Stainless steel is an alloy steel that is resistant to corrosion and aggressive environments. The basic alloying element is chromium. To enhance anti-corrosion and improve physical properties, stainless steel is additionally alloyed with other elements. Because of this, a stainless steel pipe has a remarkable set of properties:

- resistance to aggressive environments and corrosion;

- pleasant appearance of the treated surface;

- high resistance to thermal effects;

- increased mechanical strength.

Thanks to these advantages, the material has received the widest application: in industry, transport, medicine and, of course, in everyday life. Often, during repair or construction work, a home craftsman has to use structures made of curved pipes. The required configuration is not always at hand, so you have to figure out on your own how to bend a stainless steel pipe in order to obtain a bend of the required radius. We will talk about some ways to bend stainless steel pipes at home below.

Methods to prevent ovalization

Therefore, the main methods of cold bending involve techniques that preserve the original cross-sectional shape of the workpieces. There are two main ways to maintain the original round shape: supporting the wall from the inside - an internal stop and limiting the movement of the side walls of the pipe in the direction of expansion - an external stop.

A calibrating plug (mandrel) or various fillers can be used as an internal limiter.

Fillers can be rubber, fusible metals, resins or water. Rigid fillers provide more reliable results in terms of maintaining lumen shape, which is why they are more common. However, when elastic fillers are used, less stretching of the outer side of the bend is observed.

For better preservation of the cross-sectional shape and more precise manufacturing, it is recommended to use simultaneously external and internal stops.

Depending on the volume of work and the diameter of the pipes that need to be bent, either manual devices are used - pipe benders, or machines with an electromechanical drive.

LLC DESIGN PRESTIGE

Technical features and properties of stainless steel pipes

Stainless steel has a whole range of remarkable useful properties and is therefore widely used in industry, medical production, public utilities and everyday life. Its main properties include the ability to withstand aggressive environments, resistance to corrosion and high temperatures, and high mechanical strength.

Bent stainless steel elements

Steel acquired such properties due to its chemical composition, the main element of which is chromium. When steel is made, other alloying additives are added to give the resulting products a nice, smooth appearance.

Important! Stainless steel has no harmful effects on the conductive environment, so it is absolutely safe for food and water.

Methods to prevent ovalization

When bending stainless pipes, especially thin-walled ones, undesirable changes in the shape and wall thickness of the product material appear, in particular:

- the external shape changes, ovalization appears;

- there is a decrease in the thickness of the outer wall due to stretching during bending;

- the appearance of folds and kinks on the inner radius of the bend;

- After bending is completed, due to the springing properties of the product, the bending radius and rotation angle increase.

All these negative consequences affect the appearance of the product; reducing the wall thickness weakens the strength. And ovalization reduces the flow area and causes additional resistance to the movement of the working medium.

Therefore, to prevent such changes, pipe bending is carried out using methods that allow maintaining the round shape of the product without deformation. One of these methods is based on using internal filling of the pipe with a rigid or elastic material to protect the internal walls from deformation.

Change of section, ovalization

*

Sand, crushed cork, rubber and even water can be used as filler. To prevent the filler from spilling out during bending, the pipe section is closed on both sides with a plug. To prevent external displacement of the pipe walls, external stops in the form of a roller are used.

The best effect is achieved by using a hard substance as a filler, so this method is more common. Usually, when bending, two methods of preventing deformation are used at once, internal and external; it gives the best effect.

The main industrial methods of cold bending:

- with rolling; winding; drawing; rolling; on two supports; stretching; with internal hydrostatic pressure.

Methods of cold bending of pipes: a - with rolling; b - winding; c - by drawing; g - rolling; d - on two supports; e—stretching; g—with internal hydrostatic pressure; and - through a die having a curved axis; k - by copiers.

Rolling bending

In this way, you can bend a pipe with a diameter of up to 150 mm and a significant wall thickness. The principle of the method: around a stationary bending roller of the required size, a rolling roller moves in an arc, pressing the workpiece and performing the bend.

Reel bending

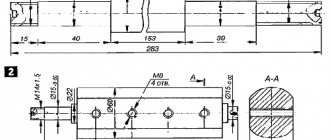

The method has become widespread in pipe billet shops with large volumes of products. Using this method, you can bend a pipe with a diameter from 10 to 426 mm in different planes. To maintain the round shape of the internal cross-section of the workpieces, calibrating plugs (mandrels), solid in the form of a rod or composite, are used.

The simplest mandrel for pipes with a diameter of up to 32 mm can be a steel rope, one end of which is fixed in the handle, and the other is connected to a wire to pull the rope into the gap. The diameter of the mandrel should be 0.1 - 0.5 mm less than the internal diameter of the pipe.

When working with a mandrel, notches and scoring may occur on the inner surface of the pipe as a result of high contact forces. This is most often observed when bending stainless steel pipes. Prevention of these shortcomings is achieved by appropriate selection of mandrel material, cleanliness of its surface and lubrication.

It is best to lubricate the inner and outer walls of the workpiece.

To do this, short pipes are immersed in a bath of lubricating oil before bending. It is better to supply lubricant to the bending point of a long pipe, remote from its ends, through the mandrel holes. For lubrication use machine oil or anti-corrosion soap emulsion.

Bending on two supports

The pipe is laid on two supports, which rotate around their axes as the workpiece bends.

The bending template is connected to the rod of a hydraulic or screw jack so that the bending force is applied in the middle of the pipe between the supports. This method can bend pipes with a diameter of up to 351 mm. Equipment of this type is especially convenient when pipeline elements need to be bent directly at the construction site.

Rolling bending

Used to bend a small diameter pipe into a ring or spiral. On bending rollers, the workpiece moves in the direction of rotation of the rollers and acquires curvature determined by the relative position of these rollers.

Bending by drawing

A thin-walled, seamless pipe can be bent using the drawing method.

The essence of the method is that a pipe with a larger diameter than the required one and a shorter length is taken as a blank. The end of the workpiece is crimped to the required diameter, then threaded through a die and held with a clamp mounted on a bending template. By rotating the template, the pipe is pulled through the die and at the same time bent around it.

Bending with stretching

The advantage of this method is to reduce the possibility of deformation of the inner wall of the pipe at the bend. In this case, the pipe is fixed at the edges, stretched and at the same time bent by extending the bending template.

Pipe bending using rolling.

Bending with internal hydrostatic pressure

Liquid is injected into a pipe, into the ends of which plugs are pre-inserted. As a result of stresses arising in the wall, the metal is brought to a state close to plastic. Then a bending template is brought to the bending point, which bends the pipe.

Push bending

Mainly used to bend stainless steel pipes with a diameter from 3/16″ to 3/8″.

The method consists of pushing the workpiece through a movable and stationary die. The amount of displacement of the matrices relative to each other determines the curvature of the bend. Using this method, up to 20 bends in different planes can be made on one pipe.

The described pipe bending methods are effective in industrial production and construction conditions and allow obtaining high-quality results regulated by industry standards.

LLC DESIGN PRESTIGE

Glass coil

Glass is the least used material for the coil of a moonshine still, although it ensures the absolute purity of the alcohol after distillation. Glass should only be bent in a special glass-blowing workshop, otherwise local stress spots will certainly appear in the bent tube, which will lead to spontaneous destruction of the coil even without mechanical or temperature influence. In addition, glass has a significant disadvantage when connecting the coil to other elements of the device: it cannot be threaded or a tight clamp can be installed on it.

How to bend a pipe manually

In individual construction conditions, there may be a need to bend a stainless steel pipe by hand. In this case, the possible negative consequences of bending described above should be taken into account.

Types of manual turbo benders.

At home, you can bend a stainless steel pipe using a manual pipe bender. Most often, a pipe bender is used in the form of a crossbow, which bends the workpiece, squeezing it out at the bending point.

To avoid deformation of the lumen, it is necessary to use means of internal resistance to deformation - internal limiters. For these purposes, you can use clean, dry sand.

A plug is tightly driven into one end of the pipe, and the gap is filled with sand through the free hole. Then it is also plugged with a plug. Then the pipe is bent around a blank of the required size.

A specially made spring can be used as an internal limiter. It is wound from wire 1 - 4 mm thick so that it fits freely inside the pipe at the intended bend. Bend the pipe with the spring inside around a metal blank or with a manual pipe bender.

After this, the spring is removed using a wire previously left outside. This technology is especially useful for bending square-section profile blanks. Accordingly, the spring must also have a square cross-section.

Another option for an internal limiter is a bundle of wire, which is sequentially, one at a time, inserted into the pipe to the bend point. After the work is completed, the wires are also removed one by one.

By hand, you can bend stainless steel pipes with a diameter of no more than 40 mm and a wall thickness of 3 mm. In all other cases, it is necessary to use professional equipment.

Share a useful article:

Related Articles: Featured Articles

Coil manufacturing technology

You will need a copper, aluminum, brass or stainless steel tube 1.5-2 meters long, with a cross-section of 8-12 mm and a wall thickness of 0.9-1.1 mm. I advise you to find a housing (reservoir) in advance to install the coil. The coiling diameter of the pipe depends on the size of the housing. For example, a plastic sewer pipe with a diameter of 75-80 mm is suitable. For effective cooling, the coil must occupy at least 15-20% of the tank volume.

The coil installed in the housing is called the refrigerator of the moonshine still, the drawing is shown in the photo.

Subsequence:

1. Fill the tube tightly with dry bulk material, for example, river sand or soda, so that the metal does not flatten when curling. As a last resort, you can fill the tube with water and freeze it.

2. Place wooden choppers (pegs) on the ends of the tube. An alternative is to solder or clamp tightly. It is advisable to weld a nut on one end.

3. Wind the tube onto any smooth object with an even circular cross-section of the required diameter (in the example, 35 mm) with a pitch between turns of 12 mm.

4. Release the ends of the coil, pour out sand, and rinse with running water.

5. Install pipes for water supply and drainage on the cooler body.

6. Place the coil in the housing, install plugs at the top and bottom, and seal all connections with superglue or another method.

Finished metal refrigerator

Bending copper pipes is a technically simple task, but it requires attention and accuracy from the performer. Copper, as a fairly plastic material, is easily mechanically affected, and therefore the pipe can easily be bent at home using human physical strength. But accuracy is very important, because... If the load is exceeded, the metal may deform and become unusable.

To bend a copper pipe, you do not need complex equipment: all the work can be done at home using simple devices, for example, an ordinary spring or river sand, or using a special tool - a pipe bender.

Copper pipes are often used for arranging intra-house and apartment utility networks. Hot and cold water supply, heating system based on copper shows itself to be durable and retains the thermal energy of the coolant well.

During installation of a system based on copper pipes, it is necessary to change their direction and lead it around obstacles. Sometimes plumbers use flange and coupling connections, tees and elbows, but in practice they reduce the reliability of the system and leak over time due to wear of the seals.

Bending the pipes maintains the tightness of the water supply, giving it the required shape. You can physically bend the pipe manually: the thinner the diameter and wall, the easier it is to be mechanically affected.

Important! Essentially, bending a pipe involves stretching the metal surface on the outside of the bend and compressing it on the inside. If you apply more force to the pipe than required, the surface may become deformed, creating a wavy section where the metal structure is less strong. In this case, it will be almost impossible to restore the original structure of the pipe.

LLC DESIGN PRESTIGE 8(495)744-67-74

In addition to fast and high-quality repair of heating pipes, we provide professional installation of turnkey heating systems. On our heating page> resant.ru/otoplenie-doma.html < you can view and get acquainted with examples of our work. But to be more precise, it is better to check with an engineer about the cost of work and equipment.

To contact us, use the contact number of LLC DESIGN PRESTIGE 8 (495) 744-67-74, which you can call around the clock.

Nylon or polyethylene pipe

A good alternative when choosing a material for a moonshine still cooler can be a tube used for installing underfloor heating systems. The main advantage of this material is its low cost and ease of processing, although it must be carried out with extreme caution. Nylon and polyethylene tubes are considered chemically neutral and do not come into contact with most known solvents. The main disadvantage of these tubes is their high elasticity, due to which the coil does not hold its shape well, so it is fixed to a frame, most often a wire one.

Heating from DESIGN PRESTIGE LLC Type: water here > resant.ru/otoplenie-dachi.html

note

Our company DESIGN PRESTIGE LLC is part of the non-profit organization ANO INTERREGIONAL BOARD OF FORENSIC EXPERTS. We also provide independent construction technical expertise services.

How to bend a stainless steel pipe? Please help!! There is a pipe bender for 12 tons, a stainless steel pipe (I don’t know the brand), polished, 25 mm in diameter. Wall thickness is 1.8 mm. Squashes!! I filled it with sand and it still squished!! What to do - tell me!! It is required to bend a targa for spinning rods onto a boat. How to bend a stainless steel pipe?

The sand needs to be dry and needs to be compacted. If it doesn’t help, heating the bend area.

How to bend a stainless steel pipe?

What bend radius do you bend the pipe with?

How to bend a stainless steel pipe? did you weld the plugs? This only works in small radii (from 12 o’clock to 2 o’clock) and after heating the stainless steel darkens. How to bend a stainless steel pipe?

First I bent with a small radius - bend right away!! Then I tried it as big as possible, same thing.

How to bend a stainless steel pipe? It’s always like this with stainless steel, one major from the airfield service said that they solved this problem simply, a water compressor, appropriate end closures, 100 atm or how long it can withstand and twist it in a knot. You can remember about composite mandrels https://www .chipmaker.ru/topic/32749/, tokarka , here https://www.chipmaker...__1#entry776596 suggested an interesting knee technique. How to bend a stainless steel pipe? Or maybe then fill it with water and freeze it? For laboratory needs, it was necessary to bend stainless steel 10 diameter 2 walls, at 90 degrees, I don’t know how the rounding is measured. but after bending there was a bent part of 25 mm. I filled the tube with solder and bent it in a vice, well, I understand that my case is special, but suddenly. The tube was not polished, so I can’t evaluate the color change, and I don’t remember anymore.

Post edited by deen22: 16 June 2011 – 22:32

How to bend a stainless steel pipe? Yes, I have heard more than once about filling with solder, and maybe in order to cheaper try coal tar with sand, pressing hot, squeezing out excess resin, plug the holes, cool, bend, drain the tar with sand - not a simple operation, burn out the remains -disadvantage: if it overheats, the hardening will be lost, and it will require vibrating tumbling and polishing. How to bend a stainless steel pipe?

If the operation is carried out more than once, then you can play around with solder; not much of it will be lost during remelting, and you can probably use something to stir it up.

How to bend a stainless steel pipe?

For a long time now I have been using toilet paper and ice to bend pipes, insert a roll of paper into the pipe, fill it with water, and leave it in the cold.

How to bend a stainless steel pipe?

master met (yesterday, 04:04) wrote:

But this should never be done, especially by people who are not very aware of the consequences of the destruction of metal under the influence of compressed air by saboteurs! This was presented to me as a standard technological process, and in those days when some things were still observed, for example for MIG 21. By the way, where is the talk about compression? , full of water, you don’t have to warn about the danger (not about the harmfulness, I don’t understand what you mean), it happened to participate in hydrotesting of pipelines and components more than once, and also to observe the consequences of the failure of plugs during testing of flexible hoses (throughput about 80 s) 300 atm. How to bend a stainless steel pipe? A funny sight I noticed that at many CNG filling stations (compressed methane gas filling stations) there are no operators, a funny sight of the depressurization of a connection with a faulty high-speed valve at a pressure of 200 kgf (up to 320 in some) there was a video showing in some gas stations the valve is manually closed , they release the pressure, and then remove the rod. Of course, it will not come out under pressure, but there is no protection against a fool

Post edited by Graduate Student56: 09 August 2011 – 19:03

How to bend a stainless steel pipe?

Graduate student56 (August 04, 2011 – 04:04) wrote:

But this should never be done, especially by people who are not very aware of the consequences of the destruction of metal under the influence of compressed air. Saboteurs! Well, why saboteurs. The high pressure liquid pump was simply called:

Sergey7 (June 16, 2011 – 22:21) wrote:

High pressure vessels are pressurized with water. Including one with a working pressure of 300 bar (which I personally know). Getting such a pump will not be easy. Although you can compress water to such pressure simply with a jack through a piston. Because Water is extremely microscopically compressible. How to bend a stainless steel pipe?

Gray78 (today, 17:10) wrote:

The high pressure liquid pump was simply called:

Wildly uneducated, I confess, I just started my career as an operator with testing oxygen cylinders, I even forgot how much I pressed so, so long ago. In production, a practical worker who assembles the equipment tests how their correct liquid pumps with air and mechanical drives from 20 to 450 kg/cm (the last one I’ve never heard of being pressed) is in the EMNIP range, although it’s not an assembler for hydrotesting from time to time, but watching how people flash in front of the plugs, yes..., however, serious pressures aside. How to bend a stainless steel pipe? I came across a test until the destruction of a methane cylinder in a fiberglass braid somewhere around 540-560 kgf/cm2; the safe option is in a closet, the process is controlled

Post edited by Graduate Student56: 10 August 2011 – 20:42

How to bend a stainless steel pipe? The liquid version is safe due to the lack of reactive force, but is extremely dangerous due to small leaks at a pressure of 200 - water cuts everything, clothes, flesh, bones, like bread. For this reason, it is recommended not to approach US at forging and pressing plants, vessels serve that after pressure release

Post edited by Graduate Student56: 10 August 2011 – 20:47

How to bend a stainless steel pipe? There is a known method for bending thin-walled pipes using water as a filler, which is frozen using liquid nitrogen. However, due to the rapid growth of crystals, voids form in the ice, which affect the quality. Output: Before freezing, medical grade is added to the water cotton wool 1g. for 30-50g. water. Cotton wool intensively absorbs air and is evenly distributed in volume, which leads to increased ice strength and increases resistance to bending. (After drying, cotton wool can be used many times) Experiments have shown excellent bending quality, no corrugation, thinning of about 12%. How to bend a stainless steel pipe? kyzik , how did you manage to win? I’m very interested, because I myself will need to bend thin-walled stainless steel from time to time. pipes of different diameters from 12 to 32. I have a little experience - I made a bike rack from 12 tubes. The first fold was satisfactory, but the second was disgusting - with deformation. from which I concluded that the sand was not compacted tightly. and it doesn’t hurt to sift it through a kitchen sieve. I took sand from diesel locomotives. not calibrated, but calcined. But how to bend a 3 meter pipe? Until you fill it with sand, it’s time to retire and you can’t cut it. The radius is large, about 300 mm. Ron Kovel in the film about working with pipes with his hands bends an empty one without heating (14 minutes of the video). but there, as I understand it, the tube will be thicker. But what about thin-walled, will it roll or bend?

Post edited by haun: 07 October 2011 – 01:16

How to bend a stainless steel pipe?

Graduate student56 (10 August 2011 – 20:41) wrote:

at a pressure of 200 - water cuts everything

By the way. I have a Karcher 7.85 washer. The pressure in the nozzle is 150 atm. It also happened that I got hit on my fingers from a distance of about a couple of centimeters. It’s a little painful, of course, but everything is in place. How to bend a stainless steel pipe?

Has anyone tried filling it with lead? And then smelt it.

This problem can be encountered by anyone who independently carries out plumbing work using various types of pipes. If you are not a specialist in this field, then you, of course, do not have special tools and professional equipment to carry out such work. Next we will talk about different ways to bend a pipe at home without a pipe bender, depending on the material from which they are made.

1.When bent, such pipes may decrease in diameter or even break. The simplest and most effective way to avoid deformation or breakage of our product at home: fill the pipe to capacity with dry, finely sifted sand and install plugs at its ends. At home, the easiest way is to drive in wooden choppers, but only in such a way that you can easily pull them out later, avoiding deformation of the pipe itself.

Now the pipe can be safely bent. If the metal or alloy is soft, then this procedure is easy to do with your own hands, or you can use, for example, another pipe of larger diameter fixed or dug into the ground, using the lever method, we make a bend. In winter, instead of sand, you can use plain water: pour; waiting for it to freeze; bend and heat the pipe, turning the ice back into water.

2. If we are dealing with aluminum or steel pipes, then we will need a gas burner or blowtorch. Before starting work, fill the tube with sand (as described above) and securely fasten one end (for example, in a vice). We evenly heat the area of the future bend.

An indicator of sufficient heating of a steel pipe will be its bright red color, and we bring a piece of paper to the place where the aluminum pipe is heated, it should smoke or catch fire. We put on gloves to avoid burns and begin to bend slowly.

REMEMBER! Galvanized pipes cannot be heated for bending.

3. Square profile pipes with a small cross-section can be bent without heating, only with the obligatory filling of sand, or pouring water in winter.

In this case, you will additionally need a rubber mallet. We place the ends of such a pipe on two supports and use a mallet to slowly bend the product to the desired shape. If the bending angle is too large, the square-shaped steel pipe can be heated at the bending point.

We have a profile pipe. How to bend a pipe without a pipe bender if you want to preserve its shape?

For this we need a strong spring. We insert the spring inside our pipe at the bend, having first tied it securely with wire so that we can then easily pull it back out. We bend our product.

How to bend a metal-plastic pipe?

We will need a lot of bends in the metal-plastic pipe when installing heated floors. Such bends will help to more effectively use the heat-conducting surface of our product.

1.The easiest way is to smoothly bend such a pipe with your hands. It should be taken into account that the bend should be within 15 degrees for every 1.5 - 2 cm. In this way, we can make all the bends we need for installing a heated floor.

2. There is another way. For it we need small pieces of wire, which we pour inside the product until it is completely filled. The wire will give us the opportunity to make smoother bends.

3.What if you can’t make an accurate and smooth bend without a pipe bender? To do this, we will need to install a plug at one end of the pipe, maybe a wooden cap, and fill it with dry, fine sand to the edges of the pipe. We also place a plug on the other end of the pipe.

We securely fasten one end of the product and heat the bend with a blowtorch. We bring a piece of paper to the place of heating; if it smolders, it means that the heating is sufficient. We take gloves and make a bend of the desired shape, remove the plugs, pour out the sand.

Spring to the rescue

For this procedure, regardless of the bending method, a heating instrument will be needed. Therefore, work should be carried out in the fresh air or in a room with good ventilation. An excellent option would be a yard or garage with an open gate.

There are several methods of bending at home, but they all differ in the level of complexity, price of materials and the use of specialized equipment.

The most common method is to bend a copper tube using a steel spring, which must consist of frequent turns and a thick wire, and its diameter should be smaller than that of the tube. This condition is necessary so that the spring easily enters the product. The best option is when the lengths of the products are approximately equal. In the case of a short spring, you will need a piece of wire that is attached to it, and then the whole thing can be easily removed.

Many people do not know how to bend small diameter copper tubes. In this case, the size of the spring must exceed the diameter of the pipe that will fit inside it.

Next, the workpiece is heated using a heating device. A gas heating pad or blowtorch is suitable for these purposes. By changing the color of the pipe, you can understand that it is heated well enough and has become plastic. Now you can easily give the copper tube any shape and you can leave it to cool.

Do not forget that you can remove the spring from the pipe only after final cooling.

How to bend a polypropylene pipe?

In general, manufacturers of polypropylene pipes do not recommend bending their products at home, but it can still be done. There are two such methods.

1. For the first method, we need to preheat our pipe using a hair dryer to a temperature of about 150 degrees Celsius and, using gloves, bend the product to the desired angle.

In this case, one condition must be strictly observed: the thickened wall of the pipe must always be placed on the outside of the curved corner. After the pipe has cooled, inspect the bend in the pipe. There should be no dents or cracks.

2. In the second way, you can bend a polypropylene pipe cold, but the bending radius should not exceed 8 diameters of the pipe itself.

Copper tube

The most popular material for making the coil of a moonshine still is copper. It has high thermal conductivity and is a very soft metal that bends easily. To coil a copper tube into a coil, it does not need to be preheated, unless the bend radius is less than five times the nominal diameter of the tube itself. On the other hand, such coils are not chemically neutral, although the copper itself does not react with alcohol. Upon contact with oxygen, a thin coating of copper oxide forms on the surface of the copper tube, which inevitably ends up in the distillation product, albeit in very small doses.

How to bend a plastic pipe?

To work with plastic you will need to do the following operations:

- Make a special frame from the fiberboard in order to give the plastic blank the required shape; Sand this frame with fine sandpaper; Next, use a special silicone molding machine to make a suitable shell for the plastic blank, it is needed specifically for fastening the pipe in our frame, including it will not allow scratches, chips and various dents to appear on the surface of the plastic; Install the plastic pipe into the manufactured shell; Fix the part well in the frame, then place all the elements on the molding machine; As soon as the plastic begins to soften when heated, it will gradually begin to settle on frame, as a result of which the workpiece will be given the necessary shape; And the last thing to do is wait about ten to fifteen minutes, remove the plastic pipe from the frame and wait until it cools completely.

In our article, we looked at many ways to bend a pipe at home without a pipe bender. We can do all of the above methods with our own hands, without having practically any special devices or tools. Bent pipes may also be required in other cases: to make a coil for a moonshine still, to connect a washing machine without special factory-made curved pipes for power supply and drainage, and so on.

Application of pipe bender

Let's consider another way - how to bend a copper tube without applying any additional effort. A reliable assistant in this matter will be a special device - a pipe bender, thanks to which you can save time, speed up and facilitate the bending procedure itself.

What kind of device is this? This is a mobile tool that bends a pipe according to a given parameter, fixing one end of the pipe and moving the other. And the bend point is always in a stable position.

All pipe benders, according to their operating principle, are classified into:

- Lever (manual), including a pair of levers with a shoe and a bending template. To set the desired angle, you need to take a reference from the marks on the surface of the levers. Then fix the workpiece in the bracket, combine the zeros and do the main work. Using this pipe bender, you can bend a pipe at almost an angle of 180° at home.

- Hydraulic, which are professional-level devices and bend the tube much more quickly than the previous ones. Thanks to the hydraulic operating principle of the pipe bender, you don’t have to strain yourself too much.

- Electrical, which are used in industrial production or business. With the help of such devices it is quite possible to fulfill a serial order. Electric pipe benders are powered by an electric drive and are very similar to their manual counterparts. The tubular product is placed in a bracket and bent according to the parameters specified by special segments.

Having understood the topic - how to bend a copper pipe, you still have to choose the right equipment in accordance with the parameters of the workpiece to be bent. For example, a manual pipe bender, spring or sand will come in handy when bending a product of small length and diameter. But only hydraulic and electric tools can change the profile of a large workpiece.