Features of pressure in a gas cylinder, safety precautions

The article describes the properties of propane gas and the formula for calculating gas flow. Pressure measuring instruments. Rules for storing gas cylinders.

The uninterrupted operation of gas equipment is determined by the uniform combustion of the flame. A uniformly heated surface gives better results than a surface heated by an unstable flame. In gas-cylinder equipment, the pressure generated in the gas cylinder is responsible for the stability of operation.

Features of pressure in a gas cylinder

Pressure is the force exerted on a gas as it expands. Gas expands when heated. Pressure is expressed in kgf/cm2 or in atm./atmospheres. The pressure in a gas cylinder is indicated by MPa.

Once in a limited space, in other words, in a vessel or container, the gas fills it evenly. This is due to the fact that its molecules are in constant motion. Therefore, the pressure is evenly distributed in the vessel. The chaotic movement of molecules creates a force pressing on the walls of the vessel. Without going into details, we will determine that gas pressure is calculated using a formula based on Newton’s law.

Typically, the pressure in a domestic gas cylinder is about 1.6 MPa and can vary depending on various conditions - ambient temperature, the composition of the gas in the cylinder, and the degree of its filling. Different types of gas cylinders have their own pressure standards.

A gas cylinder is a rather complex high-tech device, the main part of which is a container for storing, moving and using the gas it contains. Various gases are used in production, transport, and everyday life. Now such equipment is available to almost everyone and is widespread. Private individuals use compressed gas in cylinders mainly in two ways.

The standard gas pressure in a full cylinder - the maximum - must be indicated on the tag among other indicators. This tag is attached to the cylinder after each periodic inspection. The label also indicates the minimum residual pressure at which the cylinder is considered empty and not suitable for direct use. However, it is often necessary to know what pressure is in the gas cylinder at a particular current moment. Accurate knowledge of this value allows you to calculate the amount of gas in the cylinder and, based on this knowledge, plan your further expenses and other actions. The residual gas pressure in an incomplete cylinder is measured with a pressure gauge, which is installed on the gas cylinder. A pressure gauge is a sensitive pointer device that fails when the pressure for which it is designed is exceeded. Therefore, there are suitable types of pressure gauges for different types of cylinders. If the pressure gauge shows zero residual pressure, this is a sure sign of a gas leak, such a cylinder cannot be used, it has become unusable.

Why is it profitable to refuel?

Gasification of remote villages is an eternal problem of our country. This also applies to various holiday villages located around cities. The cost of materials for installation is high.

Refilling household propane cylinders is the best choice . The container and components can be purchased at a specialized or general construction store. After purchasing and installation, cooking will no longer be a problem. The only problem will be periodic refilling of the propane tank.

Some people mistakenly believe that the technical pipelines and cylinders contain the same gas. In fact, the pipelines contain methane, which is also called swamp gas, while the cylinders are filled with a technical propane-butane mixture, or more simply put, SPBT. In principle, methane and propane are hydrocarbons. They belong to the same group, but differ only in their chemical formula.

For autonomous heating, large cylinders should be used , since gas consumption in domestic boilers is much higher than that of gas stoves. Using a small capacity container will reduce the frequency of refilling the propane tank.

Experienced car enthusiasts know that using liquefied gas instead of gasoline allows you to save money at the gas station. Correctly configured equipment can reduce fuel costs by half.

It is curious that the pressure in a propane cylinder does not depend on the amount of gas and has a constant value .

Factors influencing changes in gas pressure

The pressure changes if it is affected by two factors - temperature and gas volume. Uniform pressure is achieved by uniform exposure to temperature and the amount of gas mixture in the vessel.

By changing one of the factors, the pressure of the gas mixture changes. As the gas temperature heats up, the pressure increases and vice versa. As the amount of gas decreases, the pressure decreases and vice versa.

Depending on the type of container, different tools and methods for measuring pressure are used.

Such devices include:

A pressure gauge is used to measure pressure in closed containers. If it is not possible to measure pressure with a pressure gauge or other instrument, then use the formula for calculating pressure.

Pressure is measured by the force perpendicular to the surface area of the body.

P=F/SP – pressure is measured in kgf/cm2; F – force is measured in kgf; S – area measured in cm2.

What is the pressure in the gas cylinder

A gas cylinder is not just a vessel, but a device for storing and transporting gas. It maintains a pressure of 1.6 MPa or 7 atmospheres.

The design of the cylinder includes;

The propane tank must be tested for suitability for use. The frequency of inspection is indicated in the technical specifications. cylinder passport. The passport indicates special marks and the date of inspection.

In addition to inspection, gas cylinders undergo technical inspection. service

On those. maintenance check:

The cylinders use a propane-butane gas mixture, which expands when heated, so propane cylinders are filled to 85%. A cylinder filled to more than 85% becomes explosive because... when heated above 30 degrees Celsius, the gas expands significantly and increases the pressure in the container. Excessive gas pressure affects the seam of the cylinder, which may not withstand the maximum load and explode.

When filling a cylinder at a gas filling station, pay attention to the actual volume of gas filled. Unscrupulous gas stations fill up at 85%, but charge money for 100%.

Advantages and disadvantages of gas heating

The main disadvantage of heating a house with bottled gas is its high cost. Money will have to be spent not only on the fuel itself. It also takes some time to fill the cylinders. To do this, you will have to go to the gas station once a week.

However, this heating method also has some advantages:

- High efficiency with low labor intensity in installing the system, when compared with heating with wood.

- Possibility of converting the heat exchanger to mains gas.

- Autonomous operation of the system.

- Durability of equipment operation.

In general, when considering gas heating as the only option, the financial side of the decision comes up. This is not economically viable. It is better to use propane cylinders as a temporary measure, followed by re-equipment of the boiler.

How to store cylinders to maintain stable pressure in a propane tank

As mentioned above, temperature is the main factor that affects the pressure in a propane tank. When the cylinder is heated, the pressure of the gas mixture increases, the gas begins to flow faster; when cooled, the gas supply rate decreases until the flame extinguishes into the burners.

Such pressure drops lead to premature wear of the cylinder mechanisms. To ensure a stable temperature, storage rooms for cylinders are built. Which are equipped with a safe coolant with a thermostat. When the air temperature changes, a thermal relay is triggered, which turns the coolant on or off.

Recommended ambient temperature 15 degrees. Celsius. Stable temperature ensures complete combustion of gases and extends the service life of mechanisms in cylinders.

Pressure in a propane cylinder as a safety parameter

One of the important safety measures when working with gas cylinders is monitoring the pressure in the container. Under normal conditions, the propane pressure in the cylinder is approximately 5 atmospheres. It is thanks to pressure that the gas is liquefied and loses its high explosiveness, which makes it suitable for use for industrial and domestic purposes.

When operating and transporting gas cylinders, you should carefully monitor compliance with all safety measures - ensure their secure fixation and protect both the cylinder itself and additional equipment - pressure gauge, reducer - from impacts, do not shake or overheat. Only by carefully observing safety precautions and monitoring the pressure in the gas cylinder can you use all the progress achieved.

Source

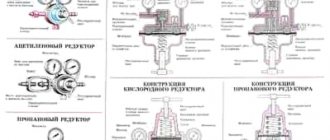

Scope of application of gearboxes

The type of gas affects the scope of use of the reducers. Therefore, there are several different models of such devices. Acetylene reducers are used by utility workers during the installation and repair of pipelines. Such devices are necessary to reduce pressure during pipe cutting and welding.

The propane reducer is used for household gas, which is used quite widely: construction work, domestic heating, welding. Oxygen reducer is used for industrial purposes. They are also in demand in medicine.

Household gas reducers stand separately. Due to their operation, the pressure of propane flowing from the cylinder into the boiler is reduced.

Main characteristics of gearboxes:

- Maximum throughput. It talks about the volume of cubic meters of gas that the device is capable of processing.

- Maximum pressure. This indicator characterizes the gas pressure at the outlet of the cylinder. Most often it is equal to 1.6 atmospheres.

- The cost of the gearbox is affected by its design and type. Such a unit can be domestic or industrial, which determines its technical characteristics.

Propane cylinder device

Structurally, they are containers made of carbon steel 3 mm thick. A stamped bottom with a stand-shoe is welded to a single-seam welded cylinder on one side, and a hemispherical neck for installing a valve on the other. Various filling or dispensing equipment is connected to the latter. The majority of propane consuming devices (gas stoves, titaniums, welding torches, heating boilers) require reduced pressure. To do this, a reducer is installed on the valve (the most common is BPO-5-5).

Weight and size of cylinders of various capacities

How many kg of propane are in 1 5, 12, 27, 50 liter cylinder? You can find this out in the product quality certificate or in the table below. Here you can also find out how much a 5, 12, 27, 50 liter propane cylinder weighs.

| Volume | 5 liters | 12 liters | 27 liters | 50 liters |

| Empty cylinder weight, kg | 4 | 5,5 | 14,5 | 22,0 |

| Propane tank weight, kg | 6 | 11 | 25,9 | 43,2 |

| Mass of stored gas, kg | 2 | 5,5 | 11,4 | 21,2 |

| Cylinder height, mm | 290 | 500 | 600 | 930 |

| Cylinder diameter, mm | 200 | 230 | 299 | 299 |

What is the thread on a propane tank?

Valves of the VB-2 type are installed on most household cylinders for propane-butane mixture. These shut-off devices are manufactured in accordance with GOST 21804-94 and are designed for pressures up to 1.6 MPa. The tap has a left-hand thread SP21.8-1 (6 turns), which allows you to connect any gearboxes with a union nut and a similar thread.

The valve provides a strong connection to the neck, complete tightness, has clear markings and a modern design. Threaded surfaces are lubricated with a special lubricant that reduces friction during operation. The screw plug with rubber gasket prevents gas leakage during transportation or storage. The device provides protection against unqualified repairs by persons who have not undergone appropriate training. The reliability of the locking device contributes to long-term and safe operation of the gas cylinder structure.

How many m3 of propane are in 1 5, 12, 27, 50 liter cylinder?

We have made special calculations that conditionally transform propane-butane into a gaseous state. Under standard conditions (100 kPa, 288 K), 0.526 m³ of propane or 0.392 m³ of butane is formed from 1 kg of liquefied gas. Taking into account the percentage of the mixture (60% prop.), the volume of combustible gas is calculated using the formula M*(0.526*0.6+0.392*0.4). How many cubic meters are in a propane tank can be seen in the table below. The last line shows the number of liters of propane-butane mixture (in the liquid phase).

| Cylinder capacity (l) | 5 | 12 | 27 | 50 |

| Capacity (cubic meters of flammable gas) | 0,95 | 2,59 | 5,38 | 10,01 |

| Liquid propane volume (liters) | 4,3 | 10,2 | 22,9 | 42,5 |

It should be borne in mind that the calorific value of the propane-butane mixture is three times higher than that of natural gas (methane).

How a gas cylinder works - important details

Any cylinder is assembled on the basis of a flask welded from sheet metal, the top and bottom of which are decorated with stamped cup-shaped lids. Moreover, a ring-shaped apron-stand (support shoe) is welded to the lower part, and a special shut-off unit is screwed into the part on top of the flask (neck ring) - a valve for a gas cylinder. The key cylinder (shell) and both bowls are made of steel sheet with a thickness of at least 2 mm. Moreover, the cup-shaped shape of the bottom and lid is explained by the physical characteristics of the gas, which, being in a closed container, presses on every square millimeter of its internal area with the same force. Due to this, the welding seams that connect the shell and bowls must meet the highest quality parameters.

Standard sizes of a gas cylinder 50l

50-liter gas cylinder - its dimensions are standard. The height is 96, and the width in diameter is 29.9 cm. The thickness of the steel wall is 3 mm, and the weight is 22 kg. For cylinders of similar volume, the working pressure is up to 1.6 MPa (kg/cm2). Well suited for gas transportation, storage, and for work in bulk production.

40 liter gas cylinder and its dimensions

40 liter gas cylinders have the same diameter as 50 liter ones, but their height is different, and can reach 146 cm. It is also used for storage, transportation and large-scale work.

The working pressure in 40 liter cylinders can vary and be, in addition to 1.6 MPa (kg/cm2), also 1.47 MPa (kg/cm2). Gas containers with a volume of 27 liters are considered convenient and are used in everyday life. The height of the container is 59 cm with a diameter of 29.9 cm, which is convenient for location in the kitchen when a gas cylinder is connected to the stove. The operating gas pressure in a 27-liter cylinder, as in a 50-liter cylinder, is 1.6 MPa (kg/cm2), which is standard for all household gas vessels.

The weight of an empty cylinder of 14.5 kg will not be an obstacle to its movement, but it is important to remember that it is better to immediately give the empty cylinder to a gas station than to store it at home.

Dimensions of household gas cylinders

Household gas cylinders vary in gas volume capacity and can be: 2, 12, 27 and 50 liters. The diameter of 5 and 12 liter cylinders is 22.2 cm. The height varies and depends on the capacity: 5 liter - 28.5 cm, and 12 liter - 48.5 cm. And since the gas cylinder has different dimensions, the weight of the empty container will be different. A 5 liter vessel weighs 4 kg, and a 12 liter vessel weighs 6 kg. Such small containers are very convenient for summer residents. They do not need to heat the house all year round, and for the cooking season these are quite suitable volumes.

Dimensions of gas cylinders for cars

One of the requirements for a car gas cylinder was initially that it be compact and that it could easily fit into the trunk. The developers took this requirement into account, and as a result, they produced gas tanks for cars with a length of 66.5 to 121.5 cm, and a diameter of 35.6 cm. The displacement of automobile gas vessels ranges from 50 to 100 liters, which allows you to drive without refueling not one day.

Dimensions of toroidal gas cylinders - new items on our market

There are also toroidal gas cylinders on the Ukrainian market, which are used to equip cars, and their shape fits very well into the spare wheel compartment, saving space in the trunk of a car. Their capacity ranges from 40 to 42 liters, and their dimensions are on average 60x20 cm.

Dimensions of new 40 liter gas cylinders sold by our company

How much gas can be pumped into a 50-liter container?

A 50-liter propane cylinder holds no more than 42.5 liters of liquefied gas. But the thing is that, according to safety standards, no more than 85 percent of the total internal volume can be pumped into the container (50x85% = 42.5). Neither refuelers nor tank owners can break this rule! Moreover, safety precautions prohibit the complete consumption of liquefied fuel. Thanks to this, the residual pressure in the propane cylinder cannot be less than 0.1 MPa, and practically the owner of the tank has from 40 to 42 liters of propane at his disposal. Well, if we translate this into kilograms, it turns out that 20-21 kg of gas can be pumped into the cylinder (1 liter of propane = 0.5 kg).

In energy units - watts - a propane tank holds 966 MJ (1 kg of propane = 46 MJ) or 268 kWh. If a propane-butane mixture with a higher calorific value is used, then one cylinder will contain up to 273 kWh. Whether this is a lot or a little depends on the consumer’s appetites. If you connect the cylinder to the boiler, then one container will be enough for you for 2-3 days (in severe frosts and a house area of 50 square meters). For a typical 3 kW gas stove, such an energy source will be enough for almost 90 hours of continuous operation of the burners at full power. Or for 60 dinner preparations (under the conditions that the first and second courses will take 1.5 hours of burner operation).

But for a stove and a gas water heater, one cylinder will not be enough. After all, even a low-power instantaneous boiler consumes at least 15 kWh, which means that the energy reserve in the tank is only enough for 17-18 hours of continuous operation. And if we take into account that the average duration of a shower is 15-20 minutes, then a family of 4 people will deplete a 40-liter supply of propane in a month, provided that they take water treatments every other day. And in this case, you can’t even dream of hot water in the kitchen.

Car enthusiasts can calculate gas consumption using a simple formula: 1 liter of gasoline = 1.2 liters of liquefied fuel.

As a result, many owners of plots without a central gas pipeline are building an independent gas supply system based on three or even four 50-liter containers. And such a stock of explosive and flammable substances requires very special storage options.

Rules for the safe operation of propane cylinders

What is the gas pressure in a propane tank?

According to GOST 15860-84, the working pressure in the tank should not exceed 1.6 MPa. In this case, the proportion of propane in the hydrocarbon mixture must be no less than 60%. This is very important for the safe operation of gas cylinder installations. Of course, products are designed for significantly higher pressures - more than 5.0 MPa. Production and periodic tests are carried out under a pressure of 3.0 MPa.

Refueling standards

At gas cylinder refilling stations, employees are familiar with the regulations. Since a cylinder that is filled too much can explode or its valve can be torn off. So, if you refuel from a reliable supplier, you have nothing to worry about.

| Cylinder type (l) | 5 | 12 | 27 | 50 |

| Maximum permissible quantity of propane, l | 3,5 | 8,4 | 18,9 | 35 |

How are gas cylinders stored and transported?

When operating 50-liter containers with pure propane or propane-butane mixture, it is customary to adhere to the following rules:

- The cylinders stand only vertically, resting on the shoe.

- Containers with liquefied gas are only placed on the street, in an iron box.

- The box for cylinders is primarily perforated, providing ventilation.

- The distance from the container to the window and door of the basement cannot be less than 50 cm.

- The distance from the place where containers can be stored to a well or wastewater pit should not be less than 300 cm.

- The cylinders should be placed from the north, because the highest operating temperature cannot be higher than 40-45 degrees Celsius. And in direct sunlight, the metal heats up more intensely.

- There must be a reducer between the cylinder and the gas-consuming device, which equalizes the pressure in the gas pipeline.

Moreover, this set of rules applies to both one cylinder and an entire group of containers connected using a gas distribution manifold.

Useful tips for using cylinders

During cold periods, it is better to warm the cylinders before using them outside. On a hike, you can take it in your sleeping bag or keep it in your bosom for a couple of hours. In everyday life, it is enough to simply store the product in a heated room. Of course, as far as possible from heat sources and open flames.

If you intend to fly by plane or travel by train, it is better to choose collet cylinders. They are the safest and will not cause unnecessary questions or problems. If the burner is intended for threaded connection, you can prepare a special adapter in advance.

Be sure to pay attention to the proportions of the gas mixture in the cylinder, focusing on weather conditions. In addition, we recommend buying only high-quality gas from well-known manufacturers, avoiding low-quality Chinese counterfeits.

Read also: Message about brass in chemistry

Both among people who carry out repairs professionally and among home craftsmen, a manual gas burner with a cylinder is very popular. The scope of their application is very wide, there are several varieties. This article tells you how to choose the right gas burner for a cylinder and learn how to use this device, which is not the most intricate design, but extremely useful in many cases when a room is being renovated.

Types and features

The structure of a propane cylinder is no different from other tanks for transporting and storing gas under pressure. It is a cylindrical metal welded container.

The manufacturing material is special grades of steel, the type of which is regulated by the interstate standard GOST 949-73 . According to occupational health and safety requirements adopted in the Russian Federation, all cylinders must be painted red with a black ring. The color of the “butane” inscription is white.

Some manufacturers offer new gas storage tanks made from various composite materials - Eurocylinders. They are distinguished by their low weight and increased resistance to mechanical damage compared to metal products.

The standard regulating their production was adopted relatively recently - in 2013 (GOST 55559-2013). The capacity of such tanks differs from classic metal products. The most common volumes are 12.5 and 33.5 liters.

The market offers consumers metal cylinders of the following volume (in liters):

Naturally, all cylinders have different dimensions. Let us consider the characteristics of the materials used in more detail.

Steel

They are produced at enterprises with special permission, since their design is subject to special conditions regarding the quality and characteristics of the welded joint.

Propane cylinders made of steel are subject to periodic verification, during which they check whether the container can withstand the required pressure, as well as the absence of leaks and the functionality of the shut-off valves. The average service life of a steel product is 20 years .

Polymeric

A product of modern technology that has just begun to gain positions in the domestic market. The use of fiberglass or epoxy resins in the structure has significantly reduced weight and increased resistance to external influences. This way, they don't have to worry about falls or bumps.

In addition, the materials used are resistant to high temperatures , which allows them to be used even near an open flame. Polymer cylinders have the only drawback - their high price. A metal container of comparable volume will cost at least half as much.

Self-removal of condensate

During operation of the container, condensation may accumulate in it, which not only takes up the useful volume of the container, but also negatively affects the quality characteristics of the mixture. Removing condensation is not a very complicated procedure that you can do yourself.

Please note that all tools that are to be used must have a protective coating that prevents the formation of sparks . First you need to prepare some unnecessary container for condensate.

Gas condensate has a strong and persistent odor, so after draining the container will have to be thrown away.

The operation must be carried out outdoors. After dismantling the shut-off valves, the cylinder must be turned over and the condensate drained into a container.

How much does a 5, 12, 27, 50 liter propane cylinder cost?

The price depends on the specific area in which the customer lives. How much an empty propane cylinder costs in our region, as well as the cost of refilling, is shown in the following table:

| Cylinder volume (liters) | 5 | 12 | 27 | 50 |

| Estimated cost of an empty new cylinder | 1080 | 1380 | 1500 | 2250 |

| Cost of refilled propane | 1155 | 1560 | 1905 | 3000 |

*prices are indicative depending on the manufacturer

The price of a cylinder is sometimes several times higher than the cost of the contents. But repeated refilling allows the tanks to be used for many years and even decades.

Source

Storage rules in suburban areas

When using gas tanks for domestic use, the following rules should be followed:

- In residential premises it is prohibited to store more than 10 liters of flammable or combustible liquid in a closed container.

- Cylinders should not be stored on escape routes, as well as in basements and attics.

- The fuel container must be located outside the residential premises, at a distance of at least 5 meters from the building.

- The container storage area must have a ventilation system and have warning signs.

- Operation of systems consisting of two or more cylinders is carried out only after obtaining permission from the relevant inspection.