And again I am glad to welcome you to the pages of Andrey Noak’s blog. Today I want to talk about which sawmill is better, belt or disk. After all, sawmill equipment is the basis for organizing both large-scale wood processing production (for example, for organizing the production of radial materials), and for small sawmills or even home use. And the profitability of the enterprise and user comfort largely depend on the quality and operational characteristics of the sawmill.

Purpose

This equipment is designed for horizontal and vertical sawing of wood without turning the workpiece. It is used in the production of lumber of various qualities, including export. With its help you can make both a thin board and a square beam of various sizes.

The corner sawmill can produce all types of woodworking products from round timber of any species. For example, edged lumber (including radial), profiled timber, parquet, etc.

Using such a machine, you can make the surface of the finished product as smooth as possible. Taking this into account, circular sawmills are now widely used in the woodworking industry.

Video on topic

Each user must decide for himself which characteristics of sawmill equipment are most important to him in the process of work. As a result of the above, I note that band sawmills are still characterized by wider application in comparison with disk models. They can produce boards of good quality, and have a greater useful yield, and, accordingly, greater profitability.

I hope my article was useful to you and you can make the right choice. Read my articles, subscribe to updates and recommend my blog on social networks. Until we meet again, Andrey Noak was with you.

Design and principle of operation

The design of any circular sawmill includes:

- motors (electric motors);

- circular saws;

- rail track;

- carriage.

Typically, an angular circular sawmill is called equipment that has two saws located orthogonally, i.e. at an angle of 90 degrees. to each other.

The principle of operation of this technique is as follows: 2 rotating disks are lowered to the required amount and move along the log, as if cutting out lumber of the desired shape. The position of the saws is adjusted using special technical devices.

When installing an electronic ruler (as a rule, this is an additional option), the productivity and accuracy of cutting increases due to the quick and accurate installation of the saw at a given coordinate.

Sawing occurs in both directions. Cutting is carried out without idling, which improves the quality of the finished product.

Idling is a special mode of engine operation characterized by the absence of useful work performed. For a sawmill, this means that work is carried out in two directions of movement of the log, and this increases productivity.

Corner sawmills are equipped with motors with controlled rotation speed. This is necessary so that you can set a certain angular speed of the power plant, which allows you to control the speed of movement (feed) of the saw spindle. The yield of finished products reaches 60 – 80%.

Purpose

A circular sawmill is equipment necessary for longitudinal cutting of logs and other lumber. The purpose and characteristics of this device allow changes in the geometric shape of lumber. However, the quality of such a sawmill will not allow for surface processing work - only dividing the initial workpiece into separate parts.

The device should be purchased primarily by those who plan to start their own wood processing business. As reviews show, this type of service is in great demand today. Quite expensive equipment, as well as its maintenance, will quickly pay for itself under conditions of intensive use.

Kinds

According to the principle of operation, circular sawmills can be divided into the following types:

- With one disc. This sawmill is equipped with a carriage with a rotating mechanism and one disk. At the beginning of the cutting cycle, the saw blade is in a horizontal position. When moving the carriage along the log, a horizontal cut is made. At the end of the carriage stroke, the disk turns over to a vertical position. On the reverse stroke, a vertical cut is made. One cycle produces one board (or other lumber). Then the sawing cycle is repeated. There is no idle speed.

- With two disks. Sawing is done with two saw blades perpendicular to each other. The cutting is carried out simultaneously in the vertical and horizontal plane. Double-disc sawmills are more economical. With the correct sawing pattern, they leave virtually no waste, which increases the profit of the enterprise.

- Horizontal. Sawing is carried out with two saw blades located in the same plane. Cutting is carried out both forward and backward. There is no idle speed. It is one of the most common. Produces minimal waste. The yield of finished products is up to 85%.

Comparison with tape

When using a corner circular sawmill, you can achieve higher cutting accuracy of the material compared to a band saw. The design of the angle disk machine allows us to obtain high-quality edged lumber that meets European standards.

Advantages of a corner sawmill over a band sawmill:

- high level of reliability and safety;

- obtaining high-quality finished products with a minimum of waste;

- there is no need to turn over and turn the workpiece;

- high purity of lumber processing;

- does not require complex repairs;

- easy to maintain.

The disadvantages include:

- expensive cutting tools;

- it is impossible to process large diameter logs;

At the same time, band machines have the following advantages:

- relatively low cost;

- low power consumption;

- thinner cut and, accordingly, higher yield of lumber (by 5 - 7%);

- the ability to visually assess the condition of the workpiece after each cut and, if necessary, make adjustments to the operation of the machine.

Flaws:

- lower productivity;

- frequent replacement (or sharpening) of band saws;

- use for processing coniferous trees is difficult, since the resin sticks to the cutting edges of the saw, which significantly reduces the accuracy of the cut.

Introduction

I won’t delay and I want to immediately offer you my new book “HOW TO MAKE THE MOST OUT OF A BAND SAW MACHINE.” The book provides simply unique information based on my personal experience working on band sawmills.

It tells you how to work to get everything from a band saw. What kind of wood to cut and what needs to be done to reduce the number of downtimes. The main advantages of the ribbon are described, which you simply need to use. More details about the book in the “BOOKS” section. I’ll say right away that you definitely won’t find such information on a regular forum!

What to look for when choosing

When choosing a corner sawmill, you need to pay special attention to the characteristics of the saw unit, namely the quality of workmanship and the diameter of the discs, the power and speed of the drive motor.

The optimal choice of saw unit parameters will contribute to the efficient operation of the entire sawmill. Do not forget about other technical characteristics, since the potential for using the equipment and the profitability of the enterprise depend on them.

A few details to remember:

- The length of the supplied workpieces depends on the size of the particular machine.

- It is better to choose machines with the same disk mounting diameter.

- The sawmill has restrictions on the diameter of the wood processed.

- More powerful circular saw motors improve operating efficiency.

If you're interested in getting the most out of miter sawing, you shouldn't skimp on cutting tools or automation.

The correct selection of a circular sawmill can significantly increase labor productivity, while saving time and reducing energy costs. In addition, a high-quality woodworking machine will have a positive effect on the quality of the finished product.

Multi-saw disc sawmill

A multi-saw machine can be an excellent helper for a sawmill. It significantly increases the productivity of the enterprise. Such complexes include sets of circular saws. Using such equipment, you can obtain timber, container boards and other clean-edged material. Such equipment is divided into single- and double-shaft sawmills. The second option has high productivity and slightly worse cut quality. But such machines are much more difficult to maintain. They require a highly qualified operator.

Today there is a tendency to replace classic sawmills with multi-saw units. Such equipment allows you to obtain export-quality lumber and significantly speed up the process of producing boards or timber. The circular sawmill has proven its effectiveness. Equipment of this type reduces the cost of production, and therefore becomes more and more in demand every year.

If you are looking for an answer to the question of what kind of disk is needed for a circular sawmill, then pay attention to this characteristic from the data sheet of your model. Use only consumables recommended by the manufacturer.

Review of popular models

One corner saw can replace multiple machines by reducing the time spent on operations, increasing productivity, and freeing up additional manpower.

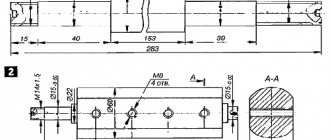

PDPU-600

The single-saw (single-disc) corner rotary sawmill PDPU-600 is equipped with a circular saw with a diameter of 600 mm. The saw unit is mounted on a carriage. There is the possibility of horizontal and vertical sawing of logs. Productivity 8-12 m/min. Product yield up to 74%.

Specifications:

- diameter of the processed log – up to 900 mm;

- processed log length – up to 6000 mm;

- saw blade diameter – 600 mm;

- saw motor power – 15 kW;

- rotary unit drive power – 0.37 kW;

- engine power for vertical movement of the carriage – 0.37 kW;

- maximum dimensions of the resulting timber – 210×210 mm;

- overall dimensions of the machine (without guides) – 1400x2000x1800 (mm);

- rail track length – 10500 mm;

- assembled machine weight – 1000 kg;

- productivity of edged lumber – up to 6m3/shift;

- lumber yield – up to 74%.

The workpiece is secured to the guides using clamps. When sawing a log, it does not need to be turned or re-secured.

Main advantages:

- vertical movement of the saw carriage and rotation of the saw blade are carried out using an electric drive;

- it is possible to install additional options (laser cut indicator, electromechanical feed, etc.);

- can be equipped with a gasoline engine;

- has a small mass;

- compact;

- relatively inexpensive.

Flaws:

- it is necessary to level the rails with a level, with high accuracy;

- very thick lower croaker due to high hooks;

- sawdust constantly sticks to the chain feed roller of the portal, causing the chain to break;

- weak iron for the resulting vibrations and loads;

- To adjust the positions of the disks, the bolts are not with fine threads.

This sawmill is perfect for sawing small volumes of wood.

GRIZZLY-1000/150A

The machine is designed for sawing wood of various species into edged boards or timber.

The saw unit is a carriage with circular saws located orthogonally, which moves along a permanently fixed log. It is possible to make both tangential and radial cuts. Product yield up to 70%.

Specifications:

- diameter of the processed log – from 100 to 1000 mm;

- length of processed log – from 1000 to 6300 mm;

- vertical disk diameter – 450 mm;

- horizontal disk diameter – 400 mm;

- total power – 24.95 kW;

- feed speed – from 0 to 48 m/min;

- the maximum dimensions of the resulting timber are 150x150 mm;

- overall dimensions of the machine – 8950x2860x2960 (mm);

- machine weight – 1800 kg;

- control mode – automatic;

The design of the feed mechanism is electromechanical, which ensures rigid coupling of the mechanisms and prevents slipping or jamming when sawing.

The machine bed is a durable and wear-resistant structure, resistant to loads and vibration, which ensures reliable operation of all components and assemblies.

The Grizzly sawmill does not require a foundation, just compacted soil.

Clamps allow you to securely hold the workpiece on the sawmill bed. Due to the stationary fastening of the log, the absence of additional loads and vibrations is ensured.

Main advantages:

- maximum radial cut;

- workpiece diameter up to 1 meter;

- ability to work in any climatic conditions;

- finished products of export quality;

- compliance with safety requirements;

- there are no requirements for log curvature;

- stepless adjustment of carriage feed;

- cleaning sawdust into the machine hopper.

Flaws:

- imbalance of the structure (the left side is loaded with the carriage, the right side is empty);

- the guide beam is not fixed rigidly enough;

- For an ideal radial cut, the horizontal and vertical discs must be identical.

Thus, having considered two models with different characteristics, the consumer can choose the most suitable option for himself.

These shortcomings were identified during actual work on sawmills of the above-described models.

Specifications

Machine power:

- three-phase motor with voltage 380 V;

- engine power - 7.5 kW;

- engine speed - 2840 rpm;

- saw mounting diameter - 50 mm;

- circular saw diameter - 450-500 mm.

Processed log size:

- length of sawn log: from 0.7 to 7 m;

- log diameter - 450-470 mm.

Machine dimensions:

- height - 1.2 m;

- width - 1.4 m;

- length - 6-8 m;

- full installation weight - up to 500 kg.

How to make it yourself using a circular saw

It is impossible to make a practical corner circular sawmill from a circular saw. Its production is impractical, because the design of such a tool, even if desired, will not allow making deep cuts in logs, which are made in the manufacture of commercial lumber.

In this case, at a minimum, you need to use a conventional electric motor and carry the disk itself on a long shaft.

It is best to make a corner circular sawmill with your own hands, using a 6.5 hp gasoline engine. We recommend watching the corresponding video on how to make such a machine:

Advantages

- The size ruler is equipped with tips for the operator. This will allow you to quickly and accurately set the desired size without lengthy calculations.

- Ideal geometry of the resulting lumber.

- Minimal adhesion of sawdust to the guides.

- The lowering and raising of the saw frame is carried out by an electromechanical drive. For more precise adjustment of the required size, the electric drive is equipped with a pulley with manual adjustment.

- Improved rail track and guides made of calibrated rolled steel.

- Easy to maintain and operate.

- There is a certificate of the Eurasian Union.

If desired, the sawmill can be supplemented with the options “smooth feed”, “electronic ruler”, etc.