Basic information

A cylindrical grinding machine is a device for automatically grinding metal products.

The installation looks like a large table on which additional grinding equipment is installed. The operating principle of cylindrical grinding machines is simple. Using headstocks or a carriage, the metal part to be processed is installed in the working area. After this, the grinding wheel is started and rotates around its axis. The circle approaches the workpiece, which leads to stripping of the metal workpiece. Using a cylindrical grinding machine, you can process cylindrical, conical and end workpieces, as well as large holes. By design, there are centered and centerless models. For center models, the workpiece is secured using special grooves. In centerless models, the workpiece is fixed in the working area of the machine using a clamping carriage. A cylindrical grinding machine performs the following tasks: abrasive rubbing of the surface of the workpiece, removing an excess layer of metal, eliminating irregularities on the metal surface.

Elements of cylindrical grinding systems

- Desktop. Acts as a base on which all the main elements are attached. The workbench may have small wheels that are used to transport the unit. The work table is made of durable metal alloys, as are other elements of the grinding system.

- Headstock grooves (center models). Used for fastening parts on the desktop. The grooves can rotate around their axis, which allows you to process the workpiece over its entire area + improves the quality of grinding. Some grooves can also move in the longitudinal direction, which allows you to change the position of the part on the work table directly during processing. The head slots can be movable - this allows you to change the angle of the workpiece on the work table. This makes it possible to grind conical workpieces.

- Carriage (centerless models). The carriage is also used for fastening parts on the work table. The main difference from the headstock grooves is that the carriage does not have its own axis of rotation (it can only be moved in the horizontal direction). To process the workpiece from different sides, the workpiece itself is rotated on the carriage.

- Abrasive disc wheel. Located in a perpendicular direction relative to the location of the workpiece on the work table. During operation, it acts as an abrasive with which processing is performed. Abrasive discs come in different shapes. Simple machines have a fixed disk arrangement. The universal cylindrical grinding machine has a movable disc wheel, which makes the installation more versatile.

- Drive unit. Used to move the abrasive wheel while the system is operating. The drive can be mechanical, hydraulic and electric. Large systems are usually equipped with an electric drive, which simplifies the procedure for moving the disk during operation. Small machines have a mechanical or hydraulic drive, which reduces electricity consumption.

- Electric motor. Acts as an energy source that powers all the main elements of the installation (rotating slots-headstocks, abrasive disc-wheel, etc.). If the machine is equipped with an electric drive, then the engine also powers this element. Electric motors usually have a power ranging from 5 to 15 kilowatts, although more powerful units are also available. Modern electric motors usually have additional protective elements to avoid system overheating.

- Cooling system. During processing, serious heating of the workpiece occurs due to friction. To avoid overheating of the workpiece, many modern machines are equipped with a cooling system. It looks like small taps that are installed in the core. The taps are connected to the refrigerant (the refrigerant is usually water). During processing of the part, the valves are activated, which leads to the spraying of coolant in the core.

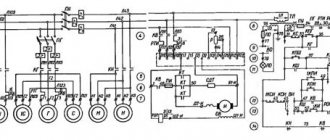

Electrical circuit diagram of the machine 3B161

Electrical diagram of the 3B161 cylindrical grinding machine

The machines are equipped with seven electric drives: grinding wheel, hydraulic pump, cooling pump, grinding head spindle bearing lubrication pump, bed guide lubrication pump, magnetic separator and workpiece.

All electric drives, except for the product drive, have three-phase asynchronous electric motors with a squirrel-cage rotor. The electric drive of the product has a DC electric motor with a parallel field winding, which receives power from a block of magnetic amplifiers and rectifiers.

The speed of the electric motor driving the product can be steplessly adjusted from 250 to 2500 rpm.

The machines are equipped with local lighting from a reduced voltage of 36 V.

A voltage of 127 V is provided for control circuits.

The local lighting and control circuits are powered through a step-down transformer.

The machines are produced for power supply from a three-phase alternating current network with a voltage of 380 V, 50 Hz.

By agreement with the manufacturer, machines can be manufactured for other supply voltages, local lighting and control circuits.

The control station is attached to the machine bed.

Description of the electrical circuit diagram of the 3B161 machine

To start the machine, you must turn on the automatic switch AB (Fig. 1) and operate the CNG button. In this case, the electric motors of the pumps will turn on: hydraulics G, lubrication of the spindle bearings of the grinding headstock C, lubrication of the frame guides 1C.

After making sure that there is oil circulation in two transparent caps located on the cover of the grinding headstock housing, by pressing the KPSh button, we turn on the electric motor of the grinding wheel Ш.

Turning on and off the electric motor of the product I can be done either manually by acting on the KPI (1KPI), KSI (1KSI) buttons, respectively, or automatically by quickly approaching (turning on) and retracting (turning off) the grinding head.

In the first case, the VI switch must be installed in a position in which contacts 45-47 are closed, in the second case - in a position in which contacts 45-55 are closed.

The switching on and off of the electric motor of the product when the grinding head is supplied and removed occurs as a result of the CI microswitch being pressed and released accordingly.

Stopping the electric motor and the product occurs in dynamic braking mode.

Turning on and off the electric motor N of the cooling pump during grinding occurs simultaneously with the electric motor of the product I, when dressing - simultaneously with the electric motor of the grinding wheel Ш.

This is achieved using the BH switch, which when grinding is set to the “grinding” position - contacts 41-49 are closed, and when editing - contacts 37-41 are closed to the “editing” position.

All electric motors are turned off by pressing the KS button.

The local lighting is switched on and off using the VO switch.

The installation diagram is shown in Fig. 2, layout of electrical equipment on the machine - in Fig. 3, symbolic images on control panels - in Fig. 4, and the diagram of the grounding route in Fig. 5.

Electrical equipment protection

Protection of the electrical equipment of the machine from short circuits is carried out by automatic switches AB, PG, PN and fuse links PI, PU, PO, and protection of electric motors Ш, Г, И from overload is provided by thermal relays RTSh, RTG, RTI.

Thermal relays have manual reset.

Protection of the electric motor from runaway in the event of a field failure is provided by the ROP relay.

Types of cylindrical grinding machines

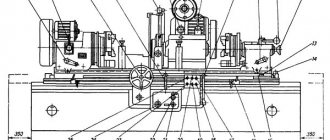

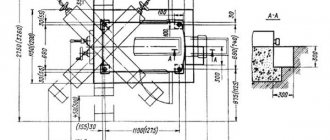

An example of the layout of the ZM151 machine

In practice, cylindrical grinding machines process workpieces of round or oval cross-section. Grinding complex parts is impossible with this equipment due to the specifics of its design. This must be taken into account when choosing a machine model.

The most common models of cylindrical grinding machines are equipment in which the parts are mounted on centers. The workpiece is fixed between the front and tailstock. To improve the quality of grinding, the body rotates. When it comes into contact with the abrasive disc, excess material is removed in the form of metal dust and shavings.

In addition to this technique, so-called centerless cylindrical grinding machines have recently gained popularity. In them, the workpiece is placed on a working carriage and is held on one side by an auxiliary wheel, and on the other is subjected to grinding with the main abrasive. In this way, high-quality fine machining of thin-walled cylinders or cones can be performed. The degree of pressing is adjusted using an automatic system.

Additionally, it is necessary to take into account the following features that the cylindrical grinding machine has:

- presence of a rotary table. With its help, you can shift the workpiece relative to the abrasive disk in the horizontal and vertical plane;

- feed mechanism device. This can be an automated complex or its mechanical analogue. In the latter case, machines of this type are used for rough grinding;

- Possibility of fixing the workpiece in centers or chucks. This parameter applies to center type equipment only.

Currently, a large number of models of cylindrical grinding machines are produced. Therefore, in addition to choosing according to design parameters, it is necessary to take into account the technical and operational qualities of the equipment.

List of main technical characteristics

Cylindrical grinding machine 3M152

As an example, we can consider the operation of a standard model of a 3M152 cylindrical grinding machine. In it, the workpiece is installed in the centers. Most of this equipment has a similar design.

It is best to roughly divide the technical characteristics of the machine into its components. Structurally, it consists of a workpiece fixation block, a processing center (grinding headstock) and a control system. The average weight of such a machine is about 8 tons. At the same time, it has large dimensions, which imposes special conditions for installation and operation.

Main technical parameters:

- maximum permissible dimensions and weight of the workpiece being processed;

- grinding diameters – minimum and maximum;

- distance from the axis of the headstock spindle to the surface of the work table.

Desktop Features:

- desktop offset – maximum length;

- parameters for manual acceleration and deceleration;

- rotation angles clockwise and counterclockwise;

- displacement characteristics using a hydraulic system. This is necessary for processing massive parts.

The part is fixed between the front and tailstocks. They should be analyzed according to the following parameters:

- rotation frequency;

- for the tailstock - the amount of displacement of the quill.

In addition, the total power consumption of the equipment, the possibility of installing auxiliary structures and the parameters of the cooling system are taken into account. The presence of the latter is a mandatory requirement for industrial models of cylindrical grinding machines.

To maintain the machine in working condition, it is necessary to periodically carry out preventive and repair work. It is especially important to apply lubricant to moving parts of equipment in a timely manner.

Device and design features

The design of cylindrical grinding machines depends on the working materials and quality requirements for the finished products. The following accuracy classes of devices are distinguished:

- increased accuracy;

- high precision;

- especially high precision.

Let's consider the design features of various devices and the most common layout options.

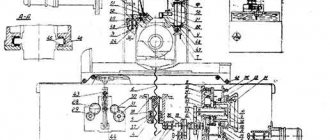

Working nodes

Regardless of the type of design, the main elements of cylindrical grinding machines are:

- bed;

- Desktop;

- grinding and headstock;

- control mechanisms.

The drive to the spindle is mounted in the headstock, and the drive to the wheel is mounted in the grinding headstock.

The main element of the control mechanism is the push-button station. Flywheels are responsible for manual movement of the work table and spindle head, which are controlled using the following handles and stops:

- fast feed of the headstock;

- moving the quill;

- adjustable desktop speed;

- disabling automatic table movement and reverse.

In addition to the above components and parts, the following elements play an important role:

- Grinding headstock. Differs in rigidity of a design. Depending on the layout of the machine, it can be a fixed or movable element. It contains a spindle mounted on hydrodynamic or other supports.

- Balancing mechanism. Reduces oscillatory processes during the working cycle. There are models with both manual and automatic machine balancing.

- Working tool editing mechanism. Adjusts the shape of the contact tool and maintains its functionality.

- Feeding unit. Responsible for moving the grinding wheel.

- Tailstock. It is one of the design elements of machines for which the working location of the workpiece is installation in the centers.

- Lunettes. Special supports for working with long parts.

Possible layout options

The most common ways to configure cylindrical grinding machines are:

- cartridge;

- center;

- centerless.

An important factor is the presence of a second table. In centerless models, the shoe is a fixed element.

Fixed knife models have found their application on automatic assembly lines. They are valued for their high quality characteristics, because this arrangement ensures the stability of the workpiece axis, regardless of the condition of the machine’s grinding tool. The design of such equipment is characterized by high technological complexity due to the movable headstock and the mechanism for its movement.

Internal grinding machines for processing metal parts

Equipment of this type is intended to improve the quality of the internal surface of finished products. Often the reason for introducing this operation is the deviation of the hole axis in the previous operation. The processing process is carried out using a spindle on which a grinding wheel is mounted. The spindle itself has a rotational motion and a reciprocating motion.

Spindle rotation and part rotation are necessary for a smooth cutting process. Reciprocating motion is necessary to shape the surface. In complex structures, the spindle moves along 5 coordinates. To improve the quality of processing, if possible, you should grind the cams before clamping the part into them. This allows you to significantly reduce runout during alignment. In an ideal situation, it is also better to check the runout of the workpiece in the jaws before machining.

The design of this type of equipment differs depending on the parameters

Single spindle machines

These equipment grinds conical or cylindrical parts;

Machines with additional spindle

These equipment simultaneously performs internal and end grinding;

Double sided machines

These equipment performs simultaneous double-sided grinding of through holes.

When working on an internal grinding machine, it is very difficult to remove grinding dust from the processing area. This problem can be successfully solved using a special magnetic device. Thanks to it, the chips are simply pulled out of the cutting zone.

Selection and purchase of a metal cylindrical grinding machine

In the Diam Almaz construction equipment store you can choose and buy a machine from the best Russian manufacturers that suits your needs. The prices of the machines differ based on the operating characteristics, namely: the diameter and length of the workpiece, spindle speed, etc. Cylindrical grinding machines with a power of 2.2-7.5 kW are available. If you are interested in purchasing a machine, other equipment and components, call our store.

Our managers will not only be able to professionally advise you on any issue, but will also help you choose the equipment model that is optimally suited for your production purposes. By ordering equipment from us, you are guaranteed to receive the best products and quality services .

Cylindrical grinding machine 3m151

This unit has been operating in our country for a very long time. It helps to process cylindrical, discontinuous cylindrical parts, as well as the surface of various cones at the highest level.

Due to its uniqueness, the 3M151 unit helps to work with the most complex workpieces. The grinding method used in such a machine is called longitudinal or mortise. The devices installed on this machine make it possible to fully control both the size of the workpiece and the processing process itself.

Additionally, you need to take into account the following subtleties that the cylindrical grinding unit has:

- Presence of a rotary table. Thanks to this table, it is possible to shift the product relative to the abrasive disk in the horizontal and vertical parts;

- Feed mechanism device. This may be an automatic complex or its special analogue. In the latter case, units of this type are used for rough grinding.

- Possibility of fixing products in centers or chucks. This factor applies only to center-type equipment.

The unit helps a specialist quickly work with products with a length of 700 mm and a diameter of 200 mm. The frequency at which the grinding wheel of the unit begins to rotate will be 1590 min-1. It turns out that the speed of movement of the table (which can be steplessly adjusted) will be 0.05−500 min-1. Recently, a huge number of models of such machines have been produced. Therefore, in addition to choosing according to standard parameters, you need to look at technical and operational qualities.

Such cylindrical grinding units bring enormous benefits and now it is very difficult to do without them; they are required almost everywhere.

Machine design

Bed and tables

The machine bed consists of two parts: front and rear. The table moves along the guides in the front part in the longitudinal direction.

The upper part of the table is rotatable, which makes it possible to grind conical-shaped parts. On the top of the table there are headstocks and tailstocks for placing the part to be sanded between them. The guides at the rear of the frame are used for transverse movement of the grinding headstock. To install the upper part of the table when grinding conical or cylindrical parts, there is a turning mechanism with a dial and pointer on the right side of the table (Fig. 163). Using the dial and pointer, approximately set the angle of rotation of the upper part of the table. To accurately set the table to the required angle, do the following: loosen the clamps, rotate the screw to move the upper part of the table, and then fix it in the desired position and grind the surface with a very small depth of cut. Having measured the dimensions of the grinded shaft at its ends, the angle of rotation of the upper part of the table is adjusted based on the measurement results if it turns out to be incorrect. After establishing the required angle of rotation of the table, the final fastening of the table clamps and grinding is carried out.

Read also: How to use blind rivets

Information about the manufacturer of cylindrical grinding machine 3151

Manufacturer of cylindrical grinding machine 3151 - Kharkov Machine Tool Plant (currently JSC Kharkov Machine Tool Plant)

The plant was founded on January 29, 1936 and specializes in the production of universal and special cylindrical grinding machines

Machine tools produced by the Kharkov Machine Tool Plant

- 2B56

radial drilling machine Ø 50 - 3A151

cylindrical grinding machine with hydraulic plunge mechanism Ø 200 x 700 - 3A161

cylindrical grinding machine with hydraulic plunge mechanism Ø 280 x 1000 - 3A164

cylindrical grinding machine Ø 400 x 2000 - 3B151

cylindrical grinding machine Ø 200 x 700 - 3B161

cylindrical grinding machine Ø 280 x 1000 - 3M132v

cylindrical grinding machine Ø 280 x 1000 - 3M151, 3M152, 3M162, 3M163

cylindrical grinding machine Ø 200 x 700, Ø 200 x 1000, Ø 280 x 1000, Ø 280 x 1400 - 3M151F2

CNC cylindrical grinding machine Ø 200 x 700 - 3M193

heavy cylindrical grinding machine with increased precision Ø 560 x 2800 - 3M194

heavy cylindrical grinding machine with increased precision Ø 560 x 4000 - 3M196

heavy cylindrical grinding machine with increased precision Ø 800 x 4000 - 3M197

heavy cylindrical grinding machine with increased precision Ø 800 x 6000 - 3130

cylindrical grinding machine Ø 280 x 700 - 3132

cylindrical grinding machine Ø 280 x 1000 - 3151

cylindrical grinding machine Ø 150 x 750

Cylindrical grinding machines: characteristics

Let's figure it out further. The main tool that a cylindrical grinding machine has is, of course, a grinding wheel. It can be of very different shapes and is intended for processing different parts. Depending on the nature of the work performed by a cylindrical grinding machine, it may belong to different groups of such equipment. For example, there are center and centerless cylindrical grinding units, internal grinding and surface grinding units. In addition to these groups, there are also machines that are used in mechanical engineering enterprises. With their help, all kinds of threads, wheel and gear teeth, as well as splines are processed.

The most modern automatic cylindrical grinding units have very large capabilities. They are provided by systems that allow a person to program the technological process and reduce interference with the operation of the equipment to a minimum. In some units, the memory capacity allows you to load a large number of programs into it. For example, Japanese machines have seven standard grinding methods. In addition, they have automatic adjustment of the unit for a specific part.

Equipment operation

You need to know how to operate cylindrical grinding machines for metal in order to achieve the maximum effect from their work and not injure yourself. Rules:

- Before starting work, check the reliability of the grinding wheel and assess its condition. Do not use abrasives with cracks, chips, or uneven surfaces.

- Check your network connection. Set machine settings in advance.

- Wear safety glasses to prevent chips from getting into your eyes.

- Allow the workpieces to cool if the equipment does not have water cooling.

- Change the abrasive depending on the required quality of processing.

- Lubricate moving parts of equipment with motor oil to make it last longer.

- Clean work surfaces from accumulated waste after processing.

- Securely fix the parts with clamps so that they do not move during operation.

Do not attempt to sand hard surfaces with a fine abrasive at low power.

Cylindrical grinding machines are used in various enterprises. They process wood, plastic, stone and metal. Depending on the selected type of abrasive material, different types of grinding are carried out (rough, finishing). You can make the device yourself. It is suitable for grinding small parts and sharpening tools.

Key Features

There are quite a few different designs of cylindrical grinding machines that allow processing of cylindrical and conical surfaces. The version with a 3M151 grinding head is used quite often; the passport indicates all the important technical characteristics, and the diagram also indicates important points about the location of structural elements.

Cylindrical grinding machine model 3M151 is used for processing the outer cylindrical surface. Shaft-type products are often processed on the 3M151 machine. In this case, conical workpieces can also be processed while the grinding headstock is displaced. The machine passport contains information about how conical the surface can be. It is worth noting that the cylindrical grinding machine model 3M151 has increased accuracy. When using it, you can carry out the following types of work:

- The design scheme makes it possible to carry out longitudinal and transverse grinding using manual feed. the passport indicates the maximum longitudinal and transverse manual feed;

- model 3m151 can be used for plunge-cut and longitudinal grinding in a semi-automatic operating cycle;

- Some versions have a system for entering a workpiece processing program; the work is carried out automatically.

Production of the 3M151 model began in the last millennium. Information from the passport and diagram determines the possibility of using the 3M151 model in small-scale, serial and large-scale production. Over many years of using the equipment, it was noted that the installed grinding head allows metal to be removed from a conical surface with great accuracy.

Types of Grinding Machines

Conventional grinding machines are divided mainly into four categories, which you can pick up in the Stroymashservice hypermarket:

- Surface grinding machine

- Cylindrical grinding machine

- Internal grinding machine

- Special types of grinding machines

Surface grinding machine

It is used for processing mainly flat and horizontal surfaces.

Surface grinding machines are classified according to the position of the spindle and work table as follows:

- Recirculation table with horizontal spindle.

- Recirculation table with vertical spindle.

- Rotary table with horizontal spindle.

- Rotary table with vertical spindle.

Cylindrical grinding machine

It is only used for processing cylindrical parts. Capable of processing only the outer surfaces of cylindrical objects, but can machine any cylindrical profiles such as conical, straight and stepped.

This machine is also classified according to the workpiece part and grinding wheel, which is as follows:

- Centerless surface grinding machine with cylindrical surface.

- Universal surface grinding machine with a cylindrical surface.

- Surface grinding machines - surface grinding and cylindrical grinding.

Internal grinding machine

As the name suggests, this machine is used to machine internal surfaces that must have cylindrical shapes and profiles.

The three main types of grinding machines are:

- Internal grinding machine with chuck.

- Central grinding machine minus internal grinding.

- Planetary internal grinding machine.

Grinding machine for tools and cutters

These are special types of grinding machines that are used to process cutting tools for milling, turning and drilling. Tool grinding consists of two parts: making a new tool and sharpening the old one.

The simple single-point cutting tool used in turning is machined or sharpened using a pedestal or hand-held grinder on a table, while multi-point cutting tools such as drilling tools and reamers are processed on some complex grinding machines such as the milling cutter and universal machine.

Thread grinding machines

This is a type of special grinding machine with a special grinding wheel. This machine is almost similar to the cylindrical grinding machine, but has a very precise lead screw for precise pitch of the threaded part.

Purpose of the machines

Using a grinding machine, you can process wood, stone, plastic, and metal. It is designed to perform various technological operations:

- Processing of cylindrical, rectangular, triangular, square workpieces. Removing different layers of metal.

- Creating a rough surface. For this purpose, a special type of abrasive is selected.

- Sharpening cutting tools, accessories. To avoid damaging the cutting edge, water cooling is used.

To process cylindrical parts, you need to select the grain size of the abrasive material. The layer of metal, wood, plastic, stone that is removed depends on this. The smaller the particles, the more precise grinding occurs.

Features of cylindrical grinding machines

Control is carried out manually using mechanical and hydraulic drives. Also, many modern installations are equipped with a numerical control (CNC) panel, which allows automation of most production processes. This not only simplifies the worker’s task, but also has a beneficial effect on the quality of processing.

To be allowed to install (both with and without a CNC panel), the worker must undergo appropriate training. He must also undergo training regarding safety rules in the workplace.

During operation, a person must be careful not to damage the part and harm his health. Depending on the design, the following types of installations are distinguished:

- Simple machine. In such installations, you can only change the angle of the table on which the main part is fixed, and the grinding disk has a fixed position. This makes it possible to process cone-shaped parts with a small apex angle. The fixed location of the disk impairs the versatility of the system, but significantly reduces its cost. Therefore, in the case of small industries (auto repair shops, home construction), purchasing a simple machine may be a justified decision.

- Universal cylindrical grinding machine. On such systems, both the table and the processing disk can be rotated. This allows you to grind all types of parts (flat, conical, end, variable diameter), as well as individual holes inside workpieces. A universal cylindrical grinding machine is usually equipped with a CNC, which can significantly increase the quality of processing. Such installations are more expensive than simple systems, and they are usually used in industry (mechanical engineering, repair of ships or aircraft, weapons production).

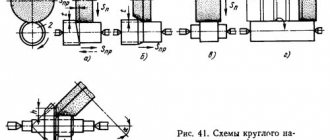

Types of grinding

Grinding using a cylindrical grinding machine can be carried out by three main methods - plunging, shoulder processing, longitudinal working stroke. Each of the techniques has several additional modifications, so there are many more actual processing scenarios.

Basic processing techniques

- Longitudinal grinding. The workpiece is installed in special grooves, which perform rotational movements during operation. The grooves move at low speed along (the speed is adjusted manually or using CNC). This leads to two effects during operation - the part not only rotates, but also moves along its axis. The polishing wheel is also turned on to perform the grinding. Due to the longitudinal stroke, the part is processed over its entire area, which simplifies its processing. The optimal depth is 0.05-0.1 mm.

- Longitudinal depth grinding. This method repeats the previous technology with one small difference - during operation the depth is from 0.1 to 0.4 millimeters. This allows you not only to clean the surface, but also to cut off the unnecessary layer of metal from the workpiece. Deep processing speeds up cleaning, but it is not suitable for working with soft metal alloys (brass, bronze, aluminum and others).

- Double longitudinal grinding. Two processing disks are installed on the machine equipment, and the processing itself is performed using the longitudinal stroke method. The first disc has a larger grain compared to the second. A small spacer can be installed between the discs to simplify the processing procedure. The meaning of such a system is this: the part is cleaned on the first disk, where the unnecessary layer of metal is cut off. Then it goes to the second disk, where it is polished and final cleaned.

- Plunge grinding. The metal workpiece is mounted in grooves that perform rotational movements during operation. The grooves are static (that is, the part does not make longitudinal movements). For processing, a wide wheel-disc is used, which is much longer than the workpiece itself. Grinding is performed as follows: the part is brought to a rotating wheel, which leads to grinding of the workpiece along its entire length. The technology is suitable for processing shaped or identical parts and solid sheets that do not have small recesses or recesses.

- Shoulder grinding. The technique is a combination of longitudinal and plunge grinding technologies. Shoulder grinding is used to grind long, rough parts that are difficult to process using only one of the standard grinding technologies. The mechanics of the process look like this. The part is mounted in special recesses that rotate it and move it horizontally. For the processing itself, one or more grinding discs are used. During penetration, one of the sections of the part is processed using the plunge-cut grinding method. Then a longitudinal stroke is performed, which makes it possible to process another part of the workpiece. If necessary, stop the machine and replace the abrasive disc (when working with grooves, recesses, holes).

Rough and fine grinding

During rough grinding, a layer of a certain thickness is cut off from the metal surface. The main purpose of roughing is to reduce the size of the part (in an individual fragment or over the entire area).

During finishing processing, polishing is performed, as well as the removal of defects (burrs, cracks, sharp corners). Rough and finishing grinding can be performed on different or on the same machine.

A universal cylindrical grinding machine performs double grinding - the first disc removes excess metal, and the second layer performs final polishing.

Design and principle of operation

It is easier to understand the operating principle when the key components of the machine are known. These include:

- Fixed stand. The base that holds the rest of the equipment on itself. It has stable legs. Compact models can be equipped with wheels for moving around the workshop.

- The headstock on which the spindle with the grinding wheel is attached.

- Calipers, knives.

- Gearbox.

- Device for changing the position of equipment.

- Vise for holding the workpiece.

- Control Panel.

- Guides along which the table moves.

- Working surface for placing parts.

Application area

Cylindrical grinding machines are used for external processing of cylindrical and conical parts made of ferrous and non-ferrous metals using the method of longitudinal, plunge and depth grinding in conditions of single, serial and mass production in the field of metallurgy and mechanical engineering at production sites in the workshops of enterprises. Also, the mentioned equipment can often be found in laboratories and research departments of factories and factories. Compact cylindrical grinding machines are actively used in repair shops, vehicle service stations, and garages. In addition, the units are used in workshops of vocational educational institutions that train machine tool specialists.

Features of cylindrical grinding machines

The equipment design includes the following elements:

- bed;

- upper and lower tables;

- device for internal grinding;

- quill;

- fastenings for grinding wheels;

- headstock;

- electrical cabinet;

- mechanism for straightening the abrasive wheel;

- Remote Control.

We offer to buy a cylindrical grinding machine, which makes it possible to process any metal surface with high precision. It is noteworthy that the work tables of these units can be equipped with additional stiffening ribs to increase strength and make it possible to work with large parts that exhibit significant mass. Hydraulic workpiece feeding systems ensure cyclic processing of parts with minimal time.

In our company's catalog you can buy a cylindrical grinding machine with sliding guides, which are covered with special covers to prevent contamination. Tables move along them, driven by a manual mechanism or a hydraulic system. The presence of a folding indicator device on the front of the high-strength frame allows you to control table movements with high accuracy. Segmental self-aligning bearings on which the spindle of the grinding headstock is mounted provide rigidity of support and increased rotational accuracy.

, which supplies customers from Russia and neighboring countries with equipment for processing metal parts, gives customers the opportunity to buy a cylindrical grinding machine with an electric locking of the grinding head motor, which protects the equipment from overloads. It is also noteworthy that the inclined working surface of the unit helps to move the tailstock and headstock without losing alignment. Grinding wheels of various grain sizes and hardness are used as tools for abrasive processing of parts. To straighten them, special devices with carbide discs are used.

Advantages of cylindrical grinding machines

We advise visitors to buy a cylindrical grinding machine that demonstrates advantages such as:

- safety in use, subject to all rules for working with equipment;

- automatic lubrication system for spindle heads, reducing wear and increasing the service life of spindles;

- a system that makes it possible to regulate the speed of longitudinal transmission without jerking;

- accelerated approach and retraction of the grinding wheel to save time and increase productivity;

- high reliability in use due to the impeccable quality of components from which industrial cylindrical grinding machines are assembled;

- the presence of an effective cooling system that allows reducing the temperature of the grinding wheel during rotation and extending its service life;

- hydraulic or manual (mechanical) high-precision movement of work tables and spindle heads;

- stability of the shape of the working area during load fluctuations;

- devices that ensure quick removal of flanges and, if necessary, replacement;

- the presence of splash guards that prevent liquid contaminated with metal particles from entering the operator’s clothing;

- the possibility of installing magnetic separators or paper filters for the grinding wheel cooling system;

- reliable and durable electric motors that consume moderate electricity;

- stable processing quality;

- maintainability and the ability to replace components.