frame, proceed to the plane of the table. Its base is made of wood, and metal plates with a width of 230-250 mm and a thickness of 1.2 mm are fixed to the surface. The plates are connected to each other by jumpers and screws. After making the table, a groove is made in its wooden part in such a way that the installed circular saw does not come into contact with its edges.

You can make a cutting tool yourself, but it is best to purchase it at a hardware store. The disk is fixed on a shaft, the drive of which is carried out using a belt drive. When securing the engine, it should be possible to move it slightly, which is necessary to tension the belt drive. The guide for the sawmill is made of boards.

Making a sawmill at home with your own hands

When it is necessary to process a large number of boards and wood, it is best to use a self-made sawmill. Many people believe that it is best to purchase a ready-made unit, but making it yourself will not be difficult. The main thing is to decide what the volume of work ahead will be, as well as the wood, after which you need to choose the type of sawmill to successfully complete the task.

When assembling the unit with your own hands, special attention should be paid to safety issues , because such a device is considered a high-risk object. The manufacture of various types of sawmills is presented further in the video.