Types of winches

On sale you can find a variety of winch options. The main classification is considered to be what type of drive is installed. Based on this indicator, the following structures are distinguished:

- Electrical structures are the most widely used today. This is due to the fact that such a design is capable of operating under very high loads. Typically, the installed electric motor is powered by the vehicle's battery, and the control unit can be located inside or outside the vehicle.

- A mechanical winch is the easiest to manufacture. The worm design has become widespread, when a gearbox is installed to transmit force and increase it. A small mechanical type auto winch is designed for low effort.

- Hydraulic. Hydraulic-type designs are also available. Their operating principle is based on the supply of liquid under high pressure, due to which the moving element moves. Typically, a hydraulic drive is installed on a structure intended to transport cargo.

Most often, a homemade design has a mechanical drive, since it is easier to manufacture and install.

Manual

A do-it-yourself manual winch is quite simple to manufacture, which has determined its wide distribution. The main disadvantage of the design is its rather large overall dimensions. A manual drum winch can extend significantly beyond the vehicle, and its installation requires a special bumper with a wide seat.

At the moment when the car is stuck, it will not be possible to pull and control it at the same time. That is why the design in question is becoming less and less common today.

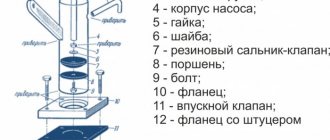

Drawing of a hand winch

Electric

As previously noted, electrically driven designs have become quite widespread. This is due to the fact that a homemade electric winch is comfortable to use and designed for a fairly high load. Let's call its features the following points:

- A high efficiency indicator determines that the design copes with the assigned tasks more effectively.

- A separate electric motor or generator can be used as a source of force. When choosing an option in which the winch is connected through the generator, you should be careful, since this component of the vehicle is important and cannot withstand overloads.

- An electric car winch must have high torque. In addition, quite a lot of attention is paid to energy consumption. This is because when the vehicle is stationary, most of the power will come from the battery rather than the alternator. Excessive power consumption can cause the battery to drain quickly. However, too low power consumption can cause a significant reduction in the power of the device.

Homemade winch

Recently, versions that can be powered by a 12-volt energy source have become very popular. In such a case, the winch device is connected to the cigarette lighter or the corresponding socket in the car, if available.

Hydraulic

The hydraulic winch is considered the most complex design option, since the design is represented by a combination of the following elements:

- Drum with cable.

- A mechanical element that transmits rotation to the drum.

- Hydraulic drive.

- Oil pump or compressor.

- Oil tank.

The advantage of the hydraulic drive version is low energy consumption and higher power. It is advisable to install a winch of this type only on large SUVs that have a high curb weight. In addition, the design is suitable for vehicles that are often used for driving on rough terrain.

Design features

The most popular today are drum models and mechanical lever-type manual winches. Although these tools have a similar purpose, however, the principle of their operation is somewhat different.

Drum type equipment

In terms of its external qualities, this type of tool is reminiscent of automobile winches with which special vehicles are equipped. Their design includes a gearbox and a drum. The first is usually a worm or gear type. The drum in this device is designed for winding tape or steel cable around it.

Worm-worm mechanism variations have an undeniable advantage, namely that their gearboxes have a much simpler system for locking the device at the right moment. Thanks to this, the safety of using this equipment significantly increases. This tool is also distinguished by its high reliability and variety of fastening tactics. Although it also has certain disadvantages:

- The large size of the equipment makes it more comfortable to use in a room like a garage.

- Relatively light weight that this type of equipment can pull.

- Complex operating mechanism.

- The need for ongoing maintenance.

- A kind of “conflict” with dirt.

From the above it follows that this type of winches is not the best option for use on mobile devices.

As for gear devices, their design also includes a gearbox and a drum, however, unlike worm devices, they are easier to manufacture and therefore somewhat cheaper. The cable is attached to them using a ratchet, which has good reliability.

The gearbox is characterized by ease of maintenance. A rather important point is the quality of the metal used in the manufacture of gears, therefore, when choosing such equipment, it is not recommended to give preference to cheaper, untested analogues. It is better to choose a well-known manufacturer.

The main disadvantages include the following:

- A method of laying a cable, which often gets into the cavities of the gearbox gears and ceases to perform its functions.

- Small internal diameter of the drum, which causes strong bending of the steel cable. As a result, the latter deteriorates quite quickly.

- Due to the dimensions of the device, the size of the drum is limited, and this, in turn, limits the range of action of the mechanism.

From the above, we can conclude that the process of using drum-type winches in field conditions may not always be comfortable. It is better to use this mechanism in the garage.

Lever type equipment

Winches of this type are most often used in mobile devices. It is these that drivers usually purchase in order to be able, if necessary, to rescue the car from a trap.

The standard structure of the device includes a frame made of metal, inside which there is a mechanism activated by pressing a lever located on the equipment body. Due to the fact that greater force can be applied to the lever, the device is effective in cases where drum winches would not cope. The traction force of such a mechanism can reach several tons. Moreover, this figure can be further increased by strengthening the standard lever. Some manufacturers immediately include a special amplifier in the equipment package or manufacture this element using the telescopic method.

The main components of the device include a ratchet that secures the cable in a taut state. It is a kind of wheel on which persistent teeth are located. A locking pin rests against them in turn, preventing the wheel from spinning in the opposite direction. This ensures tension in the cable.

In this case, the main load is placed on the equipment frame, as a result of which the latter must be made of durable metal of the appropriate caliber. Otherwise, the device will become deformed. Experts recommend abandoning the option of a winch with a frame whose metal thickness will be less than three millimeters.

The mechanism has small dimensions, so its operation is possible even in very inconvenient places and conditions. And also the lever type of mechanism does not require mandatory fastening of the case

However, when purchasing this modification, you should pay attention to the size of the winding drum, since the smaller it is, the greater the effort required during the work process. You should not opt for a product with a diameter of this element less than 45 millimeters

Device types

Classification is the first thing you need to know about the traction device. They are divided depending on the type of design, drive and technical features. Some types of winches are easy to make yourself - this is the simplest mechanism with a manual drive. And complex structures will work reliably only if they are manufactured in a factory.

This specificity must be taken into account when choosing a type for self-production. There are removable and stationary winches. The first option can be removed from the car, carried out maintenance or used for other economic purposes.

Classification depending on the type of drive:

- Manual. Its advantages are its small size and relatively light weight. The work is carried out according to the drum principle. The cable is pulled onto a separate reel, and it is rotated by hand. The disadvantage lies in the limitation of the mass with which work can be done - no more than 1 ton.

- Mechanical. The drum with the cable is rotated by the machine's engine. The design is heavy, so car enthusiasts rarely use it.

- Electric. The best option is for the drum to be driven by an electric motor. The latter is powered by a battery or the vehicle's electrical system. The load capacity in this version is 4 tons.

- Hydraulic. The design is complex, but it works silently and with great traction force. But such systems are unreliable and expensive. Another drawback is that it is impossible to make a hydraulic drive system yourself.

How to make a winch for MTZ with your own hands - Tractor Driver

One of the popular ways to make a homemade electric winch is to use a car starter. This device is equipped with a powerful high-torque electric motor with a supply voltage of 12 volts, which allows the winch to be used on an SUV.

When manufacturing, you should remember the limitations:

- The starter is designed for short-term operation. This does not mean that it will immediately burn out under prolonged load, but the motor housing does not provide sufficient winding cooling. If you plan to use the winch regularly and the work periods will be long, you should take care of additional cooling. For example, weld aluminum corners onto the body as cooling fins;

- The car starter is started using a retractor relay with a bendix. You don't need a solenoid for the winch, but a contact starter wouldn't hurt. The current at the contacts will be large, and it is better to leave the standard switching circuit. Depending on the gearbox used, the bendix should be fixed by welding in the position of maximum engagement or removed from the solenoid relay;

- The gearbox for the winch can be made independently, or selected from a power tool in accordance with the required load.

Do-it-yourself winch - price

If you have your own garage or shed with rubbish accumulated over several years of home plumbing, the cost of the product is determined by the price of a can of spray paint for final finishing.

Basically, the components are as follows:

- Starter from a VAZ 2101 car without a planetary gearbox (working, lying in the garage);

- A gearbox in a housing from a domestically produced electric drill (purchased at a flea market for the equivalent of 0.5 vodka);

- A piece of water pipe found in a barn;

- Metal for the frame, body walls, drum. Also found in a barn;

- Drum axle - purchased at a scrap metal collection point for pennies;

- The rope and hook were purchased at a tourism supply store.

Taking into account the cost of a new winch, the cost of the issue can be considered zero. At the same time, the owner can vouch for the safety of the device. Every detail and weld is personally checked by the manufacturer.

Another version of a winch from a starter for household needs

For production you will need:

- Used car starter with a working motor;

- Flywheel with gear;

- Steel wheel disc, or two brake discs - for making a drum;

- Powerful bearing with a podium (a used hub assembly is suitable);

- Corners, channels - for making a frame;

- The usual tools are a grinder, a welding machine, a drill.

The starter can be taken from a Zhiguli if you do not need to move trucks. The rest of the design elements are whatever you find. In this case, a flywheel from a Gazelle, a hub and CV joint from a VAZ 2108, and brake discs from the same were used.

- We twist the disks together in the form of a drum for the cable,

the remaining structural elements recreate the front wheel axle assembly. The only difference is that the hub body will be welded to the winch frame, and the flywheel gear will be attached to the CV joint “grenade”.

The bed is made from a powerful channel and angles

There is no point in dwelling on this structural element, unless we pay attention to strength

We weld the finished structure of the drum and support bearing to the frame

Please note that the entire power part is supported on one support. There is nothing wrong with this, the hub unit can withstand such loads constantly

We weld the outer “grenade” of the CV joint to the flywheel. The quality of welding must be high, since this unit will be heavily loaded. In this embodiment, gear architecture was used. The coupling is machined to accommodate the CV joint.

“Having measured seven times,” we weld the eye to secure the starter housing.

The design is ready, testing can begin. The solenoid relay bendix must be locked in the maximum engagement position. This can be done by welding. The relay itself performs the function of a starter.

A nice feature of this winch is the presence of reverse. By switching the polarity on the power supply, we can start the starter motor in the opposite direction. The design of the reverse trigger mechanism can be achieved using power relays.

The gear ratio of the starter-flywheel pair is so high that you don’t have to invent a homemade gearbox for this winch. The design has proven itself to be an indispensable assistant in the garage and in the garden.

Winch

Winch

it is driven using a 2.2 kV grinder. Before that, there was a 1.5 kV three-thousander engine that could not be pulled.

The side walls are made of sheet iron 3-5 mm. Thinner sheets may become deformed when the cable is pulled under load.

The most important part is attaching the drum axis. For this, powerful bearings with podiums from some mechanism from the times of the USSR were used. You can find such spare parts at scrap metal collection points or in the workshops of abandoned factories.

The podiums are welded to the side walls. If you managed to find only bearings, weld the outer race. Nothing will happen to the rolling mechanism; the bearings simply cannot be replaced.

READ Converting Interskol Screwdriver to Lithium Batteries

We attach the gearbox to the frame so that its gear meshes with the power gear on the drum shaft. We remind you that initially we had a set of a shaft and a set of gears. We install an eyelet between the walls - a leash for the cable.

We connect the gearbox with the electric motor from the starter, put the winch in good shape: we clean the welds with a grinder, remove rust, and cover the tool with paint.

The design has been tested to lift weights up to 200 kg. In this version, two gearboxes are used - from an electric drill and a homemade one from a gas electric valve. It feels like there will be enough traction for another 100-150kg.

If you install a starter with its own planetary gearbox, the gear ratio of which will be added to the two existing ones, the capabilities of the device will double.

The video shows an example of a winch using a starter.

How to use the device?

Be sure to provide for the possibility of reversing the power supply to the winch. Reverse is necessary in such devices. Since this is a regular car electric motor, changing “” to “-” will change the direction of shaft rotation.

Let the power starter be old, from the solenoid relay

. And the start buttons come from ancient electromechanical devices. The button block can provide for polarity reversal.

If the winch is used in a car, do not connect it to the standard battery with the engine turned off. With a good load, you will drain the battery in 10-15 minutes.

The dimensions allow the winch to be placed on the bumper of an SUV prepared for off-road use.

Also interesting: VAZ Niva 2121 tuning recommendations

Winch from a chainsaw

Chainsaws are used to prepare firewood by most extreme recreation enthusiasts. If you wish, you can find a set of drawings on the Internet for using this powerful tool as a power source for a winch, outboard motor, drill or gas cutter.

It is necessary to remove the bar and chain and install in their place a structure consisting of a drum, frame and gear. The result will be a completely autonomous winch, developing a traction force of 2 tons. In this case, the gears are combined with a chain, which greatly simplifies their manufacture or selection.

General safety rules when working with winches:

- The winch must be used exclusively for horizontal movement of machinery or loads

- It is prohibited to use bridge beams, power and communication line supports to secure the cable.

- Work with the cable should be carried out with gloves

- Damaged cables, blocks, shackles, slings must be replaced

- If the motor housing heats up above 600C, turn it off and allow it to cool. Otherwise, the windings may short-circuit.

- The control panel should be transferred from the passenger compartment to the outside through an open window. This ensures that the wires are not damaged by the door.

A chainsaw is often used as a power source for a winch

- You can only approach and touch the cable after the winch has stopped and loosened.

- Do not leave less than five turns of cable on the drum

- In the absence of a cable arrester, you should use any available means. You can avoid injury if the cable breaks by throwing a sleeping bag or tarp over it before work.

A simple option made from scrap materials

Some motorists often drive into a field or forest, which may result in problems negotiating difficult areas - mud and sand. The car gets stuck, and you have to puzzle over how to get it out. The simplest hand-made homemade winch can be made in the field.

Materials:

- Scrap and pipe cuttings.

- Cable.

- A piece of pipe for a lever.

It is unlikely that you will have the materials with you on the road. But everything you need can be found in the nearest village. Instead of a cable, a strong rope will do.

Manufacturing procedure:

- Drive a crowbar or a small diameter tube into the ground to create an axle.

- A larger diameter tube is placed on the axle, to which a cable is attached.

- A lever is slipped under the lower turn of the cable. This could be another tube, a shovel handle, or a pole. The main thing is that the material is durable.

The principle of operation of pulley hoists

The only simpler device for moving heavy objects is a metal scrap. The main element is a wheel with a chamfer in the middle of the outer surface, the axis of which is fixed to the ceiling beam. You can throw a hoist over it, and the lift with a gear ratio of 1 to 1 is ready. To increase the leverage, let's pass the hoist through another loose wheel, the axis of which is connected to the load, and fix the hoist at the top of the structure.

The gear ratio will become equal to 2. Now we will attach another wheel to the ceiling, and pass the end of the hoist through it, securing it to the axis of the lower wheel. The gear ratio will become equal to 3. And so on, by adding one wheel at a time and changing the mounting location of the hoist, you can increase the gear ratio.

What will you need?

If you are interested in a do-it-yourself winch from a starter, you can get by with cheap and common options. The motor from the VAZ-2101 electric starter is well suited as a power unit. They are quite common and cheap, but they do not have much power, but for a small sedan or SUV, for example, GAZ 69, they are quite enough.

Next is to look at the gearbox. You can also choose from an old Soviet drill. The main thing is that the gear ratio is approximately 1 in 20.

You also need a shaft with gear and bearings, a piece of pipe for the drum and two round metal plates. You will also need sheet metal, various rods, bolts and nuts.

A self-made electric winch is good because you can use a lot of lying around and unnecessary materials.

Among the tools, you definitely need a grinder, a welding machine, and an adjustable wrench.

A winch is often needed on long and difficult trips. If you're an adventurous person, you'll also benefit from learning about building an expedition rack. Read this article. And for a fishing trip you will also need a boat trailer. Read about making it yourself here.

Other options: a simple winch and a metal structure

A fast and fairly effective alternative to previous models is a rather old method. It is known to motorists who have had to tow a car with improvised means. In emergency cases, you can use such a winch at the dacha, when you do not have time and materials for a more serious device:

- dig the crowbar deep into the ground - it should be firmly fixed in a vertical position;

- Place a piece of pipe (lever) perpendicularly onto the resulting axis, with the help of which the crowbar will rotate;

- secure the cable to the load and to the crowbar;

- rotate the crowbar, winding the cable, and move the load.

For a metal device you will need metal, welding and various components. These are a rotating cylinder, gears, handles and bushings.

Construction details:

- Gear Glist. It transmits the rotational energy of the axis. Buy a thick element with massive teeth.

- Shaft for cable. Find a cast cylinder and weld a rounded metal sheet to it at one end, the size of the inner ring of the gear. This cylinder will subsequently be used to wind the cable. If the shaft has a through hole, great. For better fastening, thread the steel cable and connect it from the outside into a loop.

- Bushing for sliding the shaft during cable winding. It would be nice to additionally install a rolling bearing.

Attention! The tractor frame with lugs on it, the rocker, the carrier, and the stationary coupling ring mounted on hinges are also made of metal. All parts of the winch must be moderately rigidly fixed so as not to dangle and abrade each other.

Manufacturing a system with a universal drive

The manual system is easy to manufacture. Of the special skills the master is required to do, only own a welding machine. Any metal will do the job. The appearance of the device is not so important, the main thing is performance and resistance to heavy loads. The frame should not be deformed.

Materials and tools:

- Rectangular tube for frame.

- Shaft for the drum, you can use a round tube.

- A sheet of metal with a thickness of at least 3 mm for the manufacture of drum disks.

- Threaded rods M10-M12, 24 cm long – 6 pieces, nuts.

- Tube diameter 14 mm - 6 identical pieces of 20 cm.

- Asterisks - large and small. Chain.

- Hubs to secure the drum to the shaft and secure the shaft to the frame.

- Drive lever.

- Cable with carabiner.

- Welding and electrodes.

- Grinder and grinding disc for it.

- Paint and primer.

- Wrenches included in the set.

Some materials are better purchased - for example, tubes for the studs and shaft. The rest can be picked up from old mechanisms - cars or motorcycles. Any metal will do, even used.

Manufacturing procedure:

- They sketch out a drawing, because this will make it easier to navigate during assembly - you won’t have to stand guessing over the half-finished product and think about what to do next.

- Cut out the frame parts from a pipe with a cross-section of 2 by 2 cm. Connect the frame parts together strictly perpendicularly. The cut on the workpieces is made at an angle of 45 degrees.

- Lay the frame blanks on a flat surface. The joints are spot-tightened by welding, after which they check whether everything is installed correctly. The angles of the connections must be strictly 90 degrees. If there is a lack of accuracy, corrections are made and then the parts are welded.

- Scale is removed with a grinder and a grinding wheel. The finished frame is sanded and then coated with a primer. After the latter has dried, the metal is painted with enamel in 2 layers. You can use regular paint. The goal is to protect the metal from corrosion, since operating conditions will be difficult, with dirt and moisture.

- Creating a drum. Take a sheet of metal and cut out 2 circles, their diameter is about 30 cm. On each circle you need to make 7 holes:

- One in the center. The diameter must match the shaft size.

- 6 holes at a distance of 7 cm.

- The discs are fastened together using pins. The pin is inserted into the hole of one disk in a vertical position. Tubes with a diameter of 14 cm are put on the studs, and a second disk is installed on them. The studs must not only be secured with nuts, but also additionally reinforced with locknuts to ensure reliable connections.

- The drum is ready, now the shaft is mounted. It is made from a metal pipe, but you can take a finished product from any mechanism. The latter option is preferable: since the accuracy of the factory part is higher, vibrations of the drum will be small or absent altogether.

- A large diameter sprocket is mounted on the shaft on the outside of the drum. A sprocket from a motorcycle gearbox will do. To secure the drum to the frame, the outer sides of the shaft must have hubs.

- The drum assembly with the shaft is mounted through the hubs on the frame. The structure is secured with bolts. Before installing the drum, you should prepare a platform on the frame. A drive will be installed on it - manual or electric. When using an electric drive, a motor is placed on the platform with a small sprocket attached to its shaft.

- A universal drive is often installed: a handle is placed on the reverse side of the output shaft of the electric motor. In the absence of electricity, the winch can be turned manually.

- It is important to properly tension the chain. It should not sag, but strong tension is also unacceptable - this will cause the sprockets to wear out faster, and the chain may break. Check the chain tension by rotating the drum - the chain should not hinder its rotation when the cable is unwound.

- The end of the cable is secured to the shaft and wound around the drum. A carabiner is hung on the other, free end of the cable.

- A shank is attached to one end of the frame. With its help, the winch is secured to the car frame.

How to make a hand winch from scrap material

The weight of objects can be such that one, or even five people, cannot move them manually, but it is necessary. In such cases, a homemade device for lifting or moving heavy objects will come in handy. A hand winch is the most popular device in this business. It’s not at all difficult to make a manual winch for a garage with your own hands, even at home. But first you need a calculation and a drawing of the mechanism.

What the pulley for lifting loads and the construction crane have in common is the use of the idea of increasing force - the rule of leverage. In order to balance the load on the short side of the lever, you need to apply less force to its long side to the extent that the short arm is less than the long one. The ratio of forces at the ends of the lever is called the gear ratio.

The use of Archimedes' principle is implemented in different lifting mechanisms, and how depends on the purpose of the lift. Designs differ in gear ratio, principle of force transfer, mobility, strength, and energy used. The most popular types for self-production:

- chain hoists;

- drum structures;

- lever mechanism.

To choose the type of device needed for specific work, it is worth familiarizing yourself with their capabilities and limitations.

The only simpler device for moving heavy objects is a metal scrap. The main element is a wheel with a chamfer in the middle of the outer surface, the axis of which is fixed to the ceiling beam.

You can throw a hoist over it, and the lift with a gear ratio of 1 to 1 is ready.

To increase the leverage, let's pass the hoist through another loose wheel, the axis of which is connected to the load, and fix the hoist at the top of the structure.

Types of abrasive sandpaper by grain size and designation

The most compact designs are those with single-axle wheels. The design of such devices has two wheel holders. Having studied the drawings of the chain hoist, it will not be difficult to assemble it with your own hands. You will need two clips:

- traverse;

- carrying bracket;

- cheek for mounting parts;

- wheel (block);

- emphasis;

- bearing;

- sleeve;

- axis;

- axle holder;

- bearing oiler;

- hoist limiter;

- screw;

- bearing;

- cheek.

The end of the hoist is fixed to one of the clips.

In addition, bending the cable on each wheel requires force, reducing the efficiency of the device. You can reduce these losses by increasing the diameter of the wheels, but at the same time there will be an increase in the weight and dimensions of the pulley.

Other types of lifts do not have these disadvantages.

Which heat gun to choose for home use

The principle of operation of winches resembles a simple lever fixed at a fulcrum.

If the short arm of the lever is the surface of the cylinder, and the load is attached to it by a cable, you will get a winch with a gear ratio equal to the ratio of the length of the lever and the radius of the cylinder.

However, the high gear ratio of the system will require a very long handle, which is inconvenient. The solution is found in two types of drum winches, which increase the gear ratio using gears or a worm gear.

- A gearbox made of gears operates with much less friction. When using the principle of transmitting force through a pair of gears of different diameters, the easiest way to make a manual drum winch with your own hands is this:

How to make a hot smoked smokehouse with your own hands

Lever lifts

The most popular use for lever jacks is as a car jack. It is used less frequently as a universal device, since the lifting height is small and limited.

At home, you can use improvised materials and ready-made transfer units. For example, the ratchet used in a KAMAZ vehicle to equalize the braking force is a ready-made worm gear mechanism.

You can get rid of manual lifting for a long time if you assemble the motorized winch system with your own hands for work once. To do this, you need to put a gear on the winch drive axis, connecting it with a chain to the chainsaw drive sprocket on a rigid housing structure.

By combining block mechanisms with drum winches, you can work to compensate for the shortcomings of each type of lift. For example, pulley hoists do not provide a lock that prevents reverse movement of the hoist, but drum swans eliminate this very simply. But the angle between the lifting force vector and the weight vector of the pulley can be almost anything, which winches cannot boast of.

Assembly Tips

Design development is carried out carefully, as well as assembly. The task is to treat each operation as responsibly as possible. The goal is to complete the assembly with high quality. This will avoid troubles when operating in extreme conditions. Therefore, there is no need to force the work, even if it is really necessary.

Steps to achieve high build quality:

Negative results often arise due to hasty actions. The issue of moving cargo in a horizontal plane with its own device will be successfully resolved. To lift loads above the ground, the cable must be pulled over a strong support.

Do-it-yourself manual winch: detailed drawings and photos of making a homemade winch from a ratchet from Kamaz.

In this article we will look at the step-by-step production of a homemade winch made by a craftsman from Samara.

To implement the idea, the author decided to use a KAMAZ ratchet, here it is in the photo.

The design will be made on a carriage that will move the winch along the channel. The figure shows drawings of a winch for self-production.

The shaft was cut to length, two round plates 4 mm thick were welded, and a cable would be laid between the plates.

One side of the shaft needed to be ground so that a 207 bearing with a diameter of 35 mm could be pressed onto it. Made a plate.

The ratchet is put on splines, a washer is put on and a cotter pin is placed diametrically through the shaft. On one side I installed a plate with a bearing.

I welded the stud onto the shaft, put a washer on the stud and tightened it.

I assembled the carriage using 8 mm thick steel, cut out 3 plates and welded them together.

I drilled 25 mm holes in the plates, welded pipe sections to them and placed 205 bearings on them. Then I tightened the bearings with bolts and washers.

I drilled a couple of 12mm holes in the bottom plate. and pulled two plates together with bolts through the pipe.

A hand winch is used in the garage to lift the engine and other needs.

Read news about the new Niva

- Towbar (trailer) Trailer for LADA (VAZ) NIVA 4x4 2121 – buy at a great price in Moscow

- Air conditioners for Niva in Ufa

- Half a century for the Defender winner: the history of the UAZ-469 - KOLESA.ru - automobile magazine

- Trophy

- DIY all-terrain vehicles on low-pressure tires

- Tires for SUVs. Buy mud tires in Moscow for a price starting from 2,620 rubles

- Do-it-yourself car diagnostics via a laptop: scanners, programs, work procedures, adapters based on the ELM327 and VAG chip -

- Niva Chevrolet - price and features of the SUV

Types of winches

The winch includes a rope drum/pulley, drive unit, brake and frame. The devices can move the load horizontally or lift it upward. According to the installation method, they are divided into stationary and portable. If we classify equipment by design, we can distinguish 3 types: gear, worm, chain.

Gear

Considered the most common. They operate due to operator effort. They are divided into single- and multi-speed. Winches of the first type are a drum on which the main and drive gears are attached. Multi-speed devices consist of a minimum of 2 pairs of gears, which allows you to move heavier loads.

Worm

They consist of a helical gear that rotates the main gear fixed on the drum. The shafts are located at an angle of ninety degrees to the earth's surface. The main advantage of such equipment is considered to be a high gain index, which makes the work more efficient. The disadvantages include the increased load on the transmission.

Chain

Structurally, chain winches are based on a chain drive, reminiscent of the one that is equipped with bicycles. It is possible to make such a device with your own hands.

Types of automobile winch.

Do-it-yourself devices of this kind can be created with electric, manual and hydraulic wires. They all have a common operating principle: a cable is wound onto a drum, which is rotated through a gearbox using a motor or manually.

Now let's look at different types of winches with our own hands in more detail.

Do-it-yourself electric winch.

Often, converted generators from trucks and tractors, car starters, as well as any suitable electric motor from equipment are used as a motor for such a winch.

At the same time, it is very important that the electric drive has high torque, great strength, and also consumes as little current as possible, because then the battery in the car will be discharged for as long as possible

DIY hydraulic winch.

By design, such a winch is the most bulky and complex. And even despite this drawback, it has great advantages in comparison with an electric winch. They consist in providing the greatest traction forces with minimal energy consumption from the on-board network.

Well, to create it, you mainly use an oil tank, a pump drive and the oil pump itself.

DIY mechanical winch.

The principle of operation of a homemade mechanical winch is similar to the others, only instead of an engine it uses human power. Consequently, the power of this design directly depends on the physical force applied by a person, as well as the length of the lever to which this force is applied.

Winch components.

The main component of any homemade winch is a drum with a cable. It will be good if there is a ready-made drum that does not require alterations. If there is no such thing, then you will have to do it yourself. To do this, you need to take a piece of thick pipe and weld the cheeks to it, the thickness of the latter should be about 3-4 mm.

One example of a homemade drum.

To make the drum we need, we can take, for example, a hub from a Zhiguli. In it you only need to grind the welding point, that is, the thin end, and weld the drum halves of the required diameter on the mandrel.

The most suitable gearbox is a worm gearbox with a large gear ratio. The advantage of a worm gearbox is that its use for a homemade winch can do without the use of a drum brake (this is due to the properties of the worm pair). The most suitable such gearbox would be the gearbox from the trolleybus doors, because it has a sufficient gear ratio and is also quite convenient to mount on the site. Well, to make using the winch as safe as possible, it is best to make a remote control panel so that there is no need to be close to the tensioned cable. You will also need to open the gearbox housing and block the bevel clutch, which is designed to prevent passengers from being pinched by the doors. This can be done in different ways, for example by welding the cone to the gear in several places.

In the case when a homemade electric winch is made using a starter, the best one will be the one equipped with a planetary gearbox. By the way, some Zhiguli brand engines are equipped with just such a unit.

Do-it-yourself winch from the starter.

A homemade winch from a starter is made as follows. A sheet of metal is taken and a platform is made on which all the components are attached. Afterwards, the seats for the drum shaft should be welded to it and installed. Next, we weld the gearbox so that the input shaft is located on top. After this, we attach a homemade adapter to the top of the gearbox for attaching the starter and place the gear teeth with a suitable module on the input shaft. For these purposes, you can use the flywheel crown. Now you can secure the starter and install the wiring.

Video

Tuning Toyota Land Cruiser.

Tuning Chevrolet Lacetti.

Eight tuning.

DIY car stickers, step-by-step instructions.

Homemade winch for farming

All kinds of winches are an indispensable thing for motorists. But a homemade winch for the farm can also be successfully used.

Here, such devices are most often used to move loads along a horizontal surface, for example, heavy logs.

Farmers often use winches by installing them above the attic opening, thus moving loads between different parts of the room.

And some manage to use a homemade winch to plow the land.

To do this, just secure it to the edge of the site, hook the plow to the end of the cable and turn on the winch.

The mechanism pulls the plow, and the person can only give it direction. Using a winch, you can not only plow the ground, but also carry out all cycles of tillage.

We offer a winch for home work, or more precisely for hilling potatoes based on an angle grinder. Almost nothing is needed to make it. We present it as a modification of our winch with an electric motor.

When the engine turned out to be low-power, and I still had a new one, the idea arose to remake the drive. We decided to use an angle grinder. What came out of this is up to you to judge. We will tell you how the modification took place.

Let's start with altering the frame; the engine platform must be adapted to the angle grinder. The canopies and the original appearance of the site remain unchanged. The only thing you need to do is raise it on the frame with the corners to give tension to the belt.

The grinder has threaded holes for attaching handles. It is in them that we insert the bolts to secure the angle grinder to the platform, additionally weld the corner to the platform, as shown in the photo, and secure the electric drive with another bolt.

Then we weld the corners to the frame and raise the platform. We put a pulley on the grinder, put on a belt and carry out a dry test. Next, we carry out full testing on a potato field.

Price issue

Many people cannot decide whether to purchase a ready-made winch or make it themselves. If you have your own garage and certain plumbing skills, creating a homemade structure should not be a problem. The homemade winch being created consists of several main elements:

The starter, for example, is from a VAZ 2101 car. It is common, and you can purchase the mechanism very cheaply

When choosing a starter, you should pay attention to its technical condition. If it was overheated during operation, then there is a chance that it will not last long. Gearbox in a housing from an electric drill

A drill of domestic origin will be cheap, especially the version with a burnt-out electric motor. It is worth paying attention to models with a high power rating, as they will have a wear-resistant gearbox. The bed can be made of metal plates and channels. Very often in the garage you can find the required amount of metal to make a frame. The structure being created must have holes with which it will be attached to the bumper or other element of the car. The axle for the drum will have to be purchased separately at a scrap metal collection point. Do not forget that the shaft must have a gear. In addition, attention is paid to the straightness of the central axis, since bending the shaft will lead to runout and other problems.

In the store you will only have to buy a cable with a hook. Taking this into account, we can say that a homemade winch costs practically nothing, while the cost of a purchased version can reach several tens of thousands of rubles.

Gearbox selection

The next problem is the choice of gearbox. Any 220 V electric winch with your own hands must contain a mechanism that will transmit rotation with a large traction force. There are the following types of gearboxes:

- Worm drives transmit rotation at an angle of 90 degrees and do not require braking devices, as they have good self-braking properties.

- They are not used for winches due to the complexity of the perpendicular arrangement of the main drive and secondary shafts.

- Cylindrical, are one or more pairs of gears in one plane, meshed. Rotation is transferred from the smaller wheel to the larger one. They have high reliability, but less tractive effort. Convenient for use when constructing homemade winches.

Planetary gearbox, the most common at the moment. It usually consists of 3 satellites, a sun gear, a ring gear and a carrier. They have an increased working life and transmitted power, but are complex in design.

The simplest solution when manufacturing a unit, an electric winch for 220 V, of course, you can always use a converter, especially since ready-made high-power devices are available for sale. An asynchronous motor can be used as a drive motor, but it is better to use a motor from a washing machine. Modern models are quite powerful and productive.

https://youtube.com/watch?v=2eGm6pMyIlc