Nail Making Basics

A very long time ago, the standard nails that we so often see in hardware stores were produced using a complex forging method. For this purpose, a truly strong metal was chosen and a fastening element was created by heat treatment. All the work was carried out by blacksmiths.

Now this technology is hopelessly outdated, as it has been replaced by improved and lightweight methods for creating these devices. For example, a special strong wire is used as a basis. It must have a fairly high rigidity, since metal that is too soft will simply bend when driving a nail into any raw material.

They stopped doing nails by hand a long time ago, as such work is replaced by a special automatic machine. They work on the principle of cold forging, and the result is fasteners of different diameters and lengths.

High quality steel wire nail set Source pixabay.com

Formal side of the matter

The production must be formalized legally. This is the only way it can work within the framework of the country’s legislation. Choose a form of activity for the enterprise and a simplified taxation system of 6%. OKVED code for the enterprise: 25.93. It is extremely difficult to formalize legal proceedings on your own. There are a number of subtleties and nuances, ignorance of which can lead to delays in opening an organization. It is recommended to contact lawyers who will take on the formal side of the matter. The one-time remuneration for such employees will be about 30-50 thousand rubles.

Advantages of nails for different types of work

Visually, everyone can choose the nail option for their own needs. This is due to several useful qualities of the fastening material:

- versatility (suitable for fastening all components without exception, the main thing is that the nails are chosen correctly);

- a wide range of fasteners, from which you can choose not only the length and thickness of the material, but also its most suitable appearance;

- ease of use, because driving nails into any type of base does not require special skills;

- ease of installation, which consists in the fact that in addition to a hammer, you can use other available means to create a reliable fastening of two elements to each other;

- the ability to fasten two or more parts, provided that the length of the nail allows this;

- long service life (even if the fastener head rusts, the internal part will continue to perform its function in the same rhythm).

Based on the positive qualities, we can come to the conclusion that in home and any other types of conditions, there is always a use for standard nails.

Construction type medium length steel nails Source sense-life.com

To manufacture standard nails for construction and repair, low-carbon steel is used, namely general-purpose wire that meets the GOST 3282-74 standard. In this case, only wire that has not been previously thermally treated is required.

To produce the declared type of wire, factories try to use special steel grades: ST 1 KP, ST 2 KP, ST 3 PS and ST 3 KP. Next, the whole process is carried out as follows:

- A coil of steel wire of appropriate marking according to GOST is loaded into a special automated machine.

- The next step is that the raw material falls under special elements that ensure perfect straightening of the wire.

- Then the straightened material enters the feeding mechanism, where the process of forming the fastening material actually begins.

- The device sets the operating speed of the device, which actually determines the length of the future fastening material.

- The next step is to move the wire towards the wire cutters. They are configured so as not only to bite off the element, but also to create a certain pointed angle (no more than 40 degrees).

- In this way, it is possible to form a tip, after which the opposite end of the wire is struck with a special mechanism.

- A cap is formed. Next, the striking device is withdrawn, the nail falls into the receiver, and the wire processing process is repeated.

The production of nails occurs quite quickly. How much fastening material will ultimately be released from the machine depends on the length of the wire coiled.

Coils of low-carbon steel wire for making nails Source metallograd-34.ru

Factory registration

A small production of nails can be registered in the form of an individual entrepreneur (individual entrepreneur). This is suitable for small production and sales volumes. Working as an individual does not allow you to cooperate with large consumers and wholesale suppliers.

You can build a large distribution network in the form of a legal entity (LLC). Here it is possible to increase the scale of work and cooperate with construction companies and intermediaries.

When registering an activity, the OKVED code 25.93 “Production of products from wire, chains and springs” is indicated.

A certificate authorizing the industrial production of nails is not required. However, it is better to submit your product for examination to obtain a voluntary GOST certificate. Such a document will provide significant advantages to a businessman when making sales and concluding supply contracts.

Types of nails and their manufacturing features

A sufficient number of nails are used for the construction and assembly of various structures. They are all divided into different categories. Let's look at them, and also explain for what purposes they are most often used.

Building

Construction nails are considered the most common, as they are used for nailing together various materials. They are usually needed to connect wooden beams in sheathings of varying thicknesses. The maximum length of such fasteners can reach 310 mm.

This type of nail is made from low carbon steel. There is a notch on the head of each element that will prevent the hammer from sliding when it comes into contact with the fastening material. Typically, such materials have a galvanized coating, which increases the resistance of the fastener to corrosion. There are also nails that are made from acid-resistant steel. These options are ideal for use in conditions of high humidity.

Model of construction nails with notches Source terra-tools.ru

Finding premises for organizing activities

To organize activities, you will need a premises with a total area of at least 150-200 sq.m. On its territory there will be equipment for production, a warehouse, offices for an accountant, a technologist, a manager, a canteen and a locker room. It will be difficult to buy it, since an object with such a square footage will cost about 10-15 million rubles. It’s easier to rent production space. An object somewhere on the outskirts of a populated area would be suitable. It is desirable to have an asphalted area and equipped entrances. This will facilitate the delivery of raw materials and loading of finished products to consumers. The cost of renting a premises of 200 sq.m. it will cost about 100,000 thousand rubles per month. In small towns this figure is several times lower.

Recommendations that can help in using nails

There are a number of practical tips that will help you use nails for their intended purpose without causing defects in the material being repaired. Consider the following:

- when using any type of nails, it is necessary to nail a thin part to a thick one;

- when choosing the length of the material, you should take into account that the minimum insertion of the tip should be one third;

- if the wood being fastened with a nail tends to crack, then the fastening site must first be drilled with a drill diameter corresponding to the diameter of the nail rod;

- You can prevent cracking of the wood by blunting the tip of the fastener;

- It is also not recommended to drive a nail into a knot, regardless of what type of fastener it is, since the structure of the knot is completely incompatible with the metal alloy.

On a note! Nails should be used strictly for their intended purpose in relation to a specific type of material, since incorrect use of fasteners can affect the reliability of the connection.

Types of nails for construction from different alloys Source setafi.com

The history of the Sadhu board.

40 years ago, the Indian ascetic Amar Bharati raised his hand up in the name of happiness and peace on Earth and has not lowered it until now. He was very worried about the many evils and violence happening on the planet, and had compassion for all living beings. Therefore, I decided to abandon selfishness and devote my life to spiritual service.

This practice of voluntary asceticism is not uncommon in India and has existed for many thousands of years.

The word “sadhu” in India refers to ascetics who have withdrawn from the world and devoted their lives to directed spiritual practice. Often sadhus choose one practice “sadhana” and follow it for the rest of their lives.

For example, someone might choose to stand on one leg for 40 years as a sadhana, while another sadhu might vow not to cut his nails or remain silent for the rest of his life. Thus, sadhus directed all their will towards one specific intention and dedicated it to the happiness of all living beings.

Today we do something similar, but in a much more condensed form, when we stand on a board with nails. Standing on the board for at least 15 minutes requires a strong and pure intention. We can devote this intention to the fulfillment of some of our desires, and then a huge release of energy will direct our mental processes towards its implementation, sweeping away all blocks, doubts and laziness along the way.

We can also dedicate this mini-penance of standing on nails to higher intentions, such as world peace or the happiness of all beings on earth. Then it will be a real spiritual practice.

But even without the spiritual component, standing on nails has a strong healing effect on the entire body. This is why nailing has been gaining popularity in recent years.

Simple rules for hammering nails

There are several recommended rules for driving nails into the required material. This is necessary in order to complete the fixation the first time. The following nuances are taken from the example of working with wood:

- select a suitable fastener and install it at the intended mounting location;

- lightly press the head at the point where you want to hammer the nail;

- then, using gentle movements of the hammer, begin to hammer the retainer into the material, holding it lightly with your fingers;

- to protect yourself from injury, place any flat object under the head of the nail that will hold it until the very end of nailing;

- To drive in a thick and long fastener, hold it strictly perpendicular to the surface.

If the nail begins to bend, immediately stop hammering it further. Remove it from the material with pliers or a nail puller, carefully level it with a hammer on a hard surface and try to drive it back.

Let me summarize

To make one pair of Sadhu boards we will need:

- Birch plywood, thickness 18 mm, size

35*35 cm. Birch plywood 6 mm or plastic 3 mm, size

35*35 cm.

- Countersunk screws, 4*12 mm, 24 pcs

- Tar paper nails, 2.5*32 mm, 1100 pcs.

- Cork 3 mm for making 8 legs with a diameter of 20 mm

- Sandpaper No. 320

- Nail drill 2.4 mm

- Drill bit for caps 7 mm

- v-shaped cutter for edge and countersink

- furniture varnish and/or marilka

- brush for applying varnish/stain

- medical gloves (for working with varnish and/or stain)

- work gloves

- hammer

- hacksaw

- a pair of bars 3*3*16 cm (we put them under the board when we hammer nails)

- a pair of clamps for convenience

- CNC router and/or drill

- Phillips screwdriver/screwdriver

Organizational structure

| Tariff rate (salary) per month, rub. | Allowances, rub | Monthly wage fund per unit, rub. | Monthly wage fund for all units, rub. | Deductions | Total for social contributions | |||

| Regional coefficient | Northern surcharge | Personal income tax | Contributions for social needs (34%) | Injuries (1.5%) | ||||

| 27000 | 8100 | 8100 | 43200 | 43200 | 5616 | 14688 | 648 | 20952 |

| 15000 | 4500 | 4500 | 24000 | 24000 | 3120 | 8160 | 360 | |

| 12000 | 3600 | 3600 | 19200 | 19200 | 2496 | 6528 | 288 | |

| 6250 | 1875 | 1875 | 10000 | 20000 | 2600 | 6800 | 300 | 9700 |

| 6250 | 1875 | 1875 | 10000 | 20000 | 2600 | 6800 | 300 | |

| 2900 | 870 | 870 | 4640 | 4640 | 603,2 | 1577,6 | 69,6 | 2250,4 |

| 2900 | 870 | 870 | 4640 | 4640 | 603,2 | 1577,6 | 69,6 | |

| 36150 | 10845 | 10845 | 57840 | 67840 | 8819,2 | 23065,6 | 1017,6 | 32902,4 |

( 1 rating, average 5 out of 5 )

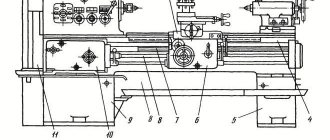

Equipment used

The production of nails is based on the use of the following equipment:

- automatic wire nailing machines. They may differ in both power and performance. Most often, such equipment is used with the value of the first indicator being in the range of 3 kW…20 kW;

- tumbling units. Designed to remove chipping and other various residues, such as corrosion products (rust), dirt deposits, technological oil stains. According to the principle of operation, these installations are divided into tumbling: drums;

- vibration type devices. Today they are used most often;

- rotary units. In terms of efficiency, they are competitors to previous devices;

- spindle installations. Increased complexity narrows the pool of potential users. Meanwhile, devices of this type provide the highest level of processing quality;

- galvanic baths. Filled with electrolyte solution. These containers contain anodes and products to be processed;

Construction staples

Formally, these are no longer nails, but such fasteners are often indispensable when working with wood. By the way, small staples are often called mesh nails. The staples have a thickness of 6 to 16 mm, but the most popular standard is 8 and 10 mm. The product size designation includes three numbers: diameter, back and leg length.

Main purpose

Fastening logs and beams in wooden house construction. Fastening the floor and ceiling joists. Strengthening the connections of a frame house. Fixing the corner logs of the crown with each other. In general, forged staples are indispensable for the reliable connection of any large-sized lumber, not only logs and beams, but also thick boards.

Popular sizes

: 8x200x70, 8x250x70, 8x270x70, 10x200x70, 10x250x70, 10x270x70 mm.

This material is also available on our website:

https://woodschool.ru/kakie-byvayut-gvozdi.html