To process parts and workpieces with shaped and flat surfaces, gears, milling machines are used. They are widely used in the industrial and metalworking fields. Despite the variety of types, the main elements of the device are similar. In all machines, the main movement is the movement of the cutter. And the feed movement is made relative to the movement of the workpiece and the cutter.

All capabilities of the milling machine are expanded with these add-ons:

- universal, slotting or vertical head;

- round dividing table;

- universal dividing apparatus;

- device for cutting combs.

Now let's take a closer look at a certain type of milling machines.

Vertical milling machines

This unit is designed for processing workpieces using face, shaped and cylindrical end mills. It is also possible to perform drilling work . Serves for processing gear wheels, frames and corners, vertical and horizontal planes, which are made of steel, cast iron, as well as non-ferrous and various alloys.

In such machines there is no console, and the table moves along the guides of the bed. Thanks to this design, it has extreme rigidity, which, in turn, ensures relatively accurate processing of the part. The spindle head is also a gearbox. The spindle together with the sleeve can be moved in the axial direction.

The vertical milling machine has two types:

- vertical console-milling;

- vertical without console.

Horizontal milling devices

This type is used for processing parts of small diameters, and it has a horizontal spindle. This design allows the processing of screw, shaped, as well as horizontal and vertical surfaces, corners and grooves. The work is carried out using cylindrical and disk, end, corner, end, and shaped cutters. Processing of a workpiece that requires a screw movement or division is permissible when using additional devices.

The feature that distinguishes it is the ability to move the table perpendicularly and parallel to the spindle axis . All important components are placed on the frame, inside of which there is a gearbox and a spindle assembly. The feed box is located on the console, and the console moves along vertical guides. The trunk with earrings serves to support the tool holder.

Kinds

Different machines of this type differ in many parameters. These are the design, specialization, dimensions, weight and power of the engine.

There are desktop options. For example, NGF110Sh3, NGF110Sh4. The first letter “N” means the “desktop” version. Machines of this class have a 0.75 kW electric motor.

Other horizontal milling machines can weigh around 12 tons with an 11 kW motor.

Consoleless machines are characterized by a low work table location. It is not raised on the console, but is located low, right on the bed. It may also contain mechanisms for moving the table, but the main adjustments to the position of the workpiece are carried out by a movable cutter.

On most models of non-cantilever machines, the cutters are movable, this is their main difference from console ones. The low location of the work table and the large space between the table and the cutter are designed for processing large parts. Most of them are modern and CNC.

Depending on the dimensions and power, the size of the parts that can be processed is determined. The work tables of powerful machines can withstand the weight of a part of about 2 tons or more.

Several of the most common models of horizontal milling machines.

6Р81

The 6P81 horizontal milling machine was produced by the Dmitrov milling machines plant (Moscow region). Currently out of production.

Peculiarities:

- you can choose from two ways to move the desktop: manually using a screw mechanism and automatically, for this there is a separate electric motor;

- increased power of the main electric motor. Possibility of cutting with carbide cutters at high speeds;

- When turned off, the spindle instantly stops the electromagnet.

Similar machines are produced today in Gomel (Republic of Belarus) and in China.

6Р83

The 6Р83 machine has been produced at the Gorky Milling Machine Plant since 1972. Belongs to the powerful category.

They replaced the 6P82 machines, received an enlarged work table and a more powerful engine.

The machine base allows it to be equipped with semi-automatic and automatic CNC systems. Widely used in industrial production. On 6P83, gears are made, horizontal and vertical planes are processed to a given size, grooves are selected, etc.

With the help of dividing, universal overhead heads, a rotary table and other equipment, the capabilities of the machine are significantly expanded.

Main characteristics:

- engine power 11 kW;

- number of speeds – 19;

- machine weight 3800 kg;

- maximum workpiece size 1000x320x350 mm.

6Р80

The 6P80 horizontal milling machine was produced by the Vilnius Machine Tool Plant.

Medium power. Installation into an automatic industrial line is not provided. Used in small industries and workshops. Despite how long ago it was developed, it remains in demand today.

Main technical characteristics:

- engine power 3 kW;

- number of speeds – 12;

- machine weight 1260 kg;

- maximum workpiece size 500x160x300.

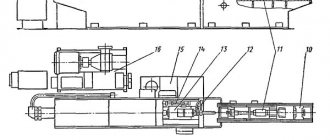

Appearance of the 6Р80 machine

NGF110Sh4

The letter Ш in the marking means that it is intended for school teaching in technology (labor) lessons. For this reason, they were produced more than all other brands of horizontal milling machines. They could be found in the workshops of most schools.

The basic model is the NGF110Sh machine. The number 2,3 or 4 at the end indicates the model. For example, from 1972 to 1979, the NGF110Sh 3 machine was produced, and from 1979, an improved model 4. The machine was a training machine, but quite functional. With its help you can do everything the same as with other GFS. Limitations on engine power and workpiece size. Accuracy class N (normal), like many industrial machines, except precision (high-precision) ones.

Main characteristics:

- engine power 0.6 kW – 0.75 kW (from model);

- number of speeds – 6;

- machine weight 340 kg;

- maximum cutter diameter 110 mm;

- working table size 100 x 400 mm.

Produced at different factories. Mainly at the Rostov (Rostov-on-Don) plant of small-sized machine tools.

IR500

A powerful, large-sized machine that belongs to heavy engineering products. Produced at the Gomel and Ivanovo factories. Today, modern machining centers are produced on the design basis of this machine (Ivanovo IS-500 (IS-500PMF4, ISB500PMF4) with a weight of processed parts up to 25 tons, Gomel - modern machining centers GDN-500, GDN-630).

Main technical characteristics of IR500:

- engine power 14 kW;

- spindle speed from 200 to 3000 rpm;

- machine weight 11.3 tons;

- maximum workpiece weight in the center of the table is 700 kg.

Drilling units

Metalworking machines, which belong to the group of drilling and milling machines, are used for processing horizontal, vertical and inclined surfaces. It is also possible to make grooves in large-sized parts using them.

This type of metal machine has a drilling and milling head, which allows drilling at an angle and processing a surface located at an angle to the horizontal axis. The fact that the working head can operate in reverse mode is its difference, versatility, a certain probability of carrying out two or more popular operations, these machines are very profitable in terms of cost savings and space saving on the production area. No home craftsman would refuse to have such a device at home, because it combines several effective and useful devices.

Universal milling

In small-scale production, this type is used to produce parts by milling. In small mechanical repair shops, as well as in tool shops.

Together with the main components, the spindle assembly and gearbox are located inside the frame. The console moves along vertical guides , and along the cantilever guides move a slide with a rotating mechanism, on which a special table is placed, which moves in a horizontal plane at various angles relative to the spindle axis. With the help of design features, the work performed on such machines is done efficiently and quickly.

Principle of operation

The cutter on such machines is fixed in one position. The accuracy of processing depends on how accurately the workpiece will be placed and moved relative to the cutting edges of the cutter.

For precise and convenient positioning of the fixed workpiece relative to the cutter, there are special mechanisms on the machines. These are located in the console under the desktop:

- work table slide cross feed screw;

- longitudinal feed screw;

- vertical feed screw.

Handwheels are attached to the screws for manual adjustment of positions. Machines of this type are non-automated, completely manual. Therefore, the accuracy of processing largely depends on the qualifications of the milling operator.

The processing accuracy is controlled using a variety of measuring instruments: various rods, calibers, pendulum protractors, plugs, rulers, indicator tools.

Tabletop machines

Tabletop ones are very compact and thanks to this they are widely popular in equipment repair shops, auto repair shops, and such machines are also installed in schools and vocational schools. With their help the following works are carried out:

- drilling holes, cutting threads, vertical milling with end, face and key cutters;

- horizontal milling with cylindrical, disk and other cutters is also carried out with their help.

The design feature of such machines is their rigidity when installed correctly . If it is installed correctly, then all work will be completed relatively accurately. This type is used in the mass production of various parts. Low energy consumption, their compactness, maneuverability and low cost are the advantages of such machines.

CNC milling machines

These machines have found their application in the mass production of high quality parts. CNC milling machines are much different from ordinary milling machines because they produce equipment using the latest technologies. With their help, you can achieve high quality parts manufacturing at high productivity speed.

In small-scale and mass production, where it is necessary to perform drilling, countersinking, boring holes in parts made of plastic, ferrous and non-ferrous metals, CNC machines are used. This equipment is equipped with a drive that is controlled by a controller connected to any computer.

Among the main advantages note:

- high increase in productivity with a manually operated machine;

- a clear decrease in the need for skilled workers;

- obvious reduction in the transition time to the production of new workpieces;

- more basic and practical equipment;

- high reduction in production cycle time.

Main characteristics

The main parameters on which the performance and capabilities of horizontal milling machines depend:

- electric motor power;

- number of speeds, max/min revolutions;

- working stroke of the slide on all axes.

Engine power affects basic capabilities - the cutter should not get stuck in the workpiece just because there is not enough drive power.

The number of speeds allows you to choose the most optimal option, exactly suitable for each type of operation. The speed varies depending on the depth of processing, the properties of the metal, the number of teeth on the cutter, and the required processing accuracy.

The working stroke of the slide determines how much area of the part the cutter can process in one installation.

The size and weight of the machine may also matter. Heavy ones require pouring a special foundation. Large-sized takes up a lot of production space.

CNC Machining Centers

In industrial sectors such as automotive, aerospace, instrumentation, and in areas where mass production of high-quality parts is impossible, CNC machining centers are used. With their help, a wide range of milling, boring and drilling work is carried out. Such machines are equipped with modern drives , which are controlled by special controllers connected to any IBM PC. It is worth noting that the monitoring and control system is equipped with high-quality software produced by global manufacturers. A distinctive feature of this machine is its high cutting speed and high accuracy.

Widely versatile machines

Widely versatile milling machines are used for milling parts made of cast iron, steel and alloys of other materials. They differ from horizontal milling machines by the presence of another spindle head mounted on a retractable trunk. It can rotate at any angle in two mutually perpendicular planes. Both separate and simultaneous operation of both spindles is possible. The overlay milling head is mounted on the rotary head of the machine to add versatility. This makes it possible to process workpieces of complex shapes both by milling and by drilling, countersinking and boring.

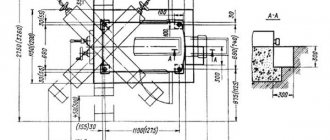

Some widely-universal machines do not have a console panel, but instead a carriage moves along the vertical guides of the frame. The carriage has horizontal guides for the slide with a working vertical surface. They are often used to install additional devices, a dividing table, or any dividing device.

The milling group of lathes consists of all the previously listed models. They are distinguished by size and nature of the work performed, but they are all equally used in industry. Each type is used to perform special work that cannot be performed on other types of machines.

Technical data entirely depends on the manufacturer and brand of a particular machine, and the quality of the work performed depends on the professionalism of the master who works on it.

Features of modifications

The NGF-110 model was the first in a series of desktop school machines. It was modified and widely universal machines began to be produced.

NGF-110Sh1

Distinctive features of the model:

- round trunk;

- the vertical feed steering wheel is located at the base of the screw;

- The gear shift lever on the body is metal.

The bottom plate is cast, low, like the NGF-110 model.

NGF-110Sh3

Visually very different from previous models:

- a rectangular trunk with an arched top - “humpbacked”;

- the base is thin;

- engine start/stop buttons on the column, below;

- next to it is a plate with the model marking;

- plastic balls are screwed onto the ends of the gear shift knobs;

- engine inside the frame;

- vertical transmission is carried out by a handwheel on the console.

The model is considered transitional to the next modification.

110Ш4

The latest, modernized model, which was produced longer than the others. Differs from previous versions of the milling machine:

- a rectangular trunk with an earring moving along its guides;

- base high 100 mm, hollow;

- local lighting;

- Gear shift knobs are completely plastic;

- The label with the marking is located on the trunk.

On the side of the base there are power buttons, inside there is a current transformer for local lighting of 36 V. The motor is located at the bottom of the stand, inside.