Catalog >> News >> Choosing drills for a concrete hammer drill

Choosing drill bits for a concrete hammer drill

A drill is a cutting tool necessary for drilling holes in concrete, brick and stone materials and is an accessory for hammer drills. Drills for concrete hammer drills come in several types, differing in the type of shank:

- SDS Plus

- SDS Max

- SDS Top

- SDS Quick

- SDS Hex

Only 2 types of drills for concrete hammer drills are widely used in household and construction areas: SDS Plus and SDS Max. The first type of drills is used in low- and medium-power hammer drills, the second type is used in powerful tools.

Device

Regardless of the above-mentioned type, material and design features, drills for concrete hammer drills are built according to a standard principle. They are actually built from two parts: the shank and the working part. The latter, in turn, consists of 4 more zones:

- Spirals - spiral-shaped turns that help remove dust generated during the drilling process.

- The core is the main rod on which spiral-shaped turns and cavities are organized that remove dust.

- Channels for dust removal - peculiar cavities obtained due to the ribs of the spiral.

- The carbide cutting edge is the tip of the drill, which bears the main load during drilling. The effectiveness of work and the durability of the equipment depend on its quality characteristics.

How a drill for a hammer drill works Source redteh.ru

Important! When choosing a good concrete drill, pay attention to the location of the cutting plate. It should “sit” firmly in the saddle and be located strictly in the center.

Design and types

There are a large number of such devices on sale, classified by design, power of compatible equipment, type of limit switch and other characteristics.

Regardless of the type, the drill consists of three parts:

- Shank. With its help, the nozzle is fixed in the cartridge.

- Body. It bears the maximum load when processing concrete and creating holes. High-strength steel grades are used for production.

- Cutting element. It can be made from carbide plates or have an additional diamond coating. The second type is more expensive, but wear-resistant thanks to the high-strength spray material.

The main difference between attachments for drilling concrete surfaces is the length, diameter and level of inclination of the edge of the cutting part.

There are three main types of shape - spiral, flat and screw:

- The former are suitable for drilling thick partitions and load-bearing walls. When using spiral nozzles, the tool removes construction debris and crumbs directly in the process.

- The second type is suitable for creating small holes; when used, concrete dust is removed manually.

- The third type of drill is characterized by high-speed rotation and no need for regular sharpening. It is used for particularly hard surfaces.

Another classification option is by purpose. Drills for concrete are divided into breakthrough and through:

- the first ones are needed for drilling wide holes;

- the latter provide accurate processing and are suitable for more precise work.

Labeling and classification

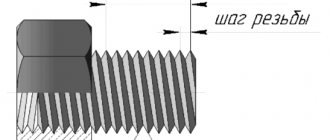

The main marking of drills takes place with an eye to the size of the equipment. The indicator is determined by its purpose: to obtain a through hole, a recess for an anchor or a thin dowel-nail. Based on the specifics of requests, generally accepted marking is carried out.

- Total length.

- Diameter.

- Shank type.

Healthy! An example of marking a drill with an SDS-plus shank 210 mm long, 10 mm in diameter: 10x210, SDS-plus. According to this principle, all equipment is “read” not only for rotary hammers, but also for drills.

Dimensions of drill bit for concrete hammer drill

Before deciding which drill to buy, you need to determine exactly how it will be used:

- For amateur repairs, a tool with a diameter of 6-10 mm is suitable.

- If you need to build stands or mounts for heavy objects, you will have to use a larger nozzle (up to 20 mm).

Standard sizes can be found in the table below.

| Section, mm | Length, mm | Cutting edge size, mm |

| 6 | 110 | 45 |

| 8 | 110 | 45 |

| 10 | 160 | 95 |

| 12 | 260 | 180 |

| 14 | 260 | 180 |

| 16 | 300 | 125 |

| 18 | 460 | 360 |

| 20 | 460 | 360 |

| 22 | 600 | 490 |

| 25 | 460 | 360 |

Shank type

Shanks on drills are classified according to external characteristics. Unlike drill bits, their dimensions are not affected by the diameter and length of the equipment, which allows them to be used with any hammer drills with a suitable type of chuck.

Popular shank for concrete drills Source uainfo.com

We will consider only those that can be encountered in everyday life, that is, applicable to modern rotary hammers. They bear the general name SDS, which is further divided into several categories.

SDS is the first model that served as a prototype for all modern equipment for this purpose. It has a diameter of 10 mm and 2 channels, ensuring reliable contact with the torque of the chuck. It goes in only 4 cm deep.

SDS-plus is the most popular group. With a diameter of only 10 mm, it deepens into the cartridge by 4 cm. The advantage and difference from the founder of the group, the SDS shank, lies in the twofold superiority in the number of recesses. There are 2 closed and 2 open channels. The latter here work as guides, while the closed ones play the role of a stopper and are intended for locking bearings. The area in contact with the wedges is only 75 mm2.

The main segment with which such equipment is used is household and professional small-sized hammer drills (lightweight). The diameter of the drills varies from 4 to 26 mm, and the length from 110 to 1,000 mm.

What is the difference between SDS-max and SDS-plus Source ferrocom-ekb.ru

Healthy! SDS and SDS-plus shanks are completely interchangeable

SDS-max is an equally popular drill shank. Belongs to the category of equipment for large tools. The element has a seat diameter of 18 mm, and the surface of the contacting wedges is 389 mm2. It has 5 grooves, 3 of them are open, 3 are closed. As already mentioned, the size of the tool with which such drills are used is fundamentally different from household equipment and is used in industry and large-scale construction. Only in a chuck this type of shank fits 9 cm.

The most popular types of concrete drill shanks Source detaltorg.ru

It is not water that wears away stones

The main working part of any drill is the tip. It must be made of durable material that can withstand work under conditions of enormous loads and overheating, because its main task is to literally break the strong structure of the stone.

The vast majority of drills are tipped with an alloy of carbon-rich tungsten and cobalt. This alloy is popularly called Pobedit alloy. It has very high strength values and is capable of making holes in such durable rocks as granite and marble.

By the way, the same material is used to make tank armor-piercing shells.

Stronger and more durable cutting tool edges are made from synthetic diamond. This super-hard material guarantees trouble-free drilling into granite and reinforced concrete of the highest strength. However, the cost of such instruments will be higher than their Pobedit analogues.

Working part

As already mentioned, the middle (helical) part of the drill is responsible for the timely removal of dust from the hole. It can be manufactured in different designs, and accordingly it will be classified differently.

- Classic auger drill - designed for drilling deep holes. Due to the optimally selected spiral design and nominal rotation speed, it effectively removes dust. This reduces the load on the tool and the time spent on performing a specific task.

- Small angle of inclination - used with a tool that has low impact inertia. The optimal purpose is to obtain a large number of holes, small in size (with a diameter of no more than 10 mm, a depth of up to 800 mm).

- Large inclination angle - such equipment has an excellent dust removal rate, which affects drilling performance. Designed for drilling through and non-through holes. However, the optimal effect is achieved by obtaining a single hole of large diameter and depth.

Characteristic features of earth drills

The attachment used to make holes or holes in the ground is called a hole drill. It is widely used in various fields of economic activity and makes holes with a circular cross-section. An earth drill for a hammer drill is necessary when arranging a site, installing pillars, creating a pile foundation, erecting gazebos or arches, installing a fence, laying utilities, constructing wells or boreholes. The nozzle is made of a thick-walled pipe, a metal sheet, a metal drill, and a steel disk.

Note! The hole drill can be used with a hammer drill with a power of at least 850 W.

The attachment for a hammer drill, which is used to make holes in the ground, is called a hole drill.

The hammer drill (for earth) is presented in two versions depending on the design of the working part. It can have a spiral shape or be made in the form of a hemispherical disk knife. Experienced craftsmen prefer to use the second option.

There are several types of products: auger, garden and TISE pile drills. A garden attachment is the simplest mechanical device. It is a double-sided product with a tubular rod, a handle and a cutter, which has two blades on the opposite side. This kind of earth drill for a hammer drill is used to create shallow holes or wells.

The auger drill is equipped, in addition to cutting blades, with a screw auger. Thanks to the split design and several cutters, high speed work is ensured. Increasing the rotation speed of the nozzle helps to deepen the tool to a certain depth.

There are auger drills, garden drills and for TISE piles.

The TISE earth drill is equipped with a load-bearing base and is supplemented with some elements. A soil receiver with auger plates and special cutters ensures quick removal of soil from the pit. Thanks to the cylindrical storage, it is possible to make a perfectly straight hole in a vertical position. The extendable section of the rod allows you to adjust the required depth. If obstacles are detected in the ground, a guide pin comes to the rescue.

Tip

Different types of metals are used in the manufacture of equipment. For example, alloy tool steel is used in the production of the rod and shank. For the cutting element (tip), pobedit or diamond brazing is used. This allows not only to significantly increase the service life of the equipment, but also has a positive effect on its productivity.

The peculiarity of drilling holes in concrete with a hammer drill, when compared with working with conventional drills, is that the degree of sharpening does not matter here. As a result of dulling, performance decreases, but not significantly. The main factor in this situation is the solder size. As soon as its width becomes less than the diameter of the drill rod, problems will arise with the subsequent installation of the anchor or dowel-nail plug.

Important! The diameter of the hole will correspond to the size of the drill only if the nozzle is not ground off by 70 percent or more.

Nozzle material

As already mentioned, the tip of a concrete drill can be made in the form of pobedit or diamond brazing. They differ from each other in many ways, from chemical composition to operational characteristics.

Carbide part of the drill and its sharpening

The brazing, which is the cutting part of the drill and affects the speed of work and the quality of the resulting holes, is made of hard alloy and can have a different number of working edges. The life of the drill is entirely limited by the degree of wear of the soldering tip. Manufacturers are constantly improving materials and methods for sharpening the drill head, trying to maximize productivity while minimizing power costs for drilling. According to the sharpening configuration of the carbide part, drills can be divided into two main groups:

- Classic sharpening - a carbide plate has straight cutting flat front and rear edges arranged crosswise. A brazed tip with such sharpening can have one or two cutting edges, which reduce runout during processing, improve the quality of the hole, but also affect the price of the drill.

- The centering head is a more advanced version of the classic sharpening. The special geometry, which varies among different manufacturers, prevents the drill inside the hole from moving away from the axis of the initial position and forms a smooth, “not broken” hole.

It should be noted that the cutting edges do not always have a linear shape; a wavy geometry with a centering spike and outer cutting ridges is another way to reduce the load on the hammer by removing hard material in layers. There are also self-sharpening bits with the correct sharpening angle, which are necessary in aggressive drilling conditions - for example, abrasive rocks - the drill wears out without dulling the extremely wear-resistant cutting edge.

What is different about a concrete drill?

It has a special brazing made of a reliable alloy with a hardness level comparable to diamond. We are talking about victorious coating.

Equipment for drilling element for concrete:

- Can be used in conjunction with a drill. The design of the drill is distinguished by the presence of a tail with a cylindrical or multifaceted shape;

- For a hammer drill. It is made in a shape similar to a shank or cylinder. For marking, the inscription SDS PLUS or SDS MAX is used.

Hammer hammer design

All rotary hammers have two types of impact devices used - ratchet and impact mechanisms.

Ratchet mechanism

The principle of operation of the ratchet mechanism is based on the sliding of two notched coupling halves relative to each other, which creates an impact effect. Similar devices are used in relatively low-power hammer drills and drills. The use of a ratchet in a powerful hand tool limits the disadvantages: the recoil force is equal to the force of impact on the working tool, intense wear of the coupling halves, the intensity of vibration depends on the force of pressing, that is, on the use of muscle force, the more powerful the tool, the more difficult it is to do this. It is recommended to use a concrete drill sds no more than 6x110mm with such a device. The most progressive has been the use of a device with an oscillating bearing. The oscillatory motion during rotation is created by the eccentric outer race of the bearing (which is popularly called drunk). The clip, swinging relative to the ellipse, sets in motion the rocker, which is connected at its outer end to the piston of the impact mechanism. The piston of the impact tool, making a horizontal movement, strikes the striker, which in turn transmits the impact energy to the working element. This device is used on rotary hammers with a power of up to 5 kW, which is optimal for concrete drill sds 10x210. More powerful hammer drills use another type of impact piston drive device - a swinging rocker, in which the role of the piston drive is assigned to the eccentric rocker of the piston drive by a connecting rod drive. The piston moving along the cylinder creates an impact load on the firing pin. This design is interesting in that there is a counter-weight on the slide that absorbs part of the recoil energy, working in the opposite direction to the main piston. (analogous to a car crankshaft). Also, in such designs, an air shockproof system is used to further soften the recoil force. Large concrete drills sds 32 1000 and concrete drills sds 25x600 are used with such hand tools.

There are different types of drills

According to their intended purpose, drills can be divided into the following categories:

Screw

They are used when it is necessary to create a deep hole of large diameter. Drilling of this kind creates a large amount of dust and waste, which is why constant removal of cuttings is necessary. The screw design allows for the most efficient removal of a large volume of dust without loading the hammer.

Gentle

The most common type of drill. They are used everywhere for drilling small-diameter holes. Such tools can last longer than the hammer drill itself if used properly. They are ineffective at removing dust, so sometimes they can get stuck.

Crowns

With this tool you can make very wide holes in the wall. Widely used to create a niche for an outlet or switch. A distinctive feature is the incomplete destruction of the removed material. Only a hole is cut in the center and a narrow circle along the edge, leaving the core.

Breakthrough

An impressive-looking drill, which is used to make holes of particularly large diameter. It is used when it is necessary to lay communications: pipes, thick cables, hoses.

What, with what and how to drill

To drill concrete for a thin cable or dowel in ordinary apartment buildings, in 99 out of 100 cases you will need a Pobedit flat drill with an SDS-plus cartridge. In everyday life, you may not need another tool for a hammer drill. Maybe a crown.

If you have to work with natural stones, or use the drill very often, then it is better to choose an SDS-max diamond drill, if this is provided by the hammer drill.

For those who will use a hammer drill for laying communications, you will have to acquire a powerful device with a max cartridge and a breach drill.

The wide variety of purposes to which the hammer drill is applied is too great to describe every case.

The most important thing is to consider the length, shank and diameter of the drill, as well as the material that will be processed.

Now you know that in order to make a hole in the wall, you don’t need to run to the store for a concrete drill. Most likely, the seller will even correct you if you make such a request and will offer you a drill.

How can you get a drill stuck in the wall?

You need to turn on the impact mode without rotation and pull out the tool little by little. Some rotary hammers have reverse, but in this mode the brushes can be damaged. A radical method, if all else fails, is to cut off the stuck drill with a grinder and bury it in the wall.

Are diamond tips really made from diamond?

Yes, however, this is not the kind of diamond that is used in jewelry. This diamond is obtained artificially; it is dirtier in terms of composition, but is not much inferior in strength to the real thing.

How to understand which cartridge is in the hammer drill?

The cartridge itself should have an engraving with the designation. The drills also have marks indicating which shank the tool has.

Can't you drill into concrete with a drill?

However, the drill may not be able to cope with reinforced concrete walls and natural stones. If you don’t want to break a drill or drill, then use a hammer drill.

My drill tip melted while drilling. How is this possible?

This phenomenon is not uncommon. Low-quality drills can actually reach the melting point if a thick steel rod comes across it along the way and the master continues to drill. However, better quality drills can also handle reinforcement in the wall.