The hand hacksaw has been replaced by a reciprocating electric saw, used for sawing various materials - wood, concrete, metal, aerated concrete and others. To cut these materials, appropriate reciprocating saw blades are used. Before purchasing them, you need to understand the types, labeling and application features.

Types of shanks for reciprocating saw blades

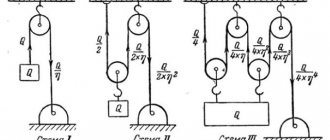

Reciprocating saw blades are consumables through which useful work is performed. To connect the attachments to power tools, they have a special shank design. This design differs from jigsaw blades, although many people often confuse them. Structurally, shanks for reciprocating saws have the following types, as shown in the photo below.

This is the most common type of L-shank and is locked into the tool chuck by a ball clamp. This is the most common shank design on electric saw blades. The sizes of the shanks differ, which depends on the power of the tool for which the attachment is purchased. For household and semi-professional reciprocating saws, blades with a small shank size are used, and for professional ones, with a large one. In addition to this shank design, U-shaped shanks are also found on saw blades for reciprocating saws. Structurally, they have a similar design, but with an additional eyelet. The design of such a shank is shown in the photo below.

Other types of shanks on saw blades for reciprocating hacksaws are also less common. These are often attachments that are designed for specific instrument models.

Many people mistakenly believe that reciprocating saw blades have a similar design to the attachments for electric jigsaws. For comparison, you can see what types of shanks are used on jigsaw files.

To buy the right blades for your reciprocating saw model, you first need to make sure what type of chuck is used on the tool. To do this, just look at the form of fastening of the existing blade, which comes with the tool. If you cannot determine on your own what type of fastening to buy hacksaw attachments for a reciprocating saw, then it is enough to tell the seller the brand of the tool and the power of the tool.

This is interesting!

The tail can be straight or angled. The presence of a slope indicates that the canvas is intended for work in aggressive conditions.

What types of reciprocating saw blades are available?

A reciprocating saw is a multifunctional tool, so it will definitely come in handy on the farm. After all, it can be used to cut various materials, such as wood, metal, brick, concrete, foam concrete, and plastic. The functionality of the tool depends on the type of blades used. This means that for sawing wood it is necessary to use special saws for wood, just as for metal, brick and aerated concrete. We will look in more detail about what blades for reciprocating saws are available and what design features they have below.

Wood blades design characteristics

One of the most popular saw blades for reciprocating saws is wood cutting attachments. The main difference between these nozzles is the presence of markings with the designation HCS. This marking indicates the type of steel from which the nozzle is made. HCS is a high-carbon alloy steel from which saw blades are made for cutting wood (both soft and hard wood), chipboard, plywood, fiberboard, rubber and even plastic. For the specific materials being cut, appropriate blades are used, differing in the design of the teeth.

Manufacturers produce canvases up to 400 mm long. If you plan to saw wood that may contain nails and other types of metal fasteners, then it is better to use wood saws with carbon fiber. The presence of carbon increases not only the reliability, but also the durability of the nozzle, however, their price is 1.5-2 times higher than conventional carbon materials. Nozzles according to the shape of the working part or the height of the profile are of three types:

- With variable profile height - when the part near the shank is wider than the end. Such attachments are used when the evenness of the cut is not important, but on the contrary, when it is necessary to make a curved cut in the material

- With the same profile - they are highly stable when sawing material. Stability lies in the fact that the file does not vibrate during the work, which means the cut is smooth

- For figured cutting, special blades with the same thin shape of the working part are used

The teeth on the nozzles come in different sizes, as well as with variable, constant, wide and narrow pitch.

- Wide pitch - the blade is used for sawing thick solid wood

- With large teeth - designed for sawing wood along the grain. The largest teeth have 3 teeth per inch (TPI). The larger the size of the teeth, the correspondingly higher the productivity of such an attachment.

- With small and large alternating teeth or variable pitch - when sawing is carried out across the grain, including for cutting damp (wet) fibrous wood

- With a constant pitch - for cutting homogeneous wood and materials

- With a narrow pitch - used for sawing plastic, as well as wood with metal fasteners, when it is necessary to ensure a neat and even cut

- With the inscription “Demolition” - intended for dismantling work. They are thicker and more durable in construction.

A reciprocating saw with wood blades is used not only when performing construction and carpentry work, but is also successful when pruning garden trees in a summer cottage or garden area. Cordless models of reciprocating hacksaws replace loppers. Popular manufacturers of canvases are DeWalt, Hitachi, Diablo, Marathon, Milwaukee and others.

This is interesting!

Wood blades are also made from bimetal (double metal).

This increases not only the service life of the equipment, but also efficiency, for example, when cutting wood with nails. If you are working on cutting wood with metal fasteners, then it is recommended to use attachments with at least 5-6 teeth per inch. One of the most popular types of reciprocating saw blades are bimetallic, which are designated BIM. They are made using two types of materials - high-carbon and high-speed steel. This combination of two types of steel in one nozzle made it possible to obtain files with such important advantages as high strength and flexibility.

Hand saw

It makes sense to use a hacksaw if the amount of work is small. A hand saw for aerated concrete is perfect for cutting additional blocks and fitting door and window openings. Also, a hacksaw is used when laying the finishing row of block masonry.

The cutting blade of such a saw must be made of carbide metals (for example, high-carbon steel). To cut gas blocks, you need to choose a hacksaw with larger teeth. It is best if they are made of monocarbide, tungsten, cobalt or other cermet alloy. Saws with pobedit teeth are very popular. One such sheet is enough for 25 m2 of aerated concrete. Also, rapid blades performed well.

The cost of a hacksaw for aerated concrete depends on the manufacturer.

The best hand saw manufacturers

Among the most popular companies:

- YTONG. A hand saw from this manufacturer will cost about 2,000 rubles. The model has a comfortable plastic rubberized handle, so it does not slip out of your hands during operation. Users also note its wear resistance and long service life.

- ANCOR. The company produces high-quality hacksaws with blades up to 670 mm long. The most popular model “Raven 9847” will cost no more than 1,000 rubles. The main advantage of this model is the handle, made of two-component material.

Metal cutting blades on a reciprocating saw, how they are marked and what can be cut

With a reciprocating saw you can cut not only wood, but also metal, but you will need a special attachment for this. Metal cutting blades for reciprocating saws have the designation HSS, which stands for high-speed tool steel. The teeth on such blades are small, and attachments are used for sawing non-ferrous metals, steel products with a thickness of no more than 5 mm, and sheet materials. The length of the nozzles for metal reaches 300 mm.

Metal blades have different thicknesses, which allows not only straight cutting, but also at an angle, for example, when it is necessary to cut off a protruding part of a pipe from a wall. The end part has a pointed shape, which allows through cuts of sheet materials. Let's look at the design features of metal files:

- For figured cutting, the nozzle has a small profile and also a short length, which makes it very convenient to make various kinds of shapes in sheet steel material. The number of teeth per inch is 18 pieces

- With the same profile height - vibration is eliminated when sawing metal

- With different numbers of teeth per inch - you've probably wondered why manufacturers of metal bits produce them with different pitches. The more teeth per inch, the smaller their size, which allows you to efficiently saw small workpieces such as wire. If you need to cut thick metal, then blades with large teeth are used, which means small pitches - 10-14 TPI

- With different pitches - there are metal blades that have different pitches. This design makes the cutting equipment more efficient and highly class=”aligncenter” width=”570″ height=”355″[/img]

- With unequal profile sizes - as a rule, they have a long design and are used to perform work in hard-to-reach places. For example, if you need to cut off a protruding pipe from a wall flush. The design of the reciprocating saw will not allow this to be done as smoothly as possible, so all hope lies in the cutting attachments

Popular manufacturers of metal cutting blades for electric reciprocating saws are DeWalt, Irwin, Milwaukee, Diablo, Bosch, Hitachi, Metabo. There are cheaper options from lesser-known manufacturers.

Manufacturers

The pendulum saw segment is represented on the market by products of dozens of companies and brands. We included in our review a description of the most reliable tools, whose durability and performance have already been recognized by specialists and amateurs.

Bosch

Bosch reciprocating saws occupy flagship positions in the segment. The technical solutions made by the company are based on the achievements of the German engineering school.

The individual features of hand-held power tools of this brand include: ergonomics, reliable operation, durability, and high cutting precision.

Bosch reciprocating saws are distinguished by their high power and advanced functionality, which makes the tool super versatile.

Product prices are quite high, but the company confidently maintains leadership in the niche of elite professional and household tools.

Budget models are represented by tools like the PSA 700 E, a universal saw for cutting wood and plastics, capable of cutting material up to 250 mm thick. Such a device can be purchased for 5,500 rubles (price for 2022)

One of the most expensive models is the Bosch GSA 36 V-Li. This is a professional tool that can work non-stop for more than 4.5 hours in autonomous mode. The two-speed unit provides 3000 saw blade movement cycles per minute. The cost of the instrument reaches 53 thousand rubles (price for 2022).

AEG

Saws with the abbreviation AEG have sufficient power and reliability, and at the same time belong to the class of budget tools.

The company offers:

- Compact devices like US 400 XE. They allow you to work with one hand in particularly hard-to-reach places. The weight of this “toy” is 1.7 kg. The saw, at the same time, provides a sufficient level of power - 400 W, and speed - 3500 strokes per minute.

- Saws equipped with both wide and thin blades. A special feature of the tool is the ability to make figured cuts with a bending diameter of 10 cm.

- General purpose saws, quite versatile, such as the AEG BUS 18-0. The 1.8 kW tool provides 3.6 thousand blade movements per minute. This saw can be used to process any material – from rubber to aerated concrete.

There are a wide range of saws for autonomous operation, equipped with lithium batteries.

AEG brand tools are sold in the price range of 3,800–13,000 rubles.

Makita

Reciprocating saws of this brand, according to numerous reviews, are distinguished by their quality and durability. The tool is able to withstand long-term loads and at the same time maintain functionality.

The costs of working with Makita include fairly high noise and vibration.

The company produces reciprocating saws in three segments:

- Compact tool weighing from 1.3 kg for small garden and repair work. Saws can be either battery-powered or corded. An example of such a product is the JR105DZ model. The minimum price for such a device can be 2.4 thousand rubles.

- Tools with a power of 1 kW cost 4.5 thousand rubles and more. These are products of a popular class with a full functional set: a pendulum mechanism, a two-position speed switch, and safety equipment.

- The most expensive members of the Makita reciprocating saw family are models like DJR181RFE. The power of their engines reaches 3.8 kW, the operating time is 3 hours. This tool weighs 3.7 kg.

Metabo

The line of reciprocating saws includes mostly compact, self-powered products. All models are characterized by high durability and excellent performance.

The disadvantages include minor malfunctions, such as opening the battery latch, caused by inconvenient coverage, fairly strong vibration, and weak wire connectors (in some network models). Moreover, defects begin to appear after the 3rd, or even after the 5th year of operation.

The price range of Metabo reciprocating saws occupies a niche between 6 thousand rubles and 26 thousand. The model range includes more than 20 saws with different powers, different speed capabilities and many functional differences.

The distinctive features of Metabo saws include ease of use: compact tools with highly ergonomic characteristics are perfectly suited for autonomous use in various conditions - in the garden, in the garage, on a construction site, etc.

Advantages of the tool: a body made of a particularly durable polymer composite, a mechanism for quick blade change, the presence of soft start and emergency engine shutdown systems.

Blade for sawing aerated concrete as designated

For cutting aerated concrete or foam concrete, blades with the designation HM or CV are used. The abbreviation HM stands for “hard material”, the degree of hardness of which reaches 79 HRC on the Rockwell scale. The nozzle with the designation CV is chrome vanadium, and they also have increased hardness, which is very important when processing materials such as aerated concrete, tiles, fiberglass, and fiberglass. To increase the strength parameters, the teeth of such blades have pobedite soldering.

This is interesting!

The presence of the CT designation indicates that the equipment is made of carbide tipped. These hard alloys include tungsten, titanium, cobalt, tantalum and others.

Types of paintings

The most important part of a reciprocating saw is the saw blade: the quality of the cut and the operating time of the tool depend on it. These components usually have a narrow specialization, intended for a specific list of materials. Various manufacturers can apply classification both according to the material used to make the fabric and according to its scope of application.

For aerated concrete

The manufacturing material is hard alloy (marked HM/CT). The tools are capable of sawing porous and hard materials with significant abrasive characteristics - aerated concrete, concrete, tiles, etc. Metabo brand components are famous for their special quality. The condition for a quality cut is sufficient power of the electric motor.

Woodworking (HCS)

The material used may vary:

- Regular high carbon steel. Most often, such blades are included with the reciprocating saw.

- With increased carbon content. They are characterized by increased reliability and durability, which is reflected in a higher cost. Purchased separately or included in special kits.

HCS blades are an excellent option for sawing various soft materials - wood, wood panels, plastic products. The arrangement of the teeth on the cutting edge can be different, but most often there are models with teeth equidistant from each other. As for devices with variable pitch, they are convenient for performing specific tasks. For example, if there are nails in the workpiece. The most popular representatives of this line are wood canvases.

For metal (HSS)

Thanks to the use of high-speed tool steel, this blade has the ability to cope with aluminum and steel products, including sheets, pipes and profiles.

To ensure the ability to cut flush or along a curve, the tool is made curved or bendable. The tip is given a specific shape, allowing for through cuts. Important! As practice shows, sawing through a metal workpiece with one reciprocating hacksaw is an almost impossible task.

In such a situation, the product is pre-equipped with a hole, which will serve as a guide for subsequent processing. As for pipes, they are usually cut by gripping the entire diameter with a saw blade. Most often, these components are manufactured by the DeWalt and Metabo brands.

For brick (HM)

Especially for sawing bricks and similar elements, the blade along the edge is equipped with a special insert made of hard alloy (HM). Popular manufacturers are DeWalt Alligator and Bosch.

Wide profile (BIM)

For the production of these canvases, a combined technology (HCS and HSS) is used. The result is that they are strong, flexible and durable. A reciprocating hacksaw equipped in this way will cut both soft and hard materials with equal success. Most of the instruments on sale are produced using this technology.

Saw blade for processing brick, ceramics and stone

If foam concrete, aerated concrete and tiles are characterized by increased abrasiveness, then brick, ceramics and stone are highly resistant to destruction. To process such materials, you will need other types of reciprocating saw blades, which are made with the addition of silicon carbide, tungsten carbide, chromium and diamond coating on the cutting part.

A distinctive feature of such blades is that they do not have teeth. The cutting part consists of spraying hard materials. They are quite expensive, but a tool with such a blade can even cope with marble and granite materials.

Which saw blades are suitable for sawing cast iron?

There are often disputes among tool owners about whether it is possible to use metal blades for cutting cast iron. Of course it is possible, only ordinary equipment for cutting metal in this case will quickly become dull and become unusable. For processing cast iron, it is recommended to use bimetallic blades coated with tungsten carbide or diamond. Moreover, diamond-coated blades cope not only with cast iron, but also glass, as well as other similar heavy-duty materials - ceramics, porcelain stoneware, concrete, reinforced concrete and others.

Which reciprocating saw attachment to choose for cutting plastic

Metal files can be used to cut plastic and plastic products, but manufacturers produce special attachments specifically for processing these materials. Different types of steel are used to make files, but the distinctive feature of the attachments is the design of the teeth. They have an M-shaped configuration, as well as the corresponding designation - Fiber Plaster or Plaster. To prevent deformation of the sawn plastic during the cutting process by heating the blade, it is recommended to use water cooling during operation.

This is interesting!

The disadvantage of blades with diamond, tungsten carbide and other similar coatings is that they are afraid of overheating. If they are overheated, the coating begins to crumble, so it is recommended to carry out work using water cooling.

Marking of reciprocating saw blades

There are markings on the reciprocating saw blades, which can be used to determine the exact purpose of the attachment. The marking is indicated on the shank of the nozzle. The first letter indicates the type of tool chuck for which the attachment is intended. It is designated by the letter S. The remaining designations indicate the design features of the nozzles, as well as their purpose. It is also worth noting that not all manufacturers label their products, which does not mean that these canvases are fake.

The blades also indicate the material from which the nozzle is made, the length in mm and inches, as well as the pitch of the teeth. These parameters must be taken into account before purchasing, which will allow you to choose the most suitable canvas for the relevant types of work.

Safety precautions

Compliance with safety precautions begins at the stage of choosing a cutting blade.

Remember the important thing: the file you install in the holder must match the type of material you are going to work with.

Before working with a reciprocating saw, you should wear safety glasses and a respirator: cutting produces a lot of fine chips that can clog your eyes and settle in your lungs.

When on a construction site, remember to wear a hard hat. You should be especially careful about your equipment when working with machinery. The reciprocating saw is very loud, your attention when sawing is aimed at achieving a high-quality result. Thus, your senses are focused on monitoring the process. You may not notice a danger that you could easily avoid in normal circumstances.

What criteria should you pay attention to when purchasing reciprocating saw blades?

It will not be possible to saw a sheet of metal with a wood saw, just as it is impossible to cut a brick with a metal bit. Moreover, the tool itself suffers from the wrong blade, so the selection of saw blades requires an appropriate, correct approach. To do this, the following indicators are taken into account:

- Teeth - this parameter includes factors such as pitch, size, degree of sharpening and shape. If the teeth are large, then the sawing speed will be high, but there can be no talk of accuracy. Fine teeth ensure not only accurate cutting of the material, but also eliminate the occurrence of chips and scuffing. The teeth on the blades are ground, i.e. Designed primarily for working with soft materials, as well as milled ones. Milled ones are respectively used for processing metal materials, as well as hardwoods

- The type of blade fixation on the tool - what types of shanks there are are described in detail above. When purchasing, you need to make sure what type of chuck is used on the tool

- Size of the workpiece to be cut - the selected blade should be 5 cm larger than the thickness of the material being processed

- Complete set - you can buy either one file for the corresponding material, or a whole set. If you bought a reciprocating saw, then you will definitely need to purchase a set of blades. If necessary, you can use the appropriate cutting attachment at any time

- Features of the movement of blades - the reciprocating saw carries out not only movements in the forward-backward direction, but also pendulum movements. Pendulum movements are needed in order to reduce heating of the canvas. Useful work with this movement is carried out only in one direction, and with the reverse movement, the chips are removed from the cutting site. When choosing, you need to consider whether it is intended for such a cut

- Color - additional information about the purpose of the attachment for processing different materials. Gray cutting equipment indicates that it can be used to process wood. Blue ones are used for metal, and red ones are used for cutting plastic.

When choosing, you should also take into account the price of the equipment and the manufacturer. If a reciprocating saw is used to perform precision work, then it is better not to save money and buy blades from well-known manufacturers, for example, Milwaukee, Metabo, Zubr. If the tool is used for cutting branches, then there is no great need to buy high-quality attachments.

This is interesting!

Saw blades for reciprocating saws differ from saw blades for jigsaws in shape, so it is simply impossible to confuse them when purchasing.

Principle of operation

The saw body is familiar and familiar: its outline resembles a drill. The power unit is traditional - a rotary electric motor of a certain power.

Only the gearbox is made with a significant difference: it consists of a flywheel with an eccentric and a connecting rod - a mechanism that converts rotational motion into reciprocating motion.

Most saws are equipped with a pendulum mechanism. This device ensures the linear movement of the knife forward, and when returning to its original position, it lifts it and deflects it along the transverse axis.

Thanks to this function, the knife does not overheat and is not pinched by the halves of the material being cut. There is another important point: when performing oscillatory movements, the canvas has time to clear itself of dust. As a result, neither the teeth nor the mechanism become clogged with crumbs from the treated surfaces.

To work with aerated concrete, it is better to select models in which the vibration amplitude of the canvas is adjustable.

The speed of the reciprocating saw can be adjusted: the mode can be set according to the hardness of the material being cut.

The working stroke of the blade on saws of different models may vary. Since the flywheel diameter is small, the working stroke of the saw in most mechanisms is 22–28 mm. This class is for household, amateur use. The tools of the described category are low-power: their motor produces up to 1 kW. These mechanisms can work for no more than 20 hours without stopping.

Professional tools are designed for more intensive work: they can be used around the clock. The power of such devices can reach 3 kilowatts, and the saw stroke is 32 mm.

Saws can be equipped with various additional devices that increase the convenience and productivity of work. The most popular additional functions are:

- Availability of a mechanism for quick replacement of the working blade. The essence of the device: the ability to change the file with one hand, without taking off mittens or gloves.

- Ease of use: the handle should be as comfortable as possible, the weight should be distributed. Access to keys and buttons, controls and switches is simple and easy.

- The presence of vibration isolation: one of the fundamental rules of industrial sanitation. Without this function it is impossible to use the tool effectively.

- The presence of a frequency stabilizer is a device that ensures smooth cutting.

- The presence of an emergency switch is a mechanism for disconnecting the electric motor when the blade jams.

- Backlight is a very necessary function in conditions of limited visibility.

Other design additions are possible. Important improvements include the availability of battery power. Such saws can function autonomously for a long time: this quality is especially valuable when a house is being built in an open field and electricity has not yet been supplied to the construction site.

How to use a reciprocating saw correctly with different blades

An electric hacksaw is a dangerous tool, as getting body parts under the cutting part will result in serious injury. To prevent this from happening, you need to know some rules when using the tool. These rules include:

- Work is carried out only and exclusively with the use of protective clothing

- Secure the blade in the tool chuck to prevent it from spontaneously falling out when starting the engine.

- Preliminarily mark the cutting line

- Avoid getting electrical cables and wires under the cutting area.

- It is prohibited to cut a pipeline through which water or other liquids flow, as the operator risks getting an electric shock.

- Do not leave the tool plugged in as children may reach it.

- Sawing materials must be carried out directly from the instrument being turned on. If you apply the blade to the surface to be cut, and only then start the electric motor, a kickback will occur.

- You need to hold the tool with both hands, as at any moment the file can jam and the hacksaw can be torn out of your hands

When cutting relevant materials, it is necessary to use suitable attachments. If you are looking for the best blades for a reciprocating saw, then it should be noted that there are no such blades. To ensure high performance of the tool, it is important to choose not only a powerful reciprocating saw, but also the appropriate attachments for it. The quality and speed of sawing materials depends not only on the power of the tool, but also on the correct choice of hacksaw blades for the reciprocating saw.

Advantages and disadvantages of a reciprocating saw in use

Aerated concrete is a durable material; you can’t take it with any blade. For successful work, you should select hacksaws with pobedite inserts on the teeth.

You can use familiar, now traditional mechanisms - a saw with band or chain blades. However, you will immediately be faced with the fact that these units are bulky and heavy. In addition, during work you will often have to change the canvas.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

In fact, there are no difficulties with selecting a tool. A way out of the situation was found a long time ago. Twenty years of practice in building aerated block houses has proven that there is no better device for aerated concrete than a reciprocating saw.

The main conveniences that you will immediately feel when using a reciprocating saw are:

- possibility of non-stop work for a long time;

- obtaining perfectly smooth, straight cuts;

- durability of the tool - low wear of the file;

- high performance.

The mechanism has a lot of advantages that other similar instruments do not have:

- Versatility: thanks to the presence of replaceable blades, the saw can process any materials - from wood to reinforced concrete;

- Safety: reciprocating movement virtually eliminates the possibility of injury;

- High cutting speed;

- Ease of access – the ability to cut in corner niches, in pockets, inside masonry;

- Reliability: the mechanism has been proven; manufacturers have long taken into account all the difficulties of operating the tool and eliminated the reasons for complaints.

Most reciprocating saws are designed to make straight cuts. However, there is a category of narrow canvases. With them you can cut off parts of various configurations and even make through or semi-through holes.