In laying communications and construction, simple but at the same time necessary elements are often used - clamps. The sizes of clamps have a fairly wide range, which allows their active use both when laying water mains and when installing heating systems. Despite their simple design, these products play a huge role in the successful completion of work.

Types of clamps

What is the difference between fastening models and repair models?

Clamps manufactured by our industry are classified according to their purpose as fastening and repair, and the name itself defines their purpose, which is their main difference. Fastening models are designed to fix pipelines in a given location for further operation.

Their main functions are:

- strength and reliability of fixation of installed pipes;

- ease of installation and long service life;

- preventing transverse displacement of the pipeline system with the possibility of longitudinal movement during use.

Fasteners must ensure reliable fixation of pipelines in places where they are laid

Repair clamps are used to repair pipes in cases where it is impossible to repair the damage in any other way, or this must be done quickly, without stopping the circulation of liquid in the damaged pipeline. The main requirements for repair models that determine their purpose are:

- ease of use and the ability to quickly perform installation work;

- reliability and long service life.

Using repair models, you can repair pipes made of various materials: steel and plastic, asbestos cement or cast iron for various types of damage: fistulas and fractures, cracks, mechanical damage and other faults.

Repair models made of stainless steel will ensure quick completion of repair work and will not spoil the visual perception of the room where they will be installed

Installation nuances, limitations and characteristics

Installation of a clamp on a steel pipe is allowed even if there is corrosion and small cracks. They are especially indispensable in the event of pipeline fractures. In this case, special models of the product are installed; the role of the holding element is ensured by fixing it to the ceiling or wall.

Installation of clamps can be done on any type of pipelines (reinforced concrete, cast iron, polypropylene, steel) and even for copper pipes, while replacing the need for welding work.

The limitation associated with the possibility of using clamps in general lies in one point. They are practically not installed at cross joints or where the pipeline is curved. Its use in such an area is not effective.

The main distinguishing feature of the products in question from, for example, fittings or any other pipeline components is the installation stage. Everything else is installed into the overall system at the formation stage, but fasteners to support the pipes are most often installed after the assembly of the structure is completed.

Clamps have a very important operational property, which largely determined their use in pipeline installation. Certain types of products, despite the 100% exclusion of lateral displacement of the pipe, allow longitudinal movement. Such linear expansion is an integral part of the operation of pipelines, allowing it to respond to changes in network temperature without threatening damage to the integrity of the structure.

Heating pipes

*

Metal steel clamps for fastening pipes

Fastening clamps are made from various types of metal and differ in geometric dimensions, design and type of fixation.

Main technical parameters and material of manufacture

In the manufacture of metal clamps, stainless or carbon steel is used with a protective layer against corrosion (zinc or other material). The main technical characteristics of such products are:

- standard size, which determines the diameter of the pipe being fixed (measured in inches);

- thickness (measured in mm);

- size of the connecting nut (if any);

- working load (measured in kilonewtons);

- breaking load (measured in kilonewtons).

Structurally, the fastening elements can support a different number of pipes simultaneously when they are laid in parallel

Structural forms and type of fixation

The type of fixation provided on the product determines the type of pipeline on which a particular model can be used, as well as its purpose. There are two types of fixation:

- rigid (immovable) – performed in places of bends and branches in water supply and sewerage systems;

- floating (movable) - used in heating and hot water supply networks, where longitudinal movements of pipes during operation are possible, associated with changes in the temperature conditions of the systems.

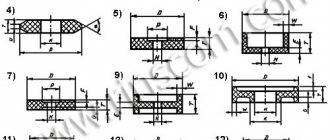

According to their design (shape), metal fastening clamps are of the following types:

- split ring;

- two half rings;

- U-shaped bracket.

The U-shaped bracket is made for each standard size of pipe, which allows you to select the necessary fastening element for pipelines of different diameters

Briefly about the main thing

Clamps are fasteners for working with ventilation ducts, water supply pipes, gas pipelines and sewerage pipes, cables and electrical wires.

Clamps are made from different types of plastic and steel with anti-corrosion properties.

Structurally, the products are represented by tapes or wires and a locking element with or without screws.

Universal and specialized clamps are manufactured taking into account the technical requirements of current standards.

Ratings 0

Types of metal pipe clamps

The type of crimped metal products determines their purpose and design features. They can be classified as follows:

- spiral - for fixation it is necessary to turn clockwise or counterclockwise, used on water supply networks made of reinforced plastic pipes;

- a power clamp is a metal strip equipped with a clamping structure that can be used for fixing and repairing pipelines of various geometric shapes (circle, square) and for various purposes;

- reinforced fastener - used for various types of hoses and hoses, it consists of a metal lock connected to a metal tape;

Clamp type “reinforced fastener”

- wire fastening - made in the form of several rings of wire connected by a mechanism for tightening them;

- a worm clamp is a metal strip with cuts (track) applied on its surface, equipped with a screw for tightening the strip;

- pipe clamp - made in the form of two half-rings, one of which is equipped with an element for fastening to building structures and screws for fastening them;

- spring clamp - used in hot water supply and heating networks, it is a metal strip with holes printed on it, twisted to a certain diameter;

- with rubber seal - various types of clamps discussed above can be equipped, which ensures fastening strength and tightness for models used for repair purposes.

Worm type clamp

Clamps of the “reinforced fastener” type are also called power hinge devices, which is due to their design and the operating principle of the fastening element. Worm-worm models can be referred to as metal band clamps, which is also due to their design. Wire products can be referred to as spiral, so when choosing a model you need to be guided by these names. All types of clamps can be produced in a reinforced version, which is expressed in the dimensions of the materials used (thickness and diameter), as well as the design of the tightening mechanisms.

Spring clamp, self-clamping

Do-it-yourself manufacturing and installation

You can easily make a repair clamp yourself. This process will not take much time. At the same time, self-made products are no worse than stamped versions. The main thing here is to make a coupling that matches the diameter of the pipe. That is, if the pipeline has a diameter of 100 mm, then the bandage must correspond to it.

You can tighten the clamp using a regular screwdriver

Making a repair bandage with your own hands:

- Measure the pipe diameter using a caliper. Multiply the resulting number by 3.14. You also need to add another three centimeters to the result for the clamping “ears”.

- It is necessary to drill a hole in the ears on each side, taking into account the size of the bolts. In this case, they must be positioned so that the ring formed between them does not exceed the diameter of the pipe. The ears need to be bent at a right angle.

- Next, the strip is tried on the pipe. If everything is in order, then it bends into a ring. It needs to be tapped with a hammer so that the ring does not bend.

Now you need to put a rubber gasket on the damaged area. A homemade bandage is put on her. Bolts are inserted into the holes on the ears and tightened until they are tight. This way you can quickly repair the damage.

Pipe clamps are a truly necessary purchase. They will help not only to install the pipeline correctly, but also to repair the breakdown in the shortest possible time. In addition, such a product is easy to make with your own hands.

Standard sizes of crimp models

The standard sizes of clamps, as well as the technical requirements for them, are regulated by GOST 28191-89 “Clamp clamps for hoses. Technical conditions". The main dimensions of products of different types are summarized in the following table:

| View | Series | Diameter, mm | Thickness, mm | Tightening torque/working load, Nm/kN |

| Worm | Light | 8-16 | 0,4-0,8 | 2 |

| 12-20 | 3 | |||

| 16-160 | 0,5-1 | |||

| More than 160 | ||||

| Heavy (reinforced) | 16–160 and above | 0,5-1 | 5 | |

| Wire | — | 18-40 | — | 0,2 |

| 40-60 | — | 0,3 | ||

| 60-85 | — | |||

| Pipe | — | 11-36 | 1 | 1,4 |

| 36-65 | 1,2 | 1,6 | ||

| 80-116 | 1,5 | 2,4 | ||

| 122-219 | 2 | 2,6 |

Wire (spiral) type clamp

Options for the mechanical part of the ties

Any model of fastening screw is equipped with a fixation unit. There are models with fastening at one point and those that are fixed in two or more places.

Products with fixation at several points are solid parts in which holes are made for installing bolts or self-tapping screws

Devices with fastening at one point can be equipped with a pin with a pointed end and threaded threads, or have a hole for mounting self-tapping screws. Fastening of such clamps is carried out using polymer dowels.

Repair clamps for pipelines

Models intended for repair work are classified according to their design and the material from which they are made.

Double-sided repair device model

The main technical indicators that determine the possibilities of using this repair device are:

- working diameter - determining the standard size of the pipe on which it can be used;

- length - determines the size at which a specific model of device can fit and fix the malfunction.

The main document regulating the production and use of repair clamps is GOST 24137-80 “Pipeline fastening parts. Clamps. Design and dimensions”, as well as GOST 28191-89 “Clamping clamps for hoses. Technical conditions".

Single-sided products for pipes of different diameters

In accordance with the classification, repair clamps are divided into:

- According to the design:

- single-sided - they are a U-shaped tape with perforation in the upper part, through which the clamp is fixed to the pipeline;

- double-sided - made in the form of two identical halves in the form of half rings, connected on the pipe using fasteners;

- multi-component - consist of several segments and are used on large-diameter pipelines.

- Based on materials from:

- steel – made from various types of steel (carbon, stainless, alloy) and are resistant to corrosion and have a long service life;

- cast iron - made of cast iron, they are wear-resistant and durable.

Installing a double-sided repair product on a large diameter pipe

In addition, when choosing a repair model, it is necessary to remember that the pressure in household pipeline networks can reach 10 atmospheres, and the coolant temperature can reach 120˚C.

general description

Clamps mean plumbing fasteners that have the shape of a closed circle. It is used for crimping pipes and hoses with a round cross-section in order to connect them to each other and seal the unit. Let's consider what types of products and sizes exist.

Varieties

Since the range of water channels is not limited to a couple of samples, there are several types of fastenings and the characteristics of the clamps may vary accordingly. To classify fasteners, parameters such as material, operating principle and purpose are considered. Based on the first criterion, two groups are distinguished:

- Made of metal . This is a durable and reliable fastener, universal for compressible water pipes. Used for sealing the connecting unit of a hose with a rigid pipe, joining pipes.

- Made of plastic . This is a less durable but elastic material. Used for stationary or mobile fixation of channels.

Screed is a type of plastic clamp. Source hepsiburada.net

Relatively recently, nylon clamps appeared on the construction market. They are inexpensive and perform well in conditions of variable temperatures and direct exposure to the sun. Fastenings are used in areas where increased reliability is not required. As a rule, these are cable lines. Additionally, color indication can be observed.

Metal crimp clamps also differ in composition:

| Metal type | Peculiarities |

| Cink Steel | The inexpensive metal is characterized by reliability and resistance to chemical reagents. Such fasteners are relevant for working with water supply, cooling and gas supply systems. |

| Stainless steel | Here steel with different magnetizability can be used. The products are characterized by increased resistance to corrosion processes and temperature changes (including sudden ones). Clamps are relatively expensive, but the costs are offset by the possibility of using them outdoors and in wet areas. |

| Combined products | Here the tape part with the lock and fasteners are made from different materials. The first is made of stainless steel, the second is made of carbon steel. This solution is considered optimal in terms of price and technical characteristics. |

See also: Catalog of companies that specialize in the design and installation of metal structures (canopies, greenhouses, etc.)

This table provides a general description of the different types of hose and pipe clamps by design and purpose. It also indicates the current standard by which their production is carried out.

| Clamp type | GOST/DIN | general description |

| Tape | 28191-89/3017 | This is a flat narrow strip made of alloy or stainless steel. On one side there are notches for tightening the ring. Available in the form of coils, the clamps are considered as components. Most often used to connect ventilation ducts. |

| Worm | This is a tape with notches and a lock, through which the diameter of the clamp can be changed using a threaded element. Used for fixing flexible hoses and cable lines, and also as a grounding conductor. | |

| With key | This is the same worm clamp, only the screw part is controlled not by a screwdriver, but by a “horn” attached to the head. Typically this is a colored plastic chroma key. Due to frequent use, they quickly break down. There are metal samples, they last longer. | |

| Power | Otherwise, this is a reinforced version of the worm clamp. Here there are no perforations or notches on the tape; the lock is made using two cylindrical nuts. There are two types of clamps for reinforced hoses and pipes: with one or two bolts. The former are also used for crimping power cables. Fixation of pneumatic and hydraulic drive elements is acceptable. The latter are used to seal connections. | |

| Wire | This clamp is designed by analogy with power samples. Only the tape is replaced by a pair of parallel rigid wires, the nuts are installed flat. Spiral type hose fasteners are used. | |

| Spring (rotary) | The all-metal sample with perforation is made of spring steel, which is characterized by elasticity and high strength. To increase the diameter during installation, the outwardly bent edges of the tape are moved towards each other. Fasteners are used for assembling cars, computers and during the construction of artificial reservoirs. | |

| CV boot | CV joint is a constant velocity joint. Here we are considering a set of two clamps of different sizes with perforation, which are similar in design to worm-type clamps. They are used to fix a corrugated rubber casing, which protects the rotating unit in the machine from dust and dirt. | |

| Silencer | Specialized fasteners consist of three parts. There is a cast wide and narrow half-ring, a pair of threaded rods with nuts for tightening the fasteners. The main application is reliable fixation of parts in the exhaust system of a car. | |

| Ventilation | 24137-80 | There are two flat half rings with longitudinal fins. Each edge is shaped like ears with a hole for a screw. On one of them in the center there is a protrusion with an internal thread for screwing onto a stud that is fixed in the wall or ceiling. An additional rubber seal can be attached inside to dampen vibrations. Products are used for assembling round air ducts. |

| Pipe (plumbing) | The design here is similar to ventilation clamps. The difference lies in wider half rings and the presence of durable rubber gaskets. One half-ring can be additionally equipped with a threaded rod or a dowel-nail. The purpose of the products is to securely fix the pipeline along the walls, ceiling or floor. | |

| Repair (emergency) | This clamp differs from all others in the large width of the tape, that is, the fastening has the shape of a cylinder. The locking connection consists of longitudinal welded plates, screws and nuts. There may be more than two fastening pairs. There is a rubber seal inside. Used for emergency quick sealing of pipelines. | |

| Screed | 62275-2015 | This is usually a plastic tape with notches. One end is smooth and tapered, the other is rigid with two loops to hold the clamp in the desired position. The main use in everyday life is to fasten parallel products together. |

| Electrical bracket | 17679/80 | This is a cast tape in the shape of a semicircle with an eyelet for fixing the fastener to the base. This clamp secures a cable, wire, hose or pipe. |

Metal hose clamps

When using hoses as a pipeline system, worm-type products and “reinforced fasteners” devices, which were described above, are used to connect them. For high-pressure hoses, the “reinforced fastener” series is best suited, because Clamps of this type are the most durable, both in terms of their design and in terms of mating the elements of the pipe system.

Connecting high pressure hoses using a worm type model

Various types of clamps are produced by a large number of domestic companies, both specializing in the production of fasteners and similar structures, and those for which these products are related, made from waste from the main production. A variety of types and models intended for different types of use and operation allows you to select and purchase the necessary product that meets all the requirements for it in a given price range.

Manufacturers of this product line

The building materials market provides various products from domestic and foreign manufacturers. Professional craftsmen deservedly highlight the high level of quality of goods from Israeli and Swiss companies.

Watch the video

Repair clamp "Gebo"

According to experts, the products of Dutch and German companies differ in the same level of quality. A lower level is occupied by products manufactured in Poland and China. The next place is occupied by clamps from domestic manufacturers. And the list ends with products from Denmark.

Almost all products that can be found on sale are manufactured according to European standards. They have all the necessary certificates for use in our country.

The line of these repair products is offered for sale in a very wide range, which allows them to be used on any mains, with any pipe diameter. The list of such highways also includes systems for transporting drinking water.

With key

This product is used like a worm clamp and their scope of application is the same. So, we take our clamp in our hands, crimp the desired section of the hose, then, thanks to tightening the hardware, you can notice a reliable fixation. This product attaches securely to the hose, but the downside is that it is not as strong as a regular worm-drive clamp.

The key or “lamb” has a plastic construction and comes in different colors. But some enterprises may also use steel ones.

Worm

This hardware is the most important fastening element. It is made from stainless, galvanized, carbon steel, as well as from passivated alloys. The worm clamp is used primarily to fix pipes on the surface, but also as a grounding device for metal hoses. Its design includes:

- ribbon

- screw part

- lock

The product in question is needed for joining the following items:

- ordinary wires

- electrical cables

- rubber hoses

Varieties

A metal worm clamp is made exclusively from steel, but steel can have different properties.

Based on this feature, the following types of clamps are distinguished:

- Made from stainless steel. They use steel: easily magnetized, poorly magnetized, and also steel with antimagnetic properties. Stainless steel fasteners are highly resistant to corrosion and sudden temperature changes, and are used in damp rooms and for open-air work. Disadvantages include a higher price.

- Combined. Carbon steel is used to make the screw, and stainless steel is used for the band and lock. Thanks to this combination, it is possible to achieve the optimal price-quality ratio.

The worm clamp has different screw sizes, depending on the shape of the head. And it comes in various configurations: hexagonal, with a straight or cross-shaped groove, with a collar. In accordance with the shape of the head, you should select a screwdriver for the job. They are also available with a plastic thumbscrew, allowing you to do without a screwdriver.

In addition, the clamps are different:

- The length of the tape and, accordingly, the possible diameter. The sizes of the worm metal clamp are distinguished, used for pipes with a cross section from 0.8 to 1.6 cm, from 1.2 to 2.0 cm, from 1.6 to 16 cm, over 16 cm.

- Tape width. As a rule, narrow ones are used when the elements being connected will experience strong vibration. The area of application for wide ones is sleeves for which too much compression is contraindicated.

- The ability to withstand loads of a certain intensity: in accordance with this criterion, light and heavy series clamps are distinguished.

Methods of application

The use of a wire clamp requires compliance with several conditions.

- This option is used for thick-walled elastic hoses. Long-term, cracked hoses that have lost their softness and elasticity cannot withstand the pressure of small-diameter steel wire. It destroys the structure of the material and can cut through, leading to leakage or even failure.

- When using a wire clamp, it is recommended to use a rubber gasket. This allows the pressure to be distributed more evenly and extends the life of the hose.

- Some products are initially equipped with a seal, which eliminates the need to use a gasket, ensuring the tightest possible fit.

- It is permissible to use this type of clamp only for fastening to solid bases - metal or plastic pipes, since at the junction of two soft-walled surfaces the wire will simply crush them.

The use of spiral steel wire provides the most reliable and tight connection. In addition to design differences, clamps have different methods of fixation. It depends on the purpose for which the device is used. On store shelves you can purchase products with a rigid fixation format. This type is most convenient in places where the pipeline branches and bends.

Ventilation

A ventilation clamp is one of the types of fastening clamps. It is used to create a high-quality connection between round air ducts and vertical or horizontal surfaces.

There are two types of ventilation hardware:

- all-metal

- rubberized

They are also divided into crimped and non-crimped types.

Scope of application

Clamps are used in various construction and repair work, but are most in demand during the installation of water supply systems. Without fasteners of this type it is impossible to achieve a static structure. In addition to the fixing effect, the clamp is able to provide a tight seal while eliminating a small leak. To do this, we compress the problem area with a gasket and apply clamps. Their uniform and tight grip ensures that the leak can be completely blocked.

The peculiarity of their design is that they can be used on horizontal, vertical and inclined pipes. For products of this type, humidity and temperature do not matter, and the presence of a rubber gasket allows the clamps to be used as grounding. An unused tap hole can be sealed using the same clamps. Wire clamps are in demand in the automotive industry; they are used to connect fittings and are used in optical systems and cooling systems, in those units where there is fluid movement with constant vibration. They are also used in water irrigation systems, where water pressure is carried out under high pressure. In addition, wire clamps are widely used in construction, machine tool industry, agriculture, and for domestic purposes.

Wire

A wire clamp is a special fastening element, as well as one of the most common types of hardware for fastening. Its outer part is made as a ring, including a tightening mechanism in one area.

They are used to hold together spiral hoses that produce vibration waves. This type of clamp is reflected in almost all types of industry, but also in everyday life.

Tape

This type of fastener is necessary to connect pipelines, hoses, and pipes. The band clamp is made from two types of steel:

- alloyed

- stainless steel

To protect hardware from rust, zinc or other anti-corrosion chemicals are applied to it.

It is used most of all in industry: automotive, construction, oil and gas industry, in everyday life and in housing and communal services.