Perhaps you need:

Screwdriver attachment PH 2x25mm

More details

Screwdriver attachment PZ 2x50mm

More details

Screwdriver attachment PH 2x50mm

More details

The use of special attachments (bits) in assembly technology was at one time due to the rapid failure of the tips of conventional screwdrivers when used professionally. In this regard, replaceable bits, invented in the first half of the 20th century, turned out to be more profitable and convenient.

When tightening several hundred screws with a screwdriver with a tip, they began to change not the screwdriver, but only its attachment, which was much cheaper. In addition, when working with several types of fasteners at once, many different tools were not required. Instead, the only screwdriver required changing the bit, which only took a few seconds.

However, the main motivation for the use of bits was the invention of centered fastener heads. The most common of them are cruciform ones - PH and PZ. Upon careful study of their designs, it can be established that the tip of the nozzle, pressed into the center of the screw head, does not experience significant lateral forces that throw it beyond the head.

Other types of fastening heads used today are also built according to the self-centering system. They allow you to twist elements not only at low speeds, but also at significant speeds with a large axial load.

The only exceptions are S-type straight blade bits. These were historically intended for the very first hand-tightened screws. There is no centering of the bit in straight splines, so when the rotation speed increases or the axial pressure decreases, the bit slips out of the fastening head.

This can result in damage to the front surface of the element being fastened. Therefore, in the mechanized assembly of critical products, connections with straight spline elements are not used.

Its use is limited to less critical fasteners with low tightening speeds. When assembling products with mechanical tools, only those types of fasteners are used that ensure a reliable fit of the nozzle to the fastening element.

Bit classification

Fastening bits can be classified according to several criteria:

- type of fastening system;

- head size;

- bit shaft length;

- rod material;

- metal coating;

- design (single, double);

- possibility of bending (regular and torsion).

The most important thing is to divide the bits into types of fastening systems. There are many of them, the most common ones will be discussed in a few paragraphs.

Almost every type of system has several standard sizes, differing in the size of the tool head and the corresponding fastening slot. They are designated by numbers. The smallest ones start from 0 or 1. The recommendations for the type indicate the diameters of the threads of the fasteners for which the bit is intended under a specific number. Thus, the PH2 bit can be used with fasteners with a threaded diameter from 3.1 to 5.0 mm, PH1 is used for self-tapping screws with a diameter of 2.1–3.0, etc.

For ease of use, bits are available with different shaft lengths - from 25 mm to 150 mm. The tip of a long bit reaches the slots in places where a larger bit holder cannot reach.

How to choose the right type

The selection of bits is made according to several criteria:

- External signs . The type of slot and its features (vandal-proof, offset, etc.) are visually assessed.

- Slot size . The bit number that is optimally suitable for the given hardware is selected. Typically, a specimen is selected that can be held in the slot without falling out of it.

Expert opinion

Kulikov Vladimir Sergeevich

As a rule, bits are purchased in sets. This is convenient and makes it possible to select the appropriate option from the available samples. However, sometimes separate bits are purchased if work is being done on a specific type and size of spline. For example, for confirmation you need an H4 type nozzle, so purchasing a whole set in this case is not practical.

Materials and coating

The alloy material from which the bat is made is the key to its durability or, conversely, the softness of the design, in which, if the specified forces are exceeded, it is not the fastening element that breaks, but the bat. In some critical connections this strength ratio is required.

However, in the vast majority of applications, the user is interested in the maximum possible number of tightenings of the fastener with one bit. To obtain strong bits that do not break due to the fragility of the alloy, and do not deform at the most loaded touch points, various alloys and steels are used. These include:

- high-speed carbon steels from R7 to R12;

- tool steel S2;

- chrome vanadium alloys;

- tungsten-molybdenum alloy;

- chromium-molybdenum alloy and others.

Special coatings play an important role in ensuring the strength properties of bits. Thus, a layer of chrome vanadium alloy protects the tool from corrosion, and sputtering a layer of titanium nitride significantly increases its hardness and wear resistance. Diamond coating (tungsten-diamond-carbon), tungsten-nickel and others have similar properties.

The titanium nitride layer on the bit is easily recognizable by its golden color, and the diamond layer by the characteristic shine of the tip. The brand of metal or alloy of a bat is more difficult to find out; the manufacturer usually does not provide or even hides this information for commercial interests. Only in some cases can a steel grade (S2, for example) be applied to one of the faces.

Units of information

Byte table:

- 1 byte = 8 bits

- 1 KB (1 Kilobyte) = 210 bytes = 2*2*2*2*2*2*2*2*2*2 bytes =

- 1024 bytes (approximately 1 thousand bytes - 103 bytes)

- 1 MB (1 Megabyte) = 220 bytes = 1024 kilobytes (approximately 1 million bytes - 106 bytes)

- 1 GB (1 Gigabyte) = 230 bytes = 1024 megabytes (approximately 1 billion bytes - 109 bytes)

- 1 TB (1 Terabyte) = 240 bytes = 1024 gigabytes (approximately 1012 bytes)

- 1 PB (1 Petabyte) = 250 bytes = 1024 terabytes (approximately 1015 bytes)

- 1 Exabyte = 260 bytes = 1024 petabytes (approximately 1018 bytes)

- 1 Zettabyte = 270 bytes = 1024 exabytes (approximately 1021 bytes)

- 1 Yottabyte = 280 bytes = 1024 zettabytes (approximately 1024 bytes)

Design options

By design, the bit can be single (a tip on one side, a hex shank on the other) or double (two tips at the ends). The latter type has a double service life (both tips are the same) or ease of use (the tips differ in size or type). The only disadvantage of this type of bit is the impossibility of installing it in a hand screwdriver.

Bits can be produced in regular and torsion versions. In the latter design, the tip itself and the shank are connected by a durable spring insert. It works by twisting, transmits torque and allows you to bend the bit, which increases the ability to access inconvenient places. The spring also absorbs part of the impact energy, protecting the bit from breaking the splines.

Torsion bits are used with impact screwdrivers, in which the impact force is applied tangentially to the screwing circle. Bits of this type are more expensive than regular ones, last longer, and allow you to screw long fasteners into dense materials that regular bits cannot handle.

For ease of use, bits are produced in different lengths. Each following standard size (25 mm) is 20-30 mm longer than the previous one - and so on up to 150 mm.

The most important characteristic of a bit is its service life. It is usually expressed in the number of fasteners screwed in before the tool fails. Deformations of the tip are manifested in the gradual “licking” of the ribs as the bit slips out of the slot. In this regard, the most resistant bits are those that are not subject to forces that throw them out of the slot.

The most commonly used systems include H, Torx and their modifications. In terms of strong contact between the bit and the fastener, there are many other systems, including anti-vandal ones, but their distribution is limited for a number of technical reasons.

Features, technical specifications

In addition to the shape of the tip, the technical characteristics of the bits are:

- Length.

- Width (thickness) of the working part.

- Availability of protective coating.

Sometimes a diamond coating is applied to the surface of the tip. It prevents the tool from slipping out of the slot. Typically these bits are used on impact screwdrivers.

Particularly durable types of bits should only be used by experienced and trained professionals. They are capable of tearing off the slot while remaining in working order. Dismantling such connections will require drilling or other complex procedures that take time and negatively affect the appearance of the parts.

Main types of bits used

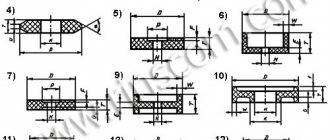

The number of types of bits, including those that have fallen out of use due to low technical suitability, amounts to several dozen. Today, the following types of screwdriver attachments are most widely used in fastening technology:

- PH (Phillips) - cross-shaped;

- PZ (Pozidriv) - cruciform;

- Hex (denoted by the letter H) - hexagonal;

- Torx (denoted by the letters T or TX) - in the form of a six-pointed star.

PH nozzles

The PH Phillips, introduced after 1937, was the first self-centering tool for driving screw-threaded fasteners. The qualitative difference from the flat tip was that the PH cross did not slip out of the slot even when the tool was rotated quickly. True, this required some axial force (pressing the bit against the fastener), but ease of use compared to flat splines increased sharply.

Clamping was also required in screws with a flat slot, but when tightening with a PH bit, it was not necessary to apply attention and effort to limit the possibility of the tip slipping out of the slot. The tightening speed (productivity) has increased dramatically even when working with a manual screwdriver. The use of a ratchet mechanism, and then pneumatic and electric screwdrivers, generally reduced the complexity of assembly operations several times, which provided significant cost savings in any type of production.

The PH bit has four blades that taper in thickness towards the end of the bit. They capture the mating parts of the fastener and tighten it. The system is named after the engineer who introduced it into fastening technology (Phillips).

PH bits are available in five sizes - PH 0, 1, 2, 3 and 4. Rod length - from 25 (main) to 150 mm.

PZ nozzles

About 30 years later (in 1966), the PZ (Pozidriv) fastening system was invented. It was developed by Philips Screw Company. The shape of the PZ tip is cross-shaped, like that of the PH, but both types have such serious differences that they do not allow the bit of one system to properly tighten the fasteners of the other. The sharpening angle of the end of the bit is different - the PZ has it sharper (50 º versus 55 º). The PZ blades do not taper like those of the PH, but remain equal in thickness throughout their entire length. It is this design feature that has reduced the force of pushing the tip out of the slot under high loads (high twisting speeds or significant rotational resistance). Changing the design of the bit improved its contact with the fastener head, which increased the service life of the tool.

The PZ bit differs from the PH bit in appearance - grooves on both sides of each blade, forming pointed elements that are absent on the PH bit. In turn, to distinguish it from PH, manufacturers apply characteristic notches on PZ fasteners, shifted 45º away from the power ones. This allows the user to quickly navigate when choosing a tool.

PZ bits are available in three standard sizes PZ 1, 2 and 3. The length of the rod is from 25 to 150 mm.

The greatest popularity of the PH and PZ systems is explained by the good capabilities of automatic tool centering in in-line assembly operations and the relative low cost of tools and fasteners. In other systems, these benefits have weaker economic incentives, so they are not widely adopted.

Hex attachments

The shape of the tip, designated in the marking by the letter H, is a hexagonal prism. The system was invented back in 1910 and enjoys continued success today. Thus, confirmed screws used in the furniture industry are tightened with H 4 mm bits. This tool is capable of transmitting significant torque. Thanks to the tight connection with the fastener slot, it has a long service life. There is no force to push the bit out of the slot. H nozzles are available in sizes from 1.5 mm to 10 mm.

Torx bits

Torx bits have been used in technology since 1967. They were first mastered by the American company Textron. The sting is a prism with a base in the form of a six-rayed star. The system is characterized by tight contact between the tool and the fastener and the ability to transmit high torque. Widely distributed in America and Europe, in terms of popularity the volume of use is close to the PH and PZ systems. A modernization of the Torx system is an “asterisk” of the same shape, complemented by a hole in the axial center. The fastener for it has a corresponding cylindrical protrusion. In addition to even tighter contact between the bit and the screw head, this design also has an anti-vandal property, preventing unauthorized unscrewing of the connection.

Other types of attachments

In addition to the popular attachment systems described, there are also lesser-known and less commonly used types of screwdriver bits. The following bits fall into their classification:

- for a straight slot type S (slotted - splined), invented in the 26th century;

- Hex type with a hole in the center;

- Robertson type square prism;

- fork type SP (“fork”, “snake eye”);

- three-bladed Tri-Wing type;

- four-bladed type Torg Set;

- and others.

Companies are developing their unique bit-fastening systems both to prevent non-experts from accessing instrument compartments and to protect against vandals looting the contents.

Marking

Experienced craftsmen can quickly navigate and select the appropriate nozzles simply by looking at the inscriptions on them or at the shape of the tip.

The table below, which will discuss the marking of bits for a screwdriver, will help beginners understand everything faster and in more detail.

This way you will find out what types of elements there are, as well as what marking of the screwdriver attachment means what.

| Marking | What does it mean |

| Slot | Standard nozzle model with a flat slot type |

| PH | Cross nozzles. Next to the letter there is a number that indicates the diameter. Varies from 0 to 4. The most universal household bits are labeled PH2 |

| PZ | Bits designed for working on metal and wood. They differ in additional ribs for fasteners that have a cross recess |

| H | Hex type bits. They differ in size in the range of 1.5-10. The size is indicated in the marking next to the letter |

| R | This is how square splines are marked |

| T | Indicates a star-shaped bit, i.e. Torx |

| SP | By these letters you can identify the anti-vandal type slot |

| Gr | This is how three-blade types of screwdriver attachments are marked. |

Recommendations for choosing bits

A good bat can perform many more fastener tightening operations than its simplified counterpart. To choose the desired tool, you need to contact a retailer whose employees you trust and get the necessary recommendations. If this is not possible, choose bits from well-known manufacturers - Bosch, Makita, DeWALT, Milwaukee.

Pay attention to the presence of a hardening titanium nitride coating, and also, if possible, to the material of the product. The best way to choose is to try out one or two pieces of equipment in your own business. This way you will not only determine the quality of the product yourself, but will also be able to give recommendations to your friends. Perhaps you will settle on an inexpensive option that has clear economic or technical advantages over the originals of famous companies.

High-quality screwdriver attachments can always be purchased at the Stroybat online store for professional fasteners.

Standard equipment

If we talk about what bits are most often needed to equip a screwdriver, then we are talking about standard components. There are several basic bits:

- Splined. The classic option and the most versatile. Used for fasteners, the head of which has a cut for a flat-head screwdriver. They differ in the width of the tip, as well as in the depth of the cut provided.

- Cross. Such nozzles have 4 ribs. Replaces a Phillips screwdriver.

- Hexagonal. Suitable for screws with an internal hexagon. Such a bat will certainly come in handy during the process of assembling or disassembling furniture.

- Under nuts and bolts. There is already an external hexagon here. The bits are characterized by increased load-bearing capacity. But they are not always included in the standard set. This is rather a highly specialized group, if you look at it objectively.

- Under the stars. They are often used in car repair and maintenance, since most of the fastenings on cars are made with a Torx key. That is, under an asterisk.

If you need to choose a suitable bit for self-tapping screws to equip a screwdriver chuck, then a standard Phillips bit will be sufficient. For other types of work and fastenings, highly specialized elements may be required.