Belting

Most common in metal-cutting equipment.

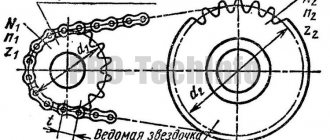

It rotates the drive pulley from the electric motor. This transmission consists of two pulleys located on shafts and connected by a belt. The belt, when stretched, creates the movement of pulleys, of which one is the drive and the other is the driven.

The pulleys can be fitted with flat or V-type belts.

Flat belts

The material for flat belts is leather, cotton yarn or rubberized fabric. The belt must be long, so more than one ribbon is sewn together. The belt can be glued or stapled together.

V-belts

For V-belts, rubberized fabric is used. The profile of such belts resembles a trapezoid. The belts are placed in grooves, which prevents slipping and promotes smooth movement. Due to this, V-belts are more popular than flat belts.

What is included in a car's transmission?

Vehicle transmission components:

- Clutch, clutch or friction clutch (the latter option is often found on agricultural machinery, such as tractors). Disconnects the engine from the transmission and smoothly connects them when changing gears, when starting to move. The basis of most clutches is a friction disc or discs pressed against the flywheel or pressed together. The clutch can be controlled mechanically (pedal), hydraulically or electrically.

- Gearbox (gearbox). The main function of any gearbox is changing the relationship between angular speeds, shaft torques, angular and linear movements (that is, changing the gear ratio). The unit allows you to change the torque, speed and direction of movement of the vehicle, as well as disconnect the engine from the transmission. The design of the unit depends on the type of gearbox.

- Transexl - drive axle in a block with a gearbox.

- The cardan is a mechanism that transmits torque between the shafts in front-wheel drive cars and from the gearbox to the rear wheels in rear-wheel drive cars.

- Carter. The casing in which the main gear, axle shafts for attaching the hubs of the drive rings and the differential are located.

- Main gear. Increases torque and transmits it to the axle shafts of the drive wheels, adapts engine power to operating conditions.

- Differential. Distributes torque between drive shafts and allows the wheels to rotate at different angular speeds. Driving safety when turning on a dry, smooth road depends on the differential. The differential can be made in the form of a clutch (viscous or frictional) or worm semi-axial gears (Thorsen differential) with automatic self-locking of the mechanism at the moment of the difference in torque on the drive shaft and the housing.

- Half shafts Transmits torque from the differential gear directly to the wheel (via the hub).

- Angular velocity joints. They transmit torque from the differential to the drive wheels. CV joints, unlike transmissions, are able to operate unhindered at significant angles of rotation (up to 70 degrees).

- Transfer case (“transfer case”). A device aimed at distributing engine force over the drive wheels. The transfer case helps increase torque when driving on bad roads, off-road, and distribute torque between the drive axles of the vehicle.

To increase functionality, ergonomics, and competitiveness, the vehicle transmission structure is constantly being improved. Let's consider the popular all-wheel drive MT 4Matic, xDrive, 4Motion, Quattro.

Features of popular transmissions 4Matic, xDrive, 4Motion, Quattro

- 4Matic all-wheel drive systems (installed on numerous Mercedes-Benz passenger models) with permanent all-wheel drive include freewheel and center differentials that allow the engine torque to be divided into two axles. Each axle, thanks to free differentials, can rotate freely at different speeds. In addition, the 4Matic provides driving control through a stability control system (traction control, anti-lock brakes and traction control are provided).

- xDrive all-wheel drive transmissions (developed by BMW) are distinguished by the presence of a friction multi-plate clutch. It acts as a differential. Also, one of the main features of the solution is that the system provides the ability to redistribute the interaxle torque in the widest possible range (0 to 100%).

- Quattro system (Audi). A distinctive feature is that the MT and ICE are located longitudinally. Most Quattro transmissions have an electronically locking differential. Thanks to it, the problem of slipping of the drive wheels when accelerating on a slippery road surface automatically disappears.

- 4 Motion (popular MT Volkswagen). The peculiarity of the scheme is that the torque of the internal combustion engine is distributed among the axes depending on the situation on the road.

Most Quattro and 4Motion transmissions have an electronically locking differential. Thanks to it, the problem of slipping of the drive wheels when accelerating on a slippery road surface automatically disappears.

Worm-gear

Transmits rotation to shafts that do not intersect, but are located at an angle of 90 degrees. The worm and the worm wheel interact, where the worm is the leader, and the worm wheel plays the role of the slave.

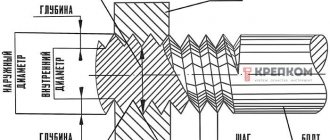

The worm has the shape of a screw with a trapezoidal profile and can have one, two or three starts. Typically, worms with more than three entries are a rare occurrence.

Used in the apron mechanism. Falling worms are also used, which, in addition to the main function, automatically turn off the caliper.

Classification

Transmissions are usually classified depending on the method of energy transmission (type of torque converter, vehicle drive, used gearbox.

Depending on the method of energy transmission, the following types of vehicle transmission are distinguished:

- Mechanical. Energy is transmitted through mechanical friction in the clutch, the interaction of hinges, and gears.

- Hydromechanical. Torque occurs due to mechanical friction and hydraulic work. TMs work here thanks to a fluid coupling, a torque converter.

- Hydraulic. Rotation is due to the injection of oil to the hydraulic turbine under high pressure. That is, energy transfer is carried out through liquid.

Depending on the drive, there are front-wheel drive, rear-wheel drive and all-wheel drive transmissions.

How they differ can be judged based on the features of the device diagram given at the beginning of our material. Depending on the gearbox, the transmission is:

1. Mechanical. 2. Automatic. 3. Robotic. 4. Variable (stepless) - with a variator.

Read more about transmissions with different types of gearboxes in our material “Gearbox”.

Helical gear

Serves to convert rotational motion into translational motion. A screw with a nut attached to it rotates, as a result of which, through the nut, linear motion is transmitted to the parts connected to it. In this way, translational movement is imparted to the cutter when cutting threads or transverse feed. As a result, you get smooth and precise movement and, when reverse gear occurs, self-braking. Most often used on turning and screw-cutting equipment.

Hydromechanical transmission

The unit is characterized by the presence of a hydromechanical gearbox (the design combines a mechanical gearbox + a hydrodynamic torque converter).

The greatest efficiency of the system is observed when it has automatic control. A torque converter with wheels with curved blades, which is a mandatory element of such a unit, automatically changes the torque transmitted from the engine.

The process of transmitting torque is subject to changes in the load on the gearbox output shaft.

- The freewheel starts the process of rotation of the reactor wheel in only one direction. It coincides with the rotation path of the pump wheel.

- The working area is filled with oil under pressure.

- The pump wheel rotates.

- The pump vanes capture the oil.

- Under the influence of centrifugal force, the oil ends up on the turbine wheel.

- Oil enters the reactor.

- The direction of fluid flow changes.

- The oil flows back into the pump wheel.

Thus, there is a closed circulation of oil on the face.

Pros and cons of hydromechanical solutions Hydromechanical solutions are valued for their wide range of adjustment of gear ratios, the ability to provide stepless changes in energy flow parameters, reversal, and quick response to changes in operating conditions and the situation on the road. It is possible to automate the process of switching speeds and establish full control over the filtering of torsional vibrations. Hydromechanical MTs are very popular with agricultural, municipal vehicles, and heavy-duty road trains. The solution is perfect for transferring power flow from the internal combustion engine to the drive of the drive axles. The installation of such units is also common on mining dump trucks. It is possible to eliminate dynamic loads on shafts and excess disk friction.

The most popular and efficient are hydromechanical automatic transmissions.

True, with many advantages, they also have disadvantages:

- The ratio of the torque on the driven link to the torque on the driving link (that is, the transformation ratio) is quite low (does not exceed 3).

- There are difficulties with increasing braking force (this problem is acutely felt when entering the internal combustion engine braking mode.

- High material consumption.

Hydrostatic transmission

The GST transfers rotational energy from the internal combustion engine to the wheel or auger through a pump by directing the working fluid to the hydraulic motor.

The solution is most often installed on vehicles if it is important to provide a large gear ratio. The main objects where MTs of this type are installed are grain harvesters, road construction machines, and bulldozers.

GST does not prevent vehicles from slipping on viscous soils, and when moving back and forth it is easy to ensure straightness of movement. Even if the bulldozer blade is released as much as possible, the vehicle does not stall when moving slowly forward. This is especially valuable when working with a bulldozer.

GTS does not have a high level of efficiency, but the internal combustion engine of such TMs operates more economically when compared with a mechanical transmission.

Hydraulic transmission

Instead of dry friction of mechanical MTs, a torque converter is used. Planetary gears are used to transmit torque, helping to create ideal conditions for implementing a wide range of gear ratios. In particular, such solutions are not afraid of strong vibration loading.

Huge advantages of the solution:

- There is no interruption in the power flow when changing gears.

- The solution provides excellent transmission of torque.

- There is no need to apply impact forces to operate the gears smoothly.

But in order to get the most out of a unit with a torque converter, you have to take care of installing your own fluid coupling for each gear.

The most common transmission breakdowns

- A loud noise when the clutch is engaged is a “symptom” of wear of the springs (fork, damper) or the appearance of a gap in the spline joint. Most often, the solution to the problem is to replace the driven disc or springs, but sometimes it is enough to simply secure the fork spring more thoroughly.

- An increase in noise when the clutch is disengaged is a signal of wear and damage to the gearbox shaft bearings. As a rule, the problem is solved by replacing the bearing.

- “Lubricated” gear shifting. It occurs as a response to the wear of many parts. A detailed diagnosis and replacement of one or more parts is important - retainer springs, balls, “crackers”, gears, clutches, gear selector levers, synchronizer locking rings.

- Oil is leaking from the gearbox. Most often the problem is wear of the oil seals or gaskets, and they need to be replaced. But the problem may also be a loosening of the crankcase or its covers. In this case, adjustment of the fasteners (nuts) is required.

- The gearbox makes a hum and noise. This often happens when the oil level in the box is insufficient. And here it is important to understand the cause of the oil leak, eliminate it, and then restore the oil level to the required standards. In addition, the problem may be related to wear of synchronizers, bearings, and gears. In this case, they need to be replaced.

- When the vehicle goes uphill, slippage begins. Downshifting begins prematurely. Here, as in the previous case, the reason is most often a drop in the oil level. But simultaneous wear of the piston cuffs and clutch discs cannot be ruled out. This may be a direct incentive to replace them.

- Engine knocking at idle. This is evidence of the end of the life of the friction clutch discs. The problem can only be solved by replacing them.

Interactive training!

Based on LCMS ELECTUDE, a special training course and test system for testing knowledge of “Car Transmission” are available. 29 training modules are excellent opportunities to study the structure and operating principle of different transmissions. Great attention is paid to the device and service.