OKP 14 1200

By Decree of the State Committee of Standards of the Council of Ministers of the USSR of December 19, 1973 N 2717, the introduction date was set from 01/01/75.

By Decree of the USSR State Standard dated August 14, 1991 N 1352, the validity period was lifted.

This standard applies to cylinders made of carbon and alloy steel, small volume - up to 12 liters and medium volume - from 20 to 50 liters with a working pressure of up to 19.6 MPa (200 kgf/cm2), made of seamless pipes and intended for storage and transportation of compressed, liquefied and dissolved gases at temperatures from minus 50 to plus 60°C.

The standard complies with the CMEA standardization recommendation PC 2496-70.

Steel gas cylinder design

For transportation and storage of light hydrocarbons such as propane, propane-butane or butane, composite cylinders with a capacity of up to 47 liters can be used.

However, more capacious, 50 liter vessels for liquefied hydrocarbons are made of steel. To store other liquefied or compressed gases, only steel tanks of various capacities are used.

GOST 15860 describes in detail the types, characteristics and permissible sizes of gas cylinders for hydrocarbons. GOST 949-73 specifies the parameters of gas tanks suitable for operation, with internal pressure up to 19.6 MPa.

The wall thickness is dictated by GOST standards regulating the design of cylinders. The blanks for steel 50 liter cylinders are seamless pipes made of steel grades: 45, 34CrMo4, 30ХМА and 30ХГСА

Both GOSTs indicate that for safe transportation and storage of gases, each vessel must have the following structural elements:

- Support shoe.

- A body consisting of a shell, lower and upper bottom and a backing ring.

- Information plate.

- Neck.

- Valve or tap.

Modifications are allowed that include a collar, handle/handles and a cap.

In addition to the basic standards for the manufacture of gas cylinders, there are additional standards that manufacturers must comply with.

Supporting documentation includes safety rules: PB 03-576-03 “Rules for the design and safe use of pressure vessels.” They describe in detail the requirements for valves and other auxiliary mechanisms.

MAIN PARAMETERS AND DIMENSIONS

1.1. Cylinders must be manufactured for a working pressure of 9.8; 14.7; 19.6 MPa (100, 150 and 200 kgf/cm2) from carbon steel and for working pressure 14.7 and 19.6 MPa (150 and 200 kgf/cm2) from alloy steel.

1.2. The main parameters and dimensions of the cylinders must correspond to those indicated in the drawing and table. 1.

Official publication Reissue (June 1992) with Changes N∙ ], 2. 3, 4, approved in October 1976, October 1980, February 1982, June 1986 (IUS 11-76.1-81, S-82.10-86).

© Standards Publishing House, 1974

© Standards Publishing House, 1992

Rice. 1 1 — support shoe; 2 — cylinder body; 3 — neck ring; 4 - valve; 5 - safety cap.

Dimensions in mm

Table 1

| Cylinder volume, l | Diameter of cylindrical part | Wall thickness of pressure cylinders, MPa (kgf/cm2), not less | Pressure cylinder body length, MPa (kgf/cm2) | Mass of cylinders for pressure MPa (kgf/cm2), kg | ||||||||||||

| carbon steel | alloy steel | carbon steel | alloy steel | carbon steel | alloy steel | |||||||||||

| 9.8 (100) | 14.7 (150) | 19.6 (200) | 14,7 (150) | 19.6 (200) | 9.8 (100) | 14.7 (150) | 19,6 (200) | 14,7 (150) | 19,6 (200) | 9,8 (100) | 14,7 (150) | 19.6 (200) | 14,7 (150) | 19.6 (200) | ||

| 0,4 | 70 | 1,6 | 2,2 | 2,9 | 1,0 | 1,9 | 165 | 170 | 175 | 165 | 165 | 0,6 | 0,8 | 1,0 | 0.6 | 0,7 |

| 0,7 | 255 | 260 | 270 | 255 | 255 | 0,9 | 1,2 | 1,5 | 0,9 | 1,0 | ||||||

| 1,0 | ,89 | 1,9 | 2,8 | 3,6 | 1,9 | 2,5 | 240 | 250 | 255 | 240 | 245 | 1,2 | 1,8 | 23 | 1.2 | 1,6 |

| 1,3 | 295 | 305 | 315 | 295 | 300 | 1,5 | 2,2 | 2,? | 1.5 | 1,9 | ||||||

| 2,0 | 425 | 440 | 455 | 425 | 435 | 2,1 | 3,1 | 4,0 | 2,1 | 2,7 | ||||||

| 2,0 | 108 | 2,4 | 3,4 | 4,4, | 2,4 | 3,0 | 320 | 330 | 340 | 320 | 325 | 2,5 | 3,7 | 4.7 | 2,5 | 3,1 |

| 3,0 | 445 | 460 | 480 | 445 | 455 | 3,4 | 5,0 | 6.4 | 3,4 | 4,3 | ||||||

| 3,0 | 140 | 3,1 | 4,4 | 5,7 | 3,1 | 3,9 | 310 | 325 | 335 | 310 | 320 | 4,1 | 6,0 | 7,9 | 4,1 | 5,3 |

| 4,0 | 385 | 400 | 415 | 385 | 395 | 5,0 | 7,3 | 9,6 | 5,0 | 6,5 | ||||||

| 5,0 | 460 | 475 | 495 | 460 | 470 | 5,8 | 8,5 | 11,4 | 5,8 | 7,6 | ||||||

| 6,0 | 535 | 555 | 575 | 535 | 550 | 6,7 | 9.8 | 13,1 | 6,7 | 8,8 | ||||||

| 7,0 | 610 | 630 | 660 | 610 | 625 | 7,6 | 11,1 | 14,9 | 7,6 | 9,9 | ||||||

| 8,0 | 140 | 3,1 | 4,4 | 5,7 | 3,1 | 3,9 | 680 | 710 | 740 | 680 | 700 | 8,5 | 12,4 | 16,6 | 8,5 | 11,1 |

| 10,0 | 830 | 865 | 900 | 830 | 850 | 10,2 | 15,0 | 20,1 | 10,2 | 13,4 | ||||||

| 12,0 | 975 | 1020 | 1060 | 975 | 1005 | 1,9 | 17,6 | 23,5 | 11,9 | 15,6 | ||||||

| 20,0 | 219 | 5,2 | 6,8 | 8,9 | 5,2 | 6,0 | 730 | 740 | 770 | 730 | 28,5 | 33,3 | 42,0 | 28,5 | ||

| 25,0 | 890 | 900 | 935 | 890 | 34,0 | 38.7 | 50,5 | 34,0 | ||||||||

| 32,0 | 1105 | 1120 | 1165 | 1105 | 42.0 | 47,7 | 62,5 | 42,0 | ||||||||

| 40,0 | 1350 | 1370 | 1430 | 1350 | 5i,5 | 58,5 | 76,5 | 51,5 | ||||||||

| 50,0 | 1660 | 1685 | 1755 | 1660 | 62.5 | 71,3 | 93,0 | 62,5 | ||||||||

Notes:

- 1. The weight of cylinders is indicated without valves, caps, rings and shoes and is a reference value and a nominal value for the manufacture of cylinders with a weight limit.

- 2. The lengths of the cylinders are indicated as reference and are accepted as nominal when manufacturing cylinders with a limited length.

- 3. The approximate weight of the metal cap is 1.8 kg; from fiberglass - 0.5 kg; rings - 0.3 kg, shoes - 5.2 kg.

1.1; 1.2. (Changed edition, Rev. N4).

1.3. Cylinders must be manufactured with normal and increased precision.

1.4.

Conventional precision cylinders are manufactured with a limited volume; cylinders of increased precision - by volume and outer diameter or by length and outer diameter. Maximum deviations should not exceed those indicated in the table. 2. Table 2

| Limit deviations | For standard precision cylinders | For high precision cylinders |

| By volume: | ||

| for small volume cylinders | +10% ‘ | . +5% |

| for medium volume cylinders | + 5% | +5% |

| By lenght: | ||

| for small volume cylinders | — | ?6 mm |

| for medium volume cylinders | — | ?15 mm |

| By outer diameter: | ||

| for carbon steel cylinders | — | ?1,5% |

| for alloy steel cylinders | — | ?2,0% |

Notes:

- 1. Maximum deviations in outer diameter for medium-volume cylinders made of carbon steel, which have been assigned the State Quality Mark, must not exceed ? 1.0%.

- 2. The curvature of medium-volume cylinders is no more than 0.5% of the length of the cylindrical part of the cylinder.

(Changed edition, Amendment No. 1, 3).

1.5. At the customer's request, alloy steel cylinders can be manufactured with weight restrictions. In this case, the mass of the cylinders should not exceed by more than 10% the mass indicated in the table. 1. Examples of symbols:

cylinder with a volume of 4 liters for a pressure of 14.7 MPa (150 kgf/cm2), made of carbon steel, standard manufacturing precision, for air:

- Air cylinder 4-150U GOST 949-73

the same, from alloy steel, increased manufacturing precision, with volume limitation, without weight limitation, for nitrogen:

- Nitrogen cylinder 4p-150L GOST 949-73

the same, with normal manufacturing precision, with mass restrictions, for air:

- Air cylinder 4-150 L-M GOST 949-73

the same, with increased manufacturing accuracy in terms of volume, with mass restrictions, for medical oxygen:

- Cylinder for medical oxygen 4P-150L-M GOST 949-73

the same, increased manufacturing precision, cylinder body length 400 mm, with weight limitation, for nitrogen:

- Nitrogen cylinder 4-150L-400-M GOST 949-73

the same, short volume 2 liters for a pressure of 14.7 MPa (150 kgf/cm2), made of carbon steel, increased manufacturing precision with a length limitation, without a weight limitation, for air:

- Cylinder for. air K2-150U-330 GOST 949-78 (Changed edition, Amendment No. 4).

Propane cylinder device

Structurally, they are containers made of carbon steel 3 mm thick. A stamped bottom with a stand-shoe is welded to a single-seam welded cylinder on one side, and a hemispherical neck for installing a valve on the other. Various filling or dispensing equipment is connected to the latter. The majority of propane consuming devices (gas stoves, titaniums, welding torches, heating boilers) require reduced pressure. To do this, a reducer is installed on the valve (the most common is BPO-5-5).

On the upper part of the neck there is a passport on which the main technical parameters of the device are stamped. These include: name of the manufacturing plant, quality control department stamp, individual number, month and year of manufacture, inspection date (updated every 5 years), volume, weight in empty and filled state.

Weight and size of cylinders of various capacities

How many kg of propane are in 1 5, 12, 27, 50 liter cylinder? You can find this out in the product quality certificate or in the table below. Here you can also find out how much a 5, 12, 27, 50 liter propane cylinder weighs.

| Volume | 5 liters | 12 liters | 27 liters | 50 liters |

| Empty cylinder weight, kg | 4 | 5,5 | 14,5 | 22,0 |

| Propane tank weight, kg | 6 | 11 | 25,9 | 43,2 |

| Mass of stored gas, kg | 2 | 5,5 | 11,4 | 21,2 |

| Cylinder height, mm | 290 | 500 | 600 | 930 |

| Cylinder diameter, mm | 200 | 230 | 299 | 299 |

What is the thread on a propane tank?

Valves of the VB-2 type are installed on most household cylinders for propane-butane mixture. These shut-off devices are manufactured in accordance with GOST 21804-94 and are designed for pressures up to 1.6 MPa. The tap has a left-hand thread SP21.8-1 (6 turns), which allows you to connect any gearboxes with a union nut and a similar thread.

The valve provides a strong connection to the neck, complete tightness, has clear markings and a modern design. Threaded surfaces are lubricated with a special lubricant that reduces friction during operation. The screw plug with rubber gasket prevents gas leakage during transportation or storage. The device provides protection against unqualified repairs by persons who have not undergone appropriate training. The reliability of the locking device contributes to long-term and safe operation of the gas cylinder structure.

TECHNICAL REQUIREMENTS

2.1. Cylinders must be manufactured in accordance with the requirements of this standard and the “Rules for the design and safe operation of pressure vessels” approved by the USSR State Technical Supervision Authority according to working drawings approved in the prescribed manner. (Changed edition, Amendment No. 4).

2.la. Cylinders must be made from pipes that have undergone ultrasonic testing of metal continuity.

Note. The requirement of clause 2.1a is introduced from 01/01/89. (Introduced additionally, Amendment No. 4).

2.2.

The mechanical properties of the cylinder material must correspond to those indicated in the table. 3. Table 3

| Name of properties | Carbon steel | Alloy steel |

| Temporary resistance 6V, N/mm2 (kgf/mm2), not less | 638 (65) | 883 (90) |

| Yield strength Ov, N/mm2 (kgf/mm2), not less | 373 (38) | 687 (70) |

| Relative elongation bz, °/о, not less | 1.5 | 10 |

| Impact strength KCU, J/cm2 (kgf-m/cm2), not less, at 20°C | 29,4 (3) | 98,1 (10) |

(Changed edition, Amendment No. 4).

2.3. The materials of the cylinder valve bodies depending on the gas being filled, as well as the direction of the thread of the side fitting are indicated in the appendix. The side fittings of valves for toxic and flammable gases must be equipped with plugs. (Changed edition, Amendment No. 1, 4).

2.4. The outer and inner surfaces of the cylinders must be free of caps, holes, dulls, and cracks. Depressions, marks, traces of scale or tools, compacted and open wrinkles on the inner surface of the necks and bottoms and other minor defects should not be removed. wall thickness for the smallest values indicated in the table. 1. (Changed edition, Amendment No. 1).

2.5. The thread of the neck of the cylinders must be made in accordance with GOST 9909-81, in this case:

- the outer diameter of the thread in the plane of the end should be: for small volume cylinders - 19.2 mm, . for medium-volume cylinders - 27.8 mm,

- for medium volume cylinders (acetylene) - 30.3 mm;

2.6. At the request of consumers, cylinders can be manufactured with agreed dimensions of the outer diameter of the neck.

2.7. A steel ring must be securely fastened to the neck of cylinders with safety caps.

2.8. Rings and safety caps must be interchangeable.

2.9. In the threads of rings and caps, local minor tears and gouges with a length of no more than one third of the circumference are allowed on no more than one third of the total number of threads.

2.10. Shoes made from a section of steel pipe. must be tightly fitted onto the cylinders with a gap between the supporting plane of the shoe and the bottom of the cylinder of at least 10 mm.

2.11.

Valves of cylinders intended for liquid chlorine. must be equipped with a steel siphon tube, the length of which must correspond to that indicated in the table. 4. ' Table 4

| Cylinder volume, l | 20 | 25 | 32 | 40 | 50 |

| Tube length, mm, no more | 675 | 825 | 1045 | 1275 | 1575 |

2.12. Before screwing in valves or installing plugs in the necks, the inner surface of the cylinders must be cleaned of chips and loose scale. A thin remaining layer of oxides obtained during normalization, as well as individual stains caused by the method of cleaning the cylinders, are allowed. Small volume cylinders intended for medical oxygen, as well as on special orders from consumers, must be completely free of scale.

2.13. Cylinders for oxygen or hydrogen must be degreased, and those without valves must be additionally degreased at the customer’s site. Water and dirt are not allowed in the cylinders. .(Changed edition, Amendment No. 2).

2.14. Cylinders must be painted on the outside with oil, enamel or nitro paint. The marks must be clearly visible after painting. At the customer's request, the cylinders may not be painted.

2.15. Cylinders must be equipped with the following parts:

- a) small-volume cylinders with valves, and upon customer’s request, without valves;

- b) medium volume cylinders for acetylene - rings, caps and shoes;

- c) medium volume cylinders for ammonia, chlorine, phosphene, pseudobutylene, sulfur dioxide - valves, rings and caps;

- d) medium-volume cylinders, with the exception of cylinders specified in subparagraphs b and c, with valves, rings, caps and shoes.

It is allowed to complete cylinders with separate parts upon customer request.

How many liters of gas are in a 50 liter cylinder? How many cubic meters of gas are in a 50-liter cylinder?

Design of a cart for semi-automatic cylinders

When gas comes to a rural settlement, civilization comes to it. Stove heating, or individual water heating with a solid fuel boiler, is not only the romantic crackling of firewood in the firebox.

Heating with solid fuel always means soot, smoke and soot, and the need for annual repainting of the ceilings.

And besides the troubles associated with constant dirt, you also need to prepare or purchase and somewhere store a supply of firewood for the whole winter.

Unfortunately, natural pipeline gas is not installed everywhere. In many settlements, residents have to make do with bottled gas. And people are wondering how many liters of gas are in a 50-liter cylinder?

What is domestic gas

Let's remember the basics of school organic chemistry. The first saturated hydrocarbon is methane. The molecule of this gas consists of one carbon atom surrounded by four hydrogen atoms.

- methane CH4;

- ethane C2H6;

- propane C3H8;

- butane C4H10.

The last two compounds - propane and butane - are the contents of household gas cylinders.

Physical properties of these chemicals

Propane at normal atmospheric pressure is a liquid in the temperature range from –187.7 to –42.1 °C.

Below the specified interval, propane crystallizes, and above, accordingly, it passes into the gaseous state. Butane has this range: –138.3 … –0.5 °C.

As you can see, the transition temperatures into liquids for both gases are not much below zero, making them quite easy to liquefy by increasing the pressure.

Gas storage methods

In everyday life, as a rule, a propane-butane mixture is used. In private homes, standard 50-liter gas cylinders are used to store the liquefied mixture. They act a little differently when supplying gas to high-rise buildings. Well, how many liters of gas can fit in a 50-liter cylinder?

And to change cylinders with 42 liters of gas (this is exactly how much liquefied gas is stored in the cylinder) plus the weight of the cylinder itself on all floors and apartments... Therefore, in such cases, as a rule, a grounded storage facility is installed in the courtyard of the house, into which the gas mixture is delivered by special gas carriers. In a special device it is converted into a gaseous phase and in this form enters the household pipeline.

Gas cylinder volume

So how many cubic meters of gas are in a 50-liter cylinder? To answer this question, we need to decide what gas we are interested in. 42 liters of liquid mixture of gases are poured into the cylinder. But how much is this in kilograms, cubic meters? Density of liquefied liquids: propane – 0.528 kg/l, butane – 601 kg/l.

In order to find out how many liters of gas are in a 50-liter cylinder, let’s make some small calculations.

| Propane | ||

| Liquid phase density | 0,53 | kg/l |

| Liters per cylinder | 42,00 | l |

| Mass of gas in the cylinder | 22,18 | kg |

| Gas phase density | 1,87 | kg/m3 |

| Volume occupied by 42 kg of gas (1 cylinder) | 22,44 | m3 |

| Butane | ||

| Liquid phase density | 0,60 | kg/l |

| Liters per cylinder | 42,00 | l |

| Mass of gas in the cylinder | 25,24 | kg |

| Gas phase density | 2,52 | kg/m3 |

| Volume occupied by 42 kg of gas (1 cylinder) | 16,67 | m3 |

Thus, how many liters of gas are in a 50-liter cylinder depends on what composition is pumped into it. If we assume that the cylinder is filled with one propane - 22.44 m3, butane - 16.67 m3. But since a mixture of these chemical compounds is used in everyday life, the indicator will be somewhere in the middle.

If we assume that propane and butane are in equal proportions in the cylinder, then the answer to the question of how much gas is in a 50-liter cylinder (m3) is about 20.

Safety precautions when handling gas cylinders

- Never remove signs or labels from cylinders.

- Do not lift or move the cylinder while holding the valve.

- Determine leaks using a soap solution rather than a lit match.

- Open the cylinder valve smoothly.

- Never heat the cylinder.

- Independent pumping (transfer) of liquefied gas into other containers is prohibited.

ACCEPTANCE RULES

3.1. Each cylinder must be subjected to smoke acceptance tests.

3.2. Cylinders are accepted in batches of up to 400 pcs. the same volume, size and the same heat treatment regime.

3.3. Acceptance tests include:

- test of endurance;

- leak test;

- tensile test;

- impact bending test;

- visual inspection;

- determination of mass;

- determination of volume.

3.4. The tensile test should be carried out on short longitudinal specimens. Samples in their calculation part should not be straightened.

3.5. The impact test shall be carried out on longitudinal specimens of type V. The axis of the notch shall be perpendicular to the wide edges of the specimen. Cylinders with a wall thickness of at least 5 mm are tested.

3.6. For tensile and impact bending tests, samples are cut from the bodies of finished cylinders or witness pipes, cut from the pipes from which a given batch of cylinders is made, and heat treated together with the cylinders of a given batch, and from alloy steel also from the same heat. For each test, at least two samples are taken from the lot. (Changed edition, Amendment No. 4).

3.7. If the test results do not comply with the requirements of this standard, tests are carried out on twice the number of samples. The results of the spot check apply to the entire lot. (Changed edition, Amendment No. 3).

3.8. Acetylene cylinders must be tested for leaks at factories that fill the cylinders with porous mass. (Introduced additionally, Amendment No. 3).

4. TEST METHODS

4.1. Pneumatic and hydraulic pressure tests are carried out in accordance with the “Rules for the design and safe operation of pressure vessels.” Test duration is at least 1 minute. Pneumatic tests of cylinders intended for filling with gases, the penetrating ability of which is higher than that of air, must be carried out in accordance with regulatory and technical documentation. (Changed edition, Amendment No. 4).

4.2; 4.3. (Excluded, Amendment No. 4).

4.4. Cylinders equipped with a chlorine valve are tested with a pneumatic pressure equal to 2.94 (30 kgf/cm2).

4.5. Tensile test according to GOST 10006-80. The test speed up to the yield point and during its passage is no more than 10 mm/min, beyond the yield point is no more than 40 mm/min. It is allowed to control the mechanical properties of carbon steel cylinders using a non-destructive method according to the regulatory and technical documentation. In controversial cases, tests are carried out in accordance with GOST 10006-80.

4.6. Impact bending test - according to GOST 9454-78 on longitudinal samples of type 3.

4.7. If the test results do not comply with the requirements of this standard, tests are carried out on twice the number of samples. If the results of repeated tests are unsatisfactory, the entire batch of cylinders is sent a second time for heat treatment. No more than two repeated heat treatments are allowed. Additional tempering is not considered repeated heat treatment. (Changed edition, Amendment No. 4).

4.8. The volume of the cylinder must be controlled by limiting templates along the length; in this case, the volume of the cylinder should not be lower than the nominal one. The volume of two cylinders from a batch is checked by filling with water and determining the volume or mass of water.

Note. From 01/01/89, determination of the volume of all medium-volume cylinders is introduced. (Changed edition, Amendment No. 1, 2).

Rules for the safe operation of propane cylinders

- When using and storing, do not allow the cylinders to overheat (for example, leave them in direct sunlight for a long time);

- It is not recommended to bleed out the propane-butane mixture until the tank is completely empty (under certain conditions it can suck in air, and this is dangerous);

- When transporting, be sure to use plugs and safety caps;

- in case of detection of dents or other defects, the product must be sent for an unscheduled recheck;

- Individuals are allowed to transport no more than five cylinders in one vehicle (they must be separated by spacers from each other).

- It is necessary to constantly monitor the condition of the cylinders, because it is not for nothing that they are considered fire and explosive objects.

What is the gas pressure in a propane tank?

According to GOST 15860-84, the working pressure in the tank should not exceed 1.6 MPa. In this case, the proportion of propane in the hydrocarbon mixture must be no less than 60%. This is very important for the safe operation of gas cylinder installations. Of course, products are designed for significantly higher pressures - more than 5.0 MPa. Production and periodic tests are carried out under a pressure of 3.0 MPa.

Refueling standards

At gas cylinder refilling stations, employees are familiar with the regulations. Since a cylinder that is filled too much can explode or its valve can be torn off. So, if you refuel from a reliable supplier, you have nothing to worry about.

| Cylinder type (l) | 5 | 12 | 27 | 50 |

| Maximum permissible quantity of propane, l | 3,5 | 8,4 | 18,9 | 35 |

LABELING, PACKAGING, TRANSPORTATION AND STORAGE

5.1. Cylinders are marked in accordance with the requirements of the “Rules for the Design and Safe Operation of Pressure Vessels”. Additionally, data on the type of heat treatment is applied:

- N - normalization;

- V - hardening and tempering.

Note. Until 01/01/89, the nominal volume of the cylinder is indicated.

5.2. The inscriptions on the cylinders and their painting are carried out in accordance with the “Rules for the design and safe operation of pressure vessels” and Table. 5.

5.3. Cylinders transported without valves must be protected from contamination with polyethylene or nylon plugs.

5.4.

Small volume cylinders are transported in containers made according to GOST 18477-79, without packaging. When shipped by carload in covered wagons, small-volume cylinders are transported packed in boxes in accordance with GOST 2991-85 (type III-1) with a cargo weight of no more than 200 kg or stacked up to the full capacity of the wagon. Dimensions of boxes according to regulatory and technical documentation in accordance with the requirements of GOST 21140-88; Medium-volume cylinders are transported without packaging. covered cars, gondola cars or containers manufactured in accordance with GOST 18477-79. It is allowed to transport cylinders in multi-turn packaging means in gondola cars or in packages in special cars. Table 5

| Name of gas | Coloring of cylinders | Inscription text | Lettering color | Stripe color |

| Nitrogen | Black | Nitrogen | Yellow | Brown |

| Ammonia | Yellow | Ammonia | Black | — |

| Argon raw | Black | Argon raw | White | White |

| Argon technical | Black | Argon technical | Blue | Blue |

| Argon pure | Gray | Argon pure | Green | Green |

| Acetylene | White | Acetylene | Red | — |

| Butane | Red | Butane | White | — |

| Butylene | Red | Butylene | Yellow | Black |

| Hydrogen | Dark green | Hydrogen | Red | — |

| Air | Black | Compressed air | White | — |

| Helium | Brown | Helium | White | — |

| Nitrous oxide | Gray | Nitrous oxide | Black | — |

| Oxygen | Blue | Oxygen | Black | -=- |

| Medical oxygen | Blue | Medical oxygen | Black | — |

| Oil and Gas | Gray | Oil and Gas | Red | — |

| Hydrogen sulfide | White | Hydrogen sulfide | Red | Red |

| Sulfur dioxide | Black | Sulfur dioxide | White | Yellow |

| Carbon dioxide | Black | Carbon dioxide | Yellow | — |

| Phosgene | Protective | — | — | Red |

| Freon | Aluminum or light gray | R (indicating its number) | Black | — |

| Chlorine | Protective | — | Green | |

| Cyclopropane | Orange | Cyclopropane | Black | — |

| Ethylene | Purple | Ethylene | Red | — |

| All other flammable gases | Red | Name of gas | White | — |

| All other non-flammable gases | Black | Name of gas | Yellow | — |

5.1; 5.2. (Changed edition, Amendment No. 4).

The arrangement and fastening of cylinders on vehicles must comply with the requirements of the “Technical conditions for loading and securing cargo” approved by the Ministry of Railways. (Changed edition, Amendment No. 4).

5.4a. Transport markings must be applied to one of the sides of each box, including main, additional and informational inscriptions in accordance with GOST 14192-77. (Introduced additionally, Amendment No. 4).

5.5. Cylinders are transported by all types of transport in accordance with the rules in force for each type.

5.6. Each batch of cylinders must be accompanied by a quality document certifying the cylinders’ compliance with the requirements of this standard, which must indicate:

- name of the manufacturer and its location (city or conventional address);

- product designation;

- number of cylinders and their numbers;

- results of hydraulic and pneumatic tests;

- designation of this standard.

5.5; 5.6. (Changed edition, Rev. N4).

5.7. Storage of cylinders according to group Zh2 GOST 15150-69.

5.8. Each cylinder that has been assigned the state Quality Mark in the prescribed manner and the certificate must be marked with an image of the state Quality Mark. in the manner established by Gosstandart. (Introduced additionally, Amendment No. 3).

Fuel consumption

One such container usually holds up to 50 liters of gas, and in liquid form this is more than 22 kg. The price for refilling a cylinder is quite reasonable, and 50 liters of gas last for quite a long time. Having made some simple calculations, you can find that the use of gas fuel is very beneficial in any situation where an effective and inexpensive fuel is required.

Constant operation of a heating boiler can consume about 1.5 containers per day with a heated area of up to 140 square meters. For a small residential building, even one cylinder will be enough. The calculations are approximate, and were made on the condition that the street temperature would be -23, and the temperature in the house would be maintained at +23. If the difference in temperature conditions is greater, then it is logical to assume that fuel consumption will ultimately be different.

It is possible to reduce the consumption of propane, which is used in residential buildings for heating or even kitchen stoves, by installing automatic control of gas-type equipment. So, at night the temperature will be lowered, and this will reduce, for example, the use of fuel by a gas boiler in the house. Overall, this allows you to reduce consumption by 25 or even 40%! In this case, it is possible to stretch one gas cylinder over two days.

Correct configuration of software and automated equipment allows you to reduce gas fuel consumption for heating and operation of the gas system of a residential building with an area of up to 140 square meters to 10 cylinders or even less per month. This is a significant saving on heating costs, and thus it is possible to efficiently heat a large house with minimal cost.

Propane comes in containers of different sizes, and a 50-liter cylinder is a fairly large volume. They are intended to store and transport propane-butane gas in complete safety. Such systems are used for domestic purposes in residential buildings, as well as when carrying out gas welding work.

Cylinders can differ not only in volume, but also in operating pressure. For propane, the maximum pressure during operation is 1.6 MPa. Gas has a fairly high coefficient of volumetric expansion, and therefore consumables must be filled so that there is enough air in them, which will absorb the liquid if it expands when heated.

MANUFACTURER'S WARRANTY

6.1. The manufacturer must ensure that the cylinders comply with the requirements of this standard provided that the consumer complies with the operating, transportation and storage conditions established by this standard.

6.2. The warranty period is 2 years from the date of putting the cylinders into operation. For medium-volume carbon steel cylinders that have been awarded the State Quality Mark - 4 years from the date of commissioning. (Changed edition, Amendment No. 1). Sec. 7. (Deleted, Amendment No. 4).

Scope of application

The technical and operational characteristics of polymer-composite gas cylinders provide them with great potential and an almost unlimited scope of application. This is an autonomous source of one of the most popular energy carriers in a variety of situations.

Cooking - both at a seasonal dacha or in a capital country house (kitchen gas stoves), and on a picnic or while traveling (gas grills and barbecues, mobile stoves).

In heating systems - a variety of home gas heaters, sauna stoves, outdoor heaters (trips to nature).

In construction and finishing - welding machines, heat guns.

In autonomous power supply systems - generators.

The ease of use of compact and presentable composite cylinders in almost all conditions is undeniable.

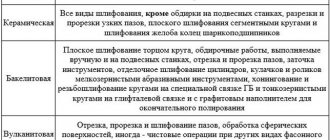

CYLINDER VALVE CASE MATERIALS AND SIDE FITTING THREAD DIRECTION

Table 6

| Name of gases | Valve body material | Side fitting thread direction | Name of gases | Valve body material | Direction of Side Fitting |

| Nitrogen | Brass | Right | Methane | Brass | Left |

| Ammonia | Steel | Right | Propane and other flammable gases | Steel or brass | Left |

| Argon | Brass | Right | Sulfur dioxide | Steel | Right |

| Butane | Brass or steel | Left | Carbon dioxide | Brass | Right |

| Butylene | Brass | Left | Phosgene | Steel | Right |

| Hydrogen | Brass | Left | Freon | Steel or brass | Right |

| Air | Brass | Right | Chlorine | Steel | Right |

| Helium | Brass | Right | Chlormethyl-til | Brass | Left |

| Oxygen | Brass | Right | Chloroethyl | Brass | Left |

| Xenon | Brass | Right | Ethylene | Brass | Left |

Editor L. I. Nakhimova Technical editor O. N. Nikitina Proofreader V. I. Varentsova

Delivered to embankment 02.09.92 Sub. in the oven 16.10.92 Conditional p.l. 1.0. Conditional cr.-ott. 1.0. Uch.-ed. l. 0.83. Shooting gallery 1247 copies

Orders ■Badge of Honor■ Publishing house of standards, 123557, Moscow, GSP, Novopresnensky lane, 3 Type. ■Moscow printer■. Myskva, Lyalin lane, 6. Zak. 1462

Note. When ordering cylinders for gases not listed in the table, the customer must indicate the type of valve in the order.

Examples: how to convert cubes to liters?

Let us now consider the inverse problems of finding the number of cubes in the specified number of liters.

| Problem #1: How many cubes are in 100 liters? Solution: 100 * 0.001 = 0.1 cubic meters. meter. Answer: 100 liters is 0.1 cubic meters. | Problem #6: How many cubes are in 1500 liters? Solution: 1500 * 0.001 = 1.5 cubic meters. Answer: 1500 liters are 1.5 cubic meters. |

| Problem #2: How many cubes are there in 200 liters? Solution: 200 * 0.001 = 0.2 cubic meters. meters. Answer: 200 liters are 0.2 meters. | Problem #7: How many cubes are in 3000 liters? Solution: 3000 * 0.001 = 3 cubic meters. Answer: 3000 liters - 3 cubic meters. |

| Problem #3: How many cubes are in 140 liters? Solution: 140 * 0.001 = 0.14 cubic meters. Answer: 140 liters are 0.14 cubic meters. | Problem #8: How many cubes are in 5000 liters? Solution: 5000 * 0.001 = 5 cubic meters. Answer: 5,000 liters are 5 cubic meters. |

| Problem #4: How many cubes are in 500 liters? Solution: 500 * 0.001 = 0.5 cubes. Answer: 500 liters are 0.5 cubes. | Problem #9: How many cubes are there in 10,000 liters? Solution: 10,000 * 0.001 = 10 cubic meters. m. Answer: in 10,000 liters - 10 cubic meters. m. |

| Problem #5: How many cubes are in 1000 liters? Solution: 1000 * 0.001 = 1 cubic meter. Answer: 1000 liters are 1 cubic meter. | Problem #10: How many cubes are there in 30,000 liters? Solution: 30,000 * 0.001 = 30 cubic meters. m. Answer: 30,000 liters are 30 cubic meters. m. |

To make calculations faster, we suggest you use our online calculators:

- cubes to liters conversion calculator

- liters to cubes conversion calculator

Follow the appropriate links and instructions.