A vacuum pump is a regular air compressor that uses the suction side.

You can make a 12 volt vacuum pump out of an air compressor if you can connect a hose to its air intake.

This guide will show you how to make a vacuum pump with your own hands. Such a device is useful for vacuumizing food products and increasing their shelf life, or for vacuum packaging things, since a bag with removed air takes up less space than a regular bag with things. You can also do vacuum molding - the production of products from thermoplastic materials in hot form using vacuum.

The vacuum created by such a device is several times higher than what a conventional vacuum cleaner can create (about 0.8 kgf/sq.cm, or 0.08 MPa).

This vacuum is sufficient to use the pump for industrial purposes that require vacuum.

A compressor for inflating car tires in a store costs about 1,300 rubles. You will also have to purchase some spare parts and glue.

You will also need:

- About one meter of PVC tube with an internal diameter of 6 mm.

- Plastic herringbone connector for 6mm ID tubing.

- Epoxy resin (cold welding).

All of these materials are readily available and can be purchased at the store.

Since a 12V pump draws about 4A of current, it will need a fairly powerful DC power supply. A 6 A car charger can be used as a power source.

NOTES.

If you use a cheap air compressor to inflate your tires, like the $700 Harbor Freight one, don't expect too much from it. (A cheap pump will only work for a few minutes, then it will overheat. A good compressor can work continuously for up to an hour). The fact is that the compressor is not designed to work as a vacuum pump. Turn it on for a period of 1/3 to 2/3 of the time specified in the compressor data sheet, then let it cool for 5 minutes.

For example, if the passport for an air compressor indicates a continuous operation time of 15 minutes, then in vacuum pump mode you can run it for 5-10 minutes. with a break of 5 minutes. for cooling. A good pump is one with an aluminum cylinder, a large area of cooling fins, a cooling fan and a powerful motor designed to last for a long time.

Here are some tips on using the pump and its limitations:

For vacuum packaging:

- Do not use the pump to vacuum large volumes of food or items, or to create a vacuum in a container with air leaks.

- Use small containers for vacuuming and fill their volume with products (things) to the maximum in order to pump out a minimum of air from them.

- Turn off the pump from time to time to cool it down.

- If after a long time the pump cannot create a vacuum, then there is a leak somewhere.

For vacuum forming:

- Do not attempt to remove air from a 100 liter tank with this pump.

- To reduce the load on the vacuum pump, use a two-stage air pumping system: first, most of the air is pumped out using a vacuum cleaner, then a vacuum tank with a vacuum pump is put into operation: link.

- Do not start the pump until the vacuum in the system drops to 0.8 kgf/cm2. Typically, a vacuum in the range of 0.6-0.7 kgf/cm2 is sufficient for molding products. Therefore, you should not once again turn on the vacuum pump to increase the vacuum by a couple of tenths of atmospheres, in order to avoid its rapid wear.

Application

Similar devices are used in everyday life to create a vacuum in plastic packaging for storing food and things.

When air is sucked out, the volume of the container decreases, the shell tightly fits the product. With this storage, food does not spoil for a long time, and can be stored for some time without freezing. The best mobile application for experienced players has appeared and you can have a phone with all the latest updates and discover sports betting in a new way.

When storing clothes or other soft textile products (blankets, pillows, rugs), noticeable compaction occurs, things become compact and take up less space. With this method of storage, things become inaccessible to moths or mold.

Using a vacuum pump, you can cover parts made of wood, plywood and other building materials with laminating film.

The vacuum pump is used for household removal of gases, steam and liquids, to restore the tightness of household appliances. And also in split-system air conditioners and during the operation of brake systems in vehicles.

Aquarium compressor conversion

A very practical version of a vacuum pump can be made from the aquarium compressor already mentioned here. The design of this product needs to be modified quite a bit:

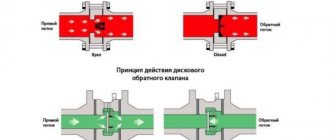

- Having carefully examined the compressor, you need to find fastening elements, removing which you can dismantle the check valves.

- After disassembling the product, remove the valves and then swap them.

- All that remains is to assemble the compressor, connect it with a tube to the evacuated container and put it into operation.

A small improvement will help improve the operation of the device: you need to make a hole in the housing through which condensation or moisture that accidentally gets into the compressor will be removed.

Harm and contraindications

If used incorrectly

, you may cause

harm or injury

.

And men suffering from certain diseases are completely prohibited from using

.

- If you have a tendency to bleed, you should not try the pump. High pressure in the cylinder will have a detrimental effect on your health.

- Do not combine painkillers with procedures under any circumstances. The absence of pain will not let you know when it’s time to stop the process. In this case, penile injury cannot be avoided.

- Excessive use and abuse will lead to hematomas and bruises on the penis.

- People with painful erections should not use the pump.

Compound

The materials used to make a homemade penis pump are simple. It consists of 4 elements:

- The plastic cylinder is the mold into which the penis is placed.

- Seal – a rubber bottom with a hole serves to fix the penis.

- Tube - air is pumped out of a cylindrical shape through it.

- The piston is like in a device for measuring pressure. Serves to form a vacuum, attached to the tube.

By putting the parts together, you get an effective device that solves the problem of insufficient penis size.

Purpose

When studying the operating principle of a small treatment plant, one pattern can be noticed. After pumping out wastewater, deposits of silt and other contaminants regularly accumulate on the walls of a cesspool or well. Such an environment promotes the proliferation of harmful and pathogenic microorganisms. Regular removal of sewage from the septic tank makes the sewage system more efficient and creates a favorable sanitary environment.

The use of factory-made equipment will allow you to more effectively cope with the task, but it has a rather high price. In this case, at your summer cottage or in a country house, you can use a homemade pump to pump out the sewage system. Proper assembly of the device will ensure effective removal of wastewater.

Flaws

There are more disadvantages to creating a homemade device than advantages. First of all, they are associated with the labor intensity of the process. Not every person will be able to create a safe device that allows them to achieve the desired effect, which would meet sanitary and hygienic requirements and would be suitable in size.

The second disadvantage is the aesthetic appearance. The finished device looks much more attractive.

And, of course, the operating principle is a little more complicated. In a sex shop you can buy an automatic mechanism. You just need to press a button and you can enjoy the process. At home, you can only create a manual device.

Instructions for use

Achieving the effect of exercising with a vacuum pump is possible if certain rules and safety precautions are observed. We recommend that you listen carefully to your own feelings during the procedure - if any discomfort or pain occurs, the session should be stopped immediately. This will mean that you have assembled the device incorrectly - using such a device can cause harm to the body.

As for the general rules for using a vacuum pump, they are as follows:

- Beginners are not recommended to use a vacuum pump for more than 5 minutes;

- After each use of the device, you must thoroughly wash both it and the penis;

- It is recommended to use a water-based gel lubricant during the procedure;

- Classes with a vacuum pump are not carried out at low temperatures;

- After placing the penis in the pump flask, the air must be pumped out gradually until the penis reaches a fully erect state in a vacuum;

- To avoid accidental pumping out of air, use a clothespin on the tube;

- One procedure should not take more than thirty to forty minutes.

If you follow these recommendations, it is possible to safely increase the length of the penis by 3-4 cm, and its volume by 1-1.5 centimeters.

Important points

The size of a man's manhood matters when building relationships. That is why representatives of the stronger half of humanity often decide to create a pump with their own hands to increase the length of the penis. Many “masters” make mistakes at the manufacturing stage. It's worth talking about some important points.

Many men have been injured due to improperly sized seals. When a vacuum was created by the device, the base of the penis was damaged or the testicles were sucked into the flask. It is very important to measure the width of the penis and make the o-ring 0.5 cm larger.

Possible difficulties

In the process of self-production, home craftsmen face a number of difficulties:

- Incorrect calculation of downforce. The spring has to be shortened or, more unpleasantly, wound again. This problem is usually solved by selection.

- Insufficient quality of surface treatment of the seat. The valve does not press against it completely and allows water to pass through. Solved by grinding the surface.

- The flow resistance is too high for the specific system conditions. I can’t decide whether I’ll have to choose a different type of valve or buy an industrial one.

Making a check valve yourself will be a good test of your engineering and plumbing skills.

Source of the article: https://znatoktepla.ru/truby/delaem-obratnyj-klapan.html

Tools

To make devices, you will need the following tools and equipment, which are probably available in every self-respecting home workshop:

- Desk or workbench.

- Vise or massive clamp.

- Hacksaw for metal.

- Drill or benchtop drill press.

- Pliers.

- Assembly knife.

- Set of files and needle files.

- Sandpaper of different grits.

- Jigsaw (electric).

Different materials and components are required for different designs and will be listed in the appropriate section.

The most common mistakes

Assembling correctly is not a difficult task. Beginners make mistakes in the methods of processing the device, choosing components and exercises.

Mistake #1 – Incorrectly selected seal

Refusal of the seal or incorrect selection of the hole size leads to the suction of the testicles into the cylinder. This should not be allowed, as there is a high risk of injury.

Mistake #2 – The tube is not secured

Mistake #3 – Plastic lid

We construct a vacuum pump with a rubber cover. The plastic rubs and puts pressure on the penis during an erection.

Mistake #4 – Narrow tube

We do not use material with an internal diameter of less than 2-3 mm . It bends and air does not enter the cylinder.

How to make a pump: instructions

Following the guide described below, it will be quite possible to make a vacuum pump yourself in half an hour, using available materials - a water bottle, a syringe, a pump, and so on.

Glass bottle pump

- To do this, you need to get a glass bottle - for example, from an alcohol bottle, which will become a flask for placing the penis. It needs to have a standard length - about 25-28 centimeters;

- After thoroughly cleaning the bottle, remove the bottom using a glass cutter. This may not work the first time, so we advise you to stock up on several bottles in advance. If the future cylinder is cracked, it cannot be used;

- The edge of the cut must be carefully processed using sandpaper;

- Then you need to take a plastic or silicone tube, which can be easily purchased at a hardware store, with a diameter of 0.3 cm (internal 2.5 cm). The length of me should be about 60 cm;

- In addition, you need to take a special faucet that will match the diameter of the tube;

- The resulting hose together with the tap must be connected to the cylinder; if it does not fit tightly to the neck of the flask, this situation can be corrected with the help of a clamp. If the tube is smaller, then the tip can be slightly heated with a lighter, due to which stretching will occur and the hose will fit tightly onto the neck of the bottle;

- Then you need to put the cuff on the finished edge. The best choice would be a cuff made of dense pimply foam. To do this, you need to cut out a circle of the required diameter, in which a small hole is then made for the genital organ.

At this point, a primitive vacuum pump made from a glass bottle will be ready. This device does not have a pump; air can be pumped out with the mouth.

With pump

You can make such a vacuum pump yourself using a cuff pump. The process is quite simple - the pump itself is suitable for inflating bicycle tires or balls.

The procedure consists of the following steps:

- First you need to prepare all the necessary elements: the pump itself, a check valve (for example, from a compressor for an aquarium) and a flask (a large pastry syringe);

- Then the pump must be unscrewed, the cuffs must be moved in the opposite direction and reassembled. This will allow the assembled device to work with the opposite effect - drawing air out rather than releasing it.

- Next, align the compressor valve with the hose from the pump;

- The resulting structure must be attached to the pump.

Using a syringe

One of the most convenient parts that replace the cylinder in a vacuum pump if you create a design with your own hands is a large confectionery syringe or a large medical version. To do this you will need: two large syringes, a tube made of silicone, two tees, a rubber seal, a sealed element for fixation, a faucet, two check valves and ordinary scissors. Many of these parts can be found at aquarium supply stores, or in the aquarium section of your average pet store.

The assembly process in this case occurs as follows:

- The silicone seal must be placed on the syringe and secured tightly;

- Then the tee is combined with a suitable hose;

- A check valve is inserted into this tee;

- After this, you need to check the operation of the mechanism and find out whether the air escapes when pressed;

- In the remaining free third hole of the tee, it is necessary to attach a hose and a second check valve, which will allow air to be sucked in;

- After this, it is necessary to secure the second valve in the place of the second tee;

- You also need to install a faucet in the second tee;

- The second syringe, which is without a piston and serves as a cylinder for the genital organ, must be connected to the second end of the tee;

- Using a rubber seal, you need to wrap the edge of the syringe in which the penis will be placed to soften it.

From a plastic bottle

This is perhaps the fastest and least expensive option for creating a pump for penis enlargement yourself. The costs in this case are minimal; You can assemble the pump in half an hour. You will receive a homemade version of a vacuum pump that allows you to increase the size of the penis. In this case, it is important to choose a bottle of a suitable size that will be comfortable to accommodate the erect penis.

The build process is like this:

- On the side of the bottle cap, you need to make a small hole for the genital organ;

- On the bottom side, also make a cut for the tube/hose;

- Connect the other end of the tube to a syringe; if necessary, secure the structure with a clamp.

Varieties of homemade structures

There can be many types of pumps. It depends on their intended purpose. The simplest vacuum sealer can rightfully be considered a medical syringe. But its disadvantage is that a vacuum can be created in small volumes. And even if you don’t have a medical syringe at home, you can easily buy one at the pharmacy, just pay attention to the size.

But in order to be able to pack large volumes, a car pump is well suited. It just needs to be reworked to the required parameters. Moreover, making a vacuum pump from a car compressor with your own hands is not difficult.

You can also construct a vacuum pump from a compressor from a refrigerator, or remake accessories from an aquarium.

Using a car pump

A homemade vacuum pump can be made from different raw materials. The most popular options are car and bicycle hand pumps.