Vibrating plate is equipment designed for tamping/compacting earth and bulk materials when performing construction and other types of work. It differs in the type of energy used, size, method of movement and other parameters. Below we will consider the purpose of such devices, talk about classification, provide recommendations for maintenance and consider other issues.

Vibrating plate rating

Tampers of domestic and foreign production are presented on the market. Experts studied user reviews, opinions of road workers, builders, publications in specialized magazines and selected models that are in demand among buyers. The main attention was paid to the following parameters:

- Engine type – affects cost, performance, ease of use;

- Sole area - affects maneuverability;

- Compaction depth – opens up the possibility of compacting different materials;

- Reverse – simplifies maneuvering, reduces time;

- Irrigation system – wets the surface to be treated;

- The weight of the equipment has a positive effect on the compaction depth.

Equipment with defects in the frame and sole, or interruptions in engine operation were excluded from our rating.

Dimensions and types of working surface

Of two tamping tools, with the same weight and vibration force, the one with the smaller working surface area will produce the greater pressure on the surface being processed. However, if it is necessary to tamp over large areas, it is better to choose equipment with a larger working surface area of the slab to save time.

But in this case the power should be higher. There are many options for standard working plate sizes, for example: 380×380, 440×350, 525×500, 730×450 mm and so on. The material for making the working platform is steel or cast iron. Both metals can withstand the required loads.

The best reversible vibrating plates with a gasoline engine

Gasoline engines are easy to start in any weather, light in weight, and easy to maintain. The engines are economical, but poorly tolerate vibration loads. It is recommended to buy a gasoline vibrating plate for a personal plot and summer cottages. The equipment will cope well with laying paving slabs in a small area and laying garden paths.

Diam VMR-115/5.5H 630036

A gasoline model equipped with a Honda engine, which is characterized by an increased resource, efficiency, and reliability. The main feature is a long, narrow sole, which allows you to comfortably work in small trenches, when laying paths in the garden, in close proximity to the foundation of a building. The compaction depth makes the technique effective on soil, crushed stone, sand, and asphalt mixtures.

Switching the direction of movement and controlling the engine speed are located on the handle, which makes maneuvering convenient. The moving components are protected by a metal casing, which ensures the safety of the operator. Users note the convenient location of the tank, which makes refueling easy.

Advantages:

- Cost-effective;

- Good maneuverability;

- Robust frame design;

- Capacity 500 sq.m. at one o'clock;

- Wheels for moving around the site;

Flaws:

- Not detected.

The vibration unit is mounted on bearings; rotation is transmitted to the coupling pulley using a reliable, easy-to-maintain V-belt drive. The design is designed for intensive use and professional use.

DDE VP125-HK

Vibrating plate for compacting soil, gravel, sand in conditions of limited free space. The elongated platform simplifies work near the building wall, in trenches. Equipped with a Honda engine, which starts using a manual starter. Reinforced motor mount increases service life and allows intensive use during the working day.

The steel elements are made of sheet metal, 6.5 mm thick. A casing is installed to protect against sand and crushed stone. Transport wheels are provided for moving around the construction site. The greater weight increases the depth to which compaction is possible, and the reverse makes the equipment maneuverable. The control handles are reliably protected from vibration loads.

Advantages:

- Convenient control location on the frame;

- Durable design;

- The belt drive is protected from dust and dirt;

- Three-jaw reliable clutch;

- Informative oil level sensor.

Flaws:

- Overcharge.

Wacker Neuson BPU 2540A 5000008758

Equipment from Germany is equipped with a four-stroke Japanese engine from Honda, consuming 0.8 liters of fuel per hour. The design provides high centrifugal force and good thrombus quality. The model is designed for compacting viscous and granular mixtures; according to user reviews, it copes well with asphalt. Transport wheels are made of heat-resistant material.

The vibration reduction system increases the level of comfort during operation. The presence of a reverse and a narrowed plate increase maneuverability in cramped conditions. The frame is made of high-quality steel, ensuring the reliability of the structure. The transmission of torque is protected from sand, crushed stone, and dirt by a metal casing.

Advantages:

- Cost-effective;

- Folding guide handle;

- Cast iron sole;

- Rotating lifting eye.

Flaws:

- Not detected.

Self-production

A vibrating plate is a simple device, which is why many people decide to make this unit themselves. To make a vibrating plate with your own hands, you will need a small amount of materials and skillful hands.

There are several ways to make a vibrating plate yourself. One of them is to buy a platform vibrator. Such a purchase will make it easier to create the unit, since you will not need to mount an eccentric, and you only need to make a plate and attach the purchased vibrator to it. If this method suits you, then when purchasing a vibrator, choose a 220V motor, because three-phase power is not available in all areas.

The best vibrating plates with a gasoline engine without reversion

The absence of reverse simplifies the design, reduces the price, but makes the equipment less maneuverable. This type of tamper is used to compact soil in open areas. A distinctive feature is its low weight, making it easy to move. The technical characteristics of vibrating plates make them a good choice for dachas and solving local problems when arranging the landscape near the house.

Zitrek z3k50 Loncin 154F

The model has a narrowed platform made of steel. High vibration frequency made it possible to increase productivity to 750 sq.m. at one o'clock. Used when working with sand, granular soil, crushed stone. Large transport wheels make the equipment maneuverable. The folding handle and low weight make it easy to transport equipment in the trunk of a car.

Good reviews of Zirtek vibrating plates are associated with an increased service interval. The manufacturer managed to achieve this by installing a shock absorber, which reduces the load on the motor, and increasing the reliability of the vibration unit. The drive belt is protected from accidental damage and dirt by a steel casing. The oil level in the crankcase is controlled using a sensor.

Advantages:

- Low fuel consumption;

- Durable frame;

- Easy start;

- Simple controls.

Flaws:

- Weak muffler mounting.

Loncin 200F, 6.5hp Zitrek z3k81w 091-0216

The tamper is designed for soil, loose soil. Equipped with an easy-to-maintain Loncin engine that starts with a manual starter. The fuel tank is conveniently located; the capacity is sufficient for two hours of intensive work. The control is located on the handle. The presence of a water tank allows for pre-wetting, which allows you to cope with viscous materials and reduces the amount of dust.

The slab is made of thick sheet steel and has a narrowed shape, which is convenient when laying paving slabs on garden paths. Users note the good balance of the platform. The vibration unit has a reliable fastening, which prolongs its service life. The frame design reduces vibration loads.

Advantages:

- Easy start;

- Long service intervals;

- Durable protective casing.

Flaws:

- Increased fuel consumption.

Honda GX160 4.8HP Splitstone VS-246 E12 143246

The dimensional model has increased weight compared to other tampers in its class. This allows you to compact sand, soil, and gravel. The plate steel platform has an elongated shape, which simplifies maneuvers. The Japanese gasoline engine is economical, does not require complex maintenance, and is equipped with a manual starter.

The design includes a water tank; pre-flooding improves the quality of compaction and reduces dust levels. The belt drive is protected from crushed stone and dirt by a steel casing. The handle fits comfortably in the hand, the use of anti-vibration materials reduces stress and fatigue. The transport wheels move and do not interfere with compacting the soil.

Advantages:

- Headphones included;

- Large wheels make it easy to move around the site;

- Increased power;

- Compaction depth is the same as heavier models.

Flaws:

- Small fuel tank.

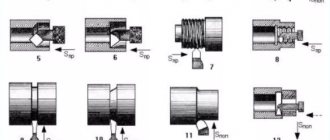

Operating principle

Structurally, a vibrating plate consists of a group of components: a supporting part, a main body (which creates vibration), a motor with different types of power, and controls. The lower part of the device, which is in contact with the surface of the earth, is the sole or slab. Its function is to create pressure on the soil and increase its density through vibration.

Important

The greater the mass and dimensions of the base, the higher the efficiency of the vibrating plate. To improve the characteristics of the sole, thick metal of 8 mm or more is used.

Most often, a steel or cast iron sole is used, reinforced by creating a ribbed surface. In addition, the base of the vibrating plate is used to fix the drive and other mechanisms.

The support part has curved edges at the front and back, which simplifies the movement of equipment and prevents the top layer of earth or building materials from being caught. When compacting tiles, a rubber or polyurethane gasket is used to prevent mechanical damage. As a rule, it comes included.

To create vibration, a so-called eccentric/imbalance shaft is used. It receives vibrations from the motor through a centrifugal clutch and is then transmitted to the base. As a result, the treated area experiences pressure from the weight of the product and additionally takes on strong vibrations. Depending on the model, vibration frequency and force may vary.

The vibrator is large in size, because the efficiency of the equipment directly depends on this. It can be with one or two shafts. The first is used for straight sections, and the second is distinguished by its ability to move forward and backward.

The best vibrating plates with an electric motor

Electric models are powered from the mains, which reduces maneuverability. They use equipment near the house, when compacting soil inside a constructed building, in tunnels. The advantages of the technology are low noise levels, no harmful emissions, unpretentious electric motors that do not require regular maintenance, and low price. Power characteristics do not allow solving complex problems.

Vibromash VU-11-75

Powered by a 220V household power supply, it copes well with compacting sand, bulk mixtures, and asphalt concrete. The platform is made of sheet steel, balanced, and has an elongated rectangular shape. With a low electric motor power, it has professional compaction depth indicators.

The handles are made of anti-slip material that absorbs vibration. The frame with control handles is connected through insulators, which reduce the load. The switch is conveniently located on the handle. Double unbalances allow you to adjust the force of impact. The Vibromash electric vibrating plate is equipped with a vibrator with an increased service life.

Advantages:

- Asynchronous electric motor;

- Mobility;

- Low noise level;

- Squirrel-cage rotor.

Flaws:

- Rubber mat is not included.

Bison ZVPE-5 G

Lightweight model for working in confined spaces. Designed for compacting soil, sand, asphalt. The platform is small in size, made of carbon steel, and has an increased service life. The handle is adjustable in length, rubberized handles reduce vibration. The electric motor is protected from mechanical impact by a metal frame. The motor is unpretentious and runs on 220V.

The manufacturer managed to select the optimal centrifugal force, this has a positive effect on the quality of compaction of bulk materials. The shape of the plate ensures good maneuverability in the absence of wheels and reverse. Shock absorbers have an increased service life and effectively reduce the load on the operator.

Advantages:

- The handle is completely removable;

- Low noise model;

- Simple controls;

- Increased productivity.

Flaws:

- The electric motor takes a long time to warm up at subzero temperatures.

The best vibrating plates with a diesel engine

Equipped with powerful diesel engines. They have a lot of weight and are used in the implementation of large-scale projects. Diesel reversible vibrating plates are used in the construction of highways, laying tram tracks, and laying paving stones in city squares. The equipment is economical, but requires regular maintenance.

Weber mt CR-6 100535309

The reversible vibratory rammer, manufactured in Germany, is equipped with a powerful, economical motor that provides high centrifugal force. The heavy cast iron plate copes with compacting any type of base. The sheet steel housing covers all important components and provides protection from dirt or gravel.

The platform has a rectangular shape, and rounded edges make working in trenches easier. The machine is heavy, equipped with a durable protective frame with a stop, behind which the equipment is moved by a crane. The compaction effect can be controlled using a lever on the handle that controls the throttle valve of the power unit. The cable displacement mechanism is reliably protected from mechanical impact.

Advantages:

- Smoothly operating hydraulic reverse;

- Automatic belt tension;

- Electric starter;

- High speed;

- Possibility of installing a compaction control system.

Flaws:

- High price.

TCC WP90TL 207195

It is recommended to buy one of the smallest diesel models for compaction on small construction sites. It has great power for its class, the compaction depth reaches 30 cm due to its weight and centrifugal force. Despite the lack of reverse, it is characterized by high performance and maneuverability. The shape of the slab allows working in trenches.

Control by adjusting the throttle valve, which is located on the handle. The base of the platform is open, which promotes effective self-cleaning. The casing protects all components from sand and dirt, shock absorbers reduce vibration. A durable frame, which has a special support for moving equipment with a crane, helps prevent accidental damage to the engine.

Advantages:

- Built-in wheels;

- Capacious water tank;

- Easy start;

- Folding handle.

Flaws:

- Small fuel tank.

How to choose a stove

It is necessary to select equipment taking into account the specifics and scope of work. It is recommended to pay attention to the type of installed motor, the area of the sole, and evaluate the possibilities for compaction depth. The weight of the equipment and its dimensions affect the complexity of transportation, and in areas with complex layouts it is impossible to do without the reverse function. Only taking into account these characteristics can you choose the best rammer to solve production problems.

engine's type

Equipment with an electric motor is characterized by the absence of emissions of harmful substances into the air and low noise levels. The equipment is used in enclosed spaces, with a small amount of work in the country or in a personal plot. For a small construction team, the best choice is a gasoline model. The equipment solves any problem and easily copes with compaction under foundations or paving stones.

Gasoline engines are less demanding to maintain, but require high-quality fuel. Diesel vibrating plates provide high performance, but do not start well at subzero temperatures. This is the best technique for large-scale road construction.

Sole area

Affects productivity - the larger the size, the faster the equipment copes with the tasks set by the builders. Important features - an increase in dimensions leads to an increase in the weight of the platform. To operate efficiently, a powerful motor is required, which increases the cost.

With dimensions of 50x50 cm, a vibratory rammer can easily cope with compacting large areas, but with such equipment it is difficult on narrow garden paths. For trenches and summer cottages, it is better to choose a model with a 40x40 cm sole.

Weight and compaction depth

For laying paving stones on sidewalks and garden paths, a machine with a compaction depth of 15 cm and a weight of no more than 75-80 kg is sufficient. When arranging a personal plot according to a landscape designer’s project, it is better to use equipment weighing up to 90-95 kg. This equipment compacts the soil by 20-25 cm and works equally effectively with asphalt and bulk materials.

When building private houses and paving sidewalks on a municipal scale, machines with a capacity of 120-140 kg and a compaction of up to 300 mm are recommended. In areas with complex viscous soil or clay, heavier equipment is required. Road builders use asphalt pavers, but where this special equipment cannot maneuver, vibratory rammers are used - 250-400 kg, compacting the soil by 450-500 mm.

Machine weight

Plays a role during transportation and unloading. Equipment weighing 40-60 kg can be transported in the trunk of a car and unloaded alone. Models over 80 kg are transported in trucks and unloaded using cranes.

Availability of reverse

Reverse gear increases productivity and improves maneuverability. This equipment is indispensable in cramped spaces and in areas with complex layouts. Reversing increases the price of equipment. If you purchase equipment for working in open spaces, you can do without reverse gear.

The best deep-throat vibrators

Equipment Specifications

A vibrating plate, like any other construction equipment, functions thanks to the coordinated work of several units, parts, and mechanisms. The design of such devices consists of:

- Working plate. It is a smooth flat bottom made of metal. Thanks to progressive vibration vibrations, it affects materials that are being compacted or tamped.

- Vibrator (vibration exciter). Refers to the main mechanism of this construction equipment. Responsible for the process of vibrations that are fed directly to the plate itself. Basically, the vibrator is made in the shape of a cylinder. It contains special debalance shafts.

- Frame and engine. The engine is mounted on the surface of a motor frame equipped with shock absorbers. Thanks to the V-belt drive, the pulley is connected directly to the shaft itself, located on the vibration exciter shaft.

- I drove. It is the handle of the tool, thanks to which the operator controls the direction of its movement.

It is worth noting that some manufacturers equip their models with special additional devices and equipment. However, regardless of the configuration, all models of vibrating plates work on the same principle. Often, some units are equipped by manufacturers with additional equipment such as water tanks and special transport wheels. They can be equipped with shock-absorbing gloves and special mats that dampen the resulting vibration loads.

Material

During the manufacture of various structural elements of vibrating plates, as a rule, a material such as steel is used. This is due to the fact that it has high resistance to strong vibration loads. In some devices, the vibrator body or carrier can be made of aluminum. Wear-resistant steel or cast iron is used in the manufacture of the working platform. This is due to the fact that these materials are less susceptible to severe wear.

On a note! When choosing a model that is equipped with a stove made of cast iron, it is recommended to always check the grade of metal before purchasing. This is due to the fact that cheap, low-quality cast iron under heavy loads can quickly become covered with cracks and chips when compacting dense, coarse materials, such as gravel.

engine's type

An electric motor or internal combustion engine can be installed on construction equipment such as vibrating plates. Devices equipped with electric motors are best used for indoor work. This is due to the fact that no exhaust gases are emitted during their operation.

However, the disadvantage of units that are powered by an electric motor is that they have a limited operating radius. In addition, they require a power source to function. It should be noted that machines operating on an electric drive have much lower power ratings compared to devices that operate using an internal combustion engine.

The most powerful are devices equipped with diesel or gasoline engines. The most popular among most consumers are devices powered by gasoline engines, as they are easy to operate. In addition, such devices can be actively used in the winter season. Diesels are much less common on such equipment. As a rule, they are installed on large vibrating plates that have a large mass.

Which vibrating plate is better

The models presented in this review are the best in their classes. There is no universal equipment: a tamper for road work on laying asphalt concrete will not fit in a trench under the foundation of a summer house or bathhouse. The VyborExperta.ru team recommends:

- Diam VMR-115/5.5H – for arranging a personal plot;

- Wacker Neuson BPU 2540A – indispensable when laying asphalt paths;

- Zitrek z3k50 Loncin 154F - will help to equip a plot at the dacha;

- Vibromash VU-11-75 – for work in closed buildings;

- Weber mt CR-6 – road builder's assistant;

- TCC WP90TL – for a team building cottages.

The correct choice of rammer will allow you to complete the planned work in accordance with current SNiPs and standards.