Craftsmen used a lathe to make a wide variety of products: dishes, spinning wheels, toys, furniture elements, and decorative items for the interior. A lathe allows the craftsman to create the most intricate and exquisite wooden shapes. Wood turning will be successful if, in addition to skillful hands, you have a high-quality tool, as well as solid and flawless wood.

How to choose cutters yourself?

Wood cutters are a must-have tool for woodworking.

You can make them yourself or buy them in a store. Wood cutters have the same design, although different shapes. The following tools are the most popular among wood cutters:

- A universal knife-jamb, which is shaped like a triangular shoe knife.

- Clukarza is a chisel-like tool with a curved blade.

- A spoon cutter is a ring-shaped cutter that is used for cutting out dishes with deep recesses.

- Chisel, the most common type of wood cutter.

Chisels, on the other hand, come in all sorts of shapes to perform a variety of tasks.

Cutters for manual turning of wood are divided into the following types:

- Semicircular.

- Flat obliques.

- Cut-off.

- Cut-off with figured sharpening.

- Angular.

- Shaped.

- Hook cutter.

- Ring cutter.

- Beveled corner.

Special ones can consist of two metal plates that can be moved relative to each other, so that a unique cut or pattern can be obtained. The most popular cutters for turning work are:

- Reuter is a tool with a semicircular cutting tip.

- Meisel is a tool with a beveled flat blade.

It is used for processing wood and bringing it to the state of a finished product.

What tools are used for metalworking on lathes?

For metalworking, equipment parameters such as the number of revolutions of the chuck per unit of time, the thickness of the steel layer to be removed are adjusted, and the necessary tool is selected.

The type of material is decisive for setting the parameters and selecting the cutter. The stronger and harder the metal, the smaller its layer is removed in one pass and the better quality the cutters should be.

The following tools are used in metalworking:

- For rough grinding of workpieces, tools with a larger cutting plate, straight, bent and reinforced, are used. Such cutters are capable of removing a thick layer of material in one pass without damaging the working part;

- Finishing cutters with a narrow insert are used to remove metal in thin layers. Depending on the parameters of the workpiece, the appropriate cutting tool is used;

- Special cutting tools are used to cut workpieces to size. In appearance, the tool differs from its through and thrust analogues, since its movement is carried out only in the transverse direction;

- Boring and reaming of holes is also performed using special cutters, the working surface of which faces outward. There are many varieties of such instruments.

When choosing a tool, special attention is paid to the angle of rotation of the cutting part. For example, if the work is done with workpieces made of hard steel and large diameter, then the standard angle of rotation of the cutter varies from 35 to 40 degrees. To process smaller workpieces made of soft steel, the reamer angle increases to 60-90 degrees.

Photos of DIY woodworking machines

Selecting wood for turning

Before you start turning your planned product, you need to do some preparatory work: select a suitable material and dry it.

Dense, fine-grained wood species are best suited for turning work. It is desirable that the material does not have defects: cracks, falling knots, tar and sprouts. But curling and cross-layering, usually considered defects, are not problems when turning. On the contrary, due to the fact that twisted wood is difficult to split, it is often used to make mallets and handles.

Almost all types of wood are suitable for turning, but birch, alder, beech, maple, walnut, pear, linden and hornbeam behave best when processed, but pine, oak, spruce and ash are a little worse. Pear and apple trees are ideal for turning, especially wild species. The wood of these trees is easy to process and polishes well. The paint adheres well to it.

Beautiful toys and souvenirs come from aspen, linden, Karelian birch and elm. You can turn them into utensils and decorative items. Walnut wood makes good small items: powder compacts, boxes, frames. And to create interior decor, it is best to use species that have a beautiful texture - walnut, oak, juniper, cedar, mahogany, pine.

Beech, hornbeam, alder, maple, boxwood and Karelian birch are widely used in furniture production.

Read also: Palladium in radio components of the USSR

Precautions during operation

Before you start getting acquainted with wood carving, you need to learn about safety rules. The entire instrument is very sharp. They can easily get hurt, and sometimes you can get so seriously injured that you end up with disability.

What needs to be done to reduce these risks:

- Install the countertop securely and firmly. The table should not sway from side to side or move around the floor.

- The workpieces should be secured to the table with special tools - clamps. Only they are able to reliably fix the part. Any other available materials are not suitable for this purpose.

- Lamps and lamps should not blind the carver. They need to be placed so that the tabletop is well lit and no shadow falls from the master.

- When sharpening chisels and knives, you should wear gloves and safety glasses. Small chips can get into your eyes, and the knife blade can accidentally slip off the machine and injure your hands.

- The quality of sharpening of any tools should be checked on a special whetstone, and not with your fingers.

- When working with cutting tools, you should hold them away from you, and also make sure that your other hand is at a safe distance from the knife.

- There should be no foreign objects in the workplace.

- After each cutting stage, you need to remove chips from the table using special brushes. If too much debris accumulates, a sharp tool may get lost underneath it, and when cleaning, it will stick into your hand.

- All knives and chisels should have a place. Experienced craftsmen recommend placing a jar on the table in which the carver will put away the tools and take them out when necessary. When the work is completed, all accessories must be placed in places for permanent storage.

- When using electrical appliances, it is important to ensure that the cord does not become tangled or twisted.

- You cannot plug several devices into an outlet at once. Many wires on the floor can become intertwined. It's easy to trip and fall on them.

Wax mastic is often used for work. It should be heated on an electric stove, but not over an open fire.

It is unacceptable to place heating elements where chips will fly. It ignites quickly. Wood blanks smolder at a temperature of 214 degrees, then begin to burn, so it is important to monitor fire safety.

The workshop should always have bandages, cotton wool and disinfectant solutions for the skin. Even professional craftsmen are not immune from accidental injuries. Wounds need to be treated as quickly as possible. If the damage is serious, you should postpone work until complete recovery.

Wood turning

Most crafts require processing by turning. To make a craft on a lathe in the shape of a vase, plate or glass - objects that have the transverse shape of a circle, the workpiece must be secured in a special chuck of the machine. To fasten long parts, a trident is used, which presses them in with the center of the tailstock.

By moving the chisel along the axis of rotation, the part will be sharpened. This type of turning is called longitudinal. If the homemade product is small, it can be secured with screws to a faceplate or flat disk.

First, you need to mark the workpiece for screws, and then drill a blind hole, the depth of which is equal to the screw-in length of the screw. You can also poke a hole with an awl. To determine the location of the screws, the workpiece must be attached to the plank washer and through the holes that are located on the reverse side, outline the places for the screws.

When processing a flat part on a faceplate, it is necessary to prepare a chisel and, by moving it perpendicularly, grind the workpiece in a frontal or end-to-face manner.

The cutting part of lathes, called the blade, is wedge-shaped. The front and back surfaces form a cutting edge at the intersection. Turning wooden products may involve cutting off part of the workpiece, marking the centers of rotation, inspecting the condition of the workpiece and giving it the desired cylindrical shape.

Using all the possibilities provided by a lathe, you can achieve the ideal barrel-shaped shape of the desired product with your own hands. You can’t do without turning when making furniture handles and legs.

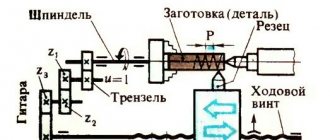

General design and structure of a homemade unit

When designing a homemade lathe for turning, you can consider two design options: with an electric drive and without an electric motor.

Despite the antiquity of the method of processing wood using human muscles, this option has the right to exist in conditions where it is necessary to process wood, but there is no possibility of using electricity. The main structural elements of a lathe are listed below.

bed

The bed is the frame of the entire mechanism. The safety of the craftsman and the quality of the future product depend on the reliability of the frame.

Drive: motor rotor or pedal for foot drive.

Headstock

The headstock is a chuck for clamping the product and its subsequent rotation. Rotation from the engine is transmitted to it through a gear transmission, pulleys or a belt. At the end of the headstock there is a spindle with a faceplate for fixing the product.

Tailstock

The tailstock is needed for additional fixation of the workpiece, which will help improve the accuracy of the rotation axis and avoid unnecessary vibrations. It is a freely rotating blade that can be moved along the axis of rotation of the product to adjust the distance between the headstocks.

Podruchnik

A tool rest is necessary to support the chisel while processing wood. Without a stand for a hand tool, it is impossible to maintain high accuracy of the blade tip hitting the sketch lines and it is extremely difficult to regulate the pressing force of the cutter.

Metal turning products to order

If you have a need to manufacture metal parts, then you should not continue looking for a contractor. Consider that you have already found it in us. We are aimed at long-term and mutually beneficial cooperation with you. is located in Moscow, but we will be happy to fulfill orders from other regions.

We are always in touch

We perform with high quality and on time

We work all over Russia

CNC equipment

Our specialization is not only turning, but also drilling holes with subsequent countersinking and reaming, milling, and metalworking. We produce metal bushings, rods, hardware and other rotating bodies.

Turning is divided into the following main types:

- Grinding of external surfaces (cylindrical, conical, shaped) with a cutter, thread cutting.

- Boring. This includes machining internal blind and through holes.

- Trimming (trimming) and cutting.

- Cutting threads in holes with a cutter or tap.

Our workshop has the necessary equipment: universal screw-cutting lathes, semi-automatic machines, modular machines with adjustable units. We strive to reduce the cost of production; in the end, products produced on a metal lathe are not too expensive. The most profitable manufacturing technology is being developed, combining affordable cost and high quality.

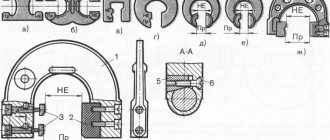

Workpiece fastening

According to the markings, notches are made on the ends of the blank using a marking core. They guarantee reliable fixation of the workpiece and simplify its installation.

There are two main ways to work on a wood lathe:

- processing of a workpiece fixed between two centers;

- turning a product clamped in the headstock.

Regardless of the option chosen, before turning on the machine, you must ensure that the fixation is secure. If the tailstock is used, it must press down firmly on the workpiece while being securely locked to the bed.

After fastening, the tool rest is placed. Its edge should be parallel to the workpiece and recede about 5 mm from it. During the work, as the material is removed, it will need to be moved.

Preparation for work ends with a test rotation. To do this, turn the blank by hand to make sure there is no excessive fighting.

Making the Steering Wheel as an interior item with a secret, part 1

- home

- Master Classes from “Master Class Direction” by tag: turning

A new project on Rubankov TV from the Moscow Rubankov Carpentry School. Uncle Vanya, the head of the workshop, started an interesting design project for the interior with a real steering wheel, see the details for yourself) In the video we will do a lot of planing, sawing, gluing, turning on lathes and much more. Enjoy watching and see you at our craft school courses.

Making the Steering Wheel as an interior item with a secret, part 1

7:53 Glue brush - https://goo.gl/yRqPg6 10:35 Japanese drills - https://goo.gl/yr7JR2 13:21 Rubankov turning school - https://goo.gl/iShd6R 19:50 Hegner jigsaw https://goo.gl/5mwLWx 20:50 Self-centering drills https://goo.gl/J4ohWr

Decor, souvenirs, advertising, jewelry, etc.

The ability to process completely different materials using several strategies - 3D milling, cutting and engraving - allows you to use CNC milling in completely different areas and produce an endless variety of objects.

Possibilities of a CNC machine in the production of promotional products and decorative items

The use of a milling machine allows us to produce a wide variety of products: toppers and words for celebrations, photo frames, boxes, plaques and signs from various materials including plastics, wood, metals and artificial stone. By engraving two-layer plastics of various colors you can make signs, badges, license plates, and nameplates.

Workshop of Daria Shved https://.com/id232777509 (Krasnodar), aluminum machine Modelist90120al

1/8

Nikita T., (Perm), aluminum machine Modelist60120

1/8

(Ekaterinburg, Belinskogo str. 34, office 321, tel. 89122455596, 89028733571) is engaged in the manufacture of products for advertising activities, decoration of premises and furniture made of artificial stone, aluminum machine CNC-6090al

1/6

FROSTBERG company (Dmitrov, https://.com/frostberg_decor), aluminum machine CNC-6090al

1/4

Using a CNC machine to make jewelry

A collection of works on the manufacture of jewelry, costume jewelry and souvenirs is listed on a separate page

Here is an example of using a CNC machine to make jewelry. Alexey Yuvelirov (Gelendzhik, https://.com/gelengrav), machine cnc2535al2

1/7

Milling of model wax in 5 axes on a 5-axis CNC machine

Milling a ring from model wax using a specialized rotary device, which, together with a special software plugin, makes it quite easy to create models of rings of complex shapes that require processing both from the end and sides of the ring, an example of such a ring in the photo

video of making this ring on a CNC machine

Using a CNC machine in furniture production.

A collection of works from our users on the production of furniture decor, milling furniture fabric, etc. is included on a separate page

Milling machines can be used to process a wide variety of wood types. Using the machines, it is possible to create signs and indicators made of wood, prototypes, unique products, toys, molds for casting furniture fittings and much more.

(Gorokhovets, gorfurnitura.ru) is engaged in the production of furniture decor, aluminum machine CNC-6090al. The slide show uses photos of decor made using molds made on a CNC-6090al

1/8

Andrey E. (Rostov-on-Don), made boxes for his workshop on an aluminum CNC-3040al2 machine

Souvenir products.

A CNC machine allows you to make souvenirs, award diplomas, dedicatory inscriptions, engrave a wide variety of products made of plastic, glass and non-ferrous metal, including cups, medals, tokens, pendants, bottles, and much more.

Dmitry U. (Novosibirsk), plywood machine Modelist3040

1/9

Andrey E. (Rostov-on-Don), aluminum machine CNC-3040al2. Making molds for creating gift chocolate bars

1/2

Vitaly F. (Orel), plywood machine Modelist3030. Cookie mold

Sergey K. (Gagarin), plywood machine Modelist4060. Coat of arms, bottle packaging and night light Eiffel Tower

1/3

Alexey P. (Moscow), plywood machine Modelist3030

1/2

Sergey (Krasnodar), plywood machine Modelist4090. Making models for construction companies from PVC

Vladislav G. (Krasnodar), aluminum machine CNC-3040al2. Milling parts of RC models for drag racing

1/4

Using CNC for equipment production. Devices, printed circuit boards, cliches.

Using engraving and milling machines, you can produce instrument cases, panels, engrave inscriptions, signs, serial numbers on a wide variety of parts, from plates on equipment and instrument panels, to final products.

Andrey K. (Primorsko-Akhtarsk), aluminum machine CNC-3040al2. Engaged in the manufacture of devices for video operators and video cameras from duralumin alloys. In the photo POOLiRiG is a shoulder rest for various video cameras.

Konstantin K. (Krasnodar), aluminum machine CNC-2020al. Printed circuit board manufacturing

Alpha, LLC (Simferopol), aluminum machine CNC-2535al. Magnesium cliche

A collection of works on the production of molds, clichés, and sealers is included on a separate page.

What can you do with it?

A lathe in skillful hands and with the necessary materials for the job is an extremely effective tool for the manufacture of metal or wooden products, and this can include both high-precision parts for other equipment and a variety of handicrafts for home or leisure.

Wood products

You can make wood products both “for the home, for the family” and for sale. In the latter case, the things made have a magical prefix in their name “made individually,” which in our era of globalization of all processes has considerable weight in the eyes of many potential buyers.

You can make furniture elements for its subsequent assembly (we think everyone remembers school stools made and assembled in labor lessons), tool handles, medium and small decor - the basis for wall clocks, vases, figurines of creatures, a popular type of machine-made products are chess, checkers, backgammon.

Metal crafts

Lathes for metalworking are usually not associated with crafts, because with their help, a lot of enterprises and individual craftsmen work on the manufacture of nuts and bolts, bushings and couplings, rings and shafts for various purposes, the maximum that a person who does not have information can imagine is this boring some parts during repairs and similar actions.

However, the range of tasks performed is not limited to work. Metal crafts can be made by both an experienced worker and a novice trainee; most often these are figurines or individual decorative elements: balls and keychains, cubes and entire models (for example, cars).

In conclusion, I would like to note the following: the world of lathes, with all its size and diversity, is available to everyone who wants to try themselves on this path. Moreover, now, with the active proliferation of CNC devices, a small lathe can be installed even at home, and after taking courses on its use, with time and growing experience, you can become one of those who can turn a piece of material into a real masterpiece, be it it is intended for work or leisure.

Candlestick made from roots

When creating wooden candlesticks with your own hands, you can use old wood that has lain under water and roots. In this case, it is possible to create truly masterpiece crafts.

Such material must be carefully processed. It is varnished or painted. If the pieces are very small, they also make interesting compositions. After processing, several roots are collected into a single system. It must be sustainable. The candlestick seems to be stretching upward. In this case, the roots should be turned upside down. You can also create a horizontal composition.

Stands for candles are installed at the tips of the roots. All elements of the system are fixed using colorless glue. Such a composition must be stable. This needs to be checked after the glue has completely dried. If necessary, the base of such a candlestick is further leveled.

Such candlesticks look harmonious in many interior styles. Its color should be in complete harmony with the selected color scheme in the room. White candlesticks made from roots look very elegant. You can also leave the natural color of the material. It will also look interesting.

What can be done?

A lathe is a tool not only for making construction workpieces. It is often used to create various souvenirs and decorative items: boxes, vases, chess, candlesticks, wooden toys and much more.

Vase

In addition to the machine, you will need other tools: chisel, ruler, compass, hacksaw, axe, plane. Considering the variety of forms that vases can take, these products can be quite simple or complex.

Let's look at a simple example:

- the workpiece, finished along the length and at the ends, is installed on the machine;

- the top layer of wood is removed and given the intended shape: oval, straight, etc.

- using a drill, a hole is made in the center of the free end with a depth less than the length of the vase;

- the cavity of the product is cut out with a “jamb” cutter;

- the product is polished, the bottom is finished manually;

- varnish coating.

Turned chess

Small wooden blanks with a cross-sectional diameter of 50–60 mm are suitable for making chess.

On one side of the workpiece, a smaller cross-section is needed - this end will fix the workpiece on the machine.

- the free end of the workpiece is trimmed with a cutter and pressed against the tailstock;

- a layer of wood is removed to give it a round shape;

- at the discretion of the master, the shape of the figure itself is turned;

- grinding, the figure is cut off from the fixed part;

- coated with varnish/paint.

Important!

The fixed part must be machined to a rounded shape, since installing a tetrahedral workpiece in the chuck will create additional load on the cutter!

Making a box

The box is a fairly simple product to make. As a base, you can use a cylinder-shaped workpiece.

The main difficulty here is the lid, which must be flush with the edges of the box body and fit into the grooves of the walls in order to close tightly.

- we fix the workpiece on the machine and use a semicircular cutter to give it a clearer shape;

- using a straight narrow cutter we form the inner cavity of the box;

- Using a triangular cutter, we bring the resulting niche to the walls of the body;

- Using a straight wide cutter, we form the bottom of the product and the groove for the lid;

- sand, apply varnish and wax.

The lid is made from a similar blank, only thinner. It goes through the same steps as the body, and the formation of the outer and inner sides, which can be straight or convex, is carried out with a straight wide cutter.

DIY wooden products from different types of wood

Even more amazing things made of wood are made entirely by hand, without a lathe. Thus, it has become popular to create a wooden case for everyday things: a flash drive, a computer mouse.

There is even a concept model of a phone made entirely of wood and with touch-sensitive buttons.

Animal figurines

Such art depends entirely only on the level of skill of the manufacturer and his imagination. Linden is better suited for such products.

This rock does not form cracks and is easy to process. But they also work with other breeds. For production you will need:

- a chisel with a rounded and triangular end to create appropriate shapes;

- a blunt knife and a knife with a beveled blade.

Before you immediately start working with wood, it is better to sketch on paper what the future product will look like. Often the drawing is transferred with tracing paper to the workpiece, and in order to avoid mistakes, before working with metal tools, an outline is drawn on the figure with a pencil.

Crafts-souvenirs

Various handmade wood products look great as small gifts and souvenirs. These can be kitchen utensils: spoons, spatulas. Various keychains, badges, entire paintings and much more.

Machines used by INTEK-M for turning operations

Standard equipment for rough grinding and finishing metalworking are turning and turning-milling machining centers. They are universal, have excellent technical characteristics, and are suitable for performing most operations ordered by clients.

Imported machines include a headstock, a spindle with a chuck and a gearbox. Also included in the package is a tailstock, a mount for installing mandrels or a rotating center, and a clamp for the slide. The bed and feed box are included in each device.

The MAZAK SMART TURN 200 ML turning and milling processing center provides high speed and quality work with metal parts. The machine is capable of performing diverse work in accordance with the established algorithm. The MAZAK QT100MSG turning center has compact dimensions and high productivity, and is capable of working with different materials.

Metal turning products

How to make bodies of rotation: bushings, flanges, shafts, axles? Only on a lathe. Turning is one of the areas of metal cutting. Of course, there are now many modern methods for shaping parts, but turning is still successfully used in small-scale production.

The supply of metalworking usually exceeds demand. You can consider potential performers for a long time. But it’s better to contact us and save time and money.

Our company will produce custom-made products in Moscow at an affordable price, in a short time and with high quality.

- long-term cooperation

- technical support on any thematic issues

- flexible pricing policy

- discounts for bulk and repeat orders

To make turning products from metal, it is enough to have a workpiece, a machine, and a cutting tool. We still need a specialist who will perform such work. Our company has it all.

We produce any metal turning products to order; their complexity and configuration do not matter. Our machine operators have extensive experience and are capable of turning any part.

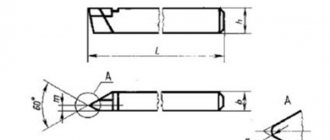

Wood turning tool

Most often, turning chisels are used for processing wood on machines. Compared to conventional chisels, turning chisels have longer handles, and their cutters are made only from high-quality tool steel. That is, the chisel consists of two parts - a handle and a metal blade mounted on it with a blade sharpened at a certain angle or a double-edged blade.

There are different types of chisels for different tasks. For a beginner in turning, in order to start working with wood, it is enough to learn how to use these two chisels:

Chisels for turning

- Reyer - this chisel has a semicircular blade, which is made of a thick plate; it is intended for rough turning of the workpiece;

- meisel - this type of chisel is intended for finishing the part; the blade is sharpened obliquely, on both sides.

Most of the other types of turning chisels are classified as shaped tools. They give the final appearance of a turned part. For example, decorative grooves can be cut out on a turned salt shaker. Here are some types of such chisels:

- chisel-hook - with such a cutter you can carve a recess at the end of the workpiece;

- chisel-comb - with its help you can cut internal and external threads or apply many decorative grooves;

- ring chisel - you can do the same thing with it as with a hook.

There are a great many types of shaped cutters. Experienced turners come up with their own cutters for a specific task and make them themselves.

Wood turning cutters