Safety regulations

Before cutting paving slabs with a grinder or a guillotine, or in any other way, it is imperative to ensure the protection of the master.

Otherwise, it is difficult to guarantee the safety of work and the absence of risk of injury. Safety precautions when cutting tiles:

- Protective equipment (especially if a method is chosen for cutting tiles that involves the generation of a large volume of dust, high speed of rotation of parts, etc.) - safety glasses, a respirator, special clothing made of very dense material will save you from dust and injuries.

- Special headphones to protect against excessively loud noise.

- Studying the rules for operating the selected tool is generally simple: do not put your fingers near rapidly rotating mechanisms, work carefully with power tools, carefully check devices and parts before starting work, do not use broken or incorrectly functioning devices. Each method involves its own set of rules: for example, if cutting paving slabs with a grinder, then the tool must be held with both hands by the side handle, a protective screen from dust and sparks is used, electrical safety is ensured, etc.

- During the work, monitor the parts and mechanisms - the guillotine knife, grinder circles must be changed on time, used only if they fully comply with quality standards.

Using a miter saw to cut metal.

I read somewhere that it is absolutely impossible. And it turns out you can” > I wonder what diameter of the circle he used.

I think 200x32 mm through the adapter washer. Everything is possible in our country)))

In some TV program I saw how men cut a steel profile with a circular saw, only not like a pendulum, but one that moves along a bar. They had a metal disk there and it seemed like they were even leaking coolant.

Yeees. Our people apparently have a lot of health.

2 BEARDED What risks do you think exist?

acrobat wrote: What risks do you think exist?

Burning of the edges of the workpiece, an increased probability of destruction of the disk at such speeds, and as a result, unfinished work and possible injuries, shaking or complete failure of the tool, waste of time and effort (which we don’t like to count) on remaking and fine-tuning an obviously poorly made tool .

It’s possible, there are special discs; usually partition installers often cut duralumin profiles with such a tool.

Serg wrote: duralumin profiles are often cut with such a tool.

Duralumin profile, aluminum profile - another story. I'm talking about steel - pipes and angles, for example.

How to cut laminate flooring at home

Laminate floors are perhaps at the peak of popularity today. Laying laminated material can be done on your own. For this you need: desire, accuracy and a little free time. To perform installation, you need to purchase materials and a set of tools. Here the question arises: what tool is needed for installation and how to cut laminate flooring at home.

Sometimes it is difficult to choose just one type of lamellas, there is such a huge variety of colors, textures, decors with different patterns, authentic imitations: natural wood, natural stone, metal and even reptile skin. As practice shows, the variety of external appearance of the lamellas is not a factor influencing the cutting of the material. Therefore, in most cases, cutting yourself will not cause any difficulties.

You can carry out all the installation work without purchasing specialized tools, using the existing stock of equipment in your home pantry. Today we will look at what tools are needed for cutting panels and how to cut laminate when installing it yourself.

Angle grinder

The grinder is a universal assistant that works great on aluminum

It is only important not to confuse a cutting wheel with a grinding wheel, choose thin-thick equipment to minimize material loss and protect your hands and face from sparks.Advantages:

- speed of work;

- decent cutting quality;

- relative cheapness of equipment;

- minimum user movements;

- durability of the equipment, which allows you to repeatedly saw metal profiles.

Sparky angle grinder

Disadvantages:

- possibility of metal burning in the cut area;

- without working skills, it is unlikely that you will be able to cut smoothly;

- To increase the accuracy of the work, the grinder should be clamped into a stand, which is not supplied with the tool and is rarely found in stores (the problem is solved if you have a vice).

Now it’s worth studying special devices for working on aluminum.

Premium models

| Model | Characteristics |

| Bosch GCM 8 SJL Professional Professional “trimming” with an excellent set of functions that significantly speed up the process of high-quality processing of various materials with a small cross-section. Main characteristics: power - 1.6 kW, saw blade rotation speed - 5500 rpm, maximum blade diameter - 216 mm. The cutting depth at an angle of 90° is 70 mm. Cutting width - 312 mm. Equipment: broach, cutting depth limiter, head tilt to the left 47° and to the right at an angle of 2°, table rotation left/right - 45°/45°. Functionality: laser marker, two-point dust removal system, work table extension and clamp for fixing the workpiece. Weight - 17.3 kg. The average cost is 32,700-39,900 rubles. Advantages:

The disadvantage is the relatively small power and diameter of the saw blade. | |

| Makita LS 1216 Professional miter saw with excellent functionality and high cutting quality. Power - 1.65 kW, spindle speed - 3200 rpm, maximum disk diameter - 305 mm. The cutting depth at an angle of 90° is 107 mm. Cutting width - 363 mm. Features: broach with double guides on linear ball bearings, tilt of the cutting unit to the right/left at an angle of 45°, rotation of the table to the left 52° to the right - 60°. Functionality: maintaining speed under load, soft start, cutting depth adjustment, dust extraction pipe, work table extension and clamp for fixing the workpiece. Weight - 26.1 kg. The cost ranges from 44,900 to 50,700 rubles. Advantages:

Flaws:

| |

| Dewalt DWS 780 Professional model with a large saw blade with adjustable speed. Main characteristics: power - 1.675 kW, saw blade rotation speed 1900-3800 rpm, maximum blade diameter - 305 mm. The cutting depth at an angle of 90° is 112 mm. Cutting width - 349 mm. Equipment: broaching, head tilt left/right at an angle of 49°, table rotation to the left - 45°, to the right 60°. Functionality: electronic adjustment of the rotation speed of the equipment, adjustment of the cutting depth, dust removal system, illumination of the work area, XPS cutting line positioning system, work table extension and clamp for fixing the material. Weight - 24.8 kg. The average cost is 53,900-65,390 rubles. Advantages:

The disadvantage is the high cost. |

Can a miter saw cut metal?

Having high-quality processing or construction tools for home use allows you to quickly complete repairs or carry out restoration, construction or restoration work better and cheaper. In modern conditions, a miter saw helps to accurately cut timber made of laminate, plastic, or wood.

Both professional carpenters and beginners have to cut all kinds of workpieces. The use of all popular equipment options helps to fully evaluate the quality of work of such hand tools.

best miter saws for home workshop

It’s worth choosing from time-tested brands:

Bosch (PCM series

With a power of 1.2 kW it will provide a cutting depth of 60 mm, a vertical angle of 120 degrees, price: 13,500 rubles.

PCM 8 S from Bosch with feed function

Elitech (PT 1625 series)

Power 1.6 kW, cut - 90 mm, angles 65 and 150 degrees, price: 12,100 rubles.

Elitech PTK 1625

Makita (LS 1040 series)

Professional tool 1.7 kW, cutting depth - 67 mm, weight 11 kg, price: 17,000 rubles.

Makita LS1040

VIDEO: Atypical operation of equipment (part 2)

How to choose a metal blade for a miter saw

A similar tool appeared on the market relatively recently. Metal cutting blade for miter saw? For many, even experienced craftsmen, this causes a smile and distrust. Not so long ago, steel could only be cut by flame cutting, a grinder wheel, and a hacksaw. Only wood and plastic materials could be processed on cross-cutting machines.

However, time does not stand still. Materials engineers, in tandem with toolmakers, are constantly working on the synthesis of new alloys. Today, a metal cutting disc for a miter saw can be purchased at any tool store. However, this tool operates in harsh conditions and is subject to wear.

Chainsaw capabilities

It should be noted that the chainsaw is multifunctional, because with its help you can cut not only wood, but also foam blocks, aerated concrete, shell rock, chipboard, and even stone. To cut the trunk, you should focus on the width of the tire and the diameter of the tree. Naturally, cutting thick wood with a reciprocating saw is difficult and time-consuming, but with patience it can be done. If there is a need to cut chipboard, then it is better to use a special tool that will not leave chips on the edges, but if you don’t have one at hand, then you can use a chain saw with low power, this will make it easier to control the evenness of the mowing line.

When felling trees, it is important to observe safety precautions, because any confusion can lead to injury. The procedure is as follows:

Remove the chainsaw from the cut you made; Turn off the chainsaw; Lower down; Leave the work area, taking into account the direction in which the tree fell.

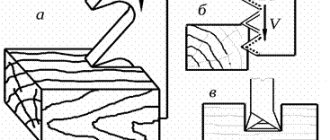

Rules for cutting with various tools

When working with a hammer and chisel, you need to act in the following order: attach the sharp part of the chisel to the cut line and methodically tap with the hammer until the brick splits. The advantage of this method is the availability and low cost of the tool. The disadvantage is that the cut plane is rough. To make both planes smooth, they will have to be sanded or rubbed against each other.

A manual tile cutter is used to work with facing bricks. Its advantage is the ability to cut at complex angles and make thin plates, which are indispensable at the final stage of cladding. The disadvantage of this tool is the inability to work with standard bricks.

Laser cutting of bricks

Laser equipment is used to cut openings in a brick wall. The compactness of modern lasers allows them to be delivered and operated at any construction site.

Laser cutting is an expensive process, the success of which depends on the following factors:

- type of brickwork;

- cut geometry;

- thickness of the cut wall;

- presence of fittings;

- water supply and electrical supply of the construction site.

Cutting bricks with a grinder

A grinder is an ideal tool for working at home if the site has electricity. It saves sawing time several times compared to hand tools. The main rule when working is the use of personal protective equipment. The brick must be securely fixed to the table or workbench.

Special machine for cutting bricks

It is the best solution for figure cutting, because it allows you to set any cutting geometry. The cutting parts are factory sharpened and specially coated, which guarantee minimum tolerances for the surfaces to be separated and the absence of chips.

Using a petrol cutter

The difference between the tool and the grinder is that it runs on gasoline rather than electricity. There are also gas cutters with a chain instead of a cutting disc for stone. All cutting parts of the gas cutter are coated with diamond coating, which increases their service life.

Manufacturers you can trust

The optimal miter saw for comfort, manufacturability and safety during operation is considered to be one of these products; DeWALT; Metabo; Makita; "Interskol". Hitachi; Bosch.

Most of THESE manufacturers provide an extension of a special table for the workpiece, however, for cutting large parts in some cases additional supports are required. These can be found, for example, in the cross-cutting model LF 1000. This addition greatly simplifies the user’s work. In addition, the movable part of the metal saw is included in a stable frame, in which there is space for assembling the cutting angle.

The best trimmer, in terms of stability and reliability, is the one whose frame is made of magnesium or aluminum alloy. They are stable, durable and also have a very reasonable weight. An example is the Bosch GCM 10 model, the most popular modification among professional models. With all other advantages, it weighs only 15 kg.

Hitachi is considered the leading manufacturer among hacksaws with a permitted inclination of the cutting edge to the workpiece. While Bosh, Metabo or Makita mostly provide the ability to measure the cutting angle only at 0, 90 or 45 degrees, this Japanese concern provides the operator with the ability to measure at 30; 15; 22 and even 5 degrees. The provided option confronts the operator with the need to add a rotating device to the design of the device. However, the weight of the installation for cutting sheets, pipes or profiles will not exceed 30 kg. However, the cost will also increase from 15 to 25 percent.

The manufacturer of DeWALT dust stands out due to the presence of the XPS system, which allows you to project a clear line. Before starting work, a shadow is projected from the saw blade, which makes cutting the metal more precise. Domestic models are, from a design point of view, very simple, since they have:

- disk

- start button

- engine

- handle

- base

Additional advantages of the device are that they are very affordable ( you can choose models from 5,000 rubles) and easy to hold in weight.

To cut a metal sheet, profile or pipe, you will need to return either a blade or a table. The disk can rotate along its axis and against it, which is very convenient for the master’s work.

Before making a purchase, we recommend that you choose the models from the above manufacturers and weigh all the advantages and disadvantages

CMT 272.190.42M (190x30 / 20 / 16x1.7 / 1.1 mm; Z42) - clean thin cut

For particularly fine cuts with a clean edge, thin blades with a large number of teeth are needed. Such equipment is used in the production of furniture, where neat, precise cuts and rational consumption of material are needed. But the price for this is a thin section of the metal, which leads to snagging or deformation

This disk should be used more carefully than the second one.

CMT 272.190.42M (190x30 / 20 / 16x1.7 / 1.1 mm; Z42) - a particularly thin disk with a thickness of 1.1 mm. It has 42 teeth and leaves a kerf with a width of 1.7 mm. Manufactured directly in Italy and designed for finishing cuts.

Pros of CMT 272.190.42M (190x30 / 20 / 16x1.7 / 1.1 mm; Z42)

- Suitable for circular saws with speeds up to 8000 rpm.

- Very quiet operation.

- It makes it easy to make longitudinal and transverse cuts in materials of various densities.

- DOES NOT leave bristling fibers on the edges.

— Cons CMT 272.190.42M (190x30 / 20 / 16x1.7 / 1.1 mm; Z42)

- The price is much higher than analogues.

- Complex sharpening, which is not easy to restore at home.

- To install on some circular saws, you need adapter rings - those included in the kit are thicker than the disk itself, so the latter is NOT clamped to the end.

- You can’t rush too much when making a cut, otherwise it will be chipped.

Conclusion. Ideal for a furniture workshop. Allows you to cut through OSB and similar materials as cleanly and accurately as possible. Eight slots inside the disc provide good vibration damping and promote quiet operation.

Which driver should I download for the network card (Ethernet controller)?

We found out that we need to download and install the driver for the Ethernet controller. You probably immediately have a question about what driver is needed and where you can download it. Let's figure it out now.

The most correct way is to look for a driver for your laptop model, motherboard, or the network card itself.

I understand that your Internet most likely does not work. If you came with a driver disk with the adapter, laptop, or motherboard (if you have a PC), then you can try installing the driver from the disk.

If there is a disk, you will have to search and download the driver from another computer, or even a mobile device. Then it transfers it to the desired computer and installs it.

Checking router operation / diagnostics

Most Internet providers today do not connect to the Internet directly by laying a network cable to a PC, but using a router / router (this device allows you to connect several devices to the network at once: phone, PC, laptop, TV, etc.).

If you have a router, proceed to the next paragraph of the article.

So, if you have problems with the Internet, first of all I recommend looking at the status of the LED on the router case. If the device is working - they should at least “burn / flicker” (see photo below).

Also pay attention to whether the LED on the network card lights up when you connect a cable from the router to it (note: most network cards have such an LED).

Often, by the way, when cables and wires become bent, break, or become unusable (sometimes this happens with the help of pets or when rearranging furniture that they like to place on the cable...). Therefore, if the LEDs on the network card/router case do not light up, look first for a hardware problem: a broken cable, lack of power, etc. malfunction.

In general, reinstalling Windows OS does NOT reset the router settings. Usually, more often the problem is that the wrong IP and gateway are specified in the network connection in Windows (but more on that later in the article).

Here, however, I recommend going to the router’s web interface and checking if everything is in order. This article will tell you how to do this: https://ocomp.info/kak-podklyuchit-i-nastroit-wi-fi-router.html

Installing a driver on a network card in Windows 10, 8, 7

So, we already have the driver. As practice shows, to install you just need to open the downloaded archive, run the setup.exe file, and follow the installation instructions.

If any error appears during the driver installation process, restart your computer and try the installation again. If the driver still does not want to be installed, then try downloading another one. But there shouldn't be any problems.

READ How to sharpen an angle saw chain

Checking the network card in Device Manager

Let's go to the device manager and see what's what. If you don’t know how to enter the device manager, then press the Win R key combination, copy the devmgmt.msc command into the window, and click Ok. Or right-click on “My Computer” - “Properties”, and there “Device Manager”.

Immediately open the “Network Adapters” tab. If everything is fine with the network card, then there should be an adapter in the name of which you will see the words “LAN”, “Ethernet adapter”, “PCI ...”, “Family Controller”, etc. I have an Asus laptop, and the adapter “ Realtek PCIe GBE Family Controller".

I think you will immediately understand whether there is a network card there. If it is there (there are no icons near it), and the Internet does not work, then perhaps the problem is not there. And in the cable, for example, or in the router (if you have one). You can see the article Internet does not work on a computer via a cable from a Wi-Fi router.

If you don’t see a network card there, then there must be an unknown device (with a yellow exclamation mark). Most likely, it will be called “Ethernet controller”. This is our network card, which does not work due to the lack of a driver. Windows without a driver simply does not know what kind of device it is and how to “communicate” with it.

We just need to install the driver on the network card. Or reinstall it if there is an adapter, but it works with errors or does not work at all.

If you need to reinstall (update) the driver

If you want to reinstall the driver, then I advise you to first remove the old one.

To do this, go to Device Manager (how to do this is written at the beginning of the article) and right-click on the Wireless Network Adapter device. Select Properties.

Then go to the Driver tab and click the Uninstall button.

A warning will appear, check the box next to “Remove driver programs for this device” and click “Ok”.

That's it, the driver has been removed. Restart your computer. Go to Device Manager. You should see that an unknown device (Network Controller) has appeared. This is our wireless adapter, we just have drivers for it, we’ll install it now.

I recommend installing the driver as follows: if the driver is in the archive, then unpack it into a folder. Go to this folder and run the installation file, usually called “setup.exe”. Follow the instructions. After installing the driver, usually Wi-Fi should work even without rebooting. And I hope it will work stably.

Reasons for lack of Internet after reinstalling Windows

One of the most common reasons for network inoperability after installing a new OS is the lack of drivers for the network card. With Windows 10, of course, this happens less often (it automatically selects drivers for most equipment during installation), but still...

By the way, in this case a vicious circle may “turn out”: the Internet is available because... drivers needed; to download drivers you need internet...

If you have a similar situation, I recommend this note: https://ocomp.info/obnovit-drayvera-esli-net-internet.html

To see if you have a driver for your network card:

- you need to open the device manager (press the WinR key combination and enter the command devmgmt.msc)

Launching Device Manager - devmgmt.msc

Next, open the “Network adapters” tab and see if your network card is in this list (note: for a Wi-Fi adapter, see the word “Wireless” in the name).

Note! If your network card is NOT in the “Network Adapters” tab, expand the “Other Devices” tab and see if there are any unknown Ethernet controllers, multimedia controllers, etc. Devices there (example below). If there are similar devices in this tab (as in the screenshot below), it means you don’t have a driver in the system...

To update the driver for a network card, you can use several methods:

- The best option: install the “native” driver that came with your card (for example, from a CD, if available);

- automatic option: download and install special. a utility for automatically searching for drivers for your equipment. They work quickly and quite reliably. I reviewed the best of them in this article: https://ocomp.info/obnovlenie-drayverov-v-Windows-10-obzor-5-luchshih-programm-na-russkom.html

- manual option: find out the model of the network card, and then download the driver for it from the manufacturer’s official website. Sometimes this is not so easy to do, so you have to resort to a unique identifier VID, PID (each network card has its own). For more details on how to search for a driver, see here: https://ocomp.info/kak-ustanovit-drayver-na-adapter-wi-fi.html

What you need to remember when working with an angle grinder on wood

The most important thing, which many people sin with, is that you should never remove the protective casing, no matter how much you would like to see the place of the cut. The destruction of the disk can occur at any moment, and fragments will fly not only to the operator, but also to others, and with such incredible speed that no one will have time to react.

- you need to check the strength of the protective cover;

- you should check the integrity of the disks, excluding those that have chips or cracks;

- the grinder must be held so that the protective casing is on the operator’s side;

- When starting work, you need to check the tool at idle speed at different speeds. The tool should not have vibration;

- Before work, you should inspect the tree for knots;

- hold the grinder firmly with both hands;

- take a break from time to time to inspect the disc;

- if the angle grinder jams, turn it off immediately;

- choose a stable body position when working;

- make sure that the cord does not get under the disk;

- Move only with the tool turned off.

Securely fix the attachments and adjust the speed. Remember, you need to work with such a tool only in a concentrated, adequate state. Use protective gloves, mask and goggles

The working process

You should start cutting with a soft start if your angle grinder has such a function

It is important that operation at low speeds is ensured, and if necessary, a little later you can begin to increase the torque along the way. Much in the tactics of changing cutting parameters depends on the degree of hardness of the workpiece, as well as its dimensions

How to cut wood with a grinder if you need to make a bevel cut? Unfortunately, a curved cut is not allowed at all, and the workpiece should be cut exclusively at a right angle, and any tilting will be excluded, since misalignment as such can be dangerous. Complex non-standard operations, including even shaped cutting, are performed as part of secondary processing with another tool, not an angle grinder. After the work is completed, you should wait until the disk stops, turn off the device and remove the plug from the socket. Next, the tool can be disassembled and cleaned of wood shavings and dust.

What is an aluminum saw blade?

"What a question?! - some enlightened reader will be surprised. – A saw blade is a consumable circle for a circular saw, a power tool for sawing almost any material!

And “for aluminum” means for processing aluminum workpieces! Everything is as simple as shelling pears!” Simpler, it’s simpler, but not entirely simple. Let's look at this issue in a little more detail.

Yes, indeed, the saw blade is designed to equip a circular saw - also called a circular saw - or for a circular saw.

And today such power tools are available not only in production, but also in every “household man”, in the garage or at the dacha.

And, yes, you can use it to cut almost anything, as long as the saw wheel is correctly selected for it. True, buying such a saw blade is somewhat more problematic than its “brother” for wood.

Model "Makita LS1040F"

This tool is universal. Its main advantage lies in its ability to efficiently handle the cutting of soft metal, wood and plastic. The power potential of the model is average (1650 W), but it is enough to provide a cutting depth of more than 90 mm. It should be emphasized that this metal trim is hardly suitable for professional cutting of material in construction or large-scale production. The lack of power and endurance will affect when working in continuous mode. But this disadvantage is compensated by the following advantages:

- A wide range of equipment, including a 255 mm disc, guides, a lamp for lighting, a bag for a vacuum cleaner, etc.

- Additional functionality in the form of a spindle lock and a soft start system.

- Reliability of the design.

Miter saw blades: what is the difference between them

There are not so many differences between the discs used on a miter saw, and the main ones are the mounting and outer diameter, as well as the geometry of the cutting tooth. If everything is more or less clear with the dimensions of the disks (the mounting hole can be either 25mm or 30mm, and their outer diameter can be 210, 250 and 305mm), then the geometry of the tooth should be understood in more detail.

You should pay attention to the size of the tooth - the larger it is, the rougher the cut will be. It is unlikely that a disk with a large tooth will be able to cleanly cut laminated, varnished or painted workpieces - for these purposes you need to purchase a disk with a fine tooth

The fine tooth also performed well when working with aluminum profiles. In general, in this regard, saw blades for a miter saw can be divided into three types: for longitudinal cuts, for cross cuts and for finishing cuts, which, as a rule, are universal. If we are talking about mass production or working with thick workpieces, you need to pay attention to the presence of thin slots on the disk - in fact, these are temperature compensators whose task is to maintain a stable size of the disk when it is heated. In addition, such drives are less noisy.

Miter saw blade photo

And in conclusion, a few words about enterprises that produce miter saws for wood. The leaders in the production of almost all electric tools are Bosch and Makita, and their miter saws are no exception. Metabo, Hitachi, and DeWalt tools also performed well in practice. If we talk about domestic miter saws, then we can mention Corvette tools. In general, there is plenty to choose from - the main thing is not to miscalculate the possibilities.

Bosch hand miter saw photo

That, in principle, is all you need to know about such a tool as a miter saw. Buy, use it and remember that this tool is quite dangerous - do not forget about safety precautions and always be extremely collected and, most importantly, sober when working!

Alexander Kulikov

This is interesting: Bison miter saw - pros and cons of various models

Tips for choosing a miter saw

The tips below are a must read before purchasing a tool.

- For rare and short-term work, choose household equipment (low power, compactness, price no more than 15 thousand rubles), for regular work - professional equipment (price 15 thousand and above, power - more than 1 kW).

- The more powerful the engine, the less it will heat up during operation, the higher the performance of the tool and the larger the disk you can install yourself if replacement is necessary.

- Many discs indicate the manufacturer's recommendations regarding the material to be cut or its type (for sheets/pipes/profiles); pay attention to this.

- Models with a spacious blade for work are more expensive, but they are much more convenient for cutting metal.

- The design welcomes the presence of a cutting depth limiter - this way you can select a groove for processing the workpiece in width.

- Evaluate whether you need laser illumination, broaching and similar options. If not, don't overpay.

- If the blade guard does not cover the blade during operation, it is a poor tool and dangerous to operate.

- The wider the workpieces will be cut with a miter saw, the larger the diameter of the disk should be.

- The heavy weight of the device will cause fatigue when cutting, although its cost is higher than its compact counterparts.

This material briefly examines the types of miter saws for metal and tips for choosing. You can describe your experience using devices or give advice on choosing a tool to visitors to our site.

Dependence of cutting speed on material

In this regard, there is the following pattern:

- for soft wood, it is recommended to use a speed of 50–90 m/s;

- cutting of hard rocks occurs at a speed of 50–80 m/s;

- cutting exotic types of wood – at 50–85 m/s;

- for MDF panels the speed is 30–60 m/s;

- for laminate panels – 40–60 m/s;

- for simple carpentry work and chipboards - 60–80 m/s.

When choosing a tool, it is necessary to take into account that saw blades for wood have different sizes and shapes of teeth and can be used at several operating speeds.

It should be remembered that all tool manufacturers indicate the required parameters, so you can easily decide which equipment you need to choose to complete the planned work. In addition to speed, speed, thickness and other indicators, it should be taken into account that circular saws can be not only hand-held, therefore, first of all, you should determine for which tool a particular disk is intended.

Why is it important to choose the right saw blade?

On the question of how to choose a saw

wood disc for a clean cut, you need to take into account parameters such as the shape and size of the teeth. Manufacturers offer several models:

Post Views: 6

Adjusting the Carburetor of Husqvarna Chainsaw 435 435e 440e

How to Remove the Air Filter of a Husqvarna 135 Chainsaw

What is a wood miter saw? Purpose of the tool

A miter saw, pendulum saw for wood and metal, or angle cutter is a stationary cutting-off highly specialized tool that is used for cutting materials at a certain angle. This possibility is provided by a rotating platform and a movable working part with a disk above the frame. The miter saw can process narrow wooden products in the form of slats, bars and boards. Can also be used for cutting hardboard, laminate and OSB. The tool copes well with cutting plastic, aluminum profiles and polyurethane moldings.

wood miter saw

Thanks to its high speed, precision and ease of operation, the miter saw has a wide range of applications. It is used for carpentry, installation and finishing work related to the implementation of wooden products. The tool is indispensable in furniture workshops where it is necessary to perform precise and high-quality spraying of products.

There are universal tools that perform metal trimming. Thanks to a special disc, the tool can be used to cut metal products made of steel, iron and cast profiles. Such miter saws for metal are widely used in enterprises that manufacture window frames from metal-plastic profiles.

Important! Do not install a diamond or abrasive wheel on the tool instead of a saw blade. The technical documentation of each specific model indicates the maximum parameters of the product that the tool can handle.

Do-it-yourself metal cutting machine from a miter saw

Small miter saws spray products up to 60 mm thick. A medium-sized tool can handle workpieces with a thickness of 70-80 mm. Large saws are used for processing products with a thickness of 100 mm or more

The technical documentation for each specific model indicates the maximum parameters of the product that the tool can handle. Small miter saws spray products up to 60 mm thick. A medium-sized tool can handle workpieces with a thickness of 70-80 mm. Large saws are used for processing products with a thickness of 100 mm or more.

In addition to the technical characteristics and class of the saw itself, its quality and cost are directly influenced by the manufacturer.

It is the brand and its reputation that become a kind of dictator of pricing policy. True, there are brands that still managed to combine such an important combination as price and quality. STIHL can easily be classified as one of these brands If we talk about STIHL, it is impossible not to mention the long and original history of the formation and development of this company.

STIHL tools are valued by both professionals and those who only occasionally use them to complete their tasks.

It is worth noting here that only a truly high-quality tool can last for many years, and STIHL quality has been tested for more than one generation.

READ How to choose a miter saw for your home

Modern models of end dusters with broaching meet high safety standards

Important! Miter saws should not be used on stone, ceramics or ferrous metals.

Bosch 2.608.640.633 190x30 mm - fast cutting

When cutting speed is a priority, discs with a small number of teeth are chosen. This design has less resistance during rotation and facilitates faster cutting of material. But due to the large distance between the cutting elements, the cut sides turn out to be rough and will require grinding to finish them.

This disc from the German brand has 12 soldered teeth and additional reinforcement on the rear side. Leaves a kerf 2.6 mm wide.

- Suitable not only for wood, but also for aerated concrete, cement-based fiber boards.

- It even cuts boards with nails.

- Very low price and proven brand.

- Interacts with a tool delivering speeds up to 4900 per minute.

Conclusion. This inexpensive blade is useful for quickly cutting wood when doing rough work.

This equipment is used for cutting small wooden materials - boards and timber up to 75 mm high. The small size of the disc allows it to be used on compact hand-held circular saws. Here is a rating of wood saw blades for circular saws with this diameter, which are distinguished by fast cutting, cleanliness and thin cuts, and are also suitable for chipboard and MDF.

Areas of application for manual and stationary models

A miter saw is an electric hand tool designed for sawing and processing various materials (wood, metal and plastic). Depending on the purpose, similar equipment is classified as follows: miter saw, miter saw, pendulum saw and circular saw (electric miter box).

A hand-held circular saw differs from a miter saw only in that it does not have a frame with a rotary table, which makes it more mobile, and all this is especially important for domestic use.

Wood miter saws are used for sawing wood blanks, as well as products made from wood products (laminate, chipboard, MDF and other board materials). Sawing is done at a straight angle or at an angle or inclination, which is necessary in the production of carpentry and upholstered furniture. Additionally, similar equipment is used when performing construction, installation and finishing work.

Introduction of a hand-held circular saw in pulpwood processing

Manual models are used on construction sites and with your own hands, and permanently installed models are used in the presence of workshops or workshops of various types of production. Pendulum saws are used when working with metal, which is necessary at the stage of production of metal structures in various fields of production. Similar equipment is installed permanently; special saw blades are used for work.

Marking

The circle label indicates the expiration date, the maximum number of revolutions, and the material marking, coded in letters and numbers. After the expiration date, the nozzles become brittle and the abrasive crumbles. The date until which the disc can be used is indicated on the label, next to the mounting hole.

When purchasing, you need to pay attention to the maximum number of revolutions. It must be equal to or less than that of the tool

Abrasive discs for grinders must have a coded marking of the abrasive material. The encoding of the material is deciphered as follows:

- The material from which the abrasive chips are made is designated by a Latin letter (or two letters). For example, a circle with a marking starting with the letter A has an abrasive made of electrocorundum. White corundum (AS) does not cut stainless steel, silicon carbide (C) is not suitable for working with metals at all.

- The grain size of the abrasive is indicated by a number following the letter designation of the type of abrasive chips. The higher the value, the smaller the particle size. To work with ferrous metals, you need wheels with coarse-grained abrasives (up to 30); for non-ferrous metals, fine-grained ones (from 40) are suitable.

- The hardness of the abrasive bond is indicated after the grit size. It is denoted by a Latin letter. The further the letter is from the beginning of the alphabet, the harder the abrasive. The softest bond is A, the hardest is Z. Nozzles with soft abrasive are used for hard metals. A hard bond overheats the surface being processed and makes cutting difficult. The soft ligament will wear out quickly.

- The bundle material is designated by one or two Latin letters at the end of the coding.

For example, a disc marked A24R BF is an alumina abrasive, coarse-grained, soft, bakelite bond.

Cutting Features

Before cutting the tiles, you need to prepare very carefully. And we are talking not only about measurements and marking of the concrete elements themselves, but also about the location of the work. It is better to set aside a special place for safe cutting of tiles, which will be located at a sufficient distance from the rest of the material and the already installed coating, as well as machines, various objects, etc.

When dust gets on the wet surface of parts, it spoils it much more quickly: for example, if the tile being cut differs in color from the one already laid and dust from it falls on top, there is a risk of having to completely change the coating.

To cut tiles perfectly, you need to take the measurements correctly. Usually about 10-15% is added to the purchased figures for stock (later you can file down the edges and remove excess). For uniquely shaped tiles, the supply is increased.

They cut the tiles strictly according to the intended mowing line, trying not to put too much pressure on the material, because the tiles may fall out of your hands or break into pieces. In a situation where the cutting process with a grinder is difficult, you can sprinkle the tiles with masonry sand in a small volume.

Cutting a profile pipe with a miter saw with a metal disc - is it possible?

IMHODom › Forums › hands from shoulders › Cutting a profile pipe with a miter saw with a metal disc - is it possible? This topic has 9 replies, 7 voices, and was last updated by kaifsheg 5 years, 11 months. back.

Greetings. I don’t have a pendulum saw and/or a band saw at hand, so a question has arisen, but I need to make a cut on a profile pipe (ferrous metal, 50x50x2).

Accordingly, the question is: is it realistic to use miter saws with a metal (cutting) blade and, if so, what should the speed/power be?

Is it realistic to use a jigsaw with metal files and, accordingly, what should be the power?

clarification to the question:

1. The purchase of a band saw/pendulum does not fit into the budget of this design; cutting to order, again, is excluded - it’s too tedious with delivery, etc.

2. The problem with the grinder is to get more or less close to 90g. cut, that’s why I want to use a miter saw (on which 90 degrees are set) or a jigsaw along the guide.

village of Dzerzhinskoye

Budget-friendly, here’s a pendulum for a simple angle grinder.

You can put a metal disc on a crosscut saw, but you can’t put a wood disc on a grinder, the speeds are different, everything can end badly...

Maybe it will be useful for someone, I haven’t used abrasive discs for a long time, like meadows..., we cut everything with diamond “turbos” on stone, one disc lasts for a year or two.. at a price of 300-500 rubles, it pays for itself every 10-20...

There are cutting machines for metal. The price of Interskolovsky and other Chinese is about 2.5 thousand... (probably). They are just right for abrasive discs. I wouldn't spoil the trim. There is a lot of plastic on it, and as you know, it burns from sparks. There are also metal discs for trimming with carbide tips (a disc with teeth but a different shape compared to wood). It costs about 6 thousand.

Tomsk

For some reason, my friend, you charged 6 thousand for the disk. At these prices, it’s easier to buy an angle grinder complete with a pendulum.

Rainbow

jigsaw - definitely not considered, nonsense, sawing pipes with a jigsaw...

cross-cutting with a cutting disc - the saw will not last long, the disc will not fit, you need to tinker with the adapter, and the speed and power are not the same... also not an option

The stand for the grinder is flimsy, uncomfortable, the corners are floating, it is very advisable to mount it permanently, otherwise the grinder may behave unpredictably. If you need to cut a little, you can get by with it. the lesser of evils. but if you need to cut in the future, I strongly advise you to buy a cutting machine. 6-8 thousand, but it's worth it.

The science

Maybe it will be useful for someone, I haven’t used abrasive discs for a long time, like meadows..., we cut everything with diamond “turbos” on stone

And which one exactly? I tried several - they get very hot. I tried solid ones for waterless cutting

I had the matrix for a year, in daily use, until the car was opened, and the grinder didn’t do a leg... Of course it saws more slowly than an abrasive, but on roofs it beats itself off in 2-3 days... I sawed tiles, pipes and fittings...

And he really turned it down. Apparently the manager deceived me at the store.

I saw how a corner with a 5 mm flange was cut with such a disc. thick. It's sawing!

Rainbow

With a miter saw in the usual sense, you can cut wood, plastic and soft metals (aluminum profile). such saws usually have a power of 1.3-1.8 kW, a blade of up to 200-300 mm, and a speed of 4000-5000 rpm.

pipes and other metal are sawed using cutting machines. they look roughly the same as trimmers, but have differences in characteristics. power from 2.2 kW, disc from 350 mm, speed up to 4000 rpm.

with seemingly small differences in characteristics, the linear speed of the disk of a crosscut saw will be approximately 1.5 times less than that of a cutting saw, with the latter having a higher power. thus, the crosscut tool simply will not carry the load when sawing metal.

We also must not forget about the problems associated with the compatibility of tools and disks (thicknesses, diameters, mounting dimensions).

Is it possible to cut metal with a miter saw - Metalworker's Handbook

Having high-quality processing or construction tools for home use allows you to quickly complete repairs or carry out restoration, construction or restoration work better and cheaper.

In modern conditions, a miter saw helps to accurately cut timber made of laminate, plastic, or wood. Both professional carpenters and beginners have to cut all kinds of workpieces. The use of all popular equipment options helps to fully evaluate the quality of work of such hand tools.

Necessity of application

A popular hand-held miter saw for wood is used to form the desired ends of the workpieces in the process of cross-cutting the timber perpendicular to the grain. This is its main difference from a large or small conventional manual circular saw, which is most often used for longitudinal dismantling of workpieces.

Installed powerful electric motors significantly expand the capabilities of this equipment. A miter saw for sheet metal, pipes, plastic or composite materials appears. In such raw materials, transverse or longitudinal operations differ little and relate to a greater extent not to the texture of the material, but to its structural features or the shape of the workpiece.

The Metabo miter saw has a simple design, which includes: base, saw blade, motor and handle with start button

A circular miter saw is used in various cases due to the ease of feeding the workpiece. The very name of the equipment, including the word “cross-cutting”, is only a historically established name, however, it does not fully reflect the rich range of possible operations performed.

Miter saws are capable of cutting not only perpendicularly, but also at the angle required by the user. In this regard, this equipment is sometimes called an electric miter box. The latest generation models provide processing not only in the horizontal plane, but also at different angles or vertically. If necessary, it is even possible to select grooves.

Using a miter saw, you can make diagonal cuts of material with high cutting accuracy

Based on the wide range of possibilities, such equipment can be found in different places:

- at a carpentry company;

- in the production of furniture;

- on construction sites;

- in repair shops, etc.

As you can see from the photos presented, the machine easily fits into any home workshop or garage. Often, an electric miter saw turns out to be almost indispensable in the manufacture of window frames, the production of door frames, while laying floors and other finishing works.

Machine capabilities and design features

You can understand how wood trimming works even by simply looking at its image. A cantilevered saw can be lowered to a work table with a variety of different rulers, measured scales and graduations, where the workpiece should be attached.

DIY miter saw table

An electric motor provides rotation to the main tool in the form of a saw blade made of heavy-duty steel. The force from the motor is transmitted through a connecting gearbox included in the functional block, and a handle with a switch is located right there.

The working unit is mounted on a frame, which has a flat platform for fixing the workpiece. At the base there is a turntable that rotates while adjusting the desired angle. The system is supplemented with an emphasis.

Most premium model beds from popular catalogs are made using aluminum or magnesium alloys, which provide not only a reliable base, but also a high degree of mobility with low weight.

https://www.youtube.com/watch?v=tXa7pel5Fec

The functional unit is securely fixed to the base base through a spring-loaded hinge. Sometimes the swing arm is called a pendulum, and because of this, some users call miter saws “pendulum”.

Device

The presence of a hinge allows you to move the working unit. To make a cut, you need to move the lever to its lowest position, launching the teeth of the saw blade into the rigidly fixed workpiece. Technological grooves in the frames help ensure a through cut. This scheme is the most popular for most models of such machines.

VIDEO: Atypical operation of equipment (part 1)

Selecting a miter saw by engine type

The most popular layout option is one where wood miter saws have the motor on the right side of the work saw. At the same time, there are models where the motor is moved slightly back. This ensures a clear view of the workpiece and does not create obstructions during the miter cutting process. Such models have the ability to tilt the working head in both directions.

The miter saw in the mini or regular model can be equipped by the manufacturer with the following types of electric motors:

- asynchronous;

- collector;

- brushless.

Asynchronous engines are considered the most economical and reliable for trimming. Thanks to their design, they are able to work efficiently for many years without compromising productivity.

Only bearings can wear out in them. At the same time, manufacturers do not strive to introduce this type of electric motors everywhere due to a significant drawback.

Their fairly large mass is combined with relatively low power.

Miter saw with broach Uralmash PT 2900/255-2: Asynchronous motor

A two-kilowatt asynchronous type reaches 20 kg. Moving it on a pendulum console will be quite problematic. Also, power supply with current of normal frequency does not allow the rotation to exceed 2850 rpm.

Brushed motors are more acceptable in terms of the ratio of power and external parameters. Approximately equal mass with an asynchronous analogue gives a torque several times more efficient. In operating mode, the electric motor is capable of rotating at a frequency of up to 10 thousand rpm. Its speed stabilization and control system are much simpler.

The disadvantages of commutator motors include:

- significant noise during operation;

- the importance of periodic maintenance;

- You need to change the brushes on the commutators in a timely manner.

You need to know that most modern miter saws are equipped with commutator motors.

The brushless version is based on modern semiconductor technologies. It is the optimal balance between the two previous versions. In the international classification, such motors are designated by the word “Brushless”.

Crosscutting with brushless motor

Instead of traditional brushes, valve motors are equipped with an electronic unit. It has low resistance and high switching speed of power valves. Positive factors are high efficiency, low noise level, long-term maintenance-free operation.

Manufacturers offer equipment with power ranging from 0.8 to 2.5 kW. For home work or small production, 1.6-1.8 kW is enough.

Allowable speeds are 3200-6000 rpm. The higher the value, the cleaner the sawn surface. For 260 mm discs, it is advisable to use a trimming machine at 2800 rpm.

Useful options for miter saws

The presence of additional functionality helps to expand the capabilities. It will allow you to make maximum use of all the capabilities of the equipment without resorting to additional expenses in the future on new equipment.

- It is advisable to select equipment with a dust collector. This way, after work, the workshop will remain clean, and the operator will not inhale harmful microparticles in the process.

- The presence of a protective casing allows you to hide the tool, preventing accidents. It is strictly not recommended to work without such protection.

Working without a protective cover is prohibited

- The cutting depth limiter will be effective when machining grooves. The guiding laser beam will also help in the work. It helps to increase processing accuracy.

- Local illumination will create an area of excellent visibility. It will come in handy in rooms with insufficient general illumination.

- The presence of a soft start will allow you to keep the motor in working condition and will not cause jerks at the start. The likelihood of jamming will be minimal.

Choose the right saw blade

Choosing the right blade for your saw and not missing is a whole art. Of course, at first glance, what’s so complicated about it? But the quality of work and productivity, as well as personal safety, depend on the disk. After all, circular saws are perhaps the most dangerous tool.

Saw and grinding discs are divided into all-alloy and with welded inserts made of vanadium alloys.

All-alloy ones, regardless of the quality of the material from which they are made, dull quickly enough. But you can sharpen them yourself at home and many times. They are inexpensive and designed strictly for working with wooden workpieces.

With welded inserts they are much more expensive, but last longer. If carbide is sharpened, the cost of this operation will be almost equal to a new disk. But the service life and quality of cutting the material justify the price. In addition, this blade can be used not only for cutting metal, but also for laminate boards or hard plastic.

Before purchasing a disc, pay attention to the following symbols:

Flaws

- The main disadvantage of carbide wheels is their high price. The cost of the product is tens of times higher than that of a conventional abrasive disc. In this regard, the payback for such a product at home may take years rather than months. You can get acquainted with the prices for carbide blades for metal cutting at this link https://www.220-volt.ru/krugi-tverdosplavnye-po-metallu/.

- Due to the fact that carbide blades are thicker than abrasive blades, their cut line will be wider. This fact must be taken into account. When cutting a product into several small pieces, you will lose some amount of metal.

- Carbide discs are resistant to corrosion. You need to understand that when you cut rusty products, the blade wears out much faster.

How to cut laminate with a jigsaw correctly

Let’s say right away that this is the most optimal and fastest way to trim lamellas; after all, the manual method is quite labor-intensive and inaccurate. If you plan to continue to carry out all kinds of repair work in the house, it is worth having an electric jigsaw in your arsenal.

Using this electrical device, it is easy to make a cut along or across the slats, at any angle. There are devices that will allow you to make cuts located at the same distance from the edge of the board, even without marking.

Even with a single cut, such a tool shows excellent results. The answer to the question, what is the best way to cut laminate flooring using a shaped cutting line, becomes clear: with a jigsaw. This tool helps to obtain rounded cuts necessary when meeting heating pipes. To do this, you just need to choose the right file with fine teeth, which will improve the quality of the cut.

Of course, this tool also performs straight cuts efficiently. The advantage of an electric jigsaw is that even a novice builder can achieve excellent results with it.

The disadvantages of the device include

- noise during operation;

- a lot of dust is generated.

Note that other power tools also have these disadvantages. How to properly cut laminate flooring with a jigsaw:

- The tool is equipped with a file with a fine reverse tooth. If one is not included with the jigsaw, you need to purchase it. This is the answer to the question of which jigsaw file should you use to cut laminate flooring.

- Markings are applied to the panel that requires trimming. the cutting line is drawn on the back of the panel.

- The board is laid on a solid base with the decorative surface up, after which trimming begins along the intended mowing line.

General information about the tool

Along with jigsaws, circular and circular saws, the miter is capable of cutting metal sheets, profiles, and various types of pipes. The design of the device is simple - the main elements are a frame (base), a handle with a start button, a saw blade, a gearbox and a motor. The latter comes in two types:

The advantage of the first is ease of maintenance, the second is a long service life and less noise during operation.

The motor is connected to the saw blade via a belt or gear drive. They have advantages and disadvantages. For example, a belt is almost silent and eliminates vibration of the disk, but can slip during long-term operation, forcing the user to stop the process. The toothed one is free from this disadvantage, but it is noisy and vibrates slightly.

The working body of a miter saw is a disc. It is made of durable metals, since it bears a serious load. There are wavy lines or cuts on the surfaces of some removable elements. This is done to reduce noise during operation, as well as to compensate for temperature deformation.

Recommendations for choosing a product brand

The best miter saw in terms of safety, manufacturability and work comfort is a product from one of the following companies:

Most of them offer table expansion for the workpiece, but cutting large parts sometimes requires additional supports. These are found in, for example, the LF 1000 model. This simplifies the user’s work. In this case, the moving part of the makita metal saw enters a stable frame, in which there is an area for setting the cutting angle.

The best trimmers in terms of reliability and stability are those whose frame is made of aluminum or magnesium alloy. They are durable, stable, but at the same time they weigh acceptable. An example is the Bosch GCM 10, popular among professionals, weighs only 15 kg.

The leader among saws with a possible inclination of the cutting edge to the workpiece is Hitachi. While Bosch, Metabo or Makita mostly allow you to set the cutting angle to only 0, 90 or 45 degrees, the Japanese concern offers the user the ability to rotate by 15; 22.5; 30 degrees. This option forces you to add a rotating device to the design, due to which, however, the weight of the installation for cutting profiles, sheets or pipes will still not exceed 30 kg. The price increases by 15-25%.

Types of pendulum saws

It is easier to classify a miter tool than, for example, an electric jigsaw, which can be mechanical or electric. The products under consideration are divided according to the following criteria:

- appointment;

- the presence of a broach function;

- saw blade parameters.

Household and professional equipment and machines are distinguished by purpose. The former are distinguished by low power (up to 1500 W), compactness, and cost up to 20-25 thousand rubles. Example - Bosch GKM 18 V-LI 0 L-BOXX (battery model for 15 thousand rubles), Kolner KMS 210/1400 for 4000 rubles, domestic Caliber PTE-900/190M with a power of 900 W at a price of 4500 rubles.

A cross-cutting machine is equipment not for home work, used only in enterprises that produce rolled metal products and are engaged in cutting or other processing on a daily basis. Such machines cost tens and hundreds of thousands of rubles, their power exceeds 1000 W, and they weigh several centners. An example is domestically produced machines TsT 10-4 (3 kW, 360 kg, 105 thousand rubles) or TsKB-40 K (5.5 kW, 700 kg, 340 thousand rubles).

Professional trimmers for sheets, profiles and pipes occupy an intermediate position according to the specified parameters. For example, Makita LF 1000 (1650 W, from 60 thousand rubles), DeWalt 27111 (1500 W, from 50 thousand rubles).

Having a drawing option gives the user a slight advantage when processing long sheets or pipes. The models have two parallel slats on which the cutting disc is mounted and moves freely along them. A tool with a broach is distinguished by a large cutting width of the part, as well as particularly small teeth on the disk. Also, the tool sometimes has a laser pointer for easy marking and process control. Metal trimming with broaching weighs more than usual, and the presence of the option increases the cost by 20-30%.

The parameters of the cutting blade are the most important classification criterion. They have two diameters - external (at least 20 cm) and internal (also known as landing; about 3 cm). The size of the teeth determines the depth and width of the cut, and the material determines the ability to work with a particular metal.

Now, a few words about manufacturers you can trust.

Rating of miter saw manufacturers

Miter saws, as well as other electric tools, are made in different countries of the world; our client is left with well-known brands operating in this equipment market. We are in particular demand for:

- From foreign (Japan) and Metabo (Germany).

- From the Russians: “Bison” and “Enkor-Corvette”.

Miter saw model "Enkor Corvette-4-430"

For obvious reasons, Russian models are in great demand in the economical equipment sector, while more expensive foreign analogues are in great demand in the class of professional tools. Models from which manufacturers are more popular cannot be found, because... they are similar in their main features; the choice of users is based on personal preferences for the brand of instrument based on previous experience with a particular brand.

Can a miter saw cut metal? — Metals, equipment, instructions

Having high-quality processing or construction tools for home use allows you to quickly complete repairs or carry out restoration, construction or restoration work better and cheaper. In modern conditions, a miter saw helps to accurately cut timber made of laminate, plastic, or wood.

Both professional carpenters and beginners have to cut all kinds of workpieces. The use of all popular equipment options helps to fully evaluate the quality of work of such hand tools.

Specifications

When choosing, it is worth analyzing a whole range of parameters that will help you get an idea of the best choice. The main list of characteristics can be presented as follows:

Power. The average value is in the range of 1000-3000 W. If you rely only on metal, then it is advisable to purchase a device with a potential of at least 1500 W. At reduced power it will be possible to work only with thin-leaved soft workpieces. Rotation frequency. This indicator does not affect performance. Peak thrust is still determined by power. But the ability to change the speed can be useful precisely in cases where you plan to process workpieces of different types. The maximum frequency reaches 5000 rpm. Disk size. The diameter varies on average from 150 to 355 mm. Moreover, the metal cutting disc is distinguished by the presence of solderings made of hard-state alloys. They increase processing efficiency and quality. Sharpening type

It is important to keep in mind that the tooth shape of a saw blade can have a positive or negative angle. For metals, only the opposite, that is, negative sharpening, is used.

Review of popular models

"ZUBR ZPT-210-1400 L"

"Metabo KGS 315 Plus"

Choosing a miter saw is a crucial moment for the inexperienced

Tips for choosing regular and combined models

In order to make the right choice and take into account what remains for our client to do, the nuances associated with the method of using such equipment, it is necessary to listen to the advice of experienced users, which can be designed in this way:

- The tool must correspond to its purpose - you should not take an expensive and powerful model if you intend to use it periodically and for personal purposes.

- In the same vein, one should consider the presence of additional options that increase the cost of the model, but are not used for small volumes of work.

- The availability of protective and safety equipment is a fundamental point when choosing a miter saw, because... If used incorrectly, there is an option to simply get injured while working on similar equipment.

- Due to the fact that power and weight are directly related, if you need to perform traveling work, the best option would be to choose a less powerful model, but with less weight.

- The size of the saw blade and the presence of a broach determine the technical capabilities of the tool for processing the material used.

- The bed can be heavy enough to secure the saw where the work is being done, and the turntable and stops are made to ensure reliable fixation of the material being processed.

READ Is It Possible to Saw Dead Wood in 2019