Beton-House.com

Website about concrete: construction, characteristics, design. We combine the experience of professionals and private craftsmen in one place

Set of drills of different diameters

Concrete is the most versatile material used in home construction. Therefore, there are often cases when it is necessary to make holes in the concrete surface when laying cables or wires, installing equipment and furniture.

This cannot be done with a regular drill due to the high strength of the material. Only special concrete drills or drills can provide the required result. The article will tell you the types of tools, their features and methods of use.

Tool selection criteria

Tool sizes by diameter and length

To make the right choice of which drills to drill concrete with, you must first determine the volume and type of work to be performed.

To carry out small repair operations in your home, it is enough to use diamond drills with a diameter of 6 - 10 mm. If you need to hang a picture, it is better to take thinner tools with a diameter of 3 mm to 5.5 mm.

The diameter of the drill affects the depth of the mounting hole:

Dependence of diameter on drill length

According to GOSTs, all tools are marked, indicating the diameter and length, which helps to choose without error the size of the drill for a concrete screw to make a hole on a specific surface.

For example:

- Drill 6×110 mm. This is the most versatile and indispensable tool when making repairs in your homes;

- Drill 8×600 mm. Such long tools are used to drill deep holes;

- Drills 12×200 mm and 12×460 mm are used when it is necessary to drill holes for fastening furniture and laying electrical cables;

- Drill 24×460 mm. This drill is quite large in size and is often used when installing water supply and heating systems.

These are the main characteristics when choosing a drill. To learn in detail what types of tools there are for drilling and drilling holes in concrete, and how to choose the right ones for a particular case, you should watch the video in this article. Particular attention should be paid to the manufacturer.

Types and parameters of drills - distinctive features

There are two main types of drill bits for working with concrete:

- With pobedite inserts - so called after the alloy, characterized by high strength and excellent cutting properties

- With diamond coating - more demanding to use, but absolutely irreplaceable when processing ceramic and stone tiles (when using other drills, splitting is inevitable)

Drills from Pobedit

Drills with pobedit inserts are distinguished by their very low cost and excellent product characteristics. The alloy will win has been used for more than 90 years and has proven itself well both when working with metal and concrete. Its composition is a mixture of tungsten and cobalt.

Being very durable, it can withstand shock loads and does not require sharpening. Tolerates overheating well. But it’s still worth taking breaks from working with drills made from it. But there are drills on the market, both domestic and imported. Technologically, they all differ in the way the pobedit inserts are soldered. It can be either straight or W-shaped. They do not have any particular advantages compared to each other.

Diameter selection

When choosing the diameter of the drill, you need to take into account the inevitable runout during operation. Therefore, you need to take concrete drill bits 2-3 mm smaller than required. In this case, the hole will be the desired size.

In general, the diameters and linear dimensions of concrete drills vary over a fairly wide range. It starts from 2-3 mm and ends at 30 mm . The length of a concrete drill for a rotary hammer depends on its working diameter, on average it is about 30-40 cm . For large diameters the length can exceed 100 cm .

If a larger hole is needed (for example, for an electrical wiring box), then you need to choose a drill bit for concrete. Their diameter can reach 15-25 cm . Both diamond and diamond coating can be used as cutting parts.

Most popular brands

Currently, the most popular drills and augers among users are the following manufacturers:

- FIT

- Makita

- Bison

- Bosch

- Anchor

- Metabo

- Hurricane

- Stayer

- Interskol

Domestic brands are more budget-friendly and do not differ much in their qualities. The choice of a specific one depends on the scope of work and the budget. If they are supposed to be of a more average level, then you should give your preference to Makita, Bosch and Stayer.

Review of popular brands of tools for drilling holes in concrete

Drills used for concrete work are produced by foreign and domestic manufacturers. The cost of the instrument depends on the popularity of the brand.

How to choose the right drill bit for concrete?

Tip: When purchasing a tool, you should keep in mind that the higher the price of the product, the higher its quality and longer service life.

Good and durable tools are produced by foreign and Russian manufacturers. The best concrete drills are presented in the table:

| Manufacturer | Tool Features |

| High quality, durable and wear-resistant drills are tipped with carbide, retaining their properties even under prolonged loads that are accompanied by heat generation. Each drill is sandblasted and coated with titanium nitride, which increases their wear resistance. They are characterized by high elasticity and are resistant to bending and impact loads. A special sharpening of the solder makes it easier to insert the drill into concrete, and a spiral groove removes construction dust from the hole. |

| Rennbohr | High-quality metal is used to make the drill, and special processing protects the product from damage by corrosion. It has high strength and wear resistance, reliable protection against deformation. Retains its original shape over a long period of use. |

| Metabo | High quality, hard tipped, durable concrete drill bits. They have special heat resistance, are very durable, and have special grooves for quick removal of drilling waste. |

| Usually produced in a set of eight drills, of different diameters from 3 to 10 mm, packaged in a cardboard box. High-quality tool steel is used for production, and special processing protects against corrosion. Has high strength and wear resistance. It is not subject to deformation during frequent and long periods of operation. The U-shaped spiral on the tools helps to effectively remove dust when drilling a hole. The cylindrical shank securely secures the drill in the equipment chuck. |

| Tools with a four-spiral shape. This significantly reduces the time and labor required to remove concrete residue from a hole. |

| Tool Feature:

|

| The presence of a pobedite tip allows you to drill concrete and other building materials. The best option is to work in electric impact drills. |

| Anchor | They have an optimal price-quality ratio and a long service life. Products are made in China. They are equipped with durable carbide plates that are not destroyed even if the drill hits steel reinforcement when drilling concrete. However, you cannot drill through reinforcement with this drill. But when purchasing such a tool, you need to pay attention to the soldering of carbide plates - they must be even. |

| Used for rotary impact drilling. Peculiarities:

|

Advice: Which drills are best to use for concrete, everyone decides for themselves, based on their material capabilities. But it is always worth remembering that more budget options may be a fake, which can be immediately recognized when drilling concrete. Therefore, which drills are best to purchase, you should consult the seller.

Main types of concrete drills

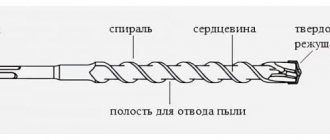

A distinctive feature of a concrete drill from others is soldering. It is created from a strong alloy, due to which a hardness similar to diamond stones is achieved. Craftsmen call these types pobedit; these products differ in strength from other types that are created for metal or wood.

There are 2 main types by which concrete drills are classified:

- for a drill - consist of a shank for a nozzle, which is made in a cylindrical or multifaceted shape. The dimensions are small, the product is suitable for creating holes in many hard materials, for example, brick, foam block. It is recommended to use a high-power drill, which will allow you to drill into concrete,

- for a hammer drill - the drill is cylindrical in shape, has a shank, designations SDS PLUS or SDS MAX. The goods themselves are quite large and long, suitable for reinforced concrete structures.

If you need to create holes in a reinforced concrete structure using a simple drill, then it is not always possible to solve the problem with just a drill. You need to use a hammer drill, and for this tool, drills are divided into the following types:

- screw - used to create deep holes,

- spiral - suitable for large holes,

- flat - used for drilling passages of different sizes and depths.

For proper operation, you will need to not just insert the drill into the chuck, but snap it into place. To make this task easier, the products have a slight thickening at the very end. It should also be noted that the products are considered professional tools, since they can be used to create holes from 4 mm to 3 cm in diameter.

If you need a larger hole, then the crown type will come to the rescue. Such products make it possible to make a recess of 12 cm in diameter. The products are very durable and are produced in several versions:

- diamond - visually made in the form of a pipe or crown, mounted on a rod, the edges are coated with diamond, which ensures high strength,

- pobedit - similar to an attachment, the main difference from diamond is the absence of sputtering; it is replaced by special teeth made from pobedit.

It is recommended to use crown products for holes for sockets, switches or wiring, and other communications. To select a suitable concrete product for a drill, you will need to take into account not only the parameters of the element, but also the dimensions of the future hole. Based on this, the length of the drill is selected, which depends on the diameter:

- diameter 4 mm - length 5 cm,

- 5 mm - 10 cm,

- 6 mm - 15 cm,

- 8 mm - 25 cm,

- 10 mm - 54 cm,

- 12 mm or more - up to 100 cm.

It turns out that for large holes a long concrete drill is used. If you use thin instruments, there is a risk of damage due to increased load.

Drilling holes

The process of drilling a hole in concrete with an electric drill

The instructions for carrying out the work are quite simple:

- Working tools are carefully selected. With a hammer drill, due to the transverse runout, the hole is slightly larger in diameter; it is better to purchase a drill of a smaller diameter. A diamond bit cuts through concrete with minimal tolerances;

- The surface is marked for drilling holes;

- To clearly position the tool in the center of the hole, it is better to mark the starting point with a concrete punch or bolt;

- The tool is installed in a pre-designated recess and a hole is drilled in the concrete using a hammer drill;

Tip: When working with a rotary hammer or impact drill, a lot of dust is generated. Therefore, when drilling holes, you should use safety glasses, gloves and a respirator.

- Pressing with great force on the handle of the hammer drill, you gradually need to move deeper into the concrete;

- When drilling a sufficiently deep socket with a low-power impact drill, it is necessary to use several techniques, periodically cooling the drill;

- For large holes, you first need to go through the center of the intended hole with a drill of a smaller diameter, and with a more powerful one, expand the cavity to the desired size;

- Upon completion of processing, the cutting edges of the tool are inspected;

- If necessary, the drill is sharpened.

Drill sharpening

Drill cutting edge

Tip: When starting to make holes in a concrete wall, it is necessary not only to choose a high-quality tool, but also to use it correctly.

In this case, you need effective preparation of the drill, which consists of sharpening it. You can do this yourself on a sharpener with a corundum whetstone.

The operating technology is similar to restoring the cutting edge of any similar tools, but taking into account some nuances:

- Severe overheating of the surfacing should not be allowed. Exposure to high temperatures reduces the adhesion of the winch and the steel base, which reduces the strength of the connection;

- If the moment was missed and the drill got hot, it takes enough time for it to cool down so that the process occurs slowly. It is forbidden to immerse the instrument in water: due to temperature changes, cracks will appear on it;

- The drill is sharpened along a cone, or along a helical surface. In the first case, no additional devices are required;

- When sharpening to a conical shape, the edges should meet exactly in the center of the drill. If the intersection of the edges shifts: the tool will be pulled to the side during operation, and one of the edges will become blunt much faster;

- It is better to use screw sharpening when working on foam or aerated concrete, and the working part of the tool should be sharpened on a special sharpening machine.

Which masonry drill is best to use?

Not every drill, especially a household one, can handle natural stone, as well as artificial ones. Various combinations of rocks dull drills very quickly, and successful work requires a completely different process - drilling, which is carried out using a hammer drill and appropriate attachments. For example, drills made from particularly strong alloys are designed specifically for impact operations. And, if the head is carefully sharpened and polished, and the longitudinal groove has a large depth with the walls bent in the shape of the letter “U”, such a drill will easily take even the hardest granite. But with softer bricks problems may arise due to the sharpening angle.

But which drill is better for concrete if deep drilling is necessary? First of all, a nozzle equipped with internal channels through which coolant (water) is supplied suggests itself. The fact is that in order to obtain a perfectly even hole, it is not recommended to constantly remove the drill to cool it. That is why special screw channels are twisted in a spiral inside the nozzle rod or are hollow tubes laid in screw grooves. Moving in a spiral along the direction of rotation, it is easier for the coolant to reach the cutting edge of the working part.

High-speed drilling is ensured by completely different features of the impact drill. Firstly, the special design of the working part, consisting of four cross-shaped cutting edges, which are equipped with an oblique sharpening. The centering tip allows you to get straight holes with virtually no heating. Secondly, deep screw channels that allow you to remove large amounts of concrete chips and dust. Separately, it is worth mentioning such an attachment as a chisel, which can have a flat, spatula or peak shape. Features of the working part of both options, intended for chiselling, are a self-sharpening edge, which significantly extends the service life.

Some useful tips when working with a drill

To drill a concrete surface with your own hands without any problems, you should follow the advice of experts.

Some of them can be found below:

- Before you start working on concrete, you should stock up on drills for different materials, including metal. This is because concrete drills are only used for drilling holes in concrete, ceramic, stone and other hard materials. But often, when entering concrete, the drill encounters metal reinforcement. This requires the use of a metal drill, which temporarily replaces the concrete tool used to drill through the reinforcement and then put the old one back;

- During operation, it is necessary to constantly monitor the temperature of the tool. Every 15 seconds of continuous drilling, you need to pause to cool the drill, but only naturally, without the use of water or other liquid;

- If, when entering concrete, the drill rests on a hard stone, it is better to use a punch, crush the stone, and then continue working with the same tool;

- If it is necessary to make a hole in the ceiling or load-bearing wall, it is better to replace the impact drill with a hammer drill;

- If drilling ceramics, use a concrete drill, but turn off the impact drill mode to prevent splitting of the tiles;

- A dull drill can be sharpened using a grinder by installing a diamond disc on it. If you purchase high-quality expensive tools for work, they will not need to be sharpened.

Tips on what and how to choose drills, concrete drills, and how to use them are useful for both beginners and experienced craftsmen. Drilling concrete is quite difficult, so it is better to first take into account all the recommendations of specialists and choose the right working tool.

How to drill concrete

Concrete walls and floors can be drilled using three types of tools:

- Drill

- Impact drill

- Hammer

The first two tools can often be made in the same body. This is a more economical option, but requires attention when selecting drills - each mode (drilling, impact) requires its own devices.

The hammer drill is capable of not only drilling, but also performing powerful high-frequency blows. This allows it to partially replace a jackhammer and use a special lance to make grooves and large recesses in concrete. They are convenient for crushing masonry and removing old ceramic tiles.

Drilling with a hammer drill

When using a hammer drill, you need to follow safety rules and select drills and drills in accordance with the type of clamp on it. It can be of several types:

- SDS - has 2 grooves and a shank diameter of 1 cm , working part from 0.5 cm

- SDS plus - has 4 grooves and a shank diameter of 1 cm , working part from 0.5 cm

- SDS top - has 4 grooves and a shank diameter of 1.4 cm , working part from 1.5 cm

- SDS quick - has 4 grooves and a shank diameter of 1 cm , working part from 0.5 cm

- SDS max - has 5 grooves and a shank diameter of 1.5 cm , working part from 2 cm

Diamond-coated drills cannot be used for hammer drills in impact mode. Their destruction is inevitable due to their high fragility. The hammer drill is ideal for large-scale work and drilling thick load-bearing walls and foundations.

Drilling

Using a drill, you can use both drills with a pobedite working part and those with diamond coating. The latter, at medium speed, can perfectly drill into ceramic tiles or stone coatings without splitting them. The drill is suitable for a variety of small-scale work when renovating a house or apartment. Drilling of walls is possible only of small and medium thickness.

- Both when working with a hammer drill and a drill, it is necessary to use protective glasses and a filter mask for the respiratory system. Otherwise, eye injuries and inhalation of fine stone dust are inevitable.