Weeding trimmer attachments

For work, it is recommended to use a factory-made cultivator attachment. This is both easier and cheaper than making the device yourself. When selecting, it is recommended that you first take your trimmer and measure:

- rod diameter;

- number of splines on the shaft.

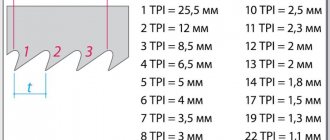

This information will allow you to choose the right nozzle. Typically, the description of the nozzles indicates the outer diameter of the rod - 26 or 28 mm and the number of splines on the shaft - 7, 9, or the cross-sectional shape of the end - square. To accurately select the right size, you should also measure the diameter of the shaft itself - they also differ in size, there are shafts with a diameter of 7, 8 and 9 mm.

If you are using a branded tool from well-known world brands, and not Chinese consumer goods, then it is better to order a branded attachment. This will extend the life of both the attachment and the brush cutter. In Moscow, for example, it is worth visiting branded stores, where professionals will select the nozzle; here you can also consult on the procedure for servicing the units.

To work on small areas, a regular disc cutter will be sufficient, but for large areas it is better to use reciprocating and drum cutters.

It is recommended to sharpen the cutters before each use.

When selecting a working tool, you need to focus on the dimensions recommended by the manufacturers. The hand will not be able to hold the blades that are too large, and the blades that are too small will not cope with the task. If you can select several sets of cutters for a cultivator, then you should consider purchasing cutters of different diameters - this will allow you to choose a tool for each specific type of task.

Is it worth making a cultivator attachment yourself?

The technology for caring for vegetation will also change: first, use a knife attachment to walk through the beds, cutting off the grass, and only then use a cultivator attachment.

Having decided to make your own cultivator attachment for the trimmer, you should first evaluate the following:

The design of the output section of the boom: if it is a flexible shaft, then you will have to forget about the cultivator: it will not withstand the constantly changing amplitude of torques. The cardan transmission is more functional, and the most successful design is considered to be a multi-slotted rod, and a straight one, not a curved one. Drive power: If it is less than 1000W, the motor will overheat and the cultivation performance will drop sharply. Fuel tank volume: energy consumption will increase significantly, since the cultivator attachment will have to be made from scrap materials. Therefore, the tank must contain at least 1 liter of fuel. Handle design. Ergonomics experts believe that the most comfortable is the T-shaped handle, which provides the most accurate and reliable direction. The J-shaped handle common in some models makes it difficult to hold a gasoline trimmer with a cultivator attachment.

If the existing trimmer meets the listed requirements, and its owner has sufficient experience in performing such work, then it is quite possible to make a disk attachment with your own hands. As for gear-type nozzles, making them yourself is very labor-intensive and will not provide the desired quality.

Design and mounting options

The cultivator attachment comes in two versions:

- A disk, the cutting elements of which are a pair of cutting disks;

- Gear, which is a series of cutters located sequentially on the shaft.

The fundamental difference lies only in the design of the ripening unit. Disc attachments are more rigid and therefore suitable for processing heavier soils, while toothed attachments have a lower dead weight but are designed for working on lighter soils.

The transmission of torque from the trimmer motor to the cultivator attachment is carried out using a special shaft, which is arranged in a special rod (it will have to be purchased separately). This unit is not interchangeable, and differs in the number of splines on the end of the rod: there can be seven or nine. Therefore, when thinking about purchasing a cultivator attachment, you need to understand that an Oleo-Mac attachment will not fit a Husqvarna trimmer, and vice versa.

The spline method of attaching disks or cutters to the shaft allows free movement of the cutting elements, which is ideal for cultivation, since it allows you to loosen the soil with a fairly wide grip (up to 200...250 mm per pass), without requiring a large amplitude of movement of the rod. Restrictions on the density of beds located on the site are also lifted. As the beds lengthen, the convenience of working with the attachment in question increases, since turns will have to be made much less frequently.

Features of the nozzle

Any cultivator attachment for a trimmer significantly increases the weight of the entire device assembly (by at least 5...6 kg). Therefore, not everyone can work with such a tool for a long time. It is also necessary to include mechanical limitations on the power of the trimmer drive into the calculation. If the engine is designed for a power of no more than 1500 W, then the cultivator can only cultivate regularly loosened soil, or limit itself to hilling breasts, potato bushes, etc.

Since the drive of gasoline trimmers is located behind the operator, and the drive rod is quite long, vibrations constantly occur during the cultivation process. Their size is determined by both the length of the rod and the changing load on the disks or cutters. These vibrations are transmitted through the shoulder strap to the user’s hands, so it is not always convenient to operate the trimmer power button and hold a rather capacious unit. Therefore, long-term soil cultivation using a cultivator attachment is unsafe for health.

But it’s not all bad: the mobility of a gasoline trimmer makes it easy to cultivate the soil between rows, and the absence of wheels on a mounted cultivator does not damage the plants in the beds.

The cultivator attachment “does not like” compacted soil, and when first introduced into such soil, the boom is abruptly thrown back. Therefore, disc cultivators are equipped with a safety guard (toothed cutters are more likely to bend than break, although even in this case a low protective shield on the leg side would be helpful). The presence of a safety screen impairs the visibility of those working with the cultivator.

https://youtube.com/watch?v=lnrCg1_b3t4%3F

Advantages and disadvantages

The cultivator attachment for a gas trimmer, regardless of its type, increases the weight of the assembled unit to 5-6 kg. This is a product that is quite in demand among buyers and is easy to maintain. This device is characterized by a more reasonable cost compared to equipment for a motor cultivator. The cultivator attachment for a gasoline trimmer is convenient in greenhouse conditions; it not only loosens the soil, but also saturates it with oxygen.

Considering that this device is made with high-quality assembly, it is durable, which cannot but please the user. The devices themselves really simplify the work of the summer resident and allow him to speed up his work.

As for the disadvantages of cultivator attachments for gas trimmers, many buyers note their weight. The lack of weight of the device is the reason that, when faced with difficult soil, it may not go deep into the soil at all, but only scratch its top layer. In addition, as practice shows, with such attachments it is impossible to press the cutters to the ground. This risks the rod starting to spring back, and, as a result, the equipment quickly wears out.

If you try to press the device to the ground more strongly, the rod cannot stand it and bends, which can cause the scythe or the working attachment itself to break. The drive rod is quite long; vibrations cannot be avoided during cultivation, the magnitude of which is directly related to the length of the rod itself. In addition, it depends on the complexity of the area being processed, because the load on the discs and cutters will be greater in the case of dense soil.

Holding a vibrating tool for a long time is difficult, as is managing it. In this case, it is also worth knowing that constant work with a vibrating tool can be fraught with negative consequences for human health. For example, constant vibration can damage the blood vessels and nerves in the fingers of those who have problems with blood supply. When using a brush cutter with a cultivation attachment for a long time, problems can also occur in healthy people.

If you are going to take a hitch for cultivating land, then it is better to choose the disk option. It is equipped with a safety guard, although this makes the user's work somewhat more difficult. As for making the nozzle yourself, this process does not always give an effective result. In addition to the fact that the work of making a hitch for soil cultivation is labor-intensive, it is not always of high quality and reliable. In addition, home-made products do not always cope with turf.

To wash the cutters, you need to remove the equipment. In addition, the device needs to be lubricated with oil from time to time. Given the sharpness of the blade, you should wear gloves. During soil cultivation, you cannot go to high speed. In order to correctly put on a protective screen with a line stop, you need to remove the stop nut from it, insert the bracket into the slot and rotate the screen until it passes through the groove of the bracket. After this, you need to tighten the wing nut tightly onto the bolt.

To install the attachment on the brush cutter, you need to remove the plug from the attachment rod. After this, the connection is made so that the locking (releasing) button fits into the recess on the hitch. The nozzle is pushed forward until the button snaps into place. Before starting the work process, you need to tighten the handle tightly by turning it clockwise. If the holes do not fit, this attachment cannot be used for your existing gas trimmer.

Features of operation

Taking into account the capabilities of the trimmer and the attachment itself, work with the attachment is carried out before the period when the weeds have not yet grown and become stronger. Thus, the user’s work will be more efficient, because it is easier to cut short grass than to deal with coarse and thick stems. Timely loosening of the soil using a cultivator attachment will contribute to the accelerated growth and strengthening of planted crops and, as a result, high yields.

It is important to securely attach the attachment itself to the gasoline trimmer. It is important to take into account the fact that not every gardener can work with a brush cutter with a cultivator attachment, the reason for which is the weight of the scythe and attachment

If the engine of the unit is not designed for a power of more than 1500 W, this attachment can only be used as a ripper or a light hiller. It is important to understand that the attachment for cultivating soil using a gas mower in no way replaces the unit for weeding, plowing and hilling. This is a mini device for small purposes.

Knives rotating during operation are quite dangerous, and therefore you must work with a gasoline trimmer with extreme caution. Do not attempt to clear weed blades while the device is on. This can only be done when the engine is completely stopped. Do not grab knives with your hands or try to block them. The device must be inspected in a timely manner, eliminating breakdowns and worn parts.

You need to refuel the unit outside

It is important to ensure that there is no oil or fuel leakage. Do not allow the engine to overheat

During operation, the operator must stay away from rotating elements, since the cutters can damage limbs. Before starting work, you need to inspect the area of future processing and rid it of solid objects. For example, it is advisable to get rid of stones that can cause the cutters to stop or even break.

You can learn more about the cultivator attachment for a gasoline trimmer in the video below.

From a chainsaw

Many different attachments have already been invented for chainsaws that expand the capabilities of this unit, for example, a cultivator, a drill, a boat motor, and also a scythe attachment. You can see what it looks like in this video. If you want to make a trimmer out of a chainsaw, the most you can make is a lawn mower on wheels, since the engine of the unit is quite heavy, and it will not be possible to apply the above-described options for making trimmers (with a bottom drive) to it.

Therefore, the trolley is made first. It can be welded from a 25x25 mm corner. The frame dimensions should be 500x600 mm. The wheels are attached to the corners of the frame.

Next, you need to unscrew the “steering wheel” and tire from the unit. The cart handle can be made from water pipes. The “steering wheel” is screwed to it. It is also necessary to lengthen the fuel hose and throttle cable.

The gasoline engine is installed (screwed through the holes to secure the tire) onto the frame so that the gearbox is rotated 90 degrees and the shaft is at the bottom.

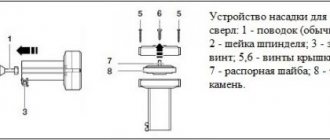

Now all that remains is to attach the cutting tool to the shaft of the unit. This is done as follows.

- It is necessary to weld a small piece of pipe, 80 mm long and 50 mm in diameter, to the “star” of the device. It is better to cut the pipe on a lathe so that the ends are perfectly straight.

- Next, find a pipe with a slightly larger diameter - equal to 58 mm. It also needs to be cut to a length of 80 mm. Thus, you will receive a telescopic shaft, which is connected using 2 bolts (m6) located opposite each other. The bolts must have locknuts. Below is a diagram of how the trimmer head is made, which is used to secure the cutting tool.

Several holes need to be made in the telescopic pipes so that the height of the knives above the ground can be adjusted.

It is better to make a knife of such a design as in the following figure.

Due to the fact that movable knives are attached to the disk with rivets, they will simply bounce off when they encounter a stone or a dry branch. This will protect the shaft and gearbox from damage that may occur when the tool jams.

The diameter of the disk (made from 4 mm sheet steel) should be 180 mm. The knives are made from strips 30 mm wide and 120 mm long, cut with a grinder from a hacksaw blade for wood.

Types and principle of operation of cultivators

The principle of operation of the cultivator is simple: the element that loosens the soil begins to work after the mechanical part of the device starts. Depending on the external size, engine power and performance, cultivators are divided into three types: light, medium and heavy equipment.

- Light equipment is used in small areas with soft soil (flower beds, greenhouses).

- Medium weight is used on clay soils.

- Heavy equipment refers to universal equipment. It can be used for any soil.

There are different types of cultivators: disc, rotary, tine and milling. In terms of operation, they can be: manual, electrically driven and gasoline-powered, as well as trailed, mounted, and process one or several rows.

When cultivating a plot of land, everyone chooses the model they need. The good thing about hand cultivators is that you can make them yourself with minimal cash outlay.

Advantages and disadvantages

Each cultivator, regardless of whether it is manual or electric, has its pros and cons.

- Hand cultivator. Easy to use and much more convenient than a shovel, compact. Doesn't put stress on the lower back. It loosens the soil well and does not spread roots throughout the area. But this technique cannot cope with unplowed land, as it has low productivity. It is best used in small areas such as flower beds or greenhouses.

- Electric cultivator. Lightweight and compact equipment, powered by mains. Easy to maintain. The only downside to this technology is the electrical cord. It can interfere during work, and due to its length, there is a limitation in the area to be processed. It has low power and low tillage depth. Not intended for attachments.

- Gasoline cultivator. Thanks to the attachments, it has many functions. It is not connected to electricity, so it can move around the entire site. Suitable for processing small areas. Weighs much more than electrical equipment. It is difficult to maintain and requires fuel to refill.

Design and mounting options

Modern cultivator attachments can be made in two versions:

Toothed, in which the cutters are located sequentially on the shaft;

Disc, when several cutting discs act as cutting organs.

The torque is transmitted to the cultivator attachment from the engine thanks to a shaft, which is arranged using a special rod. The latter, unfortunately, often has to be purchased separately.

The unit in question cannot be called interchangeable, and the number of slots on the end of the rod can vary from 7 to 9. Based on this, when buying a cultivator attachment, for example, from Oleo-Mac, you should know that it is not suitable for working with a Husqvarna brand trimmer , as well as vice versa.

The spline method of fixing cutters or discs to the shaft provides for the free displacement of the cutting elements, due to which the soil will be loosened over a fairly wide coverage - 200-250 millimeters. This option is excellent for cultivating land on the site, since it eliminates the large amplitude of displacement of the rod during operation. In addition, this method allows you to reduce or completely eliminate restrictions on the density of beds.

The cultivator attachment comes in two versions:

- A disk, the cutting elements of which are a pair of cutting disks;

- Gear, which is a series of cutters located sequentially on the shaft.

The fundamental difference lies only in the design of the ripening unit. Disc attachments are more rigid and therefore suitable for processing heavier soils, while toothed attachments have a lower dead weight but are designed for working on lighter soils.

The spline method of attaching disks or cutters to the shaft allows free movement of the cutting elements, which is ideal for cultivation, since it allows you to loosen the soil with a fairly wide grip (up to 200...250 mm per pass), without requiring a large amplitude of movement of the rod. Restrictions on the density of beds located on the site are also lifted. As the beds lengthen, the convenience of working with the attachment in question increases, since turns will have to be made much less frequently.

The principle and effectiveness of the weeding method

Weeding as a treatment with a cultivator aims to destroy the weed by the method of exhaustion - after treatment, the plants need time to recover and gain the necessary strength. At this time, potatoes or other vegetable crops will be able, on the contrary, to continue their successful growth.

Weeding potatoes with a trimmer is usually carried out using three methods:

- mowing weeds with a mowing head or disc attachment;

- processing with a cultivator with a drum attachment;

- processing with a cultivator with saber or disk attachments.

Mowing is usually carried out when the weeds reach a height of 7-10 cm. In this case, only the part that is above the ground is mowed, and the roots remain intact. Usually, after this, rapid growth of green mass begins, so the effectiveness of such treatment is low.

When weeding with a trimmer is carried out using a drum cutter, the roots of the weeds are also treated. The big advantage of this method is that the top layer of soil fluffs up, and thus the air exchange of the soil increases. The effectiveness of this method is much higher than simple weeding by hand or working with a mechanical cultivator. The drum cutter allows you to loosen the soil to a depth of 3-5 cm.

When using saber or disk attachments, the efficiency increases even more - the processing depth increases to 5-7 cm. At the same time, plant roots, as well as the green mass of weeds, are repeatedly ground, which contributes to the rapid decomposition of plant residues in the soil. After such weeding, repeated weeding is usually carried out at least 10-14 days later. True, there is one nuance that needs to be taken into account - when working with drum cutters, the width of the processed strip is about 30 cm, but when working with reciprocating or disk cutters, the width is no more than 15-20 cm.

Weeding potatoes with a trimmer

Lawn aerator attachment for lawn mowers - what is it and what is it used for

Owners of private houses will find a useful device such as a lawn aerator attachment for a trimmer. Its main purpose is to saturate the soil layer with air. This is done to improve the growth of lawn grass. The action of the aerator is absolutely safe for vegetation.

Aerator

Externally, the nozzle resembles a rake, but its main purpose is to restore the breathability of the soil to saturate the root system of plants with air. The device can also be used for uniform distribution of organic fertilizers.

The cost of the aerator is about 10 thousand rubles, which depends on the manufacturer.

Rules for weeding with a trimmer

The rules for growing potatoes provide for several operations - continuous cultivation until the potatoes have sprouted, weeding the rows, hilling the bushes.

For simple cultivation, drum cutters are used; for weeding, you can use disk, saber, or drum cutters. But for hilling it is better to make a stacked structure - make the internal cutters of a larger diameter, and the outer cutters of a smaller diameter. This design ensures ease of use of the tool when hilling under a bush.

Weeding rules are quite simple:

- a sunny day is chosen for work, so that the weeds dry out in the sun as quickly as possible;

- For protective equipment, you should wear goggles and a respirator, and for shoes, boots;

- when working, as well as when mowing grass, it is recommended to use a shoulder strap;

- weeding is carried out with a deepening of 1-1.5 cm, this is enough to loosen the top layer and increase gas exchange in the soil;

- It is recommended to weed the entire row spacing until the plants rise to a height of 10-15 cm;

- Weeding is done in a zigzag, the nozzle is first moved to the left, and then at an angle to the right. The next move to the left, taking over the next lane.

- Hilling is done to a depth of 10-12 cm, with the first movement being forward in the center of the row spacing, and after that, turning the nozzle left and right, a mound is formed near the bushes.

- It is recommended to select the operating mode with short breaks so that the trimmer has time to cool down;

- At the end of the work, the nozzle must be cleaned, unscrew the screws of the technological holes and add molybdenum grease to the gearbox.

How to weed potatoes with a trimmer

Following the rules for properly weeding potatoes with a trimmer will allow you to avoid mistakes and carry out the work quickly and easily:

- It is better to weed potatoes while wearing a respirator and safety glasses, since when the cutters rotate, dust and weed particles fly up.

- Treatment with a trimmer is carried out at least once every 14 days, since weeds that have not yet taken root are susceptible to it.

- The best time for weeding is early sunny morning.

- Simultaneously with getting rid of weeds, potato beds are loosened if the cutting elements are deepened by more than 1.5 cm.

- The lower the engine power, the more often you should take a break, giving it rest.

- Before work, the cutters are treated with silicone grease, and such weeding is not carried out on heavy soil.

- Trimmer attachments must be periodically treated with a disinfectant that will destroy pathogens.

- There should be no other people nearby when working.

Kinds

Depending on the type, the device may or may not have cutters. Based on this feature, it can be classified into gear or disk. Products of the first type are characterized by the presence of cutters, which are located on both sides of the drive shaft. The second options work using cutting discs. However, the presence or absence of cutters does not affect the functionality - cultivator attachments for a gasoline trimmer are purchased for loosening the soil.

The differences between varieties lie in the type of soil that the cultivator attachments themselves can handle. For example, gear-type varieties are lighter in weight, however, because of this they are not able to process difficult soil. Disc analogues can work not only with light soil. These nozzles are characterized by greater rigidity, they are stronger and more durable.

Classification of cutting accessories for trimmers

Often, owners of adjacent plots use various knives and disks to maintain their territory. Their main function is to combat large weeds and old dried out bushes. In most cases, manufacturers use the following materials to produce knives:

- metal – steel knives have one important function - they are intended mainly for cutting the thickest weeds and or shoots of young wild trees, the maximum thickness of which does not exceed 3 mm. The metal trimmer blade can only be used for regular installation on brush cutters with a power of at least 1.5 liters. With.;

- plastic – a headset made from this material is more fragile, but it is lighter, which makes it possible to use it on amateur trimmers with a capacity of 0.8 to 1.5 liters. With. In addition, the plastic blade for the brush cutter is not subject to corrosion.

Trimmer knives also differ in the type of cutting edges. The headset can have 4.8 or more teeth, which are located at the same height or one above the other. In addition, knives come with carbide tips or with holes inside the teeth.

The cutting set can also be made in the form of several blades or have the shape of a solid disk to which durable metal teeth are attached.

Top 5 best gas trimmer attachments for weeding

Before ordering a trimmer attachment, read the description and characteristics of the top designs. Study their advantages and disadvantages, value for money. Well-known manufacturers: Bosch, Echo, Elitech, Husqvarna, Patriot, Oleo-Mac, Stihl, etc. The best attachments for gasoline trimmers are:

- KAAZ Kat-MC250P for VSP255S;

- ECHO PAS-Tiller Cultivator for PAS-265ES;

- KR400MP MAKITA 195710-3;

- Oleo-Mac CULT;

- for TAC petrol mowers.

KAAZ Kat-MC250P for petrol mowers VSP255S (244G03)

Trimmer attachment KAAZ Kat-MC250P for VSP255S

The cultivator attachment for the VSP255S trimmer has a subsoiler, thanks to which you can change the plowing depth. Suitable for processing small gardens. Due to its compact size, the nozzle is suitable for cultivating soil cultivated around flowers in flower beds, loosening the soil around trees and in hard-to-reach places. It effectively fights weeds. More details:

- price: 9990 rub.;

- characteristics: suitable for Caiman VSP255S, knife material – high-strength steel, working width – 240 mm, depth – 360 mm, manufacturer – Kaaz (Japan);

- advantages: wide range of action, ability to adjust plowing depth, strength;

- cons: fits only on one trimmer model.

ECHO PAS-Tiller Cultivator for brush cutters PAS-265ES

ECHO PAS-Tiller Cultivator attachment for brush cutters PAS-265ES

This attachment was created specifically for the PAS-265ES brush cutter for the purpose of processing small areas, flower beds and lawns. It is compact, but not effective for weeding large areas. The design is characterized by good strength and durability. It can replace a whole range of working tools for the garden. Weeding will be quick and effective. Options:

- price: 17800 rub.

- characteristics: manufacturer – ECHO (Japan), compatibility – with PAS-265ES, gross weight – 3.36 kg;

- pros: compact, maneuverable, high quality workmanship, easy installation;

- cons: expensive, suitable for one brush cutter.

KR400MP MAKITA 195710-3

Nozzle KR400MP MAKITA 195710-3

The trimmer attachment from the Japanese manufacturer will greatly simplify the care of your summer cottage, small garden or garden. It is also well suited for landscaping lawns and flower beds. Weighs slightly less than other analogues for weeding. The design is generally reliable, made of metal. The cutting element is cutters. Options:

- price: 17160 rub.

- characteristics: tool model – EX2650LH, DUX60Z, width – 16 cm, cutter diameter – 23.2 cm, manufacturer – MAKITA (Japan);

- pros: good efficiency, high reliability, ideal for weeding small areas;

- cons: high cost.

Oleo-Mac CULT

Oleo-Mac CULT nozzle

A cultivating addition to the trimmer, designed for processing small vegetable gardens, beds, flower beds and even greenhouses. The tool has the ability to adjust the plowing depth, because it is equipped with a subsoiler. The knives are made of high-strength steel, which can indicate their reliability and durability. Detailed parameters:

- price: 12990 rub.

- characteristics: brand – Oleo-Mac (Italy), knife material – steel, cutter width – 200 mm, weight – 6 kg, suitable for Oleo-Mac 740T, 746T, 753T, 755 Master models;

- pros: you can adjust the plowing depth, durable knives, good efficiency in small areas, wide cutters;

- Cons: heavy, slightly larger than analogues.

Attachment for TAC lawn mowers (shaft – 7 splines, rod 26 mm)

Attachment for TAC trimmers

This is a weeding trimmer attachment that thoroughly digs up the soil, facilitating the penetration of moisture and nutrients and saturating it with oxygen. The device is securely attached to the trimmer. In order to quickly and easily loosen the soil in a small area, the cultivator has rotating cutters. A protective shield, like other models, will help prevent debris from entering the operator. Detailed parameters:

- price: 7900 rub.;

- characteristics: manufacturer – Taiwan, power – gasoline engine, cutting element – knife, cutter diameter – 200 mm, passage width – 120–240 mm, rotation speed – up to 180 rpm, internal shaft – 7 splines, outer diameter rods – 28 mm, weight – 5 kg;

- pros: reasonable price, durable design, efficient, wide passage, quickly and easily loosens the soil;

- cons: heavier than analogues.

How to make a manual cultivator for cultivating row spacing

To cultivate narrow spaces between rows, first of all, the cultivator must be compact. A hand-held device called “Hedgehog” is well suited for this type of work. Having all the necessary parts, it is easy to make it yourself. To assemble the “Hedgehog” you will need: a U-shaped bracket with holes, a shaft, a handle and wheels with metal spikes.

- In order for the walk-behind tractor to move easily around the site, you need good wheels. To do this, take medium-sized steel pancakes and weld metal spikes to them. Spikes are easy to make; you just need to sharpen the reinforcement into a cone shape.

- Ready-made cutters are put on the axis.

- The axle is inserted into the bracket and fixed on both sides.

- A fastener is welded to the end of the bracket and the handle is inserted.

The equipment is assembled and ready for cultivation and weeding between the rows.

https://youtube.com/watch?v=B2_Gnt8sK2o

From the trimmer

You can assemble it from available materials: a working gasoline trimmer, an angle grinder or welding tool, a garden fork, a steel pipe

- To make a cutter, teeth from a fork are used, which are bent into the desired shape. Usually the soil is loosened to a depth of 10 to 15 cm, so the length of the teeth should be no more than 15 cm.

- Next, we do the working part. The tines of the fork are flattened to a width of about 1 cm.

- The cutters are sharpened with emery and secured to a round penny.

- A nickel with a diameter of 10 cm should be perfectly even in shape. Three cutters are placed evenly on the heel. If you put more than three pieces, the device will be severely overloaded.

- The final part is connecting the base with the cutters and the trimmer. It is good if the shaft tip has a thread. Then the trimmer is simply screwed to it.

The equipment is designed for loosening soil at shallow depths.

https://tytdacha.ru/sadovaya-tehnika/mini-traktory/nasadka-na-trimmer-dlya-propolki/https://proinstrumentinfo.ru/nasadka-kultivator-dlya-trimmera-tsena-otzyvy/https:// tokar.guru/instrumenty/kultivatory/ruchnoy-samodelnyy-kultivator-iz-trimmera-i-velosipeda.html

How to choose?

When buying a cultivator attachment for a gas trimmer, in addition to the power of the gas trimmer engine, they rely on several factors. These are the processing width, weight, cutter diameter and number of revolutions per minute. On average, the diameter of the cutters can be 20 cm, the number of revolutions can be 180.

As for the design of the boom, it is useless to buy a cultivation attachment for a flexible shaft; it will damage the unit quite quickly. The ideal option would be to purchase a product with a multi-slotted rod paired with a cardan drive. Such a unit will perform more efficiently and be reliable.

To prevent the engine from overheating, it is important that the power is at least 1000 W, otherwise labor productivity will decrease

Trimmer attachment Support wheel

The new support wheel for the trimmer makes it much easier to work with the trimmer with different attachments. This attachment can be attached to the trimmer shaft in a variety of positions, providing versatility and adaptability. The support wheel allows you to maintain the same cutting height, as well as the same cutting depth and width when using the edger on flower beds and garden paths. The attachment is equipped with two support wheels for working as an edger or one rotary wheel for working as a trimmer. The support wheel can also be used with a blower or brush.

Pros and cons of the method

Weeding a garden with a trimmer, and especially the area where potatoes grow, has its own characteristics and specifics.

First of all, you need to pay attention to the fact that you need to choose the right tool for the job. It is preferable to choose powerful four-stroke engines as a working engine.

Such brush cutters have lower gas consumption and greater productivity compared to two-stroke ones. For two-stroke engines, the recommendations boil down to choosing a higher engine power; the more powerful the engine, the more efficient the work.

Weeding potatoes, unlike making hay or mowing the lawn, is a more labor-intensive process, so you need to be prepared for the fact that after work not only your back, but also your arms and legs will hurt. The fact is that during work you will have to keep the nozzle suspended, preventing the lugs from completely burying themselves in the ground. In addition, you will have to move the unit along the surface from right to left, which also requires significant effort.

But from an economic point of view, such potato weeding will be much more effective than manual weeding - in a season, using a cultivator, you can cultivate a much larger area than with your hands. In this case, repeated processing will be required after a longer period of time.

Alas, there is also a minus. This is a lot of gas mileage. In normal mode, gasoline consumption is usually 0.44-0.92 liters of combustible mixture per 1 hour of operation of the unit, depending on the design and type of engine. With the device installed, this figure increases by approximately 35-40%. So you have to choose either saving time and quality of work or saving money.

Cultivator attachment in action

Boat motor from a gasoline trimmer

Fishermen who have a boat, but have not yet had time to purchase a motor, can take advantage of the rational offer from modern manufacturers of gas-powered tools

Attention should be paid to the attachment of the outboard motor for the lawn mower. The equipment is suitable for propelling wooden, rubber and even metal boats, but it all depends on the power of the motor of the trimmer used

boat propeller

The attachment is also called a “boat propeller”, as it is a rod with a fixed three-blade propeller, which is driven by a trimmer motor. The gas of the tool is output to the handle, which also serves as a steering wheel. Only the motor is used from the trimmer, so the rod is completely detachable. The internal combustion engine is attached to the nozzle using four bolts. The device with the engine is fixed to the boat using a built-in clamp.

Naturally, a boat with such a drive will not develop high speeds, but it is quite suitable for going out into open water to a fishing spot. The maximum speed developed by the drive, consisting of a boat propeller attachment and a trimmer motor, is up to 20 km per hour, which depends not only on the power, but also on the load of the vessel. Fuel consumption does not exceed 1 liter per hour, so the equipment is recommended to all fishermen as an alternative to expensive outboard motors.

This is interesting! For metal boats, it is better not to use such a drive, since due to heavy loads, rapid overheating of the internal combustion engine and failure of parts cannot be ruled out.

Non-existent attachments

On the Internet you can find several exotic attachments that are physically difficult to use on a lawn mower. Let's figure out where the truth is and where these rumors come from.

Drill attachment

This attachment is confused with a motor drill. In fact, it is an independent tool, the gasoline engine of which is similar to the engine of a lawn mower. This was the reason for the untrue rumors about the super-nozzle. In fact, such an attachment would require complete disassembly of the trimmer, which is ineffective.

A gasoline drill is a useful tool that allows you to work in the absence of electricity. The powerful drive increases the productivity of the drill. The tool is characterized by durability and increased reliability. A distinctive advantage is the colossal torque (due to the presence of a reduction gearbox with a gear ratio of 17:1).

snow blower

Such designs are not commercially available, primarily because removing snow with a brush cutter is inconvenient. The snow auger is heavy and difficult to hold in front of you. A small and light auger will have low productivity. There are homemade models created by folk craftsmen, but their effectiveness can be judged from the video below. An ordinary shovel will cope with this volume faster.

To remove snow, you need to use specialized tools, which are characterized by better performance and ease of operation. A special bell sets the direction of snow ejection, which allows you to clear paths, parking lots or backyards more efficiently and quickly.

The good thing about the listed tools and accessories is that they are suitable for most modern trimmers. They are affordable and easy to use, and, most importantly, they make caring for your garden easy and enjoyable.

Terms of use

When using any equipment, including manual and agricultural equipment, you should follow safety rules. The user must carefully read the instructions for the unit and work without violating them. Accessories on the trimmer can be attached to it in the following ways:

- instead of a reducer at the bottom of the trimmer hose;

- instead of a hose near the engine;

- by disconnecting the hose in the center.

The motor from a brush cutter can operate in various positions, as it is characterized by high power density, reliability and small size.

Owners of gasoline trimmers with attachments claim that they are much cheaper than bulky walk-behind tractors, but are not much inferior to them in efficiency. The purchase of these units is a profitable investment, since they can be used to process the garden, vegetable garden, and clean the area in the warm and cold seasons

When purchasing equipment of this type, you should pay attention to the quality and design features, as this will guarantee long-term use of brush cutters with attachments, as well as efficient work on the territory and a high yield

For information on the features of the brush cutter attachment, see the following video.