For most farmers, a walk-behind tractor is an indispensable device on the farm. Its versatility allows you to simplify many jobs on land. However, modern models are equipped with wheels that are not highly reliable and do not have good driving performance. Many of them are not able to fully work even for one season. The tire sidewall bursts under constant loads, and in wet weather the unit gets stuck in the mud.

And yet there is a way out. The standard disks on the device can be easily replaced with regular car ones. Anyone can do this if they take into account some nuances and follow the recommendations given below.

Do-it-yourself lug lugs for a walk-behind tractor

In modern practice, there is no need to purchase such versions of structural elements, since it is possible to do everything necessary yourself. As a rule, this will require certain materials, as well as some auxiliary tools for the manufacture of the corresponding mechanisms. In this case, the procedure for making special homemade lugs is as follows:

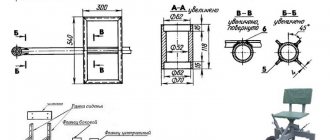

- First of all, you will need to find the appropriate execution diagram, or make it yourself, taking into account the available assembly option.

- The next step will be to prepare everything necessary to install attachments on the motor cultivator.

- Next, you need to correctly calculate all the dimensions of the home-made lug for the cultivator to be completed.

- Additionally, it is necessary to decide on the option of coupling the homemade device and mechanized equipment.

- Subsequently, according to the prepared scheme, the necessary product for plowing the soil is manufactured.

- Here, a holding frame is produced separately, and in addition the device itself for cultivating the soil on a plot of land.

- Subsequently, the manufacture of the appropriate mechanism for coupling with the mount present on the walk-behind tractor is carried out.

- Next, a complete assembly of the entire mechanism is carried out from previously made individual structural elements and devices.

- Separately, weighting is arranged here, which can be done with the addition of weights determined by weight.

- Also, if necessary, you can use a specialized frame that will have the required weight and a shiftable center of gravity.

- After the structure is assembled, it will need to carry out its initial coupling with the mechanized cultivator.

- Additionally, a test run of the manufactured equipment is carried out, and, if necessary, adjustments are made.

When producing such technical equipment, the main thing in the work is the search or development of a diagram of a future version of the lug. Having the necessary drawing at your disposal will significantly reduce time costs, since the diagram contains a visual drawing of the device, and in addition, all the necessary dimensions are indicated.

https://youtube.com/watch?v=MBuTNftRf-w

It should be understood that in each individual case the dimensions of the structure are calculated based on the power of the installation, its size, and also the clutch option. In other words, it is not recommended to install a large lug on a walk-behind tractor with low weight and a weak motor, since such equipment can quickly damage the main mechanism due to excessive load.

Important. In practice, to independently carry out such equipment for tillage, any strong metal object can be used, including car wheels, whose service life has already expired

From car rims

Currently, the arrangement of attachments from these elements is quite widespread. This popularity is due to the following characteristic points:

- All car wheels have the necessary structural rigidity, as well as a suitable size and weight.

- Such devices are easy to find (often old devices are stored in the garages of almost all car owners).

- These variants of structural elements are quite easy to process, since they were initially made with an eye to possible repairs.

- The mechanisms already have the cuts and other openings necessary for fastening on their central plane.

- This type of device has a long service life with proper surface treatment.

There are only advantages to using rims from car wheels, since they are the easiest to use to make milling lugs for attachments, which will subsequently be mounted on a walk-behind tractor. Here, when working, you only need to make the necessary cuts with a grinder, and then hang the devices on a special frame, which will be coupled with a walk-behind tractor. The frame itself is made quite heavy to weigh down the structure.

Important. After completing the work of making cutters from discs, all that remains is to sharpen them correctly, so that later when processing arable land, additional weighting is not required

Chainsaw cultivator

Perhaps the best option when making a homemade motor cultivator is to use a chainsaw engine to create it. The advantages here are the performance and power of the unit, undemanding fuel requirements, light weight and compactness.

General diagram of the walk-behind tractor:

- the walk-behind tractor frame is made in the form of a diamond from a metal corner measuring 3200x3200x3200 mm;

- the engine is mounted on the cross members from above, the gas tank, as a rule, is mounted slightly below;

- the intermediate shaft supports are attached to the front struts;

- The running shaft supports are installed on the longitudinal ribs

To regulate the speed, the original gearbox is used; motorcycle sprockets (main and intermediate) are also used, the number of teeth of which is selected taking into account the required power output. The working tools of the unit are made in the form of wheels with knives and can perform the function of a trimmer, a rotary cutter or a rotary hoe.

As an alternative, you can use the engine from a lawn mower, which is similar in its characteristics to the drive of a chain saw.

Wheels for walk-behind tractor - varieties, manufacturing, video

Wheels for a walk-behind tractor are one of its most important components. The cross-country ability, maneuverability and functionality of the walk-behind tractor as a whole will depend on their quality, size and variety.

In order to decide on the optimal choice of wheels for a walk-behind tractor, before purchasing or manufacturing them, you should familiarize yourself with their varieties and features.

Traction wheels

Designed for use of walk-behind tractors in different conditions. They will cope perfectly with the load when transporting heavy objects, and are simply useful for driving on roads and flat surfaces.

Thanks to the special herringbone tread pattern, pneumatic traction wheels can also be easily used for heavier work - plowing, cultivating, hilling, etc. This type of tread allows you to work on sticky or loose soil without much difficulty, without fear of that the unit will get stuck.

- Typically, this type of wheel has fairly wide tires (more than 20 cm) and a large rim diameter (40 cm or more).

- Special types of traction wheels for walk-behind tractors are solid and lug wheels.

- Solid wheels are characterized by increased strength and a more powerful tread.

Lugs are a special type of wheel, consisting of steel rims and special teeth, which are shaped like the same herringbone tread. Although this type of wheel is not large, its weight and design allow it to perform work even on the most difficult soils.

Twin wheels

- The design of these wheels from a walk-behind tractor involves connecting (pairing) together two identical rims and placing these devices on both sides of the unit.

- This type of tires for walk-behind tractors significantly increases the cross-country ability of the walk-behind tractor, eliminates the risk of slipping and overturning of equipment, and increases speed on a flat surface.

Support wheel

A special type of wheel attached to the walk-behind tractor is responsible for reducing the load on the operator, taking on the load from the motor and the entire body of the unit. Despite its small size, it is also useful in that it increases the stability of the walk-behind tractor when not in use and makes it easier to transport.

The design of many modern models of walk-behind tractors provides such a wheel or support foot, which is also very convenient.

Wheel extensions for walk-behind tractor

- In order to increase the track width, make the walk-behind tractor more stable and durable, you can make such a simple device as wheel extensions.

- You can make this device with your own hands using the following algorithm:

- Buy 2 metal pipes. Their diameter should be approximately 1 - 1.5 mm smaller than the diameter of the axle.

- To attach the pipe to the axle, cut a thread and screw the extension to the walk-behind tractor.

- The other end of the pipe must be adjusted as closely as possible to the hole in the disks. If necessary, the product can be sharpened. If, after adjusting the extension cord, there are gaps between it and the disk, debris and dirt will clog in them, which will negatively affect the operation of the walk-behind tractor.

- Steel plates are bolted to the disk, which will connect the extension to the disks.

We invite you to watch the video, which shows in detail the process of manufacturing an extension for the walk-behind tractor axle:

DIY walk-behind tractor wheels

Making wheels on a walk-behind tractor yourself is not such a difficult task.

It is important to have only suitable blanks and tools. Old motorcycle wheels are ideal as blanks.

You can also construct wheels for a walk-behind tractor from car rims.

You should take into account the dimensions in advance - the wheels should be wide enough and massive, with good tread, about 20 inches in diameter. Also take care of an extension cord to increase the track width (the process of making an extension cord is described in the previous section).

Making homemade wheels from car rims should be done according to the following algorithm:

- Take 4 disks from the car. Their sizes must match exactly.

- Sand the discs with a file, clearing them of burrs and chips.

- Weld the discs to each other with the convex side.

- Put pre-selected tires for a walk-behind tractor on these blanks, inflate them and attach them to the axle.

The manufacturing process for twin wheels is the same, with one small difference. Between the future paired wheels you need to weld a square of appropriate sizes, welded from strips of metal.

Important Technical characteristics of the KS-65713-1 Galician truck crane and other modifications

Wheels made in this way are ideal for walk-behind tractors of the Neva, Agro, Krot and other well-known manufacturers.

How to install the chassis on a cultivator with your own hands

Let's look at how to make wheels for a walk-behind tractor. Craftsmen offer the following homemade products:

- For impassable terrain (swampy area, snowy ground) iron lugs are suitable. Can be used for automotive, all-terrain and snowmobile products. The winter option for the Neva walk-behind tractor will allow you to use the unit for transporting snow, clearing snow from a summer cottage, and transporting goods over different distances.

- The optimal modification option is considered to be Zhiguli wheels on a walk-behind tractor. They have a sufficient disc diameter, and the alteration is carried out using a welding machine, which is easy to use. Moreover, Zhiguli tires are better suited than pneumatic wheels for a walk-behind tractor. The latter are quite difficult to find for a model that has been discontinued by the manufacturer, and ordering new ones via the Internet is expensive and impractical.

- Products can be assembled independently from several disks, creating a new modification with weighting agents.

- You can install wheels for the Neva walk-behind tractor, which are large in size, have excellent maneuverability, and have a long service life.

The Zhiguli chassis has a number of advantages:

- It does not change under the influence of the work performed, so it can be used for a long time and almost constantly.

- An axle shaft is installed on the inside for greater maneuverability. This part must be welded to a plate in which holes for the bolts must be made. They will be needed to connect the axis with the guides that are installed on the product.

- A special protective cap is installed on the outside.

- Good grip will be provided by winter tires. In this case, you can only use Niva tires without tubes.

It is not difficult to install such large wheels on a walk-behind tractor with your own hands, and if necessary, you can remove them and attach them to an all-terrain vehicle or a small tractor, which is often used by farmers in agriculture. To improve the ride of the machine, weights or weights are installed on its chassis. This significantly increases the level of adhesion to the soil.

To work on difficult soils, it is necessary to select products that will ensure the stability of the cultivator and its high productivity.

The lugs will help out; they are a special type of design that has maximum traction with the soil. This is achieved through the installation of spikes that are driven deep into the soil. Such products are made independently. You can take the chassis from a Zhiguli or Neva as a basis.

The remodeling process takes place in several stages:

- Attach the axle shaft.

- Remove the tires, since rubber is not needed for the hooks.

- Weld metal spike teeth that will be responsible for adhesion to the soil. They are installed in the form of strips, which are welded diagonally, or in the form of spikes arranged in several rows. The distance between the hooks should not be less than 15 cm.

- Attach the structure to the rim using bolts.

- To change the disks, you need to unscrew the fasteners.

To create lugs for a walk-behind tractor, you need the following parts:

- old car wheels, maybe without tires;

- a steel corner from which the hook teeth must be made;

- bolts;

- steel thick squares;

- Metal or traction wheels are best for creating lugs.

If there is a need to use not only a cultivator with an improved chassis, but a mini-tractor at the dacha, then you need to create a special frame. To do this, larger products are installed on the motor-cultivator, and a support wheel for the walk-behind tractor is also installed.

At home, you can create an economical version of a small all-terrain vehicle, on which products from a VAZ car or a pair of dual Zhiguli products with lugs will stand. Such a machine will be easy to drive off-road, work in field conditions, in swamps.

At the same time, the chassis of all-terrain walk-behind tractors must be equipped not only with large, wide products, but also with special body kits. The frame of the equipment must be raised to make it convenient to move around on the cultivator. This is why it is worth installing large wheels.

Wheels from a Zhiguli on a walk-behind tractor

You can also install Zhiguli wheels on walk-behind tractors with your own hands. The diameter of the Zhiguli wheels exactly matches the original wheels. Using Zhiguli wheels is more profitable, since original products, as a rule, are much more expensive. In addition, VAZ wheels are wider, heavier, have better cross-country ability and less slippage.

Attention! Experienced owners of motor cultivators do not recommend wheels from the Niva car due to their inappropriate sizes. In the absence of Zhiguli wheels, Moskvich ones will be quite suitable. When replacing factory wheels with car wheels, the design becomes heavier

An axle shaft is installed inside, onto which metal plates with holes are mounted, acting as weighting agents. Caps are installed on the outside to protect against external damage. The camera moves away. For greater traction of the wheels with the soil, it is possible to tighten a chain on them

When replacing factory wheels with car wheels, the structure becomes heavier. An axle shaft is installed inside, onto which metal plates with holes are mounted, acting as weighting agents. Caps are installed on the outside to protect against external damage. The camera moves away. For greater traction between the wheels and the soil, it is possible to tighten a chain on them.

Zhiguli couple on the Neva

The installation process occurs in the following sequence:

- Installing the axle shaft.

- Removing a tire from a wheel.

- Installation of spikes.

- Attaching the structure to the rim with bolts.

- Replacing disks.

- The structure is screwed to the hubs installed on the walk-behind tractor.

If the goal is to use Zhiguli wheels only for transportation, then the task is simplified - the tire and tube are left, the studs are not welded.

Walk-behind tractor at work

You can make wheels for garden motorcycles yourself, improving the design to suit your needs, the tasks assigned to the equipment, and any desired type of soil and terrain. There are quite a lot of options for independent modifications; every gardener and farmer can easily make what he needs for comfortable work.

Which car wheels to choose for a walk-behind tractor?

For installation on an agricultural device, the simplest wheels from a Zhiguli with a bolt pattern for 4 fasteners are suitable. However, there may be hubs with 5 mounts. For such models it is worth choosing wheels from Moskvich.

As for the tread, it is better if its width and depth are more impressive. This will improve the permeability of the device. And yet, if you have old tires with a worn pattern on hand, they are quite suitable for this device and will last for several more seasons.

For further installation work you will also need worn brake discs.

Choosing wheels for a walk-behind tractor and replacing them yourself

When purchasing a walk-behind tractor for their household, people focus on engine power and equipment performance. However, the performance of the unit is directly affected by the wheels for the walk-behind tractor. The chassis allows the unit to move around the garden.

Factory models are usually equipped with the correct wheelset. But given the loads on this structural element, the wheels often break. Accordingly, the farmer has to buy the failed part himself.

We will advise you on how to choose suitable wheels and suggest options for making your own chassis yourself.

Types of wheels for walk-behind tractors

As with any other equipment, the wheels that are used when operating walk-behind tractors come in several types. It is worth noting that if low-quality wheels are used when working with such equipment, there is a high probability of their rapid failure, which can lead to delays in the time allotted for cultivating the soil. Quite often, such units are used to transport goods over short distances. In this case, when a small four-wheeled tractor is made from such a device, you need to choose the right shoes for it. To work with walk-behind tractors, there are three different types of wheels:

- special metal models equipped with lugs;

- pneumatic, which are equipped with a camera;

- solid rubber.

It is necessary to select equipment for a walk-behind tractor taking into account the conditions in which its further operation is planned. For example, specimens with rubber inner tubes are not in all cases capable of providing such a unit with high maneuverability. When using such equipment in particularly difficult conditions on difficult terrain, it is recommended to use special metal wheels that are equipped with lugs.

For heavy models of walk-behind tractors with a diesel engine, it is recommended to use large-diameter wheels that are equipped with aggressive treads. To operate lighter gasoline units, depending on the model, you can actively use wheels from a vehicle such as a Zhiguli.

Criterias of choice

Any garden equipment is available in several variations. The chassis for the walk-behind tractor is no exception to this rule. If you look at the assortment of any store that sells spare parts for walk-behind tractors, you will see that there are three types of wheels:

- Pneumatic. Such products have a rubber tire and inner tube.

- Rubber. Monolithic design, which consists of a rim and durable rubber.

- Lugs. Metal elements aimed at increasing the cross-country ability of vehicles.

The difficulty of choice lies in determining the operating conditions of the equipment. For example, for processing clay areas or wet soil, it is recommended to use lugs.

A walk-behind tractor equipped with conventional rubber wheels will not show good performance in difficult conditions.

In addition, you should focus on the wheel radius and tread pattern

What wheels can be put on a walk-behind tractor? Here a lot depends on the intended use of the technology. If the unit is needed for planting and harvesting work, you can choose pneumatic wheels.

Such products are optimal for working on soft ground. The recommended radius is about 40 centimeters. At the same time, we recommend choosing wheels with deep tread, which will increase maneuverability and cross-country ability.

Cast wheel

For primary cultivation of virgin soil and soil with a high content of stones, it is better to use cast wheels. They receive virtually no mechanical damage due to the absence of an internal chamber.

However, such elements have increased weight, so they are installed on medium and heavy walk-behind tractors.

The lugs not only increase the maneuverability of the equipment, but also increase its productivity. The teeth enter the soil, which creates additional force to move the unit in a given direction.

Wheel lugs

Such elements are used mainly for arable work on large areas of land. It is not advisable to use lugs on a small plot of land.

How to choose a chassis for a walk-behind tractor

Let's look at how to choose wheels for homemade products. It is necessary to take into account the operating conditions of the equipment, which will allow you to select the right products from one or another machine. The rubber passes well on soft ground and on flat surfaces, and for difficult soils it is recommended to use lugs.

For diesel motor cultivators, it is necessary to use metal wheels with an aggressive tread and a large disc diameter.

If Zhiguli products are not suitable, then the chassis for the walk-behind tractor must be selected according to the following parameters:

- diameter - not less than 40 cm;

- width - within 20 cm;

- aggressive drawing;

- entire chambers, sealed areas or damage are not allowed - it will be quite unpleasant when the machine breaks down during operation in the field, where it will be difficult to repair.

For rocky ground and soil that can damage the wheels, only a solid cast chassis should be used.

Be sure to install a support wheel, which helps optimize work on the field, especially during plowing.

The wheels that the master wants to install himself must be of excellent quality.

To ensure a high level of work, it is necessary to take into account the power and performance of the motor cultivator.

Do it yourself

Now let's talk about how to make wheels for a walk-behind tractor yourself. Let us immediately clarify that creating pneumatic and cast wheels at home is in principle impossible.

And why reinvent the wheel if you can equip garden equipment with tires from a car or motorcycle. You just need to install a suitable hub and you can get to work.

It's a different matter when it comes to lugs. You can actually make such homemade wheels for a walk-behind tractor yourself. Here is a basic assembly diagram:

We take old car wheels

Please note that only the rim is needed. The diameter of the wheels depends on the power of the walk-behind tractor, given that the design will be all-metal, the weight will be considerable. We weld metal plates to the disks

The edges of the plates should touch the edge of the rim. This is an important structural element, so the plates are welded along the entire outer radius; they can be secured with bolts to increase reliability. We weld the teeth to the metal plate. They can be made from a corner, after cutting it into pieces of the required length. Please note that the distance between the teeth should not exceed 15-20 centimeters. Otherwise, the effectiveness of such wheels will be reduced to zero. We weld the axle shafts into the disk, supplement the structure with bearings and install the chassis on the walk-behind tractor.

You can make lugs from an old gas cylinder. In this case, you need to cut two rims, about 6-7 centimeters wide, and then proceed according to the above diagram.

In general, lugs can be constructed from any available material that has the shape of a circle. The main thing is to show desire and apply a little skill.

https://youtube.com/watch?v=OE-CglYKTkc

TELL YOUR FRIENDS

Source

Why is this necessary?

At the moment, there are several types of mini-equipment for cultivating land:

- motor cultivators;

- walk-behind tractors;

- mini tractor.

At the same time, consumers often do not realize that each type of this equipment is designed to solve certain types of work. Therefore, buyers focus on price and purchase cultivators, as they consider them a cheap version of walk-behind tractors. Epiphany comes immediately after the owner of the cultivator realizes that his cultivator is only capable of loosening the soil with cutters, and it is impossible to use attachments while working on this unit for the following reasons:

- weak power;

- unreliable gearbox (reduction gear);

- no wheels.

However, the money for the purchase has already been spent. Therefore, the owner of a cultivator is faced with the question of whether it is possible to convert it into a walk-behind tractor.

ICE-based technology

Homemade products with installed internal combustion engines have greater power and functionality compared to their electric counterparts.

This allows you to significantly expand the scope of their use. Attachments in the form of a plow, flat cutter, cultivator, rake are easily mounted on the frame bracket. The unit can also be easily transformed into a roller skating rink or a home mini-tractor. Having asked the question “how to make a homemade walk-behind tractor,” first of all you need to understand its structure. To assemble a homemade motor cultivator with your own hands, you first need an engine, transmission and reduction gearbox.

For assembly work, you will need a standard set of tools: a set of wrenches, a drill, an angle grinder, a welding machine, and when assembling more complex and load-lifting machines, also turning and milling of some components.

Wheels for hilling on a walk-behind tractor

When setting a task such as hilling for a walk-behind tractor, a special type of wheels will be required. Hilling wheels, also popularly known as hillers, are used for both planting and hilling various crops, such as potatoes, carrots, beets, rutabaga, radishes, turnips. The most commonly used are four types of hilling wheel models:

- Lister - you can easily make them with your own hands. They have a number of varieties, including a non-adjustable type, consisting of two plates arranged mirror-like and diverging at an angle with a common stiffener. And also an adjustable type, with which it is possible to change both the width and depth of tillage;

- disk - the principle of their operation is based on the fact that the disks capture the soil and then fill the plant growth areas with it;

- propeller - are a type of propeller. They are valuable because, due to the serrated shape of the blades, they are aggressive towards weeds and are excellent at combing them out of the soil, making them ideal for weeding. It is also possible to make this type of hiller with your own hands, individually for the strictly assigned tasks;

Important Meaning of computer diagnostic error codes for KamAZ Euro-4 trucks

Propeller type hiller

with variable working width - its use allows you to perfectly adjust the row spacing, which makes this type of hiller simply irreplaceable when processing beds.

Walk-behind tractor at work

As you can see, there are a sufficient number of options for walk-behind tractors, designed for a wide variety of tasks, types of work and types of soil. Some of them can be bought, some can be installed from other cars and motorcycles, and some can be done with your own hands. To everyone who chooses and selects the wheels they need for a walk-behind tractor - good choice, easy work and high yield!

https://youtube.com/watch?v=OE-CglYKTkc

How to choose the right low-pressure tires for a walk-behind tractor

The correct choice of wheel for a motor cultivator determines its further operation, as well as the service life of the chassis.

Experienced unit owners give their advice and recommendations.

Adviсe

When choosing tires for a motor cultivator, it is necessary and strictly:

- study the characteristics of the device, take measurements to ensure that the selected tire fits perfectly. A correctly selected tire will be the key to excellent performance of the walk-behind tractor;

- decide on the type of work that will be performed on the equipment, based on this, make a choice of wheels, and, accordingly, tires for them;

- decide on the type of soil, based on this you can already make a choice of the type of tread. In some cases, tires from Zhiguli or Oka cars may be suitable. For softer and more viscous soils, tires with a more textured tread and higher cross-country ability are suitable, for example tires from Germany for motorcycles 140 80 15.

Recommendations

It is recommended first of all to pay attention to the following parameters when choosing tires for a walk-behind tractor:

size, i.e. this is the number that appears after the name of the wheel. Tire size is usually indicated in inches. For example, a tire 6.00-12, where 6.00 is the diagonal width of the tire, and 12 is its seat diameter;

Rubber for walk-behind tractor 12

- purpose – a number of tires are intended only for walk-behind tractors, a number only for transport, and also for other purposes. This must be taken into account when choosing rubber, in accordance with the purpose of the cultivator;

- quality or compliance with standards, quality of materials. It is recommended to purchase tires from well-known manufacturers, which are guaranteed to be durable, strong and resistant to environmental conditions.

Options for wheel design drawings for a walk-behind tractor

Factory configurations of wheels for a motor cultivator are classified according to the number of axles, as well as the principle of traction. Manufacturers produce home mini tractors, the design of which involves the movement of the unit due to:

- two wheelsets;

- paired wheel structure on one axle;

- one drive wheel;

- on three wheels.

Single-wheel mechanisms are often equipped with additional devices on the axle, which also serve as support for the structure. Analyze the model of your home cultivator to improve its functionality. Choose a durable, reliable material or a suitable base for making homemade chassis elements.

Four wheel option

Small-sized agricultural tractors on four wheels are a miniature of a similar vehicle without a cabin. The configuration of the models allows the user to move on a walk-behind tractor.

To improve the factory configuration, you can replace only the drive pair or change all the disks. Choose one of the options to improve the performance of home agricultural equipment:

- equipping factory tires with additional protectors;

- putting new tires with a textured pattern on the wheels;

- installation of wheelsets of different radii on the axles - larger ones under the mechanisms, smaller ones under the driven part;

- installation of car wheels.

Important!

Designing wheels is an important stage in improving a walk-behind tractor, at which it is necessary to make accurate calculations of the optimal dimensions, arrangement of elements, and locations for drilling fasteners.

Four-wheeled walk-behind tractors are classified as heavy-duty models. A number of machines are configured with non-removable wheel elements. Before modifying a mini tractor, make a drawing according to which you plan to improve.

On one wheel set

Two-wheeled motor cultivators are equipped with one axle with a pair of wheel elements. The platform with the installed engine is controlled by the user using handles. Installing a passable wheelset will solve the problem with:

- slippage;

- slippage;

- filling the poorly expressed tread pattern with earth;

- poor handling;

- insufficient plowing depth, etc.

Draw a sketch of one element on paper yourself or make a drawing in a computer program. In the figure, indicate the diameter of the disk, the location of the holes for the axle, fastenings, and their dimensions.

With one driving wheel

Single-wheeled cultivators are devices in the form of a wheel element in a tire with a pronounced tread. The speed of work and efficiency when performing farming work depend on the permeability of the disk.

When preparing a drawing for replacing the drive wheel, use the following recommendations:

- select the diameter of the wheel element similar to the factory configuration;

- choose materials with greater weight when making a wheel yourself;

- replace the rubber with a more textured and wider one.

The walk-behind tractor on one wheel is controlled by manual manipulation. It will be easier for you to drive a design with a wide wheel and a powerful tread.

Three-wheeled models

On small-sized agricultural tractors for cultivating a summer cottage with three wheels, the front element performs the function of following a given trajectory. The rear wheel pair is supplied with torque from the unit engine. In most models, the chassis located at the front is made of a larger diameter.

To design the replacement of wheels on a single-axle small-sized tractor, use the following recommendations:

- calculate the same radius of the wheel and tire that is provided in the factory configuration. Installing a smaller or larger wheel in diameter will make the mechanisms work incorrectly;

- make identical wheel elements. Replacing wheels with different tread patterns or different weights will complicate the use of the mini tractor.

When making a drawing with your own hands, take as a basis the model designed by the manufacturer. Consider the full radius of the elements. You can design a disc with a smaller diameter, but install thick tires on it, and vice versa.

How to make your own weights for the cultivator chassis

Weights play a big role in the functionality of a motor cultivator. Where work is carried out in virgin soil, on slopes, in damp or viscous soil, the running gear of the unit may slip because it lacks its own weight.

Weighting materials have been created to solve this problem. You can make them yourself. For this you will need:

- disc weights (from 5 kg);

- pancakes from a sports bar (10 kg each);

- clutch baskets for cars;

- hexagonal profile;

- Bulgarian;

- welding machine;

- electric drill.

Homemade weights

The process occurs in the following sequence. Holes are drilled in two small sections from the profile, plate discs from the bar are attached to them, clutch baskets are welded to the plates and then weights are attached. The weighting material is ready, it can be attached to the cultivator.

Note! Installing weights solves a number of problems at once and significantly simplifies many tasks for the owner of garden motorcycles.

What third-party wheels are suitable for the Neva walk-behind tractor?

Wheels from Muscovites and Lada are best suited for installation on the Neva walk-behind tractor. There is no need to change anything in them, since their diameter is ideal for installation on a walk-behind tractor. They only need to be slightly modernized by welding.

Zhiguli wheels on a Neva walk-behind tractor

Factory options will cost much more.

The main task when modernizing Zhiguli wheels is to make them heavier, since in the factory configuration they are very light.

Listed below are the main stages of manufacturing wheels for a walk-behind tractor from car tires:

- An axle shaft is installed inside the wheels;

- To make it easier to change wheels, square plates are installed on the axle and holes are made in them. And then the wheels from Zhiguei are attached to these plates;

- A cap is placed on the outside to protect against external factors;

- The tubes should be removed, and only the tires should be left (to improve the quality of traction, winter tires should be used).

Important Design of the ZIL-131 diesel engine

Using tires from other cars is problematic because they have a larger diameter or width, so they need to be additionally adjusted using an axle extension or some other method, and this is not always possible for everyone.

To improve the lug-holding properties, some people additionally cover the wheels with a chain. When driving, the chain digs into the ground and provides additional traction. The effect of it is especially noticeable when driving after rain or snow.

The video demonstrates how to install Zhiguli wheels on a Neva walk-behind tractor:

How to do everything right?

Installing Zhiguli wheels on a walk-behind tractor is quite possible even for non-professionals. The holes on the two structures that need to be aligned do not match. It is imperative to take this nuance into account when performing work. In any case, slopes of the same size should be used. It is desirable that their mass also coincide.

If different tires are installed, the severity of the slopes can vary quite significantly. As a result, it becomes difficult to control the walk-behind tractor; as they say, it “leads” in some direction. Holding the steering wheel in this case becomes very difficult.

To solve the problem, there is only one option: return to the rework and still make completely identical slopes. But it is quite possible to adapt old, “battered” and even seemingly rusty disks - after all, the walk-behind tractor is used for purely utilitarian purposes.

Wheel extensions for walk-behind tractors - homemade

In order to expand the wheelbase of the walk-behind tractor and make it more stable on uneven terrain, it is best to install wheel extensions on the unit. These simple devices are quite easy to make at home, if you have certain tools and materials on hand. The algorithm for making extension cords is as follows:

- Take two metal pipes, the diameter of which should be 1–2 mm larger than the diameter of the walk-behind tractor axis;

- In the part where the products will be installed on the axle, it is necessary to make a thread that will allow the extension cords to be screwed onto the walk-behind tractor;

- The other side of the pipes should be 1–2 mm smaller than the holes in the wheel rims. If necessary, the pipes must be cut down to obtain products of the required size;

- To fix the wheels on the extensions, you need to make steel plates that will be attached to the disk with bolts.

Using all the tips listed above, you can make high-quality wheels for walk-behind tractors Agro, Neva, Krot and units of other domestic and imported brands.

Manufacturing of wheels with lugs

Elements equipped with lugs are best installed on a walk-behind tractor with a capacity of at least 6 hp. With. A motor with this indicator will not be subject to excessive loads and overheat.

To work on such wheels, you will need to prepare certain materials:

- Car wheels with pre-removed rubber;

- Squares made of thick steel;

- Steel corners;

- Bolts.

With everything you need at hand, you can get to work. First of all, weld the steel plates to the wheels. The edges of the latter must be securely fixed to the rim. Cut the corner into tooth-shaped pieces and weld them to the rim. In this case, the distance between the plates and teeth must be at least 15 cm. Finally, you will need to install rubber tires on the rims and secure the wheels to the axle of the walk-behind tractor.

Movement elements equipped with lugs not only allow the walk-behind tractor to move, but also clear the soil on the plot of land from weeds. At the same time, do not forget to clear the moving elements from vegetation from time to time, otherwise the walk-behind tractor will slip in the ground.

Increased speed and maneuverability

These questions are relevant for those who have to work on heavy and damp ground, on ups and downs. Even the most advanced models can slip, forcing the operator to exert additional effort to push the machine forward. Many people are not satisfied with the speed of the unit when towing equipment or transporting various loads.

There are several ways to solve these problems:

- Increase wheel diameter. Most walk-behind tractors are equipped with wheels with a diameter of 25-30 cm. If you install 45-50 cm wheels from an old small car, the speed of the unit will double. But you should not make a racing car out of a walk-behind tractor, since this device is not highly durable and has good stability. You can accelerate to 25-30 km/h only on a flat road without sharp turns.

- Manufacture and install weighting materials. For such factory-made devices in the store you will have to pay a large sum. It is better to make them yourself from scrap materials. Weights are placed on the wheels and on the frame. The wheel weight is made of steel wheels and a hexagonal solid profile. The welded parts are inserted into the hubs with a hexagon and secured with cotter pins in the drilled holes. Instead of iron disks, you can use reinforced concrete blanks or flat round flasks with a neck, into which sand is poured. The body of the walk-behind tractor is weighted using removable frames from the corner. Loads of various weights and configurations are already screwed to the frame.

- Secure the tracks. This solution will allow you to turn the walk-behind tractor into a full-fledged low-speed snowmobile. It is enough to install another axle with wheels and purchase wide rubber tracks. Stoppers need to be attached inside the tracks to prevent them from jumping off the wheels. A homemade snowmobile can also be useful in the spring, when the soil is wet and the terrain is impassable for conventional equipment. As a kit for a homemade snowmobile, you can make a sled for transporting various property through the snow, going hunting, fishing, or to the nearest store after a snowfall.

There are many opportunities for radical transformation of even a small domestically produced walk-behind tractor. This equipment can be transformed into any agricultural implement and off-road vehicle.

Wheels for walk-behind tractor "Neva"

Motoblocks "Neva" are one of the most common and quite multifunctional types. Regardless of what work is performed on them, work on this walk-behind tractor without wheels and attachments is impossible. The choice for this model is quite extensive, given the versatility of this unit and the truly popular love for it.

"Neva"

The following types of wheels are available for the Neva walk-behind tractor:

- Pneumatic wheels, they are equipped with a tire, a tube, a cultivator wheel hub and a disk. Pneumatic wheels are installed on the gearbox shaft so that the tops of the spikes are located in the direction of movement.

- Metal, or lugs, are used to increase traction due to greater grip on the ground. There are wide, tall and narrow types of metal wheels. In addition, metal wheels with blades, spikes and other devices are used for various types of soil cultivation.

In general, the wheels installed on the Neva can be classified as follows:

- transport 4 0x8 – used for transporting goods onto walk-behind tractors, installing them on trailers, and moving walk-behind tractors on the roads. They are distinguished by a relatively small diameter and tire pressure, their width is about 4 inches;

- kits for widening the track, consisting of two stoppers and several extensions, their functionality is widening the track. It is optimal to purchase a set of extensions that allow you to install wide wheels on the walk-behind tractor;

- draft 16x6 50 8, installed as a set, used for draft work. The tires are tubeless, so they do not fail due to overinflation, have an outer diameter of about 16 inches and a working pressure of four atmospheres;

- lugs KUM-540, 680 for hilling, lugs N for plowing. Allows ideal passage on soft and difficult-to-pass soils. It is also recommended to additionally equip them with weights.

On a note. In addition, home-made lugs are installed on Neva motor-cultivators, which are made for the specific tasks and needs of the owner of this equipment. Ideally suited to the Neva, from the Zhiguli, Oka, Niva and Moskvich cars can be installed as pneumatic wheels.

The owners of the Neva themselves are enthusiastic about such alterations, since they are often dissatisfied with the driving performance of the wheels from the factory.

Kits for moving equipment on wheels with cutters

The set consists of a pair of cutters and wheels connected on one axis. Wheels make it easy to transport a walk-behind tractor or cultivator to the work area. Then they are quickly removed, allowing the walk-behind tractor (motor-cultivator) to work on the cutters.

Upon completion of the work, the wheels are put on again, and the user, having engaged first gear, easily moves the equipment with installed cutters to the desired location. Installation is quite simple and takes a few minutes. The kit for motor cultivators includes a 4.0x8 wheel (2 pcs.), a wheel adapter (2 pcs.), a stopper (4 pcs.

). In the walk-behind version - an adapter for a wheel (2 pcs.), a stopper (4 pcs.).

The following types of products are produced:• a kit for moving motor-cultivators MK80R and MK200 on wheels with cutters (005.68.1110);• a kit for moving the MB Compact walk-behind tractor on wheels with cutters (005.68.

1110-01); • kit for moving NEVA walk-behind tractors on wheels with cutters (005.68.1110-02);

You can find out the cost of a set of wheels for moving motor cultivators on cutters from our regional dealers, as well as at the NEVA Mototekhnika trade and exhibition complex.

Our store is located next to the plant in St. Petersburg.

Pros and cons of car wheels on a walk-behind tractor

To begin with, we should provide a list of the advantages and disadvantages of such a modification.

- Reliability. Passenger tires are designed for more impressive loads than the original tires of a walk-behind tractor.

- Durability. Tires from a passenger car, even in used condition, will last much longer.

- Patency. Thanks to the increased ground clearance, as well as a more impressive tread pattern of car tires, the walk-behind tractor will be able to drive over obstacles more confidently.

- Good traction due to greater tire contact with the ground.

- Increased speed as a consequence of the increased diameter.

- The need to dismantle the arches or redo them.

- The controllability of the device is slightly deteriorated.

How to remake a walk-behind tractor

Many owners want to improve their walk-behind tractor to improve comfort during work. The most common modifications are the manufacture of adapters and trailers. This upgrade allows you to expand the functionality of the walk-behind tractor, because the adapter allows you not only to transport various loads, but also to use the walk-behind tractor as a vehicle.

Improving the walk-behind tractor will allow you to create a whole mini-tractor. Adapters and trailers can have their own steering, which is much more convenient than using a steering wheel from a walk-behind tractor. There are many step-by-step photo instructions and videos showing how to create a trailer. One of the most important elements of such a device is the frame, which is made of channel or pipes. Wheels can be taken from any car; the ideal option is wheels from an ATV. Bridges can be taken from VAZ 21-09, they need to be shortened. The steering column can be taken from the same car. The driver's seat will allow you to work with maximum comfort.

In addition, a mini-excavator can be made from a walk-behind tractor, the creation of which requires a hydraulic system. Such an excavator is very convenient for construction on a personal plot, because it is compact and can go where heavy equipment cannot.