Production history

The Gorky Milling Machine Plant - GZFS - was the first to produce milling machines in the country in 1931. The enterprise was built according to the plan for the industrialization of the country using German projects. In 1936, the plant produced a unique milling unit for processing tubing for the Moscow metro.

The first series of milling machines, the 6B series, was launched in 1937. Cantilever milling machines of the 6P series began to leave the plant’s assembly line in 1972. Among them was the widely-universal model 6Р83Ш with a table of the third row of sizes.

After the merger of several factories, including GZFS, into the industrial group Stanko LLC, in 2003 the company underwent modernization. The production of CNC machines began, created on the basis of previously produced models, including the highly versatile 6Р83Ш.

Vityaz 6Р83Ш Cantilever-milling horizontal machine

“Vityaz” is a Russian brand that is not inferior in quality to its European counterparts. There is a main and pleasant difference - their cost. Magnet-based Vityaz machines have positively proven themselves as reliable and efficient equipment.

Stankoinkom is the official dealer of Vityaz machines in Russia. Our Vityaz product catalog presents most of the equipment from the official Vityaz website.

Under the Vityaz brand, together with the largest German manufacturer, high-quality magnetic drilling machines are produced. They are designed taking into account the shortcomings of machines presented on the Russian market. Vityaz machines are not inferior in quality to their European counterparts, but have a more reasonable price. Equipped with a soft start and overload control system. Cast construction minimizes tool runout. Special motors with increased torque.

Read more

Vityaz is one of the largest brands in Russia. This brand is based on versatility, which allows us to produce a huge range of equipment for metal processing, such as drilling machines, band saws, lathes, milling machines, sharpening machines and many others. Metalworking The metalworking production of Vityaz OJSC has equipment that allows it to perform a wide range of technological operations: Heat treatment (hardening, tempering, annealing, normalization) in chamber and shaft electric furnaces of all types of technological equipment, made of carbon and alloy tool steels. Chemical-thermal treatment (cementation and nitriding). Heat treatment with high frequency currents. Three-coordinate milling on CNC machines using control programs developed in the UNIGHRAPHICS system. Electrical discharge machining (electrode piercing, wire cutting) on CNC machines. Jig boring machining on vertical and 2-spindle portal-type machines with operating control system. Grinding is flat, round, coordinate, and profile on optical grinding machines. Sharpening cutting tools and circular saws on universal sharpening machines. Turning on universal machines and machines with automatic control systems. Milling on machines with OSU. Drilling processing on vertical and radial drilling machines. Electrochemical chrome plating of form-forming parts of equipment.

Purpose and areas of application

The 6P83 Sh milling machine is designed for processing workpieces of steel and cast iron. It does:

- milling on 5 planes;

- drill;

- cutting grooves;

- boring;

- formation of grooves and ridges;

- processing a plane with a complex configuration.

The use of a rotary and inclined table increases the capabilities of the 6Р83Ш model.

The machines are used in enterprises producing single and mass products in metalworking shops for the manufacture of flat and rectangular parts:

- molds;

- stamps;

- slats;

- pillows;

- frames;

- gears;

- levers.

Using additional devices, spiral grooves, worms, grooves and splines are cut on a 6R83Sh milling machine.

Important!

The widely-universal machine 6Р83Ш is equipped with a slotting head.

SPECIAL MECHANISMS

Price: Check

Widely versatile milling machine mod. 6Р83Ш is designed for performing a variety of milling, drilling and boring work with cylindrical, face, end, shaped and other cutters. It is used for processing horizontal and vertical planes, grooves, frames, corners, gears, spirals, stamp models, molds and other parts made of steel, cast iron, non-ferrous metals, their alloys and other materials. The machine is equipped with a trunk on which overhead and rotary spindle heads are installed with an individual gearbox and a separate drive, providing the ability to process a part with a tool mounted to the working surface of the table at almost any angle in any plane. The presence of a separate horizontal spindle allows this machine to be used as a conventional horizontal milling machine. The drive power and high rigidity of the machine allows the use of cutters made of high-speed steel, as well as tools equipped with plates made of hard and super-hard synthetic materials.

Design Features:

- basic model (automatic cycles on 3 coordinates);

- wide-universal type;

- Main design advantages of the machine:

- mechanized tool fastening in the spindle;

- a device for periodically adjusting the size of the gap in the longitudinal feed screw pair;

- safety clutch protecting the feed drive from overloads;

- spindle braking when stopping using an electromagnetic clutch.

- Main technological advantages of the machine:

- various automatic machine operation cycles;

- wide range of spindle speeds and table feeds;

- high drive power;

- increased accuracy class;

- possibility of simultaneous operation of two spindles;

- high rigidity;

- reliability and durability.

The technological capabilities of the machine can be expanded by using a dividing head, rotary or globe tables.

| Specifications | |

| Dimensions of the working surface of the table, mm | 1600x400 |

| Maximum table movement, mm: | |

| longitudinal | 1000 |

| transverse | 320 |

| vertical | 420 |

| Distance from the axis of the horizontal spindle to the working surface of the table, mm | 30-450 |

| distance from the spindle axis to the trunk, mm | 190 |

| Distance from the end of the rotary head spindle to the table, mm | 70-570 |

| Distance from the axis of the rotary head spindle to the frame guides (extent), mm | 250-900 |

| Horizontal spindle rotation speed limits, rpm | 31,5-1600 |

| Number of horizontal spindle speeds | 18 |

| Spindle rotation speed of rotary and overhead heads, rpm | 50-1600 |

| Number of spindle speeds of rotary and overhead heads | 11 |

| Maximum load on the table (center), kg | 300 |

| Table feed range, mm/min: | |

| longitudinal | 25-1250 |

| transverse | 25-1250 |

| vertical | 8,3-416,6 |

| Drive electric motor power, kW: | |

| main spindle | 10 |

| table feeds | 3 |

| vertical head | 3 |

| Spindle cone according to GOST 30064-93 | |

| main | ISO 50 |

| vertical head | ISO 40 |

| Overall dimensions, mm | |

| length | 2680 |

| width | 2260 |

| height | 2040 |

| Weight of the machine with electrical equipment, kg | 4500 |

Write to us

Return to home page

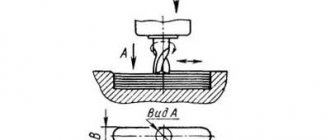

Design

The 6Р83Ш milling machine is widely universal, single-column, cantilever type. The gearboxes and gearboxes are located in the frame body. The trunk extends from above, with guides for earrings, and a rotating head. The table moves along 3 axes. On the working surface there are T-shaped guides for fastening parts and devices.

Design features of the 6Р83Ш model:

- the tool is mechanically fastened in the spindle;

- the gap size in the screw pair is periodically adjusted by a built-in device;

- spindle braking by electromagnetic clutch;

- The drive is protected by an overload fuse.

The highly versatile machine 6Р83Ш has advanced technological features:

- wide range of spindle speeds and table feeds;

- higher power engine;

- automatic work cycles;

- increased accuracy class;

- rigid structure of the base and frame.

The 6Р83Ш universal machine model is distinguished by easy, intuitive operation, reliability and durability.

Reference! The horizontal and vertical spindles operate from one drive and are connected by gearing to one gearbox. When one node is turned on, the second one is blocked. It is impossible to work with 2 tools at the same time.

Widely versatile milling machine 6Р83Ш

The widely-universal cantilever milling machine 6Р83Ш is one of the most common in its category and is designed for processing vertical, horizontal surfaces, dies, grooves, corners, gears, etc. Work on the machine is carried out with various cutters: face, end, disk, shaped. The use of additional accessories increases the functionality of the equipment. Sufficient lifting capacity of the table allows processing large parts. Generally, 6R83Sh universal cantilever-milling machines are used in single and serial production and repair shops.

Design features

- automatic mode allows the machine to be integrated into production lines

- high processing precision

- simultaneous movement of the table along two and three axes

- joint work of vertical and horizontal spindle

- processing different surfaces in one installation

- overload protection system

- wide range of spindle speeds and table feeds

- rigidity, reliability, durability

- high main drive power

- use of additional devices and accessories

Specifications

| Table size, mm | 400x1600 |

| Accuracy class (GOST 8-82) | P |

| Table longitudinal movement (X), mm | 1000 |

| Table transverse movement (Y), mm | 320 |

| Table movement vertical (Z), mm | 420 |

| Table load, kg | 300 |

| Distance from vertical spindle to table, mm | 30-450 |

| Distance from horizontal spindle to trunk, mm | 190 |

| Accelerated longitudinal movement, mm/min | 3000 |

| Accelerated transverse movement, mm/min | 3000 |

| Accelerated vertical movement, mm/min | 1000 |

| Number of feed stages | 18 |

| Spindle speed, rpm | 50-1600 |

| Range of longitudinal working feeds, mm/min | 25-1250 |

| Range of transverse working feeds, mm/min | 25-1250 |

| Range of vertical working feeds, mm/min | 8,3-416,6 |

| Number of spindle speeds | 18 |

| Spindle inner taper | N 50 |

| Maximum torque, Nm | 1430 |

| Spindle head rotation angle, degrees | ± 45 |

| Quill stroke, mm | 80 |

| Main drive power, kW | 10 |

| Overall dimensions, mm | |

| length | 2680 |

| width | 2260 |

| height | 2040 |

| Weight, kg | 4500 |

Equipment

| Main | Additional |

|

|

Cost of equipment

You can receive a commercial offer for a universal cantilever milling machine 6Р83Ш by sending a request to the email address: This email address is being protected from spambots. You must have JavaScript enabled to view it, and also call our office. Our company’s specialists will answer all your questions. The warranty period for widely-universal cantilever milling machines 6Р83Ш is 12 months.

Technical specifications, passport

The 6Р83Ш milling machine is an improved version of the 6Р82Ш model. it has a larger table, a powerful motor.

Main technical characteristics of the widely-universal machine 6Р83Ш:

- main drive power 7.5 kW;

- number of spindle speeds 11;

- rotation speed 31.5–1600 rpm;

- maximum torque 1430 N.m;

- quill movement along the axis 80 mm;

- rotation of the milling head 360⁰;

- rotation of the overhead head 360⁰;

- table size 400×1600 mm;

- the distance from the end of the spindle to the table at the extreme points is 30 and 450 mm;

- maximum length of manual and mechanical longitudinal movement 1000 mm;

- transverse mechanical 300 mm, manual 320 mm;

- number of working feed stages 18.

Machine accuracy class N in accordance with GOST 8–82.

Reference! When roughing, end mills with a maximum diameter of 200 mm for a horizontal spindle and 100 mm for a vertical spindle are used.

The passport of the milling machine can be downloaded for free from the link - Passport of the wide-universal milling machine 6Р83Ш.

Dimensions and weight

The 6Р83Ш milling machine processes medium- and large-sized parts. The ability to install massive workpieces is ensured by the increased strength of the equipment. The model has:

- machine dimensions 2680×2260×2040 mm;

- weight of the completed unit is 4500 kg.

Reference! The weight of the machine is taken complete with all components, without tools and additional accessories.

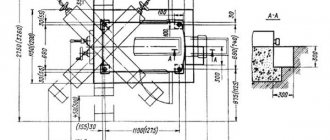

Landing and connecting bases

Location of components

The milling machine has a massive frame on which most of the working units are mounted. The console moves vertically due to the rotation of the running shaft mounted in the base. It moves along guides in the front of the rack. Main components and parts:

- high base with fastenings for a stand and lead screw;

- hollow bed;

- trunk;

- rotary milling head with spindle;

- overhead head;

- massive, protruding console;

- table with slide;

- gearbox inside the frame at the top;

- switch box on the side;

- feed box in the console body;

- electrical equipment at the bottom of the rack.

The main drive and feed motors are installed at the rear of the frame. To install the mandrel when working with a horizontal spindle, earrings are attached to the trunk guides.

Controls

The main controls of the machine when performing work are conveniently located in the front part of the machine. The electrical panel for turning on the spindle is located on the slide body. Nearby are:

- table clamps;

- button to quickly move the table;

- handwheel for manual longitudinal movement;

- switch for manual or automatic table movement mode.

Below on the console body there are: a handle for manual movements of the console and a handwheel for manual transverse movements. On the side of the feed box cover there is a spindle rotation reverse switch and a speed shift knob.

There are also duplicate buttons for starting and stopping rotation of the spindle, table, and light switch. The spindle clamp handles, the rotary head, and the quill movement handwheel are located directly on the milling head body.

Electrical diagram

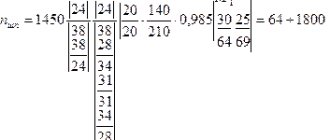

Kinematic diagram

6Р82Ш, 6Р83Ш characteristics

The technical characteristics of widely-universal cantilever milling machines allow milling parts of both small and large dimensions. For processing large-sized workpieces, a retractable trunk is provided in which a spindle unit is installed.

| Characteristic name | Unit change | 6R82SH | 6R83SH |

| Accuracy class according to GOST 8-71 | P | P | |

Table | |||

| Dimensions of the working surface of the table (L x W) | mm | 1250 x 320 | 1600 x 400 |

| Number of T-slots | 3 | 3 | |

| Moving the table | |||

| longitudinal (X) | mm | 800 | 1000 |

| transverse (Y) | mm | 250 | 320 |

| vertical (Z) | mm | 420 | 420 |

| Distances from the spindle end to the table | mm | 30..450 | 30..450 |

| Distance from spindle axis to trunk | mm | 155 | 190 |

| Distances from the end of the rotary head spindle to the table | mm | 35…535 | 70..570 |

| Distances from the axis of the rotary head spindle to the bed guides | mm | 260…820 | 250..900 |

| The largest mass of the workpiece | kg | 250 | 300 |

| Moving the table one dial division | |||

| longitudinal, transverse | mm | 0,05 | 0,05 |

| vertical | mm | 0,05 | 0,05 |

| Moving the table one turn of the dial | |||

| longitudinal, transverse | mm | 6 | 6 |

| vertical | mm | 2 | 2 |

Spindle heads | |||

| Spindle quill movement | |||

| One turn of the dial | mm | 6 | 6 |

| One division of the dial | mm | 0,1 | 0,1 |

| Rotating the head in the transverse plane of the table | |||

| To the bed | hail | 45 | 45 |

| From the bed | hail | 90 | 90 |

| Rotating the head in the longitudinal plane of the table | hail | 360 | 360 |

| Rotating the socket head | hail | 360 | 360 |

| Rotate the heads by one scale division | hail | 1 | 1 |

| Maximum movement of the spindle quill | mm | 80 | 80 |

Machine mechanics | |||

| Feed stops | Eat | Eat | |

| Locking manual and mechanical feeds | Eat | Eat | |

| Blocking separate feed switching | Eat | Eat | |

| Automatic intermittent feed | |||

| longitudinal | Eat | Eat | |

| transverse and vertical | No | No | |

| Spindle braking | Eat | Eat | |

| Overload protection (clutch) | Eat | Eat | |

Electrical equipment | |||

| Main drive of the machine | |||

| Speed | rpm | 1460 | 1460 |

| Power | kW | 7,5 | 10 |

| Type | А02-51-4-С2 | A02-52-4-C2 | |

| Feed drive electric motor | |||

| Speed | rpm | 1430 | 1430 |

| Power | kW | 2,2 | 3,0 |

| Type | A02-31-4-C2 | A02-32-4-C2 | |

| Electric coolant pump | |||

| Speed | rpm | 2800 | 2800 |

| Power | kW | 0,125 | 0,125 |

| Type | PA-22 | PA-22 | |

| Performance | l/min | 22 | 22 |

| Rotary head spindle drive motor | |||

| Speed | rpm | 1430 | 1430 |

| Power | kW | 2,2 | 3,0 |

| Type | A02-31-4-C2 | A02-32-4-C2 | |

Dimensions and weight | |||

| Overall dimensions of the machine | |||

| length | mm | 2470 | 2680 |

| width | mm | 1950 | 2260 |

| height | mm | 1950 | 2040 |

| Machine weight | kg | 3300 | 4500 |

The subtleties of do-it-yourself repairs

To determine the scope of repair of the machine, it is checked in idle mode. You should pay attention to the equipment’s execution of commands and switching between different operating modes. The wear of the guides is measured. After this, unit disassembly is carried out. All working elements and parts should be washed and inspected, the scope of repairs should be determined, and a defect list should be drawn up.

- All guides are scraped; in case of large defects, they are processed on a surface grinder.

- Sprockets and wheels with broken and heavily worn teeth are replaced with new ones.

- The spindle bearings are washed, lubricated and adjusted.

- The adjusting wedges are scraped down and the gap is selected along the guides.

After replacing worn parts, the machine is assembled. The gaps are selected, the parallelism and perpendicularity of the guides are set. Medium repairs involving scraping the guides and replacing gaskets and couplings can be done at home. Replacing bearings and gears is expensive, but affordable for hobbyists.

Important!

The milling machine has a complex electrical circuit. It is better to entrust its inspection and repair to a specialist.

Where to order and buy?

The GZFS enterprise stopped producing milling machines in 2009 and transferred the documentation to the young Stanochny Park LLC. The plant manufactures equipment of older models to order. Organizations involved in major equipment repairs offer machines for 900,000–950,000 rubles. with a guarantee of 6 months.

The old machine made by the Gorky plant is offered by workshops and owners on various trading platforms on the Internet. The asking price is from 400,000 rubles, depending on the condition.

The durable milling machine 6Р83Ш was designed for round-the-clock operation with maximum load. The surviving examples are usually in good condition and, after reconstruction, work for a long time and without failure. The equipment is in demand for work in private workshops for single production of complex parts.