Even before the invention of the wheel by man, holes were used. In construction, manufacturing of basic parts, manufacturing, and so on. This is one of the most ancient “finds” of people. Today it is difficult to imagine technology without any holes. They can be found both in metal structures, mechanical engineering, and in the smallest mechanisms. But what kind of holes are there? It is clear that there are a huge number of them. On the other hand, the first thing that comes to mind is the division of holes into small, medium and large. There are many other classifications of holes. So, let's look at them in more detail.

Classification of holes according to various criteria

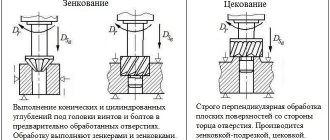

As already mentioned, holes come in a variety of shapes, sizes, with and without special elements. The main types of holes include through, coaxial and blind. Each of them has unique features and is used in the manufacture of mechanisms and parts that are not similar to each other. Another parameter by which holes differ is the processing of the top edge (this can be a counterbore or a countersink). For the latter, the upper edge is bored with a drill with a large diameter, and in the second, a cylindrical recess is made with a special device.

Drilling, countersinking, reaming

Drilling

- one of the most common methods for producing blind and through cylindrical holes in solid material with an accuracy of H12-H13 grades and a surface roughness of Rr20 - Rr80.

The cutting tool here is a drill, which makes it possible to obtain holes in solid material and increase the diameter of a previously obtained hole (drilling). The main movement when drilling is rotational, the feed movement is translational.

A twist drill (Fig. 65, a) is a cylindrical tool, on the surface of which there are two helical grooves that form cutting edges. The drill consists of a working part and a shank, connected by a neck. The shank is used to secure the drill in the chuck or machine spindle. Shanks are either conical or cylindrical.

The working part of the drill performs the main cutting work. The cutting edges are formed by the intersection of the front surfaces of the spiral grooves with the end surfaces of the drill.

The transverse edge (bridge) is formed by the intersection of the two rear (end) surfaces of the drill. Its presence negatively affects the cutting process, making it difficult for the drill to penetrate the metal.

The main angle that determines the shape of the cutting edge of the drill is the apex angle of 2φ. It affects the correct operation and performance of the drill. The value of the drill tip angle 2φ depends on the properties of the material being processed: for example, for steel 2φ = 116-120°, and for brass and aluminum alloys 2φ = 130-140°.

Types of holes by processing methods

Depending on the processing method, all holes are divided into:

- Fastening holes - for bolts, studs, rivets and other similar parts. The quality of such holes is about 11-12. Manufactured using special drilling equipment;

- Smooth or stepped holes - for rotating elements in installations, mechanisms and large special equipment. They can be made both on drilling equipment and on lathe. In this case, methods of boring, countersinking, reaming and others are used.

Please note that all of the above processing methods allow you to achieve different surface thicknesses, for example, these could be:

- Deep holes – length to diameter ratio of five or more.

- Critical holes - quality not lower than 7 (needed for machine body parts).

- Shaped holes - are made with special tools with a cutting part.

- Profile holes are made by chiselling, drawing or stitching using special equipment.

We have analyzed the main types of holes used in mechanisms and parts of special equipment. Not a single modern equipment can do without them. But creating such holes requires a special approach.

General information about drilling wood and wood-based materials

Drilling is the process of mechanical processing of parts made of wood and wood materials (fibreboard, MDF, chipboard, laminated chipboard, OSB). The result of drilling is the formation of through and non-through holes, as well as cylindrical sockets.

Drilling is not one of the basic methods of cutting wood and wood-based materials, such as sawing or milling, but is quite widespread. Drilling is especially widely used in the production of cabinet furniture, in particular for the formation of holes or sockets for connecting parts.

Drilling is a special case of creating holes in parts made of wood and wood materials. Holes of rectangular, conical and other shapes other than cylindrical are made by milling, but this is a topic for another article.

Drilling in wood and wood-based materials is done using a specially designed woodworking tool called a “drill.” Drilling can be done manually (drill, electric drill) or on specialized drilling or drilling machines.

The process of drilling wood and wood materials

Drilling holes in wood and wood-based materials, regardless of the type of force applied, can be done in two ways:

- the drill rotates and feeds onto the workpiece, which is fixed to the base;

- the drill rotates, the workpiece is fed onto the drill along with the base.

Drilling wood is a complex cutting process that combines longitudinal, transverse and end cutting to varying degrees. The proportion of one or another type of cutting depends on the direction of drilling in relation to the direction of the wood fibers and the shape of the cutting part of the drill. When drilling, the end cutting edges are cut.

The trajectories of the relative movement of any point on the blade are helical lines of the same pitch, but with different angles of elevation. The process of drilling holes is a discontinuous process. Cutting alternates with idle movement of the drill or workpiece to its original position, which determines the operating mode of the tool.

Using drilling in the production of wood products and wood materials, through and non-through holes of various diameters and depths are obtained.

The most common drilling tools are hand-held mechanical and electric drills. Such a tool, however, does not allow drilling precise holes, for example, for ties of furniture elements.

The next best quality equipment for producing holes in wood and wood-based products is a drilling machine with one drilling head or a special drilling and attachment machine, which is equipped with one or more blocks with 21 or more drilling heads in each. The workpiece or the tools used must be rigidly fixed to the machine.

Rigid fastening makes it possible to drill holes of the same depth strictly perpendicular to the surface and adjust the drilling depth. The correct choice of drill rotation speed is important. Holes of large diameters and in hard wood and wood-based materials are drilled at reduced speed.

Rules for drilling holes

Holes can be drilled in two ways: according to markings or jigs - the method is selected based on the quantity and quality of the workpieces. During work, the master must follow these rules:

- When through drilling, it is important to consider how the part is secured: if on a table, it is placed on a support to ensure free exit of the drill.

- The drill is brought to the workpiece after the spindle begins to rotate. This ensures a relatively low load when touching the workpiece surface, otherwise there is a risk of damage to the cutting edges of the tool.

- The spindle rotation should not stop when the drill is inside the part. Failure to comply with this rule may result in damage to the instrument.

- If a grinding noise is heard during operation, or there are vibrations due to jamming, misalignment, or wear of the drill, it is necessary to remove the drill from the workpiece as quickly as possible, then stop the machine.

- When creating deep holes (l > 5d, where I is the depth of the hole, mm; d is the diameter of the hole, mm), the drill is removed from the workpiece from time to time to lubricate it and free it from chips. Such procedures can significantly reduce the likelihood of tool breakage or dulling too quickly.

- Holes with a diameter of more than 25 mm are drilled in solid metal in two transitions with drilling or countersinking.

- Drilling is carried out in accordance with the modes recorded in technological maps, reference tables, or according to the recommendations of the foreman/technologist.

- Holes in workpieces made of steel and viscous materials are made using cutting fluids. As a result, the tool is protected from premature wear and cutting conditions are increased.

Drilling through and blind holes according to markings is used in the production of piece workpieces and small batches, because in this case the production of jigs turns out to be impractical from a financial point of view. The driller receives workpieces with marked control circles and the center of the planned hole. Or he can do all the necessary markings himself.

The marking method involves preliminary and final drilling. At the first stage, manual feed is used, while a small hole is drilled (d = 0.25). Next, the spindle and drill are retracted, the chips are removed, and the result is checked against the previously prepared markings.

If no errors were made during the manufacture of the preliminary hole, the work is completed. If the hole has shifted relative to the planned zone, adjustment is necessary. To do this, use a narrow chisel to cut 2-3 grooves on the side of the center into which the displacement will be made. The grooves will help guide the drill to the intended location. When the offset is removed, you can complete the job.

Recommended reading

- Cutting copper with a laser: advantages and disadvantages of technology

- Types of metal cutting: industrial applications

- Metalworking according to drawings: convenient and profitable

Another method for drilling through holes involves using a jig. Directing the cutting tool and fixing the workpiece according to the requirements of the technological process can be carried out using different jigs. The permanent mounting bases of the device and the jig bushings give the drill direction and ensure higher processing accuracy. In this case, the worker performs several simple actions: installs the jig, the workpiece and removes them, turns the spindle feed on and off.

What is a blind hole, why is it blind, how and with what to drill a blind hole?

In my opinion, it is easier to define this concept in comparison.

A through hole is a hole that passes through the entire workpiece, but a blind hole is a hole that is drilled to a certain depth and no more, that is, it does not pass through and does not have an exit from the other (opposite) side of the workpiece, or the wall.

Of course, the word “deaf” is used here not in a literal, but in a figurative sense.

To put it simply, blind means a hole that has a limited depth and no exit from the reverse side.

If we are talking about drilling a blind hole at home (that is, without a drilling machine on which you can set a limit on the drilling depth), then such holes can be drilled with a drill, or with a hammer drill.

Before choosing a drill or drill bit for a hammer drill, you need to consider what material the hole is being drilled into.

If it is wood, you need wood drills (feather, spiral, etc.).

If it’s metal, then drills for metal; if it’s concrete, then you need at least an impact drill with a drill with a Pobedit tip, or even better, a drill with a Pobedit tip and a hammer drill (an impact drill is a weaker tool compared to a hammer drill).

You can purchase a special stand for the drill with a drilling depth limiter.

If there is no stand, then I often use a drill like this with a drill depth limiter.

The limiter is essentially a “stop” beyond which the drill will not go.

If you don’t have anything (a stand, a drill with a limiter), then you can use the “old-fashioned” options.

For example, we determine the drilling depth, then we wind a wire onto the drill, preferably a soft one, and the wire is wound clockwise.

That same wire will be a guide for you (or a “beacon”); instead of wire, you can use electrical tape.

Any hole for installing a dowel, for example an expansion one, is made “blind”.

But some types of dowels require through holes in some surfaces.

For example, drill drywall for installing a butterfly dowel, or Molly dowel, a through hole is drilled.

In general, a blind hole is drilled like this:

We make markings on the workpiece or on the wall.

Next, we need to core, otherwise the drill may move to the side during entry.

If it is a tree, then you can use an awl to mark it.

If there is a drill depth limiter on the drill, set it to the desired position.

We hold the drill at right angles to the surface, begin to drill, if the situation and the base material require it, then periodically remove the drill from the hole and cool it.

If we are talking about concrete, then it is better to use a hammer drill; drilling is done with impact.

If the hole is for installing an expansion dowel, determine the length of the dowel plus a few mm.

And there are hammer drills with a drilling depth limiter.

The process is similar, we hold the hammer drill at a right angle, periodically remove (but only if necessary) the drill from the hole, cool the drill, and clean the hole.

When drilling wood, a blind hole can be made in one step without removing the drill, although consider the thickness of the workpiece and the drilling depth.

Drill bits for wood and wood materials

Drills for processing wood and wood materials have different designs - spiral, screw, feather, Forstner drill, etc. Twist drills are mainly used to create holes.

Spiral . The most common type of drill for wood and wood materials. Options are produced for hand tools and machine drilling. Available in various diameters from 3 to 50 mm. Drills for through holes have a pointed end, while drills for blind holes have a special tip design.

Screw . A subcategory of twist drills, the drilling process occurs by drilling against the growth of the wood grain. Typically used for hand tools. Twist drills are available in a variety of diameters, lengths and weights. A design feature is the presence of a threaded screw for removing chips and a tip for precise installation of the tool.

Feather . This type of drill is the most balanced in weight; it allows you to work at higher speeds, but does not provide high accuracy and quality of processing, therefore it is not suitable for finishing work.

Forstner drill . A special type of screw, designed for making blind holes for installing hinges.

To drill holes in parts made of wood and wood-based materials, spiral or screw drills with conical sharpening, made of high-speed steel, are usually used. Their blades are made in the form of helical grooves running down to the guide tip at a certain angle.

In addition to drills made of high-speed steel, for drilling into parts of especially hard wood and wood materials, drills with carbide tips are used, which form a particularly wear-resistant cutting edge.

Safety precautions when drilling

When through drilling, regardless of the depth of cut, the following rules must be followed:

- Medium and large workpieces are firmly fixed on the machine table or in fixtures. The immobility of a small product during operation is ensured with the help of hand vises. Under no circumstances should you hold the part with your hands.

- It is prohibited to change or install a tool in a rotating spindle, except in situations where the spindle is equipped with a safe chuck that allows you not to stop the machine to make such a replacement.

- Do not transfer belts from one pulley stage to another if the electric motor is turned on. Such actions are only permissible when the machine is stopped.

- The shavings cannot be brushed off the table with your hands, even with mittens; they cannot simply be blown away. Brushes or hooks are used to clean the work surface.

- Hanging ends on workwear are not allowed. The sleeves are buttoned or rolled up above the elbow. The specialist must tuck the hair under the headdress.

- Processing fragile materials may be accompanied by flying chips, so the worker must protect his face with special glasses.

- When using an electric drill, you must wear rubber gloves, and the body of the tool is grounded.

And one more rule: you cannot be distracted while drilling. You must always be sure that your hands are not under the raised tool, even when the unit is not working.