Preparing for marking.

Before marking, you must do the following:

- · clean the workpiece from dust, dirt, scale, traces of corrosion with a steel brush, etc.;

- · carefully inspect the workpiece; if cavities, bubbles, cracks, etc. are detected, measure them accurately and, drawing up a marking plan, take measures to remove these defects during further processing (if possible); all dimensions of the workpiece must be carefully calculated so that after processing there are no defects left on the surface;

- · study the drawing of the part being marked, find out its features and purpose; specify dimensions; determine the base surfaces of the workpiece from which dimensions should be taken during the marking process; for planar marking, the bases can be the processed edges of the workpiece or the center lines, which are applied first; It is also convenient to take tides, bosses, and plates as bases.

Stage 5. Chamfering

Chamfering is necessary if the edge of a part needs to be prepared for a strong and reliable connection, for example for welding.

A chamfer is a bevel of the end of a part. Sliced in two ways:

- Thermal. Using gas or plasma cutters. The chamfer turns out clean and even.

- Mechanical. The chamfer is removed using edge milling machines or chamfer removers.

The first method is fast and inexpensive, but when processing chamfers, the metal heats up, which can lead to its deformation and destruction of the structure. The second method does not have a temperature effect on the metal, however, mechanical chamfering is a more labor-intensive and time-consuming process.

Marking devices

Based on the difficulties of performing spatial markings, many tools and devices have been developed for its application. Moreover, most of these tools are suitable for application and planar marking.

Among the most common devices for spatial marking are:

- A scriber is the simplest and most versatile tool that does not require special training and allows you to apply markings in the field. Most often, it is a metal rod, one end of which is pointed. Typically, carbon steels of various grades are used for their manufacture. Either one or two ends can be sharpened, depending on the purpose of the tool. Their length is usually about 10 cm. Often, in order to prevent the end from becoming dull, it can be additionally hardened. Sketchers are usually used with rulers or templates.

- Reismas - the basis of the reismas is the devil, but it has a more complex design, as it is used for applying strokes on a vertical surface. It usually consists of a vertical post with metric markings applied, and a parallel post with a fixed scriber. This tool is used when it is necessary to apply high-precision markings.

- A compass is an indispensable tool necessary for drawing circles, arcs, as well as dividing segments into separate equal parts. There are two types: simple and spring. Simple ones will allow you to fix the legs in a certain position, measuring and selecting segments of the required length. Spring compasses are less common, but more accurate. Also highlight such a variety as marking calipers.

- A center punch is a metalworking tool in the form of a rod. It is used to make core recesses necessary for dividing circles into equal parts. One of its sides is pointed, a hole is made with it, and the other is flat, on which a blow is made with a hammer. The resulting hole makes working with the drill easier; it does not slip and is located exactly in the center.

The punch is usually made of partially hardened high-strength steel. The sharpened rod is subjected to hardening. Such a tool usually has a size from 10 to 18 cm.

You don't need to hit it with a hammer to make a hole. The most common of these is electric. It is based on a coil with a rod inside. When you press the tip, the circuit closes, a magnetic field appears in the coil, under the influence of which the rod hits the surface, creating a depression.

- A marking plate is a cast iron surface on which parts and tools for marking are installed. It should not lose shape, bend or bend during operation. Grooves can be made on the slab, forming equal squares. These grooves make it easier to install tools. Can be produced together with a stand or installed on a desktop.

- Prism – is a stand with a prismatic recess. It consists of two prism-shaped cheeks, between which the workpiece is installed. Can be installed on a screw support. With its help, you can adjust the position of the cheeks, increasing or decreasing the distance between them.

- Square with a shelf - most often used for planar markings, but can also be used for spatial markings. It is used in cases where there is a need for a precise positioning of the workpiece in the marking device.

- Marking wedges - used to adjust the installation height of an object with minimal deviations.

- Jacks are analogues of wedges, and also allow you to accurately adjust the height. The jack must be used in cases where the work involves massive workpieces.

Paint is used as an additional device for marking work. The surface is covered with it so that the marking strokes are clearly visible. It is selected in such a way that it contrasts well with the natural surface, even in dim lighting.

Marking devices

One of the different types of devices for marking parts is scribers. These are pointed rods used for applying marks. This bench marking tool is used with guide tools. There are several types of scribers, among which the following three are the most common. Round options are represented by rods with one hardened and pointed end and the other bent into a ring. Tools with a bent end are sharpened on both sides, and one of the ends is bent perpendicular to the rod. In addition, the middle part is thickened. These scribers are designed for marking hard-to-reach areas. Models with an insert needle are similar in design to watch screwdrivers.

Gauge gauges are designed for drawing parallel lines and checking the installation of the workpiece during spatial marking. This device is represented by a scriber mounted on a stand with a base. The latter can be placed on the rack in any way. For precision work, use a height gauge with a scale. For conventional options, scale rulers or gauge blocks are used to increase accuracy.

Marking compasses are designed to transfer linear dimensions to a workpiece, create circles for curved parts such as propellers, divide angles and segments, and measure. These products, used for marking, are presented in regular and spring versions. The former have the ability to fix the legs to size, while the latter allow for precise installation. In any case, they are equipped with an arc and a screw for fixing the legs. The latter are sharpened and their ends touch, and the needles are hardened over 15-25 mm. Like scribers, compasses are tools for planar marking.

A marking caliper is designed for particularly precise marking and drawing of large circles. It differs from the usual one by the presence of a micrometric screw. Includes a ruler with two legs equipped with hardened, replaceable needles. The movable leg is equipped with a vernier, and its needle moves along the scale, providing the ability to draw circles in various vertical planes.

Tools for marking metal were discussed above.

The drawbar is designed for marking wooden parts by applying marks to their edges. It is represented by a wooden block 40x5 cm. At one end of it, 1/5 in size, there is a movable scriber in the form of a needle, a sharp pin or a nail. The remaining part of the bar has a thickness of 5-7 mm less.

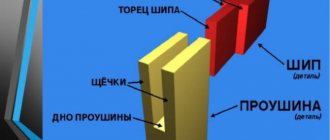

The bracket is designed for marking when creating eyes and tenons. This is a wooden block with a recess of 1/4 at a distance of 1/3 from the edge with nails located at a mutual distance equal to the thickness of the eyes or tenons.

Marking cylindrical parts

The sequence for marking cylindrical parts is as follows:

- The part is installed on the marking plate so that the horizontal position is maintained.

- Small workpieces are mounted on marking prisms.

- Applying markings, which are carried out strictly according to the given instructions:

- studying the drawing;

- checking parts for defects;

- cleaning the surface from dirt, paint residues and dust;

- painting the surface on which the marking is planned;

- using a center finder, the center of the product is marked;

- horizontal installation of the part on the prism;

- drawing two horizontal lines at the end;

- lines are drawn on the side surface, continuing those that were drawn on the end in advance, to highlight the place where the groove was created.

Using a marking tool, you can carry out spatial markings with high accuracy. The main thing is to follow the instructions and not rush; rushing in this matter can lead to mistakes.

Stage 6. Chopping

Chopping is a roughing step for preparing a part for processing.

This process is used for metalworking work where precision processing is not required, for example, for cutting off protrusions, grooves or rough alignment. Metal chopping is performed using a tool steel chisel, a cross-cutting tool for notching, and a hand or pneumatic hammer.

The part is clamped in a vice so that the cutting line is level with the clamping jaws. The chisel is tilted at an angle of 30–35° and hit with a hammer. If it is necessary to cut down a thick layer of metal, the cutting is carried out in several passes.

If the workpiece is copper or aluminum, apply soapy water or oil to the chisel blade. Brittle metals such as cast iron and bronze are chipped when chopping, so first chamfers are applied to the edges of the part to facilitate the passage of the chisel.

Spatial marking

Spatial marking using templates increases accuracy, productivity and greatly simplifies the work of the marker.

Spatial marking is the marking of workpiece (part) surfaces located in different planes and at different angles, carried out from any initial surface or marking line chosen as the base.

Spatial marking, the most common in mechanical engineering, differs significantly in techniques from planar marking. The difficulty of spatial marking lies in the fact that it is necessary not only to mark individual surfaces of a part located in different planes and at different angles to each other, but to link the markings of these individual surfaces with each other.

Spatial marking has a significant difference from planar marking.

Spatial marking, the most common in mechanical engineering, differs significantly in techniques from planar marking. The difficulty of spatial marking lies in the fact that it is necessary not only to mark individual surfaces of a part located in different planes and at different angles to each other, but to link the markings of these individual surfaces with each other.

Spatial marking has a significant difference from planar marking.

Spatial marking differs significantly from planar marking. The difficulty of spatial marking lies in the fact that the turner has to not only mark individual surfaces of the part located in different planes and at different angles to each other, but also link the markings of these surfaces with each other.

Spatial marking is the marking of workpiece surfaces (Fig. 174, b), located in different planes and at different angles to each other.

Spatial marking, the most common in mechanical engineering, differs significantly in techniques from planar marking. The difficulty of spatial marking lies in the fact that it is necessary not only to mark individual surfaces of a part located in different planes and at different angles to each other, but to link the markings of these individual surfaces with each other.

Spatial marking is much more complex than planar marking.

Spatial marking is the most common in mechanical engineering; its methods differ significantly from planar marking. The difficulty of spatial marking lies in the fact that it is necessary not only to mark individual surfaces of a part located in different planes and at different angles to each other, but to link the markings of these individual surfaces with each other.

Spatial marking is much more complex than planar marking.

Spatial marking consists in the fact that the markings of individual surfaces of a part, located in different planes and at different angles to each other, are linked to each other.

Spatial marking is carried out on several adjacent planes inclined at different angles to each other.

Spatial marking requires more complex tools and devices and is accompanied by more complex techniques than planar marking.

Spatial marking

Spatial marking is the marking of workpiece (part) surfaces located in different planes and at different angles, carried out from any initial surface or marking line chosen as the base.

Spatial marking, the most common in mechanical engineering, differs significantly in its techniques from planar marking. The difficulty of spatial marking lies in the fact that you have to not just mark the individual surfaces of the part. Spatial marking, as a rule, is carried out on a marking plate, which is an artificial plane with the help of which the specified alignment is achieved.

Spatial marking, the most common in mechanical engineering, differs significantly in its techniques from planar marking. The difficulty of spatial marking lies in the fact that it is necessary not only to mark individual surfaces of a part located in different planes and at different angles to each other, but to link the markings of these individual surfaces with each other. Spatial marking, as a rule, is carried out on a marking plate, which is an artificial plane with the help of which the specified alignment is achieved.

| Spatial marking (the blank of the corner lever is marked. |

Spatial marking (Fig. 22) is the marking of workpiece surfaces located in different planes at different angles to each other (see Ch.

Spatial marking is the marking of workpiece surfaces (Fig. 174, b), located in different planes and at different angles to each other.

Spatial marking is used for graphic constructions carried out on the surface of volumetric workpieces located in different planes at different angles to each other. When marking spatially, it is necessary not only to mark individual elements on one surface (side) of a part, but to link the markings of these surfaces (planes, axes of holes in their alignment, angles of inclination) with each other.

Spatial marking is used for graphic constructions carried out using spatial kinematic chains.

Spatial marking is sometimes called volumetric marking.

| Scheme of markings on the floor of a press column forging. |

Spatial marking errors are caused by the simultaneous action of the following reasons: an error in the angular installation of the marked installation; error in setting the height gauge and its deviations when moving along the marking plate; the use of imperfect marking methods; inaccuracy of geometric constructions; inaccuracy of marking tools and devices.

Spatial marking techniques differ significantly from planar marking techniques. The peculiarity of spatial marking is that it is necessary not only to mark individual surfaces of the workpiece located in different planes and at different angles to one another, but to link the markings of these surfaces to each other. Spatial marking is usually done on a marking plate. By properly placing the part on the plate and linking the markings of each plane of the part with the common plane of the marking plate, the markings of the individual planes are thereby linked to each other.

| Devices used for installing and securing workpieces on a marking plate. a – prisms. b – square ] c – marking box d – cli. woven linings. d – jack |

For spatial marking, the following tools are used: a metal measuring ruler, a vertical measuring ruler with a stand, checking and marking squares, a scriber, a surface gauge, a height gauge, a compass, center punches and a hammer. These tools are described in Chap.

The difference between spatial marking and planar marking is that the marking of individual workpiece surfaces is linked to previously marked surfaces by orienting the marking tool and the workpiece relative to each other using a marking plate.

Marriage during marking

First of all, when marking, defects that were made at previous stages of production emerge. Products from procurement sites or workshops, as well as materials purchased from other enterprises, reveal:

- violation of dimensions

- shape distortion

- warping.

Such castings or rentals are not subject to further marking operations, but are returned to the department or organization that caused the defect to correct it.

At the marking stage itself, defects can be caused by the following factors:

- Inaccurate drawing. The mechanic, without hesitation, displays incorrect dimensions on the part, and during further processing, defective products come out.

- Inaccuracy or malfunction of instruments. All marking tools are subject to mandatory periodic verification by the metrological service of the enterprise or an authorized metrological center.

- Incorrect use of tools or marking accessories. There are known cases when instead of calibrated measuring pads, ordinary pads were used to set the level. In this case, erroneous application of angles and slopes is also possible.

- Inaccurate placement of the workpiece on the marking table or plaza. They lead to distortions when setting aside dimensions, violation of parallelism and coaxiality.

- Wrong choice of reference planes. It is also possible that some of the dimensions were applied from the base planes, and some from the rough surfaces of the workpiece.

Marriage during marking

Separately among the reasons for defects are the marker's errors. These include:

- Incorrectly read drawing. It is possible to apply a radius instead of a diameter and vice versa, inaccurate application of the centers of holes relative to the center marks, etc. If any difficulties arise, the mechanic must seek clarification from the foreman or foreman.

- Carelessness and inattention when punching and drawing lines.

Negligence can be committed by both the mechanic himself and his supervisors, who did not check the tool on time or issued inappropriate marking devices.

Typically, marking operations are entrusted to the most experienced and responsible workers, counting on the fact that they will not mechanically transfer dimensions from the drawing to the workpiece, but will treat the matter thoughtfully and promptly notice and eliminate the reasons for possible defects on their own or by contacting their managers.

If you find an error, please select a piece of text and press Ctrl+Enter.

Spatial marking tools and devices

Categories

If it is necessary to punch the center holes at the ends of the shafts, it is convenient to use a special device for punching - a bell (Fig. 2.6, o). This device allows you to apply core recesses on the centers of the end surfaces of shafts without preliminary marking them.

For the same purposes, you can use a center finder square (Fig. 2.6, b, c), consisting of a square 1 with a ruler 2 attached to it, the edge of which divides the right angle in half. To determine the center, the tool is placed on the end of the part so that the internal flanges of the square touch its cylindrical surface and a line is drawn along the ruler with a scriber. Then the center finder is turned to an arbitrary angle and a second mark is made. The intersection of the lines marked on the end of the part will determine the position of its center.

Inspection, measuring and marking tools

To mark and control the accuracy of processing workpieces and parts, various tools, instruments and devices are used. Processing accuracy means compliance of the shape and dimensions of the manufacturing part with the requirements of the drawing and technical specifications.

Correct marking ensures the necessary precision in processing workpieces and parts and economical use of materials. Linear dimensions are measured with a tape measure, tape measure, folding meter and various rulers with millimeter, centimeter, decimeter and meter divisions.

The square is used to check and set a right angle (90°) when marking and processing materials and workpieces. The Erunok is designed for marking and controlling angles of 45° and 135°. It consists of a base to which a wooden or metal linear line is rigidly attached at an angle of 45°.

The mark is used for measuring according to the sample and transferring them to the workpieces when marking. It has a hinged base and a ruler. Malka can be made of wood or metal.

Using a compass, they transfer the given dimensions and describe the circles when marking them. A bore gauge measures the internal diameter of a round hole. The outer diameter of a round part is determined using calipers and vernier calipers, which are used to measure the small linear dimensions of parts and elements of their connections. Use a caliper with double-sided jaws for external and internal measurements (width and thickness of parts, thickness of panels and ridges, width of eyes) and a ruler to determine the depth of sockets, grooves and holes. A caliper is a sliding metal tool that has a rod with a main scale, a frame with a clamping screw and an additional scale (cone) and a depth ruler. The frame can move along the rod depending on the size being determined. When measuring, first count whole millimeters that have passed along the bar along the leftmost line of the cone, and then tenths of a millimeter according to the complete coincidence of the division of the cone with any division of the bar. Vernier calipers can have a measurement accuracy of 0.1 to 0.05 mm.

The level is used to check the horizontal and vertical surfaces of joinery and carpentry products and structures (window and door blocks, beams and joists, floors, racks). It has a wooden or metal block in which an arched glass tube containing alcohol and an air bubble is placed. When the edge of the level bar coincides with the horizontal or vertical position of the elements being tested, the air bubble will be located between the two marks on the tube. The staples mark the spikes and eyes. It has a wooden block with a cross quarter at one end.

The thicknesser is used to apply marking marks parallel to one of the surfaces of the workpiece being marked and to each other.

Plumb line - used to check the vertical installation of joinery and carpentry products and structures. It consists of a cord with a cylindrical metal pointed weight attached to it at the bottom.

The micrometer with a scale division of 0.01 mm is equipped with a bracket with a measuring heel, a micrometer screw and a drum. The end surface of the screw facing the heel is the measuring surface. The ratchet is designed to achieve a constant measuring force. Hundredths of a millimeter are counted on the drum's circular scale. The indicator is longitudinal, drawn on the stem.

An inclinometer is used to measure the inclination angles of two adjacent surfaces. Goniometers come with a cone and optical. A protractor with a cone allows you to determine external angles from 0 to 180° and internal angles from 40 to 180° with an error of no more than ±5°. Optical inclinometers are used to measure the angular parameters of the cutting part of tools. They are equipped with a magnifying glass, which ensures the measurement of angle values with an error of no more than 10″ (arcseconds).

Micrometer

A measuring instrument of this type is designed to make fairly accurate measurements of small linear dimensions. The maximum measurement limit of modern micrometers reaches 600 millimeters, and the accuracy is 0.01 millimeters.

Micrometers (as, indeed, all micrometric instruments) are equipped with special reading units based on a screw pair with a thread pitch of 0.5 millimeters. With its help, the longitudinal movement of the measuring screw is converted into circumferential movements made by the drum scale. It is on the basis of the angle of its rotation that the value of the measured size is determined.

Preparing for marking.

Before marking, you must do the following:

- · clean the workpiece from dust, dirt, scale, traces of corrosion with a steel brush, etc.;

- · carefully inspect the workpiece; if cavities, bubbles, cracks, etc. are detected, measure them accurately and, drawing up a marking plan, take measures to remove these defects during further processing (if possible); all dimensions of the workpiece must be carefully calculated so that after processing there are no defects left on the surface;

- · study the drawing of the part being marked, find out its features and purpose; specify dimensions; determine the base surfaces of the workpiece from which dimensions should be taken during the marking process; for planar marking, the bases can be the processed edges of the workpiece or the center lines, which are applied first; It is also convenient to take tides, bosses, and plates as bases.

Hole marking

Marking center holes is one of the most difficult operations in metalworking, which is associated with high precision. Several tools are used for these purposes. Most often this is a marking compass and a center finder.

Compasses are used in cases where there is no need to maintain high accuracy.

The techniques and their sequence are as follows:

- The legs of the compass are moved apart to a distance equal to the radius of the workpiece.

- then, resting one leg against the edges of the workpiece, a stroke is applied;

- repeat this at least 4 times from different sides so that a quadrangle is formed in the center, the center of which is the center of the workpiece, and is marked by eye;

- then a hole is made using a center punch.

A center finder is a simple but highly accurate tool. With its help, only two perpendicular lines are drawn, the transfer of which is the center of the workpiece.

When using, it is important to hold the center punch vertically; even the slightest deviation from the axis will affect the accuracy of the mark. In some cases, the surface of the workpiece can be covered with chalk in order to better see the inscribed marks on these surfaces

In some cases, the surface of the workpiece can be covered with chalk in order to better see the inscribed marks on these surfaces.

What tools are used as additional ones for marking, and what are they called?

There are an endless variety of processing technologies and models of final products. Therefore, non-standard solutions that are convenient for certain operations are often used. Both in metalworking and in the manufacture of goods from wood, plastic, stone, etc. The use of patterns became widespread. A line with a complex configuration is obtained by outlining a special pattern.

Before forming several radii, it is advisable to make an application point. This is done by punching. The device is somewhat reminiscent of a chisel, but with a sharp conical working surface made of hard alloy.

Marking and permanent marks are applied to metal using an electric engraver. This is essentially a micro welding machine. Due to the electric arc, a very clear local trace is formed. You can draw and write with it like a pencil.

§ 11. General concepts

Blanks for machine parts are received for processing in mechanical and metalwork shops in the form of forgings of high-quality metal. Depending on the purpose of the parts, some workpieces remain unprocessed, others are processed partially or completely. When processing, a certain layer of metal is removed from the surface of the workpiece, as a result its size decreases. The difference between the size of the workpiece before and after processing is the value of the processing allowance.

To know where and to what size to process, the workpiece is first marked. Marking is the operation of applying marking lines (scores) to the workpiece being processed, defining the contours of the future part or the area to be processed.

Marking is carried out accurately and carefully, because errors made during marking can lead to the fact that the manufactured part turns out to be defective. It may also be the other way around: an inaccurately cast and therefore rejected workpiece can be corrected by careful marking, redistributing the allowances for each marked surface.

The accuracy achieved with conventional marking methods is approximately 0.5 mm. With precise marking, it can be increased to hundredths of a millimeter.

Marking is used mainly in individual and small-scale production. In large-scale and mass production factories, the need for markings is eliminated due to the use of special devices - jigs, stops, etc.

Types of marking are divided into three main groups: mechanical engineering, construction, boiler room and ship. Mechanical marking is the most common metalworking operation. Boiler room and ship markings have some peculiarities, and special literature is devoted to them.

Depending on the shape of the blanks and parts to be marked, marking is divided into planar and spatial (volumetric).

Planar marking is usually carried out on the surfaces of flat parts, on strip and sheet material, and consists of applying contour parallel and perpendicular lines (marks), circles, arcs, angles, axial lines, various geometric shapes according to given dimensions or contours of various holes according to specified dimensions to the workpiece. templates.

Using planar marking techniques, it is impossible to mark even the simplest body if its surfaces are not straight. When marking planarly, it is impossible to apply horizontal marks on the side surface of the cylinder, perpendicular to its axis, since it is impossible to attach a square and a ruler to it. But even if there were a flexible ruler that could be wound around the surface of the cylinder, then applying parallel marks to the cylinder would present great difficulties.

Spatial marking, the most common in mechanical engineering, differs significantly in techniques from planar marking. The difficulty of spatial marking lies in the fact that it is necessary not only to mark individual surfaces of a part located in different planes and at different angles to each other, but to link the markings of these individual surfaces with each other.

details on the website globalcolors.ru production of masterbatches. SMS notifications in Izhevsk are on our website. cutting pipes at an angle mnitek.ru/rezka-trub-i-profilya-pod-uglom/

Read the abstract on everything else: “Marking in plumbing” Page 1

(Back)

The “read” function is used to familiarize yourself with the operation. The markup, tables and pictures of the document may be displayed incorrectly or not in full! “Marking in plumbing”Contents

§ 1. Purpose and technical requirements of markings

§ 2. Geometric constructions when marking § 3. Tools, devices and marking techniques

§ 1. Purpose and technical requirements of markings

Marking is the operation of applying marking marks to the surface of a part or workpiece to be processed, defining the contours of the part profile and the places to be processed. The main purpose of marking is to indicate the boundaries to which the workpiece must be processed. Depending on the shape of the blanks being marked, markings for parts are divided into planar and spatial (volumetric).

Planar marking is carried out on the surface of flat parts, on the surface of flat parts on strip or table material and consists of applying contour and parallel perpendicular lines, circles, arcs, geometric figures according to zonal dimensions or contours of various holes to the workpiece.

Spatial marking is in progress. To mark individual spatial parts located at different angles to each other in different planes, the markings of these individual surfaces are linked to each other.

Devices for planar marking are marking plates, pads, rotating devices, jacks. Tools for spatial marking: scriber, farmers, compasses, marking rod - compass, ruler, squares.

Before marking, you need to do the following: clean the workpiece from dirt, traces of corrosion, carefully inspect the workpiece to identify holes and cracks. Study the drawing and mentally place the marking plan, determine the bases (surface) of the workpiece from which dimensions should be set aside, prepare the surfaces for painting. For painting, various compositions of chalk diluted in water, a solution of copper sulfate (CuSO4), alcohol varnish, and quick-drying varnishes and paints are used.

To save time, simple workpieces are often processed without preliminary marking. For example, in order for a toolmaker to make an ordinary key with flat ends, it is enough to cut off a piece of square steel from a bar of a certain size, and then saw it to the dimensions indicated on the drawing.

Blanks are received for processing in the form of castings (produced from metal poured into pre-prepared molds - earthen, metal, etc.), forgings (produced by forging or stamping), or in the form of rolled material - sheets, rods, etc. (obtained by passing metal between rollers rotating in different directions, having a profile corresponding to the resulting rolled product).

During processing, a certain layer of metal (allowance) is removed from the surface of the workpiece, as a result of which its size and weight are reduced. When manufacturing a part, its dimensions are laid down on the workpiece exactly according to the drawing and marked with lines (marks) indicating the processing boundaries to which the metal layer should be removed.

Marking is used mainly in single and small-scale production.

At large-scale factories and... mass production, the need for markings disappears due to the use of special jigs, stops, etc. Three main groups of markings are used:

General concepts

Marking

is the operation of applying marking lines to the workpiece being processed, defining the contours of the future part or place to be processed.

The accuracy achieved with conventional marking methods is approximately 0.5 mm. With precise marking, it can be increased to hundredths of a millimeter.

Planar marking

, usually performed on the surface of flat parts, on strip and sheet material, consists of applying contour parallel and perpendicular lines (scores), circles, arcs, angles, axial lines, various geometric shapes according to given dimensions or contours of various holes according to templates to the workpiece.

Spatial marking is most common in mechanical engineering; in its techniques it differs significantly from the planar one.

Marking techniques

Marking is carried out on a workbench, work table or directly on the construction site. Marking lines are drawn with a pencil or beaten with a chalked cord, and marks are drawn with an awl, scriber, special oblique knife or wide chisel. Hard pencils are used for marking hardwood. When marking unplaned lumber, it is better to use a carpenter's or carpenter's pencil, which has a thick core and its cross-section is elliptical. Do not use chemical pencils, which leave marks on the wood that are difficult to erase. When drawing a marking line, the chamfer of the pencil must be pressed against the edge of the guide tool (ruler, square, template).

To mark the circle, the legs of the compass are moved apart by the size of the radius of the circle using a ruler or caliper. Find and mark the center of the circle by drawing two mutually perpendicular lines. Having placed one leg of the compass at the center of the circle, rotate the other leg to mark the given circle.

When performing carpentry work, marking lines are applied by beating along the surface of the material with a stretched cord, rubbed with chalk or charcoal. To make several short and parallel marks, you can use a staple.

Marking requires significant labor costs and higher qualifications of the worker, so it is necessary to make templates and use marking devices.

For marking, overhead templates for various purposes are used. They can have different shapes, sizes and designs (flat and box-shaped). Templates are made from boards, plywood, hardboard or sheet metal. Templates must have contours (or cutouts) according to the shape of the marked elements and connections of wooden parts. The template is applied to the workpiece to be marked, and then the necessary contours are drawn with a pencil or scriber.

Marking should be done correctly and carefully. It should ensure the production of high-quality blanks and parts of the required shapes and sizes with the least amount of labor involved in their production. When marking, it is necessary to provide for the rational consumption of materials with a minimum amount of generated wood waste (clippings, sawdust, shavings), and strive to obtain the greatest useful yield of blanks and parts from the material used.