Causes of damage to the cooling system

The radiator used in a car can fail for various reasons. Among the most common are the following:

If you notice the first signs of damage to this part, you need to make timely repairs. But a machine running with such a faulty cooling system can cause the engine to overheat , which can lead to even bigger problems, including the need for a major overhaul of the device. That is why, even at the first signs of problems with cooling, it is necessary to carry out diagnostics and appropriate repairs of car radiators.

Methods for repairing a car radiator

The repair prognosis will largely depend on the extent of damage to that part. If slight deformations of the cells are observed, you can try to use special compounds to seal the existing damage, after which the tightness will be restored, which will ensure high-quality cooling of the antifreeze.

If repeated mechanical damage or signs of corrosion are noted, it is very likely that it will be difficult to repair the radiator, and it will be much easier for the car owner to buy a new spare part. It is impossible to independently carry out such repairs and diagnostics of the car engine cooling system. We can recommend that you contact the appropriate workshops, where specialists with extensive practical experience will be able to determine the nature of the damage and, if possible, repair the damaged vehicle.

The three most common repair technologies today are:

- Use of special sealants.

- Soldering metal honeycombs.

- Argon welding.

Special epoxy compounds

If cell damage is minor, the system can be sealed using special sealants. Service specialists will be able to repair the damage using a sealant that consists of epoxy resin and a hardener, and accordingly, the tightness of the engine cooling system will be completely restored.

Do not attempt to repair it yourself. This is a radiator with the sealants you bought. This can make the problem worse and this misused sealant will be found in the antifreeze and then in the engine cooling passages. As a result, you will need to open the engine and clean it.

Radiator repair by soldering

When carrying out such repairs, it will be necessary to disassemble the damaged part, inspect it and, if necessary, replace rotten internal pipes. Then, using a soldering iron or gas torch, the damaged elements are sealed, after which the repaired radiator is checked for leaks. It is difficult to carry out such soldering on your own, so it is better to turn to specialists who can fully compensate for any damage with special equipment.

Using argon welding

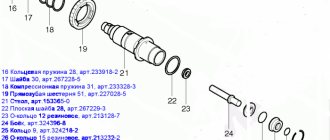

The advantage of using argon welding is the complete protection of the treated surfaces from oxidation. Accordingly, in the future, corrosion will not appear on the welded area of metal cells, and the welding quality will be at a high level. Such argon welding can be used even in the presence of significant mechanical damage, when it is impossible to use soldering and special sealants.

Prevent car radiator damage

The car owner will have to regularly change the antifreeze, which will avoid the appearance of internal deposits and corrosion on metal elements.

It will also be useful to install additional curtains or a protective metal mesh, which will protect the car radiator from various mechanical damage.

READ How to Calculate Band Saw Speed

Do not overheat the coolant. When the temperature of the antifreeze increases significantly, the pressure in the system increases, which can lead to rupture of the tank and damage to various connections, which invariably leads to a leak and the need to repair the cooling system.

During the operation of the car, its owners may be faced with the need to repair and restore engine cooling radiators. Such repairs should only be carried out by professionals. , Who can determine the technology for restoring the cooling system and completely restore its tightness, which will save the car owner from the need to buy new expensive spare parts.

Source

Circular Saw. This is special equipment designed to cut planks or wooden beams evenly. Using the device requires certain knowledge and skills. To understand how to use a circular saw, you must become familiar with its operating principle and performance capabilities.

Device and principle of operation

The design of a circular saw is quite simple. The device can be manual, or there are also combined stationary models.

Regardless of the type of equipment, it consists of a saw and a base plate. The last element is made of durable steel sheets or aluminum alloys. The main purpose of a circular saw is accurate and high-quality longitudinal sawing of wood.

A circular saw

Cutting boards and woolen stones is carried out by rotating discs, which have special covers that serve as protection against injury during the working process. The cutting part is driven by a trigger. Circular equipment allows you to process large volumes of wood.

How much grease is required for replacement

The required volume of lubricant for angle grinders is prescribed taking into account the complete coverage of the oblique teeth of the gears. Excess material will be squeezed out of the housing, and too little material will not ensure proper functioning of the gearbox.

It is recommended to take as a guide the amount of lubricant provided when the machine was assembled at the factory. It should be taken into account that during long-term storage in a warehouse or store, a certain amount of lubricant may dry out and decrease in volume.

Therefore, it is better to first put a little more material than required and make sure that the lubricant is evenly distributed after the gearbox gears are driven into action. The generally accepted norm is to fill about 40% of the gearbox volume with lubricant.

Classification of types and sizes

Circular saws are divided into two classes. Household and professional. The equipment differs in power, size and diameter of the saw:

- Household models are small equipment weighing from 4 to 5 kilograms, which are usually used for sawing wood at home. Equipment power. No more than 1800 W. The disc size of such saws is 160.200 millimeters.

- Professional circular saws are designed for processing large quantities of wood. They are able to see beams up to 85 millimeters thick. The weight of such equipment exceeds 8 kilograms, and the diameter of the disk. 250 millimeters. Professional saws have higher power. More than 1800 W.

Household circular saw model

Lubricants for rotary hammer gearboxes

| All products Select store | |

| Sort by: | Show by: products |

| Products found: 4 |

© 2006 — 2022. VseInstruments.ru

Email Tel. (from 07:00 to 22:00) 8 (from 07:00 to 22:00) The call is free

All information on the site is the property of the online store Vseinstrumenti.ru. Publishing information from the website vseinstrumenti.ru without permission is prohibited. All rights reserved.

The information on the website www.vseinstrumenti.ru is not a public offer. The indicated prices are valid only when placing an order through the online store www.vseinstrumenti.ru.

Prices at delivery points and retail stores of VseInstrumenty.ru may differ from those indicated on the website.

You accept the terms of the privacy policy and user agreement every time you leave your data in any feedback form on the VseInstrumenty.ru website.

Source: www.vseinstrumenti.ru

Article rating:

Save to:

Circular saw gear lubricant Link to main publication

Video: Cause of Circular Saw Breakage

There are several types of circular saws:

- Standard. The model is designed for cutting wooden beams up to 85 millimeters.

- Mini saw. A small round device weighing up to 2 kilograms and a power of up to 800 W. Used for cutting valuable wood.

- Submersible. The equipment is used to cut holes inside the wood. The design of such a saw consists of a mechanism that facilitates the vertical immersion of the disc.

- Diamond This type of equipment is designed for cutting hard materials. Stone, ceramics or tiles. The working mechanism of the device consists of a diamond disc, which allows cutting depths of up to 55 millimeters.

- Rechargeable. This round tool has low power and is quite compact in size. The device runs on batteries and is often used in the construction of wooden houses.

Circular saws are divided into four types depending on the depth of the blade:

- Professional. From 65 to 140 millimeters;

- Big. From 70 millimeters;

- Average. 55 mm;

- Small. From 40 to 46 millimeters.

No less important for the quality of the cut is the number of teeth on the disk. The smaller they are, the lower the productivity of the circular equipment. For large scale woodworking, special carbide cutting tools are used.

Types of work

The capacity of a circular saw depends on its size and type.

Hand saw

These electric saws are designed for precise straight cutting of thin wood materials. The hand-held, round device is small in size and is most often used for work at home.

Small sawing equipment is necessary for decorating the interior of houses. Often hand-held circular saws are used during renovations to cut laminate or wallpaper.

Circular machine

Stationary circular saws. This is equipment for everyday use. Such professional machines are capable of processing large quantities of wood per day. They are quite heavy. More than 10 kilograms and high power up to 2500 W.

READ How to Sharpen Band Saws for Wood

Circular machine

Circular machines are used mainly in industry. The cost of such a device is quite high. Some small models of circular equipment also have a stationary function. They are successfully used in home workshops.

Work algorithm

Hand-held and stationary circular saws have a similar operating principle. But hardware management has some differences.

Manual models

The circular hand saw is an effective and safe tool. However, the use of such equipment requires compliance with certain operating rules:

- Electrical connection. When using the saw in off-grid locations, an extension cord is often used. It must fully match the power of the round tool. Before connecting, check the integrity of the cable insulation. When connecting the saw to the electrical outlet, make sure that the device switch is turned off.

- Fastening the material. Wood to be cut must be well secured to a flat surface. To do this, the material is placed on the machine and fixed until it is completely stable.

- Cutting depth The required value is determined using a special scale on the device. When sawing a block, the disc should not protrude beyond the material; otherwise the workbench may become damaged. Therefore, it is recommended to fix the cutting depth slightly less than the required value.

- After setting all the necessary parameters, the cutting mechanism must be set in motion. Start cutting with the rotating blade only. The movement of the saw across the material should be smooth and uniform.

At the end of the work process, the hand-held circular tool should be unplugged.

Stationary models

The use of circular machines has its own operational characteristics. To make lumber you need:

- Set the equipment switch to the off position. Only after this the cable can be connected to the network.

- By lifting the handle, adjust and lock the cutting height of the disc in accordance with the dimensions of the material prepared for cutting.

- Check the position of the guide belt and saw blade. Their location should be parallel.

- Fire up the round saw and make a lengthwise cut out of the wood material. Sawing one board should be carried out in a single approach.

Using a stationary circular saw

Once all material has been processed, turn off the equipment switch that stops the blade from rotating and unplug the tool.

What can you do without a lathe?

It is best to make a shaft for a circular machine on a lathe. This is due to the fact that such a part requires special manufacturing precision.

If it is not possible to make a shaft on a lathe, you can make it yourself. To do this you will need the following set of tools:

- angle grinder;

- inverter welding machine;

- sharpening disc;

- hand drill or drill press.

Before starting work, it is necessary to measure all the original dimensions and transfer them to the workpiece. To make a shaft, you must perform the following steps:

- Weld guides made from a metal rod to the end parts of the workpiece.

- Fix one of the guides in the chuck of a drill or drilling machine.

- Turn on the drill, giving the workpiece a stable rotation.

- Using a grinder with a sharpening disc, grind the workpiece according to the pre-applied dimensions.

It is better to carry out work on the manufacture of a shaft for a circular machine with outside help, since it is inconvenient to hold the drill and at the same time grind the workpiece.

Nuances of additional functions

Modern models of circular saws are safe equipment with high technical parameters. Many devices are equipped with additional functions that greatly facilitate the work process:

- Sliding clutch. This device allows you to avoid injury when the disk jams. With the help of a clutch, you can significantly reduce the shock when stopping a rotating mechanism.

- Smooth start. This function allows the drive to pick up speed without jerking. A soft start protects the mechanism from shock, which has a positive effect on the service life of the engine.

- Overload protection. When the engine reaches critical levels, the mechanism automatically turns off.

- Supports the required disk speed. Under load when cutting dense materials, power is automatically added. This feature protects against disk speed degradation.

- Accelerated braking. When the power button is pressed, the drive stops abruptly.

- Start lock buttons. This feature prevents the instrument from turning on if the switch is accidentally pressed. It is usually set by pressing two keys at the same time.

Which lubricant to choose

There are several ways to reduce the frictional impact on the interacting elements of an angle grinder gearbox. The choice of how to lubricate friction units is made from the following options:

- the use of expensive special lubricants for gearboxes from well-known brands;

- the use of universal compounds suitable for any power tool;

- lubricating the gearbox with lithol or grease;

- use of self-made lubricant.

Application of special materials is the optimal solution. When choosing a lubricant for a gearbox, it is recommended to give preference to compounds produced under the same brand as the grinder itself. For example, if the machine is an AEG brand, then the lubricant must be purchased from the same brand.

When using specialized products, the service life of angle grinders increases significantly, since the manufacturer takes into account all the features and nuances of operating its own equipment. The disadvantage of using branded materials is their high cost, which can affect the family budget.

Most craftsmen use budget grinders or tools made in China. For such machines, specialized lubricating compounds have not been developed by the manufacturer and are unlikely to ever appear. However, such equipment also requires maintenance. What to do in this case?

Specialists and service technicians recommend purchasing any budget, non-branded compound designed specifically for gearboxes. You can also use a lubricant used for CV joints, the joint of front-wheel drive vehicles that operate under significant loads. It can be purchased without any problems at any auto store. This option is much worse than using branded materials. This is due to the fact that the specifics of the operation of friction units of two different mechanisms are not taken into account.

The most unfavorable solution is the use of lithol or grease, since both of these materials are not designed to lubricate friction units that heat up to high temperatures. Some owners of grinders use only these compounds, which is why their machines cannot last the service life declared by the manufacturer. In an effort to benefit here and now, they do not take into account the future costs of purchasing a new tool or replacing expensive parts.

Precautionary measures

Using a circular saw requires caution. To prevent accidents when operating electrical equipment for sawing wood, basic safety rules should be followed:

- Before connecting the device to the mains, make sure that the equipment is turned off;

- When working, use protective equipment. Gloves, safety glasses, clothing;

- Do not allow water to come into contact with the instrument;

- Do not use the round device in places with high humidity;

- After switching off, you can move or lower the equipment to the floor only after the drive has completely stopped;

- Prevent engine overheating;

- Prevent access to the tool for children;

- Cutting boards should not contain foreign objects. Bolts or nails;

- Before starting work, check that the material is securely fastened.

Proper use of a circular saw will allow you to cut any number of boards accurately. And compliance with all operational requirements will fully ensure the workflow.

Source

A circular saw is a very important tool in home construction. It is superior to all types of saws in terms of cutting quality and accuracy, especially for longitudinal processing of planks and planks. Its service life largely depends on proper handling and the quality of sharpening. But, like any mechanism, sometimes a circular saw breaks. In this article, we will look at how to repair a circular saw and how to protect it from damage.

READ Idle Speed Saw Stihl 180

disassembling the Interskol DP-1900 circular saw for lubrication

2Vitaly1972 The gearbox of this saw is relatively sealed, you just need to somehow seal the stopper drive. I collected gaskets from an old felt boot. I filled it with 158 bodyagu and spindles, it spit out a little through the rotor bearing and that’s it. It doesn’t rattle (almost).

Sukhov wrote: The gearbox of this saw is relatively sealed, you just need to somehow seal the stopper drive

Exactly. It is through this hole that it squeezes out. But there is practically no noise. I already had the idea of covering it with PVA on top (don’t hit it with your feet) so that it would just hold it a little. I understand that this is nonsense

Why experiment! Do what you need to do and that’s it! Disassemble, remove grease and put Litol!

Not a single circular saw or jigsaw, no matter what brand, has any special ones. protection or seal at the support (front) rotor bearing! Because according to all service instructions and drawings, the lubricant has a thick consistency!

As a last resort, if you really want to create a tight seal!

You can lubricate the seams and places of gearbox covers with Molycot lubricant-sealant (should be sold in car dealerships)! It is white and relatively expensive, plus it needs to be applied only to a clean, dry and grease-free surface!

2Service-man Litol is also possible, but with semi-liquid the resource will definitely be higher (for some this is important)

Before the life of the gear train in a circular saw is exhausted, the engine will fail faster, something will happen to the body or handles, and the rotor worm will wear off! And accordingly, the gearbox lubrication itself will change! (if the mechanics are conscientious about their work)!

2Service-man Rotor worm, WHERE is it? Have you seen the quality of the Chinese gearboxes (I can’t speak for everyone). I assume that an oil wedge (semi-liquid lubrication) can provide a longer service life.

Rotor worm - its end with teeth! Of course I saw it - that’s why I say that the gear teeth themselves (most often the rotor) deform faster than the shaft gear “dies of old age”! In any case, when the rotor worm wears out, the gear assembly changes, and, accordingly, the lubricant!

2Service-man Let’s clarify, the gearbox of this saw is: the rotor shaft gear (five teeth? one piece with the rotor (primitive) and the wheel (teeth? saw blade shaft) all this is located in the gearbox housing and is lubricated, we are arguing about the type (consistency of the lubricant). Right?

Sukhov wrote: I filled up the bodyagu from 158 and the spindles

This option also has a right to exist.

Sukhov wrote: I assume that an oil wedge (semi-liquid lubricant) can provide a longer service life.

The term "oil wedge" refers to a layer of lubricant between two contacting surfaces and exists in both grease and liquid lubrication applications. Semi-liquid lubricant is more suitable for gearboxes; usually, they mix the lubricant with oil, trying to obtain such a consistency that at rest the lubricant would slowly slide down from the walls. I can recommend Interskol drill shank lubricant for the DP gearbox. it is well suited for gearboxes - similar to MC1000, only a little more liquid.

Service-man wrote: Before the life of the gear train in a circular saw is exhausted, the engine will fail faster, something will happen to the body or handles, and the rotor worm will wear off!

Experience with the IE-5107 rib with much more massive gears tells a different story. The lubricant lasts approximately 50 hours of operation, if you do not lubricate the steam in the gearbox dies. If you smear on time, then after 200 hours something else will appear. For me it was a switch. The saw is still alive, but the new ones have a different capability, and they don’t make switches like that anymore.

Service-man wrote: Why experiment! Do what you need to do and that’s it!

don't take it to heart - it was a joke, maybe, of course, not very successful

Serg wrote: I can recommend Interskol drill shank lubricant for the DP gearbox..

And, here, this case is available. I was in Leroy on Friday, there appeared personalized “Interskol” tubes with lubricant, 100 ml minimum

Vitaly1972 wrote: What did I have to do with Leroy on Friday, there appeared personalized “Interskol” tubes with lubricant, minimum 100 ml

65 rubles each, if my memory serves me correctly.

I put MS in the Interskol UShM-150/1300 gearbox. The buzzing is quieter, but the seam is sweating. I'm thinking of cutting it in half and sealing it with sealant. or kill it and leave it as is.

Serg wrote: about 65 rubles, if my memory serves me correctly.

To be honest, I don’t remember. But the price did not “amaze” me (by the magnitude) and was definitely less than the price of the above lubricant from Makita (90 rubles for 30 grams)

Sukhov wrote: To clarify, the gearbox of this saw is: the rotor shaft gear (five teeth? one piece with the rotor (primitive) and the wheel (teeth? saw blade shaft) all this is located in the gearbox housing and is lubricated, we are arguing about the type (consistency of the lubricant). Right?

Yes, there seemed to be no dispute!

alex_k wrote: experience with the IE-5107 rib with much more massive gears tells a different story. The lubricant lasts approximately 50 hours of operation, if you do not lubricate the steam in the gearbox dies. If you smear on time, then after 200 hours something else will appear. For me it was a switch. The saw is still alive, but the new ones have a different capability, and they don’t make switches like that anymore.

Naturally, lubricant prolongs the service life! And the IE-5107 saw is not bad! I just wanted to say that there is no need to worry too much about saw lubrication!

Service-man wrote: Naturally, lubrication prolongs the service life! And the IE-5107 saw is not bad! I just wanted to say that there is no need to worry too much about saw lubrication!

I just didn’t anoint the first one in time. she did not live to see the end of summer. Replaced under warranty. I don’t experiment like that anymore. Moreover, in the interskol the pair of gears is tiny.

Serg wrote: I can recommend Interskol drill shank lubricant for the DP gearbox.

Well, now the strong commercial move of Interskol is clear. the lubricant is not put into the gearbox, but is sold as a lubricant for drills ">, and the spare gears work well. and lubricant for drills is traded and people are amused. collecting. by pulling apart. And this one can immediately buy a normal tool?! . responsible producers. Milwaukee SCS 65Q gearbox lubrication check after 5 years of operation

Solve the problem yourself

The reasons for failure can be very different. Manufacturers recommend starting with a thorough inspection of the tool and trying to visually determine the malfunction. If this doesn't work, then you need to start disassembling. The device of a circular saw is quite complex, the main task. Get to the collector, because there are major problems with it.

The collector must be removed, but it is not that easy. This must be done safely to the valve bearing and carefully separate the engine valve from that bearing. To do this, use a sharp tool that is inserted into a special recess in the middle of the motor shaft. After inserting it into the recess, hit the tool with a hammer until the shaft begins to move.

The anchor is removed and cleaned of soot, and replaced if necessary. Next, the contacts of the collector winding are cleaned. It is also necessary to check their inductance using an ohmmeter, and in case of malfunction, the contacts are changed. Often the breakage causes a lot of friction between the jaw and its holder, which leads to jamming. If this is the cause of the breakdown, the cheeks must be installed strictly perpendicular to the holders.

These problems are easily resolved and can be resolved on your own. However, please remember that it is strictly prohibited to open instruments under warranty, otherwise the warranty will be void. Therefore, saws under warranty should be delivered to specialized centers.

Lubricant for grinder gearbox – which one to choose?

Angle grinders (angle grinders) are widely used among people who love to make crafts and perform various repair and construction work at home. Such tools allow you not only to grind various surfaces, but also to cut stone, metal, plastic and other materials. Angles are reliable tools that require proper maintenance during operation, in particular, timely replacement of lubricant. Let's talk about choosing a lubricant for the gearbox and bearings of angle grinders.

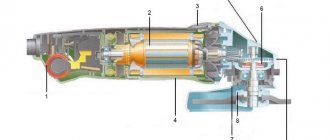

In an angle grinder, the main unit, which is subject to the greatest loads during operation of the tool, is the gearbox, which is a structure of helical gears. During operation of the angle grinder, the rotor creates a torque that is transmitted to the working tool through the small gear to the large gear. High-quality lubricant for the grinder gearbox significantly reduces the heating temperature, the friction force inside the tool and reduces the wear of its parts.

Lubrication reduces friction of parts inside the gearbox

The bearings of the grinder also need periodic lubrication, especially the spindle support bearing of the large gear. To do this, it is necessary to use only high-quality, reliable compounds recommended by manufacturers of grinders. Experts recommend using oils with the following technical characteristics:

- viscosity up to 800 Pa·s;

- tensile strength more than 120 Pa;

- drop point more than +120°C;

- absence of mechanical impurities;

- resistance to corrosion processes;

- the ability to firmly hold onto the parts of the angle grinder;

- resistance to high temperatures;

- water-repellent properties.

When choosing lubricants, it should be taken into account that in a modern angle grinder two types of bearings are used - for the electric motor and for the gearbox. For them, it is necessary to use different compositions, since bearings differ from each other in different operating conditions.

For foreign brands of angle grinders, it is recommended to use specialized compounds developed specifically for such power tools. Most often, manufacturers of angle grinders recommend using lubricants that have this marking - MoS2 NLGI 2 ISOL-XBCHB 2 DIN 51825-KPF 2 K-20. The following information can be obtained from this marking:

- MoS is an indication of the filler material used (number 2 is molybdenum);

- NLGI2 – viscosity class, here it is the second;

- ISOL-XBCHB 2 – confirms the compliance of materials with the ISO standard;

- DIN, KPF, K-20 – confirms compliance with the German DIN quality standard;

- the numbers 51825 mean that the material is classified as “K” type.

A sharp disc as a means to avoid repairs

In many ways, the quality and reliability of a circular saw depends on the ability to sharpen the blade. A weakly sharpened saw increases the load on the tool, which shortens its service life. Signs of wear on the disc are: the need to exert great effort at work, burning of the edges of the cut, strong heating of the protective cover. Sharpening of circular saws begins from the back surface directly on the machine.

Before starting work, it is necessary to mark the tooth from which grinding will begin. When sharpening the first tooth, consider the number of strokes, since the remaining teeth should be processed the same way. When the disc is removed from the machine, it is clamped in a vice with wooden blocks.

Rotate the blade while sharpening it. After completing the work, the disk is installed on the machine and a test cut of the unwanted strip is made. If there is loud noise and uneven flow of material, it is necessary to check the teeth for height. If there are protruding teeth, they should be brought to the same level.

Expert advice

Experts recommend following these tips::

- Before disassembling, conduct a preventive inspection of the equipment for correct diagnosis. The complexity of subsequent work will depend entirely on the severity of the breakdown.

- After processing all the elements, the “polishing” of the fixing cut begins. There are times when the clamps stick out a lot. In this case, the chain does not reach the surface that needs to be cut. Another situation may occur when the clamps are too deep and the blade gets stuck in the wood.

- Disassembling electric saws is an important phase during repairs, which must be carried out strictly according to the rules and in compliance with safety precautions. It is necessary to de-energize all unreliable elements and avoid getting debris into the teeth during preventive switching on of the tool.

You can repair saws of any kind with your own hands. To do this, you need to know the disassembly scheme and the rules for installing new parts in the box, observe safety precautions during the reconstruction of the tool, and regulate the power supply.

The best repair for circular saws. It's their absence

It should be noted that improper operation of a circular saw greatly affects its performance period and leads to an urgent need for repairs. Even knowing how to sharpen a circular saw will not protect it from improper use. Consider how to use a circular saw for repairs as little as possible:

- Use only blades that are suitable for this saw model;

- All discs must be sharp, since dull ones lead to overheating of the engine;

- Always check that the disc is inserted correctly and that the clamp is tightened;

- Never allow the engine to overheat.

By following these simple rules, you can protect your instrument from damage as much as possible. Remember that following operating instructions is much cheaper than the necessary repairs if a circular saw breaks down. Important! When working with a circular saw, you must carefully follow safety rules.

Source

Homemade mixtures

Situations when there is an urgent need to lubricate the elements of an angle grinder are not uncommon. And at the same time, as luck would have it, there is no way to get a lubricant suitable for these purposes. Then the owner can try to make the product with his own hands from available materials.

To ensure the required level of adhesion, lubricant for automobile CV joints is used as a basis. In addition to its excellent penetrating properties, it can be used for operation in the following conditions:

- significant loads;

- high humidity;

- temperature fluctuations over a wide range;

- significant heating;

- exposure to solid pollutants.

To liquefy the material and obtain the consistency required for the gearbox, it is recommended to add MS-20 oil. The liquid is introduced into the base gradually, preferably in drops, with constant stirring of the resulting composition with a mixer.

No less effective is the use of homemade material based on Cythiam-221 with the addition of TAD-17.

What gear lubricant do you use? Have you ever made your own lubricant? Share your experience with us, please.

Source: wikimetall.ru