A hand-held circular saw is a must-have in the arsenal of anyone involved in construction or carpentry. The most convenient models are those that are installed on a workbench or table and are used permanently.

The first circular saws were developed by SKIL in the 20s of the last century. Since then, the type of instrument has undergone significant changes. Manufacturers are constantly working to improve the design, which to this day can withstand severe competition. What are the design differences between tools with a stationary mount and what models are on the market, read on.

Subtleties of choice

Choosing a circular saw these days is not at all easy.

There are many models on sale from a large number of manufacturers. What you should pay attention to if you are purchasing a saw for your home

- Works from a network with a voltage of 220 volts.

- Bed design: for small jobs, a lightweight or even tabletop version of the machine is suitable; someone may prefer a manual unit - this factor significantly affects the price of the product.

- Availability and quality of adjustment strips: the more there are, the higher the price.

- The presence (absence) of additional surfaces that increase the size of the machine tabletop. Machines equipped with such surfaces are somewhat more expensive.

- Engine power. If industrial volumes of work are not expected, then you will have to seriously overpay for a more powerful unit.

A lightweight circular saw will quickly cease to meet the needs of production, and even if it does not fail, you will have to buy a second, more powerful machine.

Table production process

- You need to cut a tabletop of the required size from a sheet of plywood. Markings are applied to the lower area using a metal ruler and pencil. Cut the plywood with a jigsaw, milling the edges if necessary. If the plywood is not laminated, we clean the surface of the table with sandpaper.

- They shift it and make markings from the bottom for attaching a manual circular saw. To do this, remove the disk from the device and place it with the sole in the required place. We make marks on the table top and at the base for fasteners and a hole for the saw blade. Drill holes for the bolts. They will be twisted from above under the tabletop and held in place with nuts at the bottom. Therefore, the holes are countersinked from the edge of the working plane, and the bolt heads are leveled so that they do not protrude.

- If it is planned to cut the material at different angles, the slot for the saw-tooth circle is made in the shape of an inverted trapezoid. For straight sawing, an ordinary groove is made. Before marking the slot and holes for fasteners, you need to apply a saw, adjust the marks and only then cut.

- Draw with a pencil the areas where the stiffening ribs are located. They are made from boards and installed below 8-9 cm from the edge of the tabletop itself. The table legs must be fixed to the ribs. The ribs are secured with self-tapping screws at intervals of 15–25 cm, and in addition they are glued with PVA. Self-tapping screws are screwed on top, under the tabletop, the heads are completely recessed. The ribs are fastened together with self-tapping screws.

- The legs are made of timber or boards, their length will be from 100 to 113 cm. The legs diverging downwards will give significant stability. They are fixed with large bolts twisted on the outside and reinforced with nuts on the inside. Timber ties will strengthen the frame.

- In order to adjust the height of the table, nuts are attached at the bottom into which M14 bolts are screwed. Now you can secure the saw from below by passing the drive into the prepared slot.

- We attach an electrical outlet to the table, run an electrical cable from it and set the switch. Power to the outlet will be transferred from the switch. We stretch the cable from it to the nearest source in the workshop. With the support of the construction screed, we fix the ON-OFF key on the body of the circular saw in a recessed state.

- Let's start producing auxiliary stops. For the stop you will need a number 30 square cut aluminum pipe and 2 screws with wing nuts. We saw off a piece of pipe along the length of the tabletop, making holes for screws 3 cm from the edge. 2 clamps are cut out from pieces of plywood. The system is ready.

- To process across the table, we use a plywood sled. We align them with the edges of the table, press them down and move them along the toothed circle. We cut a hole in the passage area of the circle. Small components can be placed directly inside the slide and sawed. Dust will be removed from under the table, but a significant part of it will still fly upward, so it is good to supplement the device with an upper dust extractor.

Working with a circular saw is very dangerous , for this reason it is necessary to take care of protecting your fingers. Cut a pusher from a piece of wood or furniture board.

Additions to the completed design

Some craftsmen, when assembling a table for a hand-held circular saw according to unique drawings, completely remove the factory safety cover and replace the factory platform with a homemade one. If cutting at an angle is not planned, you can remove all devices for adjusting the tilt of the disk. The electric saw is fixed directly to the new base, which makes it possible to gain a couple of millimeters of cutting depth.

Without an internal casing , it is easier to remove the blade; the electric saw will not become clogged with shavings when working with wet boards. Dismantling will require extra time, but the service life of the motor is preserved and overload is prevented.

Mounting a circular saw

The matter remains small. The circular electric saw is located inside the prepared hole. The sole is secured with bolts , and the gear drive must fit freely into the socket.

The table for the circular saw is almost ready. Now it needs to be treated with a moisture-protecting material, then coated with varnish in several layers (to minimize slipping).

The resulting system can be supplemented with anything at the user’s discretion (safety cover, device for adjusting the tilt of the disk, carriage, etc.).

Device

Stationary saws are installed on a base - a frame, the rigid design of which, coupled with the engine power, allows sawing large workpieces up to logs.

To install such a massive unit, floor preparation is required. As a rule, a concrete foundation is made for the machine.

The polished work surface is also made of steel or cast iron. In lighter versions, the table top can be made of aluminum; a groove is provided in its surface, allowing the saw blade to rotate freely.

The working surface is equipped with various kinds of guides necessary for adjusting the width of the workpiece being cut, the inclination of the cut, etc.

Under the tabletop there is an electric motor that transmits torque to a pulley, which serves as a support for the saw blade. On stationary machines, the engine force is transmitted to the gearbox and only then to the pulley. A belt drive is most often used, but there are models with a cardan method of transmitting torque.

The disk is covered with a protective casing. On many models, a riving knife is attached to the tabletop immediately behind the disk, which prevents the sawn workpiece from coming back together under the influence of the elasticity of the wood fibers - this is another element of the tool’s safety system.

There are models with the ability to tilt the saw blade, allowing you to cut at different fixed angles.

Sometimes additional expanding elements are provided for the main work table to increase the working surface of the machine.

Some models are equipped with a redundant emergency switch.

Types of circular saws depending on design

Circular saws for wood differ in design, which is reflected in the mobility of the tool and the size of the workpiece.

To perform a large volume of monotonous circular work, a stationary structure is used. The tool is located on a separate frame, which has impressive dimensions. Such a device requires a separate place for installation with a reliable base. Stationary saws have high engine power, which allows you to process large workpieces.

Depending on the degree of mobility, stationary circular saws can be heavy or lightweight. In the first case, the tool is equipped with a cast base, as a result of which the structure is heavy. Such saws allow you to make cuts up to 14 cm deep. Lightweight devices are equipped with open frames or removable supports, thanks to which you can transport or move the device.

Circular saws vary in power and purpose

Some models can be placed on a table. To do this, they have a low stand, which contributes to the stability of the structure. Such saws can make cuts up to 5 cm deep.

There is a third type of device, which is represented by a hybrid circular saw. It has a smaller cast bed (compared to heavy saws). This tool operates with less noise and allows you to process a product up to 75 cm wide. This is the most justified option for a mini-workshop.

Tips for choosing

poses a health risk

Particular attention should be paid to the economic component. When choosing a saw, you should pick it up and try to understand whether it is comfortable enough for you to hold it

Don't think that the same model can suit two people, since each of us has different body structure, skills and habits. Moreover, it doesn’t even play a big role here whether a circular saw from a trusted manufacturer is being considered or not.

You should also take into account the material from which the protective casing is made. It must be highly durable and able to withstand deformation if the tool is dropped.

Test the operation of the regulators located on the body of the model. Set up several different angles. Find out if they are easy enough to unscrew and tighten.

Make sure you have easy access to the carbon brushes if you decide to replace them yourself.

Try to be very careful when studying the settings, since neglecting these points can lead to serious injury in the future.

Kinds

Hand-held circular saws give the owner great opportunities in woodworking. With their help, they solve both professional and household and amateur problems in construction, manufacturing and repairing furniture and any wood products, and preparing firewood of small thickness. This tool replaces a hand saw, two-handed and bow saw, and a jigsaw. Sometimes, it is more convenient to use a circular saw instead of a chainsaw.

Classic disc, manual type, for woodworking

Manual circulars with a traditional layout (design), which was developed for the very first devices of this type, are considered classic.

Namely, the electric motor is located perpendicularly, at a right angle to the cutting disc (cutting axis). The disk rotation speed on different models is from 3000 to 6000 rpm . This is always higher than the engine rotation speed, due to the gear ratios increasing the speed of the gearbox. Different models have average power 0.8 - 2.2 kW . The support platform, adjustable in two planes (up and down and at an angle), makes it possible to set the desired depth of cut and angle of inclination of the cut.

Almost all saws are supplied with a stop consisting of two rods and a support platform. Having secured it in the body of the device, you can saw straight any workpiece that has one flat side (edged board, timber). When sawing, the support platform is pressed against the flat side, resulting in an even cut.

This is the main functionality of a classic saw. Additional features on some models include the presence of a soft start system, speed control, etc.

Mini

The mini circular saw is externally and structurally no different from a regular “monkey” (angle grinder).

The difference is in the cutting element. Instead of discs for metal and concrete, it has a metal disc for wood. Just like on a classic hand-held circular saw, there is an adjustable support platform, the desired or full cutting depth and cutting angle are set.

The mini saw is more compact and easy to use in hard-to-reach places. It is more convenient for her to file, for example, the ends of workpieces nailed at height, and to work on a workbench with small parts. One-handed operation is allowed.

The power of such saws is low due to the fact that as the engine power increases, the weight increases proportionally. And a heavy “monkey” with a power of, for example, 2.2 kW loses all its advantages in compactness, lightness and convenience. Cutting wood with such a unit is much more difficult than with a classic saw of the same power.

Tip #1. A mini circular saw for sawing small-section wood is a convenient and productive option.

Submersible

In terms of its design, it is an ordinary, classic manual circular saw.

The difference is that before work begins, the disk is completely hidden in a protective casing. Sawing begins by placing the saw in place of the cut anywhere in the workpiece. After starting, the rotating disk crashes (immerses) into the wood. Its feature is the ability to start cutting not from the beginning of the workpiece, but from any point. This is important when selecting internal grooves that do not extend to the ends of the workpiece. The tool is also convenient for making large recesses. For marking accuracy, the support platform (tire) has a special design and measurement system.

Hypoid

A hand saw of this type repeats the design and functionality of the classic version of a circular saw. The difference is in the layout. The engine is located not across (perpendicularly), as in classic models, but along, like in angle grinders (“monkeys”). For this purpose, a hypoid gear is used in the gearbox, which gives the name to such power tools.

Tip #2. Hypoid options are more convenient to use and better balanced. Their saw blade is shifted to the left side of the center, closer to the operator if he holds the handle with his right hand.

Stationary for installation in a table

Purely stationary circular saws do not belong to hand-held circular saws; they are sawing woodworking machines of a different class.

We are talking about modifications of hand saws that can be installed on a frame with a table, the saw blade up, and used as a stationary machine. Sometimes hand saws are placed on homemade stands . It must be remembered that a hand-held cross-cut saw has a brush (commutator) motor, which is not designed for long-term operation under increased loads. Namely, in this mode, the engine operates on stationary machines. Therefore, the tool will not last long if used this way .

Some manufacturers offer universal hand/stationary saws. The set includes a bed with a table and a hand saw, which can be used both on the machine and for manual work.

Such options have an increased service life, designed for stationary use. In any case, the stationary option can be useful for domestic use, when small volumes need to be cut from time to time.

Trimming

Cross-cut (pendulum, “crosscut”) circular saws are designed for a special operation - cutting workpieces of the required length, trimming ends.

The tool is effective for carpentry work of varying complexity. With the help of a trimmer you can make a very precise cut at any desired angle. By installing a special stop-limiter, you can quickly cut many pieces of the same required length without preliminary marking with a tape measure and pencil. Of course, on a crosscut saw you can saw any workpiece that fits in size, even cutting waste into firewood.

Rechargeable

Circular saws of this type are structurally designed in almost the same way as conventional power saws and are powered by an electric motor. The difference is that they receive power not from the electrical network, but from batteries. The price for this type of tool is still high, but with the development of “battery” technologies it is becoming more adequate. A tool with a power source independent of the household network provides a number of obvious advantages:

- Mobility and independence from the presence of an electricity supply network. Can be used anywhere, even in the forest.

- No wire. This makes work in construction easier and much more convenient, especially at height. There is no need to drag a long extension cord, which has significant weight over a long length and interferes with work and can also get tangled.

The disadvantages of this technique are common to all battery devices:

- Less power than network models.

- Operating time limited by battery charging.

Otherwise, such saws, which range in price from 10 to 20, cope with their tasks quite well. declared by the manufacturer , at a sawing angle of 90 degrees, is from 50 mm and above. This is enough to, for example, when building the top of a house, cut off the ends of the sheathing at a height, saw rafters 50 mm thick, etc.

Today there are models on sale with a modern brushless motor that has a long service life. Some manufacturers solve the problem of limited battery life in a way that is convenient and profitable for professional carpenters and builders.

For example, the user is offered a whole group of cordless tools from one manufacturer - saws of various types, screwdrivers, hammer drills, wall chasers, etc. with interchangeable batteries. That is, all equipment requires only two batteries, which costs the owner much less.

The advantages of unifying batteries for tools is that one battery is suitable for both a screwdriver and a jigsaw or circular saw.

For metal and concrete work

Machines for cutting these materials are structurally designed as cutting machines (trimming, pendulum) for wood - a platform (bed) for placing the workpiece and a saw unit, which rises up/down on a hinge and can be adjusted for cutting at an angle.

In the market, such devices are sometimes called assembly saws. The two main differences from woodworking machines are the use of a special disc for stone or metal, and greater protection of the engine from fine concrete, brick or stone dust.

In theory, you can put a blade for metal and wood on a regular circular hand saw for wood. In practice this should not be done for two reasons:

- The mounting and outer diameters of the discs are incompatible.

- Such a hand saw is inconvenient to cut, for example, stone.

In practice, for cutting metal or brick, it is more convenient and practical to use angle grinders with special discs.

Today in the EU countries there are analogues of manual wood circular saws used for cutting metal and concrete. This is a relatively new type of instrument and has not yet become widespread in the Russian Federation. The main difference from wood saws is a special blade, increased speed, and protection of the engine from dust.

Design Features

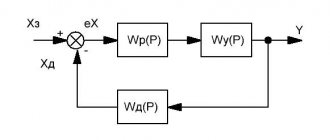

The basis of the design of any electrical equipment is an electric motor, through which all other mechanisms of the device are driven. In the design of a circular saw, the electric motor is located on the frame of the machine. Its rotational motion is transmitted to the saw blade directly or through a transmission mechanism, which depends on the design of the model. The features of such equipment include such elements as:

- the bed is the basis of the structure, made of metal (steel, cast iron), and this is what determines the significant weight of models equipped with it;

- table top - a working surface, has a groove for a saw and is also made of metal;

- the gearbox or pulley (depending on the model) is placed under the surface of the tabletop;

- on the working surface there are elements to protect the worker from injury, as well as various devices that facilitate the execution of work and expand the functionality of the machine.

Diagram of the design of one of the layout options for a stationary circular saw: 1 – stop plate, through which the width of the part being cut is adjusted; 2 – saw blade; 3 – working surface (tabletop); 4 – saw blade drive shaft pulley; 5 – saw blade drive shaft with bearing assembly; 6 – casing that ensures removal of sawdust generated during use of the machine; 7 – belt that serves to transmit the rotational motion of the motor shaft to the saw blade drive shaft; 8 – electric motor; 9 – pulley mounted on the shaft of the electric motor; 10 – movable frame; 11 – attachment point for the electric motor to the machine body; 12 – machine base – fixed frame; 13 – structural element used to close the internal space of the machine (protective panel).

The circular is convenient and quite functional when used

Do-it-yourself design production

After preparing a sketch of the structure (with dimensions) and purchasing the required materials, you can begin work. You should start by making a frame for the table top. It can be made from a profile pipe. Having a welding machine and a grinder on the farm, this is not at all difficult to do.

- The required pipe sections are cut.

- The sides are welded.

- Four sections connecting the sidewalls are welded.

- All welding and sawing areas are processed with a grinding wheel.

- Adjustment screws are attached to the ends of the legs, allowing you to install the table on a not very flat surface.

Metal frame for tabletop

The structure must be painted to give it an aesthetic appearance and protect it from corrosion processes. It remains to make holes in the frame for mounting the tabletop.

The table can also be made from timber or boards with a section of 10 x 5 cm. To assemble the frame you will need metal corners, dowels and screws.

Design example

Important! When using wood blanks, one should not forget about the mandatory treatment of them from exposure to moisture and temperature. For this purpose, special formulations are produced.

You can also use old furniture, such as an office table, as a base for a circular saw. It is only necessary that its base be strong. In most cases, the standard dimensions of such structures are quite suitable for cutting wood. But it is recommended to install a new countertop itself. An alternative is to glue two sheets of plywood 1.2 cm thick. This thickness will be quite enough to install a saw weighing about 5 kg.

You can glue 2 sheets of plywood

After making the base, you can proceed to the most important stage - preparing the surface and installing the saw.

Table. What may be needed to carry out the work.

| Tool, device | Photo |

| Jigsaw | |

| Screwdriver | |

| Drill | |

| Sander | |

| Milling unit | |

| Roulette | |

| Square |

Step 1. You need to drill mounting holes in the platform of the purchased unit (if the holes were not provided for in the design). It should be remembered that after such modification, the manufacturer’s official warranty for the purchased tool will be lost.

MDF (board made from tiny wood chips)

Step 2. The tabletop is cut out according to the required dimensions. It can be made from 1.8 - 2 cm thick plywood, MDF, old furniture or sheet metal, but this option is rarely used. In this case, chipboard is not recommended, since these boards are not very durable. Plastic should also not be used as a countertop.

Important! The thickness of the cut directly depends on the thickness of the table. The larger this size, the shallower the depth the disc can cut through the workpiece, since the working surface of the disc is reduced.

It is advisable to mill the edges of the tabletop (no one has canceled the aesthetic appearance even for working devices), after which you should go over the workpiece with a grinding machine.

Step 3. A slot for the saw blade is made in the tabletop.

Step 4. Markings for hardware are applied. The saw is attached to the bottom of the tabletop. The fastener caps should not protrude beyond its plane.

The saw is fixed to the bottom of the table top

Many people do not drill the platform when installing the saw on the tabletop, but secure it with clamping blocks and self-tapping screws.

Step 5. The tabletop is turned over into the working position and secured to the frame. For fixation, it is recommended to use not only self-tapping screws, but also metal corners, which provide the required structural strength.

Fastening the table top

Many craftsmen do not limit themselves to simply installing factory tools under the table. To gain a few millimeters in the thickness of the cut, they completely remove the saw guard, sole, and saw blade tilt adjustment device (if it is not useful in the future). After this, a homemade platform is produced, on which the saw is attached.

Step 5: The tool's power management is displayed. For this you will need: a plug for the socket, a plug for turning on the saw, a standard light switch, a piece of cable, clamps for clamping the power button on the saw, self-tapping screws and minimal electrical installation skills.

Power management disabled

A socket is attached to the inside of the table; a cable for the switch is output from it, which is installed where it is convenient. The device is powered from the nearest power source in the room. The saw power button is fixed with clamps in a recessed position. The integrated saw start control allows you to quickly and easily control the operation of the tool.

Step 6. To work on the table, you need to make stops and a carriage.

Circular table guide carriage

A carriage for sawing small workpieces or cross-cutting lumber can be made from a plywood base and two wooden walls. It will move along two guides, which are made of sections of metal pipe with a cross-section of 2 x 1 cm and installed in grooves made using a router. The parts placed inside the carriage are very convenient and safe to saw.

Finished carriage

Guides for working with workpieces can be made of boards, plywood or metal.

Metal guides

They must be able to adjust their position depending on the width of the workpieces being cut. The stops can be not only longitudinal, but also transverse, and also help to make cuts at an angle.

Example of a stop

If you don’t want to make the guides yourself, you can install a ready-made device.

You can supply a ready-made device

To cut workpieces, you cannot do without a marking ruler. To mount it in the tabletop, a shallow groove is selected using a router. It can be done with a chisel and a knife, but using a milling machine it is much faster, more accurate and easier. All areas where work was carried out are carefully sanded to eliminate the risk of splinters. Installation holes are drilled. The ruler is secured with self-tapping screws.

The ruler is attached with self-tapping screws

You can provide various devices to facilitate the operation of the tool: a bag under the table top to collect chips, a dust extractor for sawdust flying over the table, a mechanism for lifting the table top for servicing the tool. In small spaces, a folding tabletop is convenient.

Operating a circular saw is a traumatic operation, so you should push the workpiece toward the disk not with your hands, but with a pusher specially made from a block. The most common injuries that an operator can receive when working with a circular saw are injuries to the fingers and eyes when knots or chips bounce off. When working, be sure to wear safety glasses.

Sawing table made from a hand-held circular saw

A well-made frame, a securely fastened saw and prepared tools for work allow you to cut material quickly and safely.

Video - Do-it-yourself circular table from a hand-held circular saw

Making your own stationary machine from a hand-held circular saw

There are situations when a hand-held circular saw is available, but to perform the work it is necessary to have a stationary structure, which is caused by the need to process long workpieces or a large volume of similar operations performed. In this case, you can independently make a table on which to place your existing hand-held electric tool, and then use it as permanently installed equipment. All work can be divided into several stages: preparation, manufacturing and installation, performance testing.

Preparatory stage

At this stage of production, the material from which the working surface (table) of the machine being manufactured will be made, as well as its base, is prepared, and a sketch is developed. A hand-held circular saw is being prepared, as well as other elements: wires and cables, a button or automatic switch for turning the circular saw into operation.

Hand-held circular saw “Bosch PKS 55”

Manufacturing and installation

After the tools and materials have been prepared, and a drawing (sketch) of the assembled structure has been drawn up, you can begin to manufacture it.

The manufacturing sequence from wooden blanks and plywood is shown in the following table.

| Illustration | Description of actions |

| Using thick plywood 12-15 mm thick, a circular saw table is made according to the developed drawing. Holes are made in the side wall to ensure air circulation in the interior of the table. | |

| A hole is cut on the working surface of the table (tabletop) to accommodate a hand-held circular saw, corresponding to its geometric dimensions. It is being installed. | |

| The tabletop is attached to the table using door hinges, which allows it to be moved in a horizontal plane. | |

| To fix the circular saw, fastening elements are used, allowing the structure to be disassembled if necessary. | |

| An electrical socket is mounted inside the table body, and the wires are fixed with mounting clamps. | |

| An electrical switch is installed on the outer wall of the table to ensure the operation of the assembled structure. |

This structure can be installed separately or placed on any horizontal surface. Its geometric dimensions depend on the dimensions of the hand tool, as well as the needs of the user.

Functionality check

When the structure is assembled, it must be tested in operation, for which it is connected to an electrical network that corresponds to the voltage class of the circular saw used. When the performance has been verified, the manufactured product can be equipped with the necessary equipment elements (stops, clamps, etc.) and devices that facilitate use during operation.

What should a saw table be like?

When setting up a stationary area for processing materials, several nuances must be taken into account.

- The structure must be stable and rigid.

- The material from which the table is made must be strong and durable.

- It is important that the table surface is perfectly flat.

- Grounding must be provided.

Circular saw table design

- The table must be equipped with devices that ensure the safety of the operator.

- The saw start button should be located within easy reach.

- A place should be provided for collecting sawdust, which should be easily accessible.

- The work area around the table should not be cluttered, as this increases the risk of injury.

Taking into account the above, you can be confident in the reliability of the installed structure and the good quality of the workpieces being processed, regardless of the amount of work.

Table for circular saw - photo

The main components of the table: frame and smooth surface for placing workpieces.

The material from which structures are made varies depending on the purpose, installation location and frequency of use. For domestic needs, you can make a structure from boards and plywood and install it, for example, in a garage. Working with large volumes of materials implies increased requirements for the strength and reliability of the structure. The best solution in this case would be a frame made of a metal profile. To reduce vibrations and provide greater stability, many even concrete the legs into the floor.

Some tips for setting up a table:

- the saw blade must be positioned strictly perpendicular to the table surface;

The saw blade must be positioned strictly perpendicular to

- the standard and optimal size of the tabletop is 1.2 x 1.2 m, but it can vary depending on individual requirements (if the tabletop is long, additional support legs may be needed);

- the height of the table depends on the height of the master, usually it varies between 0.8...1.2 m;

- it is more convenient for the operator if the table is installed on legs rather than on solid sheets, for example, plywood;

- the width of the slot into which the disk attached to the bottom is inserted should not exceed the thickness of the disk by more than 2 mm, otherwise the tool may quickly fail due to clogging with chips;

DIY circular table from a hand-held circular saw

- the circular saw should be placed in the center of the table so that there is no strong shift in the center of gravity;

- It is recommended to place the saw control buttons on the table top or the top of the table leg.

Important! In many models of saws, holes for attaching the sole to the table are already provided by the manufacturers.

Example of a reinforced workbench for a circular saw

Circular device with permanent installation

Baikal circular mounted on the table

The circular saw is designed for transverse and longitudinal cutting of relatively soft materials: wood, wood panels, plastics, non-ferrous alloys. Hand tools work quickly and accurately, therefore they are widely used in various carpentry works, as well as for:

- performing roofing work;

- laying floor coverings;

- furniture manufacturing.

By replacing the disk on a manual circular saw, you can cut soft metals and profiles. And by installing it on a workbench using a special device, you can turn it into a machine tool.

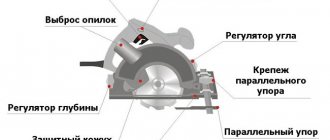

The main elements of a circular saw:

- electric motor;

- gearbox in housing;

- guide;

- platform;

- protective box;

- stationary mount.

The body of the instrument is made of durable plastic and only a few models are made of metal. Since work produces a lot of dust and chips, manufacturers provide a chip removal system. As a rule, this is an output for connecting an industrial vacuum cleaner. There are models with a built-in dust collection container - a convenient solution for one-time work.

On modern manual models, only brushed electric motors with a power of 750 - 2500 W are installed. This indicator determines the number of revolutions of the disk and the capabilities of the tool. The most powerful models have speeds up to 5000. A powerful motor requires cooling, which is provided by the housing ventilation system.

The platform matters a lot when choosing. She may be:

- stamped - cheaper, suitable for amateurs;

- cast aluminum - does not deform, strong and stable.

Often a graduated scale is applied to the platform, which helps to cut workpieces more accurately.

Guide rail - used to make an even cut. Some manufacturers equip their tools with a guide. But this doesn't always happen.

Additional accessories

A laser pointer is a convenient option that allows you to cut a part with markings covered with sawdust. Increases the cost of equipment, but is welcomed by professionals.

Possibility of disc replacement - modern models are equipped with a spindle lock, which allows you to quickly and easily remove the disc for replacement. Otherwise, the disk is removed with two keys - a lengthy and inconvenient procedure.

Criteria for choosing a circular saw with a fixed mount

manual circular saw Rebir with the ability to mount on a table

Although the choice of models with stationary fasteners is not wide, you need to choose the most suitable one among them.

Power

Sawing wood requires significant effort, so powerful saws work more efficiently. And the service life of the tool will be longer, because the powerful engine requires less effort and does not overheat. However, the more powerful the device, the heavier it is. But the issue is partially solved by the presence of a table stand.

The smallest and weakest mechanisms have a power of 1200 W, the largest 2500 W. You should choose based on the mode of use of the tool.

Cutting depth

This is also an important parameter, although it does not differ very much between large and small saws. Particular attention should be paid to the maximum angle cut. Modern models have the ability to cut at a degree. The value of a degree cut is always much less than a straight cut; it is this indicator that you should pay attention to when looking for a small hand saw.

Saw equipment

Each manufacturer offers many options for packaging their products. The most important additions are:

- limiter - used for removing smooth edges of material, turning an unedged board into an edged one, sawing off long strips of material from a piece;

- ruler - bolted to the platform and helps measure the width of the piece to be cut.

Inexpensive Asian-made saws have the most additional accessories. Famous brands are usually limited to a meager set of the device itself and the limiter. The rest will have to be purchased.

Saw wheel compatibility

Saw blades vary in number, shape and size of teeth, material, seat and outer diameter. 32 discs cannot be mounted on a 30 mm cartridge. A large disk with a diameter of 200 mm will not fit on every low-power circular saw.

The number of teeth on a wheel determines the capabilities and quality of work. So, with more teeth, a better cut is obtained. For cutting pressed boards, discs with 36 - 48 teeth are optimal. To work with a board, 20 - 24 teeth are enough. Discs with carbide surfacing are more durable; they are capable of sawing even a nail accidentally driven into a board.

Based on the shape of the teeth, discs are divided into active (sharpened at a positive angle) and passive (sharpened at a negative angle). The alignment of the teeth along the direction of movement of the saw wheel is characteristic of a positive sharpening angle. And the wiring against the movement is for negative. Solid materials are sawed with passive discs (metal alloys, tin), and wood and plastic with active discs. If you cut wood in a circle with a negative sharpening, the cut will turn out torn, with protruding fibers.

Videos about the design and modernization of the manual circular saw Baikal 514:

Desktop device

The design of a table for a manual circular saw is so elementary that most specialists produce it without preparatory drawings and techniques. This is a dense workbench that is created from wood and plywood.

The most durable table bases are made from alloy. They are the heaviest and require the presence of welding skills. Therefore, stands are often made from leftover lumber. A circular saw is attached under the tabletop, and the drive protrudes above it through a specially made slot. The lumber is advanced along the table top and sawn with a disk. For convenience and correct operation, the table is equipped with additional devices: an angular and longitudinal stop.

The tabletop “absorbs” part of the working plane of the disk; the depth of cut will decrease by the thickness of the tabletop. For this reason, it is preferable to choose a circular saw with the largest disk diameter, and a table cover that is thin but rigid.

If you have not purchased an electric saw yet, choose modifications with high power (from 1200 W). They can handle cutting large-sized wood. Holes will be drilled to secure the base. The solid base may burst. For this reason, it is advisable to select a mechanism of a different type.

Popular models of stationary circular saws

The domestic woodworking equipment market offers models of stationary circular saws produced in different countries of the world. Among them, according to reviews from real users, the most popular brands are: Bosch and Metabo (Germany), Makita and Hitachi (Japan), Interskol (Russia) and JET (Switzerland). Let's look at the characteristics of the most popular models.

| Image | Model | Specifications |

| "Metabo TS 254" | Power – 2 kW; Saw blade diameter – 254 mm; Weight – 33.4 kg; Additional options - soft start. |

| Image | Model | Specifications |

| "Bosch PTS 10" | Power – 1.4 kW; Saw blade diameter – 254 mm; Weight – 26 kg; Additional options - soft start. |

| Image | Model | Specifications |

| "Makita 2704" | Power – 1.65 kW; Saw blade diameter – 255 mm; Weight – 30 kg; Additional options - soft start. |

| Image | Model | Specifications |

| "Hitachi C10RD" | Power – 1.6 kW; Saw blade diameter – 250 mm; Weight – 24.6 kg. |

| Image | Model | Specifications |

| "Interskol DPN-250/1500P" | Power – 1.5 kW; Saw blade diameter – 254 mm; Weight – 37 kg. |

| Image | Model | Specifications |

| "JET JBTS-10" | Power – 1.7 kW; Saw blade diameter – 254 mm; Weight – 35 kg. |

Strengths and weaknesses of electric circular saws

An electric circular saw has distinctive advantages over other tool options. The device operates at high speeds, which contributes to a significant rotation speed of the disk and high-quality cutting.

The design of the machine allows you to set precise settings for processing the part

The unit is designed in such a way that its operation is safe. The saw blade for a circular saw on wood is covered with a special protective casing, which eliminates the possibility of injury from the sharp teeth of the knife in the non-working position of the unit.

Thanks to the stationary frame, made of durable material, the stability of the equipment is ensured. In addition, tool vibration during operation is reduced, which significantly improves the quality and accuracy of material processing. Despite the overall dimensions and massiveness of the installation, the circular saw operates with a low noise level, which contributes to the comfortable operation of the device. In addition, this makes it possible to fine-tune the tool.

A circular saw with a table can process workpieces longer than 1 m. This tool is also characterized by a wide range of processed materials. The saw can handle wood, chipboard, fibreboard, plywood, plastic and even soft alloy products. For the latter type of material you will need to use the appropriate disc.

Important! Most stationary models are equipped with a dust collector.

The circular saw operates with low noise levels

The main disadvantage of a stationary circular saw is the high cost of the tool, which is explained by the high-quality design and the creation of conditions for its safe use.

Tips for caring for power tools

deal with a dangerous tool

It is necessary to work with a circular saw only in protective clothing, gloves and goggles.

Before plugging in the saw, make sure it is turned off.

If you need to turn the saw on or off, it is advisable to do this at idle speed. If this is done under stress, it may shorten the tool life.

Make sure that the load does not exceed the permissible level. To do this, it is recommended to take breaks after every 15-20 minutes of work. This will prevent the engine from overheating.

Before work, make sure that the workpiece is securely fastened. It is unacceptable for it to dangle and sag. Otherwise, this could be fraught with serious consequences for you.

Make sure that there is no moisture near the workplace.

Required Features

In order not to make a mistake when choosing a hand-held circular saw, it would be useful to take into account the presence of the following functions .

- Possibility of soft start. This refers to a condition in which the disk begins to reach its maximum speed gradually. Thanks to this function, the occurrence of high starting currents can be prevented, which has a positive effect on the service life of the motor.

- Possibility of maintaining a pre-set rotation speed at any load. If you have to work with high-density material, the engine automatically begins to increase power to maintain a preset number of disk revolutions.

- Jam protection. A slip clutch solves this problem best. If the disk does jam, the engine will operate as before, but the disk will stop rotating. Although this option does not prevent the tool from being pushed back, it does help reduce the force of the tool, which reduces the likelihood of injury.

- Motor overload protection. If during operation the load on the motor reaches a peak level, it automatically turns off, which extends the life of the tool.

- Fast disc braking function. If the button is disabled, the drive will immediately stop, which will happen quite quickly.

- Possibility of adjusting the disk rotation speed. When working with different materials, specialists have to adjust their rotation speed to ensure the most productive cut.

- Possibility of adjusting the cutting depth. This option is provided in any modern model of circular saws, the presence of which simplifies the process of setting the exact depth value.

- Presence of a riving knife. A place is allocated for this unit behind the saw blade, and it itself allows you to avoid clamping it with the workpiece.

- Possibility of connecting a vacuum cleaner. Any circular saws are equipped with this option. To use it, a special plastic pipe is provided on the body of the tool. Although it doesn’t hurt to make sure it’s available when purchasing.

- The vast majority of saws also have a laser pointer. The owner can benefit from it if high demands are not made regarding the quality of the cut.

- A useful option is an LED, which can provide better illumination of the working surface.

How to choose a stationary circular saw for the home - advice from our editors

Choosing a circular saw for your home is not as simple as it might seem at first glance, and there are several reasons:

- a large number of models, similar in technical characteristics and in a wide range of price indicators;

- Lack of experience with such equipment among novice users.

In this case, sales consultants at the point of sale and specialists with experience working on woodworking machines come to the rescue.

The convenience of working on it and its mobility depend on the size of the circular saw.

The convenience of working on it and its mobility depend on the size of the circular saw.

Our editorial team has its own consultants in this field of technology, and here’s what you should pay attention to first:

- Technical characteristics determine the cost of the model, so you should initially decide on the purpose of the equipment and its potential load.

- When choosing a model with a powerful electric motor, you must ensure that the machine can be connected to an existing electrical network.

- When choosing a low-power model, you should initially understand that it will be impossible to perform large-volume work using such equipment.

- The larger the working surface, the more convenient the machine is to use, and, accordingly, workpieces can be processed with greater accuracy.

- Mobile models are more suitable for performing one-time work, while those installed on a bed are more suitable for industrial use.

- The presence of additional options and combination with other types of equipment increases the cost of the model, so when choosing it, you should evaluate the feasibility of such additions.

- The reliability of the equipment depends on the manufacturer’s brand, and the efficiency depends on the electrical power of the engine used.

The Bosch PTS 10 woodworking machine is small in size and very functional

Design requirements

Experienced craftsmen are ready to create a table for a circular table with their own hands without any techniques or drawings. However, certain conditions still need to be taken into account.

The essential requirements include:

- rigidity (stability) of the system;

- flat, smooth surface of the table;

- securely securing the saw;

- the presence of a guard from the cutting disc;

- free access to the start and pause buttons.

The availability of different functions depends on the working conditions and wishes of the specialist. These include the ability to carry out high-quality longitudinal and transverse cuts.

Standard products, of which there are hundreds in shopping centers, are made of stainless steel. This is an excellent material , but next we consider the production of a table for a saw from wood .

Circular disc

The very first criteria for choosing a circular saw with a stationary mount are the cutting discs. Their diameter, shape and material determine the type of work for which the equipment is suitable.

This element determines the depth of the cut. Engine power directly depends on it. The larger the diameter of the cutting disc, the more complex the principle of the equipment systems. For larger cutting elements, a more complex stabilization system is used.

This affects the weight and cost of the tool. For professional processing of materials, it is necessary to purchase circular saws with a disk diameter of 165-240 mm. Products 140-150 mm are quite suitable for home use. Discs of 150-165 mm are considered universal. They are suitable for almost all types of work.

How to choose and what to pay attention to?

When purchasing a circular saw, it is enough to focus on the basic parameters of the tool:

- Power - selected taking into account the thickness and density of the material being processed. The power can be small - up to 0.8 kW, medium - 0.8-1.2 kW and large - more than 1.2 kW.

- Weight - the saw is always suspended, so it’s more convenient to work with a lightweight model.

- The depth of the cut depends on the disc. For household tasks, an indicator of 40-50 mm is sufficient, for professional ones - from 60-70 mm.

- RPM affects performance and the ability to cut different materials. The higher the indicator, the denser materials can be sawed.

- Working at an angle - most tools are used for straight cuts and flooring at a 45 degree angle. There is a model with cuts at 60 and 90 degrees.

- The diameter of the discs ranges from 130 to 250 mm.

- Additional functions make it easier to work with the tool. Among them are soft start, laser mark, sawdust collection, engine blocking from accidental starting, stationary chip removal system.

Stationary mount for circular saw

This simple device slightly increases the cost of the saw, but significantly expands its functionality. This is especially true for powerful, heavy devices. The stationary mount is:

- a pair of clamps that secure the mechanism to the workbench;

- a pair of legs;

- plate fixing the protection;

- clamp for the start button (the button is clamped in the “ON” position).

There are holes for fastenings in the upper part of the tool body. Once installed, three support points are formed that hold the saw securely and firmly with the cutting teeth up. The result is a mini-circular machine with a working surface equal to the platform. Very convenient for cutting a large number of small parts.

Installing the saw on a stationary mount

- Attach the legs: take out the plug-bolts and instead screw in the bolts to secure the legs.

- We attach the plate that secures the protection. The protection must be inserted into the body and pressed with a plate.

- Using clamps, we attach the tool to the workbench, inserting the hooks into the special holes.

clamps for fastening

Only specially designed models are installed upside down! Otherwise, the tool may be overloaded or the disk may jam, leading to expensive repairs. Many manufacturers of hand-held circular saws warn against using the tool upside down. Look for information about this in the operating instructions.

There are few models on the market with the possibility of permanent installation. These are mainly domestic products. Distinctive properties are the large diameter of the circle and a powerful electric motor.

| Soyuz TsPS-50200 | EPD caliber - 2100+St | Craft CCS 2200 | Baikal | Rebir RZ 2-70-2 | Interscope DP-2000 | |

| Power, W | 2500 | 2100 | 220 | 1500\1800 | 2150 | 2000 |

| Idle speed, rpm | 6000 | 4800 | 5500 | 3700\4100 | 6000 | 4200 |

| Disc diameter, mm | 200 | 200 | 200 | 200 | 205 | 235 |

| Max. cutting depth, mm | 58 | 65 | 68 | 70 | 72 | 85 |

| Tilt angle, degrees | up to 45 | up to 45 | — | up to 45 | up to 45 | up to 45 |

| Weight, kg | 7 | 6,6 | — | 5,7 | 6,7 | 7,8 |

Table 1. Characteristics of some models of circular saws with table mounts presented on the domestic market

Main characteristics

When considering various models of circular saws for stationary installation, you first need to pay attention to their performance characteristics, which determine the effectiveness of their use in solving a particular problem.

Power

This parameter has a value in the range of 400-2000 W. The exact indicator is determined by the class and scope of application of the tool. As power increases, saw performance . This allows the user to spend less effort and time when sawing thick and dense material.

Disc rotation speed

This parameter is directly affected by power. Increasing the rotation speed allows for more precise cuts. It should be remembered that when sawing plastic, it is advisable to choose a low sawing frequency, since otherwise you may encounter such an unpleasant phenomenon as the melting of materials caused by a high speed of rotation of the disk. The standard indicator for this parameter for professional models is 5000 rpm.

Cutting depth

The value of this parameter ranges from 0 to 85 mm . The exact indicator is determined by the class of the saw. The saws offered today can provide different cutting depths, which is determined by the engine power.

Adjusting the cutting angle

Although this characteristic is mandatory for all modern circular saws, not all of them provide the ability to tilt the tool in both directions. The tilt angle is limited to 45 degrees.

The best circular saws for quality and reliability

DeWALT DWE560 is one of the best circular saws.

Among the most reliable and high-quality models are the following:

- Interskol DP-190. The saw has a power of 1600 W, the diameter of the circle is 19 cm. Allows you to make cuts 60 mm deep.

- DeWALT DWE560. The device is equipped with a 1300 W motor. This allows you to cut any tree.

- BOSCH GKS 190. Cutting depth - 70 mm. Cuts both small and dense bars.

Additional Information! All listed models are equipped with soft start.

Which circular saw to choose for your home or garden?

Many people do not know how to choose a circular saw for their home. To make the right choice, you need to decide how often the tool will be used:

- for regular use - a model with a power of 1500 W or more and a cutting depth of at least 55 mm is suitable;

- for rare use and cutting thin boards - manual circular saws up to 1000 W.

Important! If you are choosing a saw for construction, it is better to buy a professional model from a well-known company.

The Best Cordless Circular Saws

People who do not know how to choose a circular saw with a battery should pay attention to the following circular saws:

- AEG BKS 18BL-0. Equipped with a disk with a diameter of 19 cm. The rotation speed of the circle is 3500 rpm.

- Makita HS301DWAE. The saw has a 2 Ah battery. This is enough for 4 hours of work.

- BOSCH UniversalCirc 120. The most compact model, which weighs only one and a half kilograms. Used when cutting small planks.

Additional Information! Most battery models last 3-4 years. Then you will have to replace the battery with a new one.

Which company to choose

A household circular saw is an ideal choice for the home.

Before purchasing, you need to familiarize yourself with the rating of the best manufacturers of circular saws. Among the companies that are popular among buyers are:

- Bosch;

- Hitachi;

- Husqvarna;

- Makita;

- Metabo.

There are other manufacturers of circular saws, but they are less well known.

The best inexpensive circular saws for the home

There is no need to buy expensive circular saws for home use. Budget models are also suitable. The top best inexpensive saws include the following devices:

- Makita 5007N - is equipped with a powerful engine that provides wheel rotation speeds of up to 6000 rpm.

- DeWALT DWS510K is a powerful budget saw suitable for cutting dense bars and planks.

- Makita 5477NB - the disc spins up to 5500 rpm, which allows you to cut wood of any density.

The average cost of budget saws is 10-12 thousand rubles.

How and what to choose for your home and garden?

If the tool does not require many hours of daily work, and you do not plan to cut large-section workpieces, the most suitable option is:

- power from 1000 to 1600 W.

- cutting depth 50-60 mm.

- minimum weight 3.5-4.5 kg.

- a brand with a good reputation (Bosch, Makita, Hitachi, Interskol).

Price also matters. However, you should be aware that a suspiciously cheap tool may fail in the first hours of operation. There are times when a new saw does not cut at all, because in order to save money, an unusable saw blade is installed on it. Also on very cheap models, powder metallurgy instead of aluminum and magnesium casting, unreliable motors, threads, etc.

Tip #8. When choosing a circular saw for your home or garden, we recommend focusing on models from the list of budget models and the mid-price segment. They feature the most popular saws today. Editor's choice BOSCH PKS 55 - affordable price, good reliability, well-known brand, enough power to perform most tasks around the house.

For more information about popular tools, we recommend reading the rating of circular saws for the home. The article discusses the 10 most popular models, the 3 most reliable, and also battery-powered ones. Features, current prices, pros and cons are provided.