Lesson summary on the topic: “Aneroid barometer. Pressure gauges"

Lesson summary on the topic: “Aneroid barometer.

Pressure gauges." The purpose of the lesson:

find out what an “aneroid barometer” and a “pressure gauge” are, get acquainted with the design of these devices, the principle of their operation and find out where they are used in practice.

— educational:

study the structure and principle of operation of an aneroid barometer, liquid pressure gauge, metal pressure gauge; teach how to use them;

-developing:

develop cognitive, communicative, experimental, reflective competencies of students;

- educational:

to cultivate an attentive, friendly attitude towards participants in the educational process, personal responsibility for the implementation of collective work, an understanding of the need to take care of the cleanliness of the atmospheric air and comply with the rules of environmental protection, and the acquisition of everyday skills.

Lesson structure:

Organizational part. Repetition of covered material. Learning new material. Problem solving. Consolidation Homework.

Organizational part:

- a few words about the upcoming lesson (problem setting).

2. Testing students' knowledge, skills and abilities on previous topics.

Frontal survey:

— What is pressure? ( Pressure is a physical quantity equal to the ratio of the force acting on a body to the area of this surface, p = F / S

)

— What is called atmospheric pressure? ( Atmospheric pressure - the pressure of the atmosphere or air shell of the Earth

)

- What is the atmosphere? ( Atmosphere - the air shell of the earth

)

- Name of the scientist who created the first instrument for measuring atmospheric pressure ( Torricelli

)

— The names of the scientist whose student Torricelli was? ( G. Galileo

)

— Tell us about Torricelli’s experience

Solve problems from V. I. Lukashik’s problem book No. 000,547,548.

Learning new material.

In practice, a metal barometer called an aneroid (translated from Greek as liquid-free) is used to measure atmospheric pressure.

This is what a barometer is called because it does not contain mercury).

The appearance of the aneroid is shown in the figure. Its main part is a metal box 1 with a wavy (corrugated) surface. The air has been pumped out of this box, and so that atmospheric pressure does not crush the box, its lid is pulled upward with a spring 2. As atmospheric pressure increases, the lid bends down and tightens the spring. As the pressure decreases, the spring straightens the cap. An arrow-pointer 4 is attached to the spring using a transmission mechanism 3, which moves to the right or left when the pressure changes. Under the arrow there is a scale, the divisions of which are marked according to the readings of the mercury barometer. Thus, the number 750, against which the aneroid needle stands, shows that at the moment in the mercury barometer the height of the mercury column is 750 mm. Therefore, the atmospheric pressure is 750 mmHg. Art., or ≈ 1000 hPa.

Atmospheric pressure equal to the pressure of a column of mercury 760 mm high at a temperature of 0 ° C is called normal atmospheric pressure

Knowing the atmospheric pressure is very important for predicting the weather for the coming days, since changes in atmospheric pressure are associated with changes in weather. A barometer is a necessary instrument for meteorological observations.

Guys, have you ever had to inflate the wheels of a bicycle, motorcycle, or car? Do I need to know the tire pressure? ( Need to

)

What can be said about the pressure inside the tires compared to the atmospheric pressure?

How can this pressure be measured? Are the devices we know for measuring pressure suitable in this case?

To measure pressures greater or less than atmospheric pressure, instruments are used, which we will discuss in today’s lesson. These devices are called pressure gauges

.

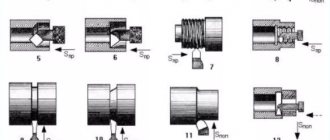

Pressure gauges are available in liquid and metal types. Let us first consider the structure and operation of an open liquid pressure gauge.

The following picture shows a liquid pressure gauge. It is shaped like a U.

It consists of a glass tube in the shape of the letter U. Liquid is poured into this tube. One of the ends of the tube is connected using a rubber tube to a round flat box, which is covered with rubber film.

Operating principle of a liquid pressure gauge

In the initial position, the water in the tubes will be at the same level. If pressure is applied to the rubber film, the liquid level in one elbow of the pressure gauge will decrease, and in the other, therefore, it will increase. This is shown in the picture. We press on the film with our finger.

When we press on the film, the air pressure in the box increases. Pressure is transmitted through the tube and reaches the liquid, displacing it. As the level in this elbow decreases, the fluid level in the other elbow of the tube will increase.

By the difference in liquid levels, it will be possible to judge the difference between atmospheric pressure and the pressure exerted on the film.

The following figure shows how to use a liquid pressure gauge to measure the pressure in a liquid at various depths.

Now let's talk a little about the metal pressure gauge.

The following picture shows a tubular metal pressure gauge.

It was invented in 1848 by the Frenchman E. Bourdon.

The main components are: a hollow tube bent into an arc (1), an arrow (2), gears (3), a tap (4), a lever (5).

Operating principle of a tubular pressure gauge

One end of the tube is sealed. At the other end of the tube, using a tap, it is connected to the vessel in which the pressure needs to be measured. If the pressure begins to increase, the tube will unbend, thereby acting on the lever. The lever is connected to the arrow through a gear, so as the pressure increases, the arrow will deflect, indicating the pressure.

If the pressure decreases, the tube will bend and the arrow will move in the opposite direction.

Problem solving.

The problems are taken from the problem book “Collection of problems in physics”, grades 7-9, authors V. I. Lukashik, E. V. Ivanova.)

Consolidation

A device for measuring atmospheric pressure.

(Barometer) A liquid-free barometer. (Aneroid) A device for measuring pressures greater or less than atmospheric pressure. (Pressure gauge) Types of pressure gauges. (Liquid and metal) Operating principle of pressure gauges. What atmospheric pressure is called normal? Homework

Tasks

Problem 1

Gasoline is poured into the canister and the height of the column is 0.6 m. The density of gasoline is 710 kg/m2. Determine the gasoline pressure at the bottom of the canister.

Solution:

We know:

h = 0.6 m;

ρ = 710 kg/m2.

The acceleration g is 9.8 N/kg.

According to the formula that determines the pressure of a liquid on the walls of a vessel:

Р = ρgh;

P = 710 × 9.8 × 0.6 = 4174.8 Pa = 4.7 kPa.

Answer: 4.7 kPa.

Pressure gauge. Types and device. Operation and application. Peculiarities

A pressure gauge is a compact mechanical device for measuring pressure. Depending on the modification, it can work with air, gas, steam or liquid. There are many types of pressure gauges, based on the principle of taking pressure readings in the medium being measured, each of which has its own application.

Scope of use

Pressure gauges are one of the most common instruments that can be found in various systems:

- Heating boilers.

- Gas pipelines.

- Water pipelines.

- Compressors.

- Autoclaves.

- Cylinders.

- Balloon air rifles, etc.

Externally, the pressure gauge resembles a low cylinder of various diameters, most often 50 mm, which consists of a metal body with a glass lid. Through the glass part you can see a scale with marks in pressure units (Bar or Pa). On the side of the housing there is a tube with an external thread for screwing into the hole of the system in which it is necessary to measure the pressure.

When pressure is injected into the medium being measured, the gas or liquid through the tube presses the internal mechanism of the pressure gauge, which leads to a deflection of the angle of the arrow that points to the scale. The higher the pressure created, the more the needle deflects. The number on the scale where the pointer stops will correspond to the pressure in the system being measured.

Pressure that a pressure gauge can measure

Pressure gauges are universal mechanisms that can be used to measure various values:

- Excess pressure.

- Vacuum pressure.

- Pressure differences.

- Atmospheric pressure.

Draft gauges, pressure gauges, thrust gauges

| NSP-16SgV3T4 pressure meter indicating signaling explosion-proof | The indicating signaling explosion-proof pressure meter NSP-16SgV3T4 is used for continuous measurement of excess pressure of gaseous media in industrial stationary installations and control of external electrical circuits from a signaling device, including in nuclear power plant conditions | from 33700.00 rub. |

| TmSP-16SgV3T4 traction meter indicating signaling explosion-proof | The indicating signaling explosion-proof draft meter TmSP-16SgV3T4 is used for continuous measurement of vacuum pressure of gaseous media in stationary industrial installations and control of external electrical circuits from a signaling device, including in nuclear power plant conditions | from 33700.00 rub. |

| TNSP-16SgV3T4 pressure gauge indicating signaling explosion-proof | The indicating signaling explosion-proof draft pressure meter TNSP-16SgV3T4 is used for continuous measurement of vacuum and excess pressure of gaseous media in industrial stationary installations and control of external electrical circuits from a signaling device, including in nuclear power plant conditions | from 33700.00 rub. |

Pressure gauge

Liquid pressure gauge

The operation of a liquid pressure gauge is based on the law of communicating vessels.

If you take two containers, pour liquid into them and connect them with a tube below the liquid level, then whatever the geometric shapes of the containers, the liquid in them will be at the same height. This rule can be extended to any number of containers. The main condition is that the liquid must be homogeneous everywhere.

Rice. 1. Communicating vessels.

From the pressure formula $p = rho gh$, a relation follows for the case when vessels are filled with liquids of different densities: $ over > = over >$ – the law of communicating vessels.

In a liquid pressure gauge, one of the tubes is subject to the measured pressure, and the other is subject to hydrostatic pressure. The measured pressure is judged by the height of the liquid column in the second tube.

Several types of liquid pressure gauges are used in laboratory practice and in production. Here are some of them:

- Double-pipe U-shaped pressure gauge. These are two glass tubes connected to each other. The first tube, which has a measuring scale, is exposed to atmospheric pressure, the other is supplied with the measured pressure. The calculation is made based on the level of rise or fall of the liquid.

- Single-pipe pressure gauge. Its difference from the previous one is that the tube to which pressure is applied is replaced with a vessel (cup).

Rice. 2. Single-pipe pressure gauge.

- Micromanometer. The principle is the same as that of a single-pipe, but the range of measured pressures is much smaller. Mainly used in laboratories.

Rice. 3. Micromanometer.

- Differential liquid pressure gauge - a range of devices of various designs. They have one thing in common - they measure relative pressure.

Other types of pressure gauges

In practice, spring pressure gauges, rather than liquid ones, are used to measure high pressures. They are based on the deformation of a solid body, in this case a spring. Under the influence of pressure, the spring is compressed and, through mechanisms, rotates the arrow of the device. Sometimes, instead of a spring, a metal pipe bent into an arc with a sealed end is used. When pressure is applied to it, it unbends and, through mechanisms, moves the pressure gauge needle.

There are compression pressure gauges. They work on the laws of thermodynamics, in particular on the Boyle-Mariotte law. Such pressure gauges can measure very low pressures.

Tasks

- Determine the manometric pressure in a closed vessel at a level of 0 cm, if in the manometer tube a liquid with a density of $rho = 13.4 g/cm^3$ has risen by 2 cm.

Solution:

$P_1$ is the pressure in the vessel.

$P_2$ is the pressure in the pressure gauge tube.

$P_2 = rho gh + P_a$, where $P_a$ is atmospheric pressure.

$P_2 = cdotcdot> + 101325 = 104005 Pa$

- How much will the water level change in the pressure gauge tube if a pressure of $P = 1.2P_a$ is applied to the vessel?

Solution:

$P_1 = 1.2P_a$ – pressure in the vessel.

$P_2 = P_a + rho gh$ – pressure in the pressure gauge tube.

What have we learned?

During the lesson, the device of a liquid-type pressure gauge was disassembled, its various types were considered (differences in design), compression and spring pressure gauges were described. At the end of the lesson, two tasks are analyzed.

Electronic blood pressure monitor with wrist mounting

Among the electronic tonometers there is a model that measures pressure on the wrist. This device does not have a cuff, but is simply attached to the wrist, and indicators are displayed on the screen. For them to be accurate, having secured the device in place, you need to sit down and relax, holding your hand with the tonometer at chest level.

Wrist device

This model shortens the time needed to measure blood pressure and is ideal for athletes because they can monitor their readings during training. True, there is a drawback - this is a high error during the exercises. Doctors recommend using this model for people under 40 years of age. In the older generation, the vessels wear out, especially in the wrist area, which reduces the reliability of measurements.

Pros of a wrist tonometer:

- light weight and dimensions, you can carry it with you everywhere and always;

- easy to use, you don’t even need to undress;

- the ability to take measurements anywhere and even on the run;

- no need to select a cuff;

- has many functions available to a conventional automatic tonometer.

Disadvantages of a wrist tonometer:

- there are restrictions on use based on age;

- a very fragile device that requires careful use;

- when moving, it shows results with a large error;

- high price.

When purchasing this type of device, it is necessary to take into account the listed disadvantages and limitations.

VI International Student Scientific Conference Student Scientific Forum - 2014

MODERN PHYSICS LESSON ON THE TOPIC “MANOMETERS”

- Authors

- Work files

- Certificates

Description: a modern lesson involves the use of innovative technologies in teaching, forms the physical concepts of a device based on a generalized plan, the use of problem situations, the use of gaming activities, consolidation of residual knowledge and reflection. The use of a structured outline of notes and presentations in physics lessons allows you to achieve such goals. Below is a lesson plan for physics in grade 7 and a presentation for the lesson.

Structure of the lesson plan

Lesson topic: Pressure gauges

Lesson objectives:

Didactic: know the structure, principle of operation, use of open liquid and metal pressure gauges.

Educational: to cultivate an attentive, friendly attitude towards participants in the educational process, personal responsibility for performing collective work, an understanding of the need to take care of the cleanliness of the atmospheric air and observe the rules of nature conservation, and the acquisition of everyday skills.

Personal development tasks: to develop students’ cognitive interest in physics through experiments, to form the need to acquire new knowledge for the success of mastering the subject.

Type of lesson: Studying new material and applying the acquired knowledge in practice.

Demonstration equipment : liquid pressure gauge, metal pressure gauge.

Technical teaching aids: Computer, multimedia projector.

Didactic material: Presentation for a physics lesson in grade 7 on the topic “Pressure gauges.” Compiled to explain the topic according to the textbook by A.V. Peryshkina. The presentation contains 17 slides, including the purpose and objectives of the lesson, a short-term test in one version, consisting of 6 questions on atmospheric pressure with answers; an explanation of the structure, principles of operation of open liquid and metal pressure gauges, their use in production, technology and medicine, as well as questions for consolidating the studied material. Textbook by A.V. Peryshkin “Physics. 7th grade".

Forms of student work: frontal, individual.

Gas pressure monitoring device buderus

The gas pressure control device is designed to turn off the boiler when the gas pressure in the mains drops and is an additional equipment for Buderus boilers.

Prevents emergency shutdown of the boiler and protects against burnout of the gas burner at low gas pressure in the line, namely, it shuts down the operation of the boiler. After normal gas pressure is restored, the boiler automatically turns on.

Technical characteristics of the Buderus boiler pressure sensor

- Type: automatic for boilers.

- Country of origin: Germany.

- Warranty: 1 year.

- External design: rectangular shape.

- External design: black.

- Technical characteristics: height - 0.17 cm, depth - 0.12 cm, width - 0.22 cm.

Functions and equipment: programmable - no, pressure indication.

To summarize, I suggest watching several videos about gas measuring instruments.

Classification by mode of operation

According to the method of operation, devices can be water, electric or digital; in addition to these categories, there are other varieties.

Mermen

Water devices operate on the principle of balancing a gaseous substance with pressure, forming a column of liquid. Thanks to them, it is possible to clarify the level of sparsity, difference, redundancy and atmospheric data. This group includes U-type regulators, the design of which resembles communicating vessels, and the pressure in them is determined taking into account the water level. Also included in the water category are compensation, cup, float, bell and ring gas meters; the working fluid inside them is similar to the sensitive element.

Electrical

Resistive electric pressure gauge

This device for measuring household gas pressure converts it into electrical data. This category includes resistive and capacitive pressure gauges. The first ones change the readings of conductive resistance after deformation and measure values up to 60-10 Pa with minor errors. They are used in systems with fast processes. Capacitive gas meters affect a movable electrode in the form of a membrane, the deflection of which can be determined by an electrical circuit; they are suitable for systems with accelerated pressure drops.

Digital

Digital or electronic instruments are high precision devices and are most often used for installation in air or hydraulic environments. Among the advantages of such regulators are their convenience and compact size, the longest service life and the ability to calibrate at any time. They are mainly used to monitor the condition of vehicle components. In addition, digital gas meters are included in fuel lines.

Other

In addition to regulators with standard characteristics and settings, other types of devices are used to obtain accurate data. This list includes deadweight gas meters, which are original samples for testing similar devices. Their main working part is the measuring column, the condition and accuracy of the readings of which changes the magnitude of the error. During operation, the cylinder is held inside the piston at the desired level, while on the one hand it is influenced by calibration weights, on the other only by pressure.

Sources

- https://sovet-ingenera.com/gaz/equip/manometry-dlya-izmereniya-davleniya-gaza.html

- https://skysmart.ru/articles/physics/manometr

- https://StrojDvor.ru/gazosnabzhenie/manometry-dlya-izmereniya-davleniya-gaza/

[collapse]