When it comes to making quick, accurate and neat cross cuts, a miter saw is an indispensable tool. Initially, this tool was created for the needs of carpenters - mainly to perform simple sawing operations - but very quickly its capabilities were appreciated by a wide range of craftsmen. From a simple cutting machine, the trimmer has evolved into an indispensable tool that has become equally popular both in factories and in home workshops. This led to a huge selection of models differing in class, design and prices.

What is a miter saw for?

This question may seem naive to some, but there is nothing shameful in it. Trimming machines have long gone beyond carpentry, expanding the boundaries of their use. Therefore, it is quite appropriate to dwell on how this tool is used today.

A crosscut saw, also known as a miter saw or pendulum saw, is a machine for cross-cutting long workpieces at the desired angle. The main advantage of the tool is the ability to maintain specified cutting angles with surgical precision. The saw unit rotates right and left, so you can cut workpieces in half strictly at 90° or at any other specified angle. The saw can also be tilted to the side - this allows you to cut the ends straight or with the desired bevel. The settings for transverse and oblique cutting are set on the vertical and horizontal cutting scale. All functions to maintain the specified cutting parameters are performed by mechanics.

This tool is used primarily with wood: cutting boards, timber, lining, laminate, etc. Trimming is indispensable for cutting skirting boards, baguette and cornice profiles and any other sawing work where guarantees of an accurate and tightly fitted miter joint are needed. Models with a cutting depth limiter are convenient for creating carpentry joints - they are used to select grooves and cut tenons. When installing the appropriate discs, the machine can be used for cutting composite materials, thin-walled pipes and light metal profiles.

Miter saw device

The trimming is not too complicated. The main structural elements of this tool are the saw unit (an inclined head with a cutting disk) and the base - a frame with a rotary table, which allows you to change the cutting angle in the horizontal plane. The cutting disc is driven by an electric motor: most often it is located on the side of the saw unit, less often - at the back. When not in use, the blade is completely covered by a protective cover, which is automatically retracted as the saw unit is lowered. This is one of the key safety elements; its malfunction is a reason to stop using the tool until the problem is resolved.

Buying a trimmer is always preceded by an understanding of what you need it for. Then begins the dive into the technical part and the search for compromises: optimal power, the required disk diameter, drive, reliable frame and many other nuances on which the quality of the cut and the overall performance of the tool will depend.

Miter saws are divided into household, semi-professional and professional. This is a conditional classification, which, nevertheless, has taken root well in our realities. The class of the tool is determined by the type of engine and its power, the diameter of the saw blade, the type of transmission, the accuracy of the mechanics and other technical aspects.

Crosscut deviation

Not every electric miter saw allows you to cut two corners at the same time because it requires not only a tilt setting, but also the ability to rotate on the table.

Miter saws with this feature are expensive, but they are the only ones that allow you to make even the most complex elements.

Power. Engine. Transmission type

Power is one of the main characteristics that determines the performance of a power tool. , this figure ranges from 850 to 2200 W. Power factor reflects the intensity of energy consumption that is needed to maintain the operation of the device.

Semi-professional and professional models are saws with a power of 1400 -2200 W. They are designed for large diameter disks and are able to work longer without interruption, eliminating the risks of critical loads. At the same time, they significantly lose in weight and dimensions to their household counterparts (850-1500 W). For comparison, for powerful trimming machines (2000-2200 W) discs with a diameter of 254 or 305 mm are selected; the weight of the entire installation can reach up to 25 kg or more. Trimmers with a power of 1200 W weigh 13-15 kg and are designed for 210 or 216 mm discs.

In order not to miss the mark when choosing a trimmer, we recommend answering several questions:

- How often and intensively will you use the tool?

- What material will you primarily work with: its structure, density, thickness? It is obvious that, for example, cutting pine lining will create incomparably less load on the machine than working with oak boards, beech, larch and other hardwoods.

- How important are the portability and compact dimensions of the tool to you?

Practice shows that the optimal power of a saw for a home workshop lies in the range of 1600-1800 W.

Engine . Miter saws are equipped with two types of electric motors: brushed (commutator) and brushless (asynchronous).

- Brush motors are an attribute of the vast majority of models. Compared to brushless analogues, they have lower efficiency, require periodic maintenance (replacing brushes), are noisier and are less suitable for intensive use. But they are less vulnerable to overloads and power surges. Also, commutator motors provide high torque, are cheaper and smaller in size. The overwhelming percentage of household and semi-professional miter saws are equipped with just such systems.

- Asynchronous motors have greater efficiency and do not require replacement of consumables. They provide smooth operation without the characteristic jerks characteristic of brush analogues, which also affects the quality of the cut. Brushless motors are quieter, but understand that the noise level of the tool is determined by other factors, such as the type of drive. Trimmers with asynchronous motors are larger and more expensive.

Transfer type . Torque is transmitted from the engine to the saw blade through a gearbox or belt drive. Geared models are more accurate in transmitting speed and rotation - the possibility of the disc slipping is excluded, but it can give a slight backlash. Belt drive is less noisy, it significantly reduces disk vibrations, and better protects the engine. The disadvantage of such systems is slippage during tool operation, which can occur as the belt wears out. The latter is a consumable that requires periodic replacement.

Main selection criteria

Before you start choosing a miter saw, you need to know which design elements and parameters you should pay priority attention to. Let us consider the main criteria for choosing a good “trimming” in more detail.

engine's type

Modern pendulum saws can use three types of electric motors. Each design solution has its pros and cons:

- Asynchronous motor. It is distinguished by reliability, efficiency and low noise level. However, this solution also has one serious drawback: low power and rotor speed with significant weight. This is why most manufacturers do not equip household models with asynchronous power plants;

- Commutator motor. It has an ideal ratio of power to weight and size indicators. Such power plants have a simpler control system and speed stabilization. The rotational speed of the commutator motor shaft can easily exceed 10 thousand rpm. There were some drawbacks: limited brush life, high noise levels, overheating of the armature windings under increased loads;

- Brushless motor. It is a kind of symbiosis of collector and asynchronous technology. In such a motor, the weakest link, which is the brushes, is replaced with an electronic unit. Such power plants incorporate all the advantages of classical technologies: high power with low weight, noiselessness, low maintenance, high reliability. The only drawback of crosscut saws with a brushless motor is their high cost, which is more than compensated by the long service life of the tool.

Asynchronous motor Brushless motor

Gearbox type

When choosing a suitable miter saw, you should definitely pay attention to the design of the gearbox - the second most important element of the cutting unit of any miter saw. This element is the connecting link between the power unit and the saw blade. This tool uses two types of gearboxes:

- with gear transmission;

- belt drive.

Miter saw with gear drive Miter saw with belt drive

The toothed gears of the gearbox are reliable and durable. They transmit torque from the motor rotor to the saw blade spindle without slipping. However, if the gear fails (tooth breakage due to excessive load), the entire gearbox will need to be replaced, or an expensive repair of this unit will be required.

Belt drive also has a lot of disadvantages: it is possible for the belt to slip on the shafts and wear out quite quickly due to the high coefficient of friction. However, manufacturers of pendulum saws widely use belt gearboxes in their products. Thanks to this design, manufacturers were able to reduce bearing wear caused by vibration, which is partially smoothed out by the belt drive. A belt that has fallen off is easy to put back in place; you can simply replace it yourself if it becomes critically worn. In addition, when the disk jams, the belt will slip on the shafts, which will save the motor windings from overheating and expensive components from destruction.

Saw blades

When answering the question of which model of miter saw is best to buy, you should decide on its purpose and operating conditions. In other words, any disc will do for working with wood. If you intend to use trimming for processing various materials, a very important point is the correctly selected equipment, which varies:

- Outer diameter. Depending on the model, saw blades with a diameter of 210, 250 and 305 mm can be used in cross-cutting machines. Circles of smaller and larger diameters are quite rare, since they are intended for specialized equipment, which is extremely rarely available for sale;

- A landing hole, the diameter of which can be 25 or 30 mm;

- Material.

Saw boards can be monolithic or carbide. The first ones are made of high-carbon steel, which tends to “shrink” quickly. You can sharpen such a disc yourself without using specialized equipment. The carbide cutting tool is equipped with pobedit tips that hold an edge perfectly; Monolithic (left) and carbide (right) disc - Thickness. Thin discs have a relatively short service life, but provide a finer cut. They are most often used when processing valuable wood species. Thicker equipment is characterized by a longer service life and cutting width;

- Geometry and number of teeth. The larger the tooth, the rougher the cutting line will be. The trapezoidal tooth is suitable for processing chipboard and aluminum. The concave shape is used on equipment intended for cutting laminate flooring. The “set” tooth is excellent for sawing fiberboard, MDF, and plywood.

In addition, miter saw blades differ in tooth angle.

Equipment with a tooth positioned at a positive angle is recommended for sawing along the grain. A tooth with a negative angle will give a clean cut when cutting wood and its derivatives crosswise. Positive tooth inclination

Power and number of revolutions

The motor power in cross-cut saws, depending on the model, can vary from 0.8 to 2.5 kW. Low-power models are often used for short-term work with small-diameter equipment. Maximum power is typical for a professional tool, which, with the appropriate equipment, can cope with almost any material. The optimal power for household trimming is 1.5-1.8 kW.

Optimal power - 1.5-1.8 kW

The number of revolutions of the saw blade affects the quality of the cut and the performance of the device. For most modern models, this parameter ranges from 3200 to 6 thousand rpm.

Important! The best models of miter saws are equipped with a system for adjusting the rotation speed of the equipment.

Dimensions

How to choose the optimal weight and dimensions of a wood miter saw? You should know that there is a relationship between the power of equipment and its weight and size indicators. The higher the power of the model and the larger the diameter of the equipment, the larger the dimensions and weight of the tool. That is why you should not chase heavy-duty models if you do not intend to use the tool for professional purposes.

Disc diameter. Landing hole. Sharpening angle

The diameters of saw blades for most miter saws range from 165 to 355 mm . The larger the blade, the greater the depth of cut the saw has. By the diameter of the equipment you can immediately judge the power and class of the power tool. When choosing a trimmer, the maximum disk size is correlated with the amount of work that is planned to be performed. This allows you to optimize time costs and reduce tool wear. The dimensions of the entire tool are directly related to the size of the disk: the larger it is, the more massive the support platform, the larger and higher the saw unit.

Disc mounting diameter. The diameter of the mounting hole for most disks is from 16 to 30 mm . In some cases, the problem of equipment that does not fit the spindle can be solved with the help of an adapter. Using blades that do not fit the saw's fastening parts may cause wobble during rotation and loss of control of the tool.

Sharpening angle . Saw blade teeth have a positive or negative rake angle. For cross-cutting sliders - saws with broaching, which we will talk about below - select discs whose teeth have a negative rake angle. Saws without broaching work better with equipment that has a positive angle. Of course, any saw blade will work on every type of trim, but following the described nuances will ensure the cleanest and most accurate cut possible.

Number of revolutions

The number of revolutions, or idle speed, is another important characteristic that determines the effectiveness of the tool. For different models, this figure ranges from 3200 to 6000 rpm. The higher the idle speed, the better the cut the miter saw produces.

Professional category models have a speed control function. It makes sense to pay attention to it first of all for cabinetmakers and everyone who uses a trim for carpentry needs. Adjusting the speed of the saw blade allows you to adjust the sawing process to the characteristics of a specific material: different types of wood, chipboard, etc. During “stream” sawing, they operate at high speeds, achieving greater speed and productivity. By lowering the speed, you gain greater control over the sawing, which is important when cutting critical parts.

Horizontal and vertical cutting capabilities

Modern crosscut saws allow you to make combined cuts. The saw blade of the tool can be rotated not only to the right or left to cut the workpiece at the desired angle in the horizontal plane, but also tilted to one or both sides, thereby providing a vertical cut. The horizontal and vertical cutting capabilities of modern miter saws are different, so let’s briefly talk about what you should pay attention to when choosing a saw based on these parameters.

- One-way and two-way tilt . The miter saw unit can tilt in one or both directions. In terms of functionality, both options are the same: with single-sided models you can perform the same sawing operations as with double-sided models. But in matters of convenience, the latter unconditionally win. To cut each end of the board on a single-sided saw, the workpiece must be removed from the bed, turned over and re-fixed. Such juggling becomes a separate challenge when you have to work with long and heavy workpieces in large volumes. Tilt in both directions - saves time and effort.

- Max cutting depth at an angle of 45° . In modern models this figure varies from 25 to 122 mm . At an angle, the miter cut does not cut as deeply as in the 90° position. Machines with a shallow corner cut depth are an option for those who plan to work with lining, laminate and other thin materials. For all other cases, it is important to prudently compare this parameter with what will primarily have to be cut. This will avoid the most common disappointment when it turns out that the tool is not able to cope with facing thick workpieces at an angle. It is also important to remember that miter sawing creates greater loads on the tool - the higher the power, the better the quality of the cut the trim provides.

- Max cutting depth at 90 ° angle. For non-industrial miter saws, this figure ranges from 45 to 122 mm. Placing the saw assembly perpendicular to the workpiece surface is the most common configuration in which most sawing operations are performed. Therefore, special attention should be paid to choosing a machine for this parameter. The greater the depth of the straight cut, the higher the class of equipment.

- Max cutting width at an angle of 90° . A parameter that reflects the maximum width of the workpiece that can be cut by the miter saw at a right angle. In modern household and professional saws this figure varies from 85 to 430 mm. In general, this is one of the key indicators that determine the productivity of the machine. It is important not to forget that the cutting width at 45° will be significantly smaller than at a right angle.

Scope of application

Miter saws are distinguished by great accuracy, so they are used for cutting molded products in the manufacture of:

- Furniture.

- Welded structures.

- Plastic windows.

- Wooden buildings.

Depending on the configuration, the saw can be used for sawing wood, plastic, aluminum profiles and pipes, as well as almost any long steel products.

Read also: Recipes for mulled red wine

The main nodes are:

- Cutting part.

- Electric drive.

- Bed.

The bed acts as the power part of the device, to which the remaining components are attached. There are also blanks for cutting on it. A cutting head with a saw blade is attached to the frame using a hinge. The main feature of the miter saw is that it uses a pendulum fastening of the cutting part. It is a swinging rocker arm. That is, the disk with the head is lowered onto the workpiece to be cut, which was previously correctly positioned at the desired angle.

The saw blade is mounted directly on the gearbox shaft, or connected to an electric belt drive motor. The electric motors used in miter saws are characterized by a high speed of acceleration. Due to this, the device starts up almost instantly immediately before sawing the positioned workpiece. This in turn provides a higher level of security. In addition, the part of the saw blade on the operator's side is covered with a protective cover to minimize the likelihood of contact with body parts or clothing.

Features and Features

Miter saws have design differences from each other. Budget devices are greatly simplified, so they are designed only to perform basic functionality. More expensive professional miter saws allow you to perform similar tasks faster and with greater speed, and also have capabilities that simpler models do not have.

A miter saw can have the following functionality:

- Rotate the table.

- Bevel cut

- Broach.

- Top table.

- Laser.

- Backlight.

- Removing dust.

- Electronic signs.

The table on which the workpieces are placed during sawing has a turning mechanism. Thanks to this, the parts are positioned at one angle. Most often, saws are used for cutting parts at 45° and 90°. Any basic model is capable of this. Professional devices have wider adjustment capabilities in 1° increments.

Read also: If the pump does not work, what are the signs?

A very useful feature of a miter saw is the bevel cut feature. It lies in the fact that the head with the saw blade can tilt directly towards the part being cut at an angle. In combination with the rotation of the table, this allows you to obtain a cut with two bevels. It should be noted that most amateur saws can only be tilted in one direction. In professional ones, it is regulated in both directions. Still, you can get by even with a slope in one direction, simply by turning the workpiece over. But in this case, free space is required on both sides of the miter saw. When it is installed in a corner, it may not be possible to turn the long workpiece over. In this case, the ability to tilt the saw in 2 directions completely solves this problem.

Trimming can have different mechanisms for removing dust and sawdust. The most effective of them is to connect a construction vacuum cleaner. This allows you to collect all the dust generated as a result of sawing, preventing it from being scattered throughout the workshop

The vast majority of miter saws provide a scale on which the required angles are adjusted. The professional level device has electronic indicators on a special display. They make it much easier to control angles than using a scale.

With or without broaching

To create longer cuts, choose models with a broach, also known as miter-sliders, in which the saw unit not only lowers down and turns to the sides, but also moves in a horizontal plane - forward and backward. In addition to the increased cutting width, broached crosscuts provide a number of additional benefits, such as allowing double cuts to be made in one pass.

Crosscuts without broaching, despite their seeming obsolescence, are no less popular. The ratio of sliders and conventional miter saws on the power tool market is about 60 to 40 - this is a rather rough statistic, which, however, clearly shows that old-type systems are not going to lose their positions.

Limitations in cutting length are compensated by the stability of adjustments and reliability of the system, which are achieved thanks to a simplified design and fewer moving parts. Models without broaching are much lighter - the difference in weight is 25-50% - this is a strong argument if the machine is often moved or transported to different sites. And finally, the price issue, in which everything is obvious - miter saws without broaching cost an order of magnitude less than saws of the same class, but with broaching.

For saws of different classes, discs with different rake angles are used, as we discussed above. For sliders, discs are selected whose teeth have a negative rake angle. For saws without broaching, use blades with a positive angle.

Characteristic versions of the mechanism

The principle of mobility of cutting units in single-saw machines is implemented by the following types of structures:

- Straightforward. The block moves on a rigid horizontal console, the height of which can be adjusted;

- Pendulum (PME). The location of the disk assembly on the suspensions allows it to move in an arc, lowering and rising;

- Balanced. The saw is located under the table, the knife is raised by pressing the pedal. Number of lifts 10 – 12 per minute;

- Stationary. The workpiece is fed to a fixed rotating wood knife.

Multi-saw installations include trimmers and slashers. On double-sided cross-cutting machines, the side and top sides of a wooden part are processed in one pass.

Pendulum type

Industrial CME (pendulum cross-cutting machine) has the following characteristic features:

- manual or pneumatic feed of the cutting unit;

- mechanized supply of parts;

- adjusting the length of the workpiece by installing stops;

- pneumatic clamp;

- electrodynamic braking.

The design of the manual feed of the DME disk works by ensuring a return to its original position under the influence of a counterweight.

The large radius of the CME installation increases the possible width of sawn timber trimming.

The suspended type of fastening makes it convenient to use the TsME machine in cutting production.

Straight stroke

Serial production of parts of a given size is carried out by a cross-cutting machine with several saw units. The distance between the disks on the wood corresponds to the required size. The lumber is pushed along a bed with rollers onto saws that cut it to size. In one shift, machines of this type process several dozen cubes of wood.

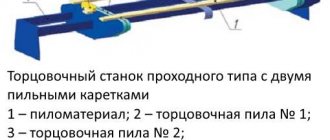

Cross-cutting machine with two saw carriages

Productivity and the accuracy of the angle between the edges of the timber are increased on double-sided equipment for trimming wood.

What design nuances should you pay attention to?

Modern miter saws come with many options. Many of these unimpressive functional additions turn out to be not such trifles. Thoughtfulness in detail ensures the quality and safety of sawing operations and expands the functionality of the tool.

Sophisticated clamping system . This design nuance largely determines the quality of the cut and safety of work. The more functional clamps capable of rigidly fixing the workpiece in various spatial positions and at the desired angle, the trimming tool has, the better.

Laser pointer . Displaying the cutting line simplifies the process of marking the workpiece and eliminates the need for constant fitting. This significantly speeds up the work process and reduces the number of cutting errors.

Adjusting the cutting depth . The cut depth limiter is an important option that significantly expands the trimming capabilities. By limiting the lowering of the saw blade to the desired limits, you can select the quarters and cut the tenons of the carpentry joints.

Maintains constant speed . During heavy loads, when pressure is applied to the saw unit, the blade speed decreases. The constant speed support system compensates for this correction in speed, thereby ensuring impeccable cutting quality with a clean and neat edge.

External dust removal .

It would be better if the trimmer provided the ability to connect an external vacuum cleaner. A standard chip collector, as a rule, turns out to be ineffective when the tool is used intensively. In contact with