Many farmers and gardeners are interested in how to make lugs for a walk-behind tractor. Walk-behind tractors and walk-behind cultivators of various brands are designed for farming and gardening and cultivating personal plots. Using these units, you can loosen the soil, plant, weed and dig up potatoes (and other crops). But all these operations are performed with additional equipment (coulters, plows, trailers, snow blowers, etc.).

How to choose?

When choosing a suitable model, first of all you should pay attention to the brand of the walk-behind tractor.

For the Neva and Neva MB model range, variations with a 43-centimeter diameter, the depth of immersion of the spikes into the ground is 15 cm, are excellent. For Salyut brand walk-behind tractors, lugs with a half-meter diameter are needed, for which the depth of immersion in the soil will be at least 20 cm. For "Bison" you need tall products - 70 cm in diameter.

Only heavy walk-behind tractors do not require lugs; their mass guarantees them stable movement on almost any surface. But if you decide to improve the maneuverability of your heavy model of walk-behind tractor (weighing more than 0.2 tons), choose wide lug devices - 70 cm in diameter.

The choice of a suitable lug model also depends on the type of soil and the nature of the outer side of the products. Their surface can be designed in the form of spikes or arrows. When purchasing products, keep in mind that the low height of the spikes is not suitable for wet and loose soils - they are ineffective and are easily clogged with soil. Arrow-shaped hooks are the most popular and are considered universal.

When purchasing additional equipment for your unit, first consider options from the same manufacturer.

Pay attention to the cost - it depends on the manufacturer and modification

Universal wheels KUM 540 for hilling

These wheels differ from the 680 model in that the rim is not solid, but has only sides, and is hollow inside.

Plus, the spikes are not tilted to one side, but have a V-shape.

When the wheel moves, not only the spikes go deeper into the soil, but also the rim itself, due to this, deeper immersion into the ground occurs and traction properties improve.

- The diameter of the wheel at the outer studs is 54 cm, and at the hoop 46 cm.

- The width of KUM 540 is 9 cm.

Extensions must be purchased separately for them, since no fastenings are provided in the standard form, only holes for connection with a standard diameter of 10.5 mm. It leaves a rut with a diameter of 60 to 65 cm.

The weight of two lugs is approximately 13 kg.

Lugs for walk-behind tractors: what to look for?

The main factor influencing the choice of a universal object is size. If a person wants to purchase lugs for a specific unit model, he should familiarize himself with the wishes of the manufacturer and follow them.

Since the Neva and Neva MB walk-behind tractors are especially popular among farmers and agronomists, we should use their example to outline the features of universal lug wheels. For the products of these manufacturers, options with a diameter of 43 cm are suitable, because they are laid in the soil to a depth of 15 cm. These dimensions will ensure maximum traction with the ground and trouble-free movement.

For absolutely all Salyut walk-behind tractors, wheels with a diameter of 50 cm will be relevant, the spikes of which sink into the ground at least 20 cm. Naturally, each manufacturer has its own requirements for lugs, so you should carefully study the operating instructions for the walk-behind tractor you have and not ignore the wishes of the manufacturers.

An important point: heavy-duty equipment does not need such additions, because its weight is already a guarantee of stability on almost any ground.

Installation Features

When installed correctly, the structure should not come into contact with the walk-behind tractor.

The bends of the wheel studs should point in the direction of movement of the equipment for traction with the soil surface. For greater processing effect on the upper surface ball, it is possible to install special weighting agents. They are not included and are sold separately. On a walk-behind tractor that is combined with a plow, it is recommended to install wider metal wheels with curved spikes to avoid slipping of the surfaces being processed. It is recommended to use lugs when working with a hiller or potato digger of a fairly lightweight design.

Lugs for walk-behind tractors come in different shapes and types; each walk-behind tractor has its own modification.

For walk-behind tractor Salute

Purpose: to weigh down a walk-behind tractor or additional equipment. The 500 mm high and 200 mm wide design eliminates wheel slip.

For walk-behind tractor Neva

They are distinguished from the previous design only by their length and width, which are 430 and 150 mm, respectively. The purpose remains the same - to make the walk-behind tractor heavier for traction with the ground and to prevent the wheel from slipping on the ground.

For walk-behind tractor Oka

Used for early hilling. The rim is one-piece with length and width of 425/130 mm. Feature: installation on an extension cord is required.

For Kadvi walk-behind tractor

The design, weighing 18.8 kg, creates additional force on the walk-behind tractor when plowing light soil. Effective use of the design, size 350 - 500 mm, with different modifications of walk-behind tractors.

Wheels with a wide base are suitable for:

- For working with a plow.

- And a hiller.

Gearbox for a walk-behind tractor: device, gearbox for the engine, oil for the gearbox (photo, video, price).

Trailed mini excavator here.

Read about the Khoper walk-behind tractor in this article.

For walk-behind tractor Favorit

A wheel with a diameter of 430 and a width of 150 mm will ensure reliable adhesion of the used unit to the top layer of soil.

Why are lugs needed for a walk-behind tractor?

Walk-behind tractor lugs are special devices that look like ordinary metal wheels, complemented by studded linings. The name itself indicates their main functional purpose - to guarantee perfect adhesion between the cultivator and the underlying surface - the soil. Thanks to these devices, the walk-behind tractor can move freely across any terrain, regardless of weather conditions.

In addition, the lugs for the walk-behind tractor perform other functions:

- contribute to better tillage of the soil;

- simplify the transportation of both the walk-behind tractor itself and the loaded trailer connected to it off-road or on loose soils;

- by increasing the mass of the unit, they provide it with good balancing and stability in space;

- allow the use of other mounted adapters, for example, for pre-sowing cultivation of land.

General description of the Neva MB 2 walk-behind tractor

The design of this walk-behind tractor, like other common models, includes certain elements. Let's look at the main characteristics of the device, as well as some inherent features:

- This model is equipped with a motor made in the USA by Briggs Stratton.

- The engine power is 6 horsepower.

- The volume of the fuel tank of the device is 3.8 liters.

- Weight without attachments – 98 kilograms.

- The engine capacity is 205 cubic centimeters.

- The transmission of the device includes two forward gears and one reverse gear (2 1) × 2.

According to the instructions, when cultivating the soil, this device can cultivate the soil to a depth of 20 centimeters. The track width is adjustable and varies from 86 to 127 centimeters.

Important! If you use lugs for the Neva walk-behind tractor or other attachments, the device performs a number of functions (clearing the area of snow or leaves, plowing the soil, hilling the soil, watering, as well as transportation).

In this video you will learn more about the Neva walk-behind tractor:

Purpose and varieties

The lugs are designed to increase the weight of the walk-behind tractor and improve the contact of the equipment with the ground, especially in areas with overly wet and/or loose soil. They are a studded design that fits onto the axle instead of/on top of pneumatic wheels with soft tires.

There are several configurations of lug devices available on the market today. There are universal and special lugs. The former can be used on any walk-behind tractor, the main thing is to choose the right size. The latter are made for a specific brand (model) of the unit.

According to their design features, lug devices are divided into those requiring the removal of wheels with pneumatic tires and those that are put on over the tires. The first type requires fixation on the wheel axle.

The use of lugs allows:

- better treatment of the soil layer;

- improve the cross-country ability of both the walk-behind tractor itself and the attached trailer with cargo;

- increase the stability of equipment due to an increase in its weight;

- hang other additional equipment.

The most effective

When choosing appropriate devices, most often, the models that are most effective are taken into account. In practice, this is only true for specific types of attachments. Let's take a closer look at what types of appropriate equipment you should choose for the full cultivation of arable land:

- here, most often, multi-component milling devices are used, which allow processing the soil in different directions;

- you can give preference to a plow with a harrow, since this equipment can simultaneously plow, loosen and cultivate the soil;

- In addition, homemade devices should be highlighted, since they allow you to use everything you need in one mechanism;

- Collapsible multifunctional component cutters and plows with harrows are also in demand.

Each individual case has its own nuances in the appropriate selection of structural elements, but an integral part of any type are special weighting agents that serve to weight the structure when immersed in the ground.

Complex lugs

The following design is a complex one, since it is not inferior to its factory counterparts in quality. We make such lugs with our own hands and they fit like a neva, fireworks, or even a motor cultivator. To make them we need: half a wheel from a Zhiguli (you can cut the wheel yourself), tractor tires, with a developed projector. Then you should choose tires with the same developed projector as the tractor. If we cut off the sidewalls we get a closed ring.

The lugs we received will be able to move along a dirt road without loosening it. On soft ground the wheels will feel comfortable, but at the same time they will not move as boldly as the metal version.

Features of operation of the Neva MB 2 walk-behind tractor

When using a Neva walk-behind tractor, a number of nuances and points requiring attention should be taken into account, namely:

- you should find out in advance the working volumes, as well as how much oil is in the walk-behind tractor;

- clarify what kind of gasoline to fill, since the service life of the equipment depends on the quality of the fuel poured in;

- It is important to take into account maintenance periods;

- you should know when to perform a full comprehensive service;

- During operation, it is not recommended to be very zealous and keep the device running for a long time;

- immediately after purchase, it is necessary to carry out a run-in on unloaded special equipment so that all the parts get used to it;

- After maintenance, it is also not recommended to immediately load the equipment.

Don’t forget to prepare the walk-behind tractor in advance

You should also take into account the fact that you should not allow the device to operate on residual fuel, since over time, impurities accumulate in the tank, which can damage the engine and shorten its service life.

Important! This type of special equipment differs from other devices, therefore the maintenance stages are established not by mileage, but depending on the hours rolled, which is why the time of use should be carefully monitored.

Optimal sizes

It's no secret that heavy equipment cultivates the land better than light equipment. This is evidenced by the fact that people began to become interested in the question of how to make lugs for a car with their own hands. Such equipment can even handle hard soil, which a light tractor cannot handle very effectively. Such units require large lugs. To generalize, the design parameters will depend on the size of the walk-behind tractor.

Thus, the following popular walk-behind tractors can be distinguished:

"Neva". Walk-behind tractors that adapt to any conditions are common. But in the case when the farm already has a Neva tractor, which due to its characteristics is not considered universal, you can make soil cutters yourself. It is necessary to take into account that the diameter of the device should not be more than 36 centimeters, and the width should not be more than 11. MTZ. Even though such units are Belarusian, the price for them is considerable due to the highest quality. You can focus on a price of 5,000 rubles or more. The bottom line is that the wheels of these walk-behind tractor models are quite large. To make high-quality lugs, a lot of labor is required

It is important that the dimensions are selected correctly and that the triangular plates that engage the ground are carefully welded to the main lug wheel. "Firework". This device is assembled according to the Neva scheme. "Centaur"

The wheels in such a device are somewhat similar to the Neva. But the first car has 11 centimeters longer wheels. If a lug is made for the Centaur, its length should be 450 millimeters and width 110. It can also fit other models of walk-behind tractors, including those from other manufacturers.

It will also be useful to make an extension for the lugs. They are designed to increase the angle of rotation of the structure and the width of the potassium and counterweight. To do this, you need to attach a sleeve with a slot to the hub. An additional axle is inserted into such a sleeve, which is secured with a bolt. Finally, you need to secure the soil cutter wheel to the axle.

Thus, there are many options for making soil cutters with your own hands without much labor and emptying your pocket on expensive factory models.

Originally posted 2018-03-28 15:28:41.

What gasoline is suitable for the Neva MB 2 walk-behind tractor

To ensure that the walk-behind tractor can operate without complaints for a long time, it is recommended to use high-quality fuel. 92 or 95 gasoline is poured here. Experts recommend periodically increasing the octane number if AI-92 is used, which allows you to clean the power plant from deposits.

The manufacturer recommends filling in high-octane gasoline no more than twice a season, provided that the walk-behind tractor is used on a regular basis. If this type of equipment is used less frequently, then you can limit yourself to filling 95 fuel once a season.

Important! You should not alternate fuel too often, and, in addition, change the place of purchase, since the content of impurities in the fuel may differ at different gas stations.

This type of special equipment, such as a walk-behind tractor, is very popular among amateur gardeners, as well as commercial agricultural companies. Currently, there are various models and manufacturers of such equipment, but the most popular is the manufacturer Neva and its model MB 2. This unit has proven itself well due to its unpretentiousness and ease of maintenance.

In addition, a whole host of attachments and auxiliary equipment is available for sale for this walk-behind tractor, which allows you to operate the device in all possible senses. However, despite the reliability and quality, in order for this device to serve for a long time, it is necessary to regularly service the equipment, as well as install only high-quality parts and consumables.

Making your own hooks

- The easiest way, perhaps, is to make lugs from unnecessary rims from car wheels. Using a welding machine, an axle shaft is attached to the disks, onto which bearings are then placed. Square metal plates are welded to car rims so that they touch the edges of the rim.

- Then the plates are bolted to the rim. Next, teeth are made - steel hooks that will go into the ground. For this purpose, you will need a steel plate, for example, a corner, which is cut into pieces by a grinder, and from these parts the same teeth are welded, which are made in the factory. The resulting hooks are placed on the wheel rim 15 cm from each other.

- Homemade hooks can be made from an old gas cylinder. Two disks are cut out of it for wheel rims, 5-7 cm wide and 30 cm high. Next, the same operations are performed as with car disks.

- To improve the performance of wheels with hooks, you can weld another tooth on top of each hook and lengthen the teeth to 60 cm. An axle is made: a metal plate is attached to one rim on which this axle will be placed.

- The lugs can be made from any round-shaped blank. The main thing is to choose the right width and diameter of the future wheel with hooks. The dimensions of the wheel are determined functionally, that is, based on the purpose of use on the walk-behind tractor.

For "Neva"

Each brand of walk-behind tractor has attachment options that are more suitable to its design than others. It is better, of course, to purchase a universal walk-behind tractor, for which almost all awnings are suitable. Wheels with lugs Ø 340×110 are produced for the Neva.

In design, these lugs are slightly larger than the homemade ones we described. You must follow the instructions above, but choose different rim sizes. The height of the wheel to hook the Neva should be 340 mm, the width of the homemade device should be 110 mm.

For "Centaur"

The lugs for walk-behind tractors of this brand differ only in size. The dimensions that needed to be taken into account when converting old wheels into lugs for the Neva were described above. The same scheme is used for the manufacture of wheels with large hooks. The wheel height is selected 450 mm. The wheel width should be 110 mm, as for the Neva. Such hooks are suitable for the Centaur 2060 and 2090 walk-behind tractor and units with similar parameters. The factory version will cost about $30.

For "Bison"

The walk-behind tractor of this brand is a heavy professional equipment, and it can be equipped with the best available attachments. In order for the “Bison” to penetrate the ground perfectly, it needs lugs. The standard devices that fit it have a 200 mm tire and a height of 700 mm. Wheels of this width are only suitable for heavy walk-behind tractors and, in addition to the Zubr JRQ78 and 79, are also suitable for the Centaur 1070D, Aurora 101 and Aurora 81, Zirka LX1080D and 1090. In the factory version, the distance between the hooks is 14.5 cm. The wheel hub has a diameter of 60 mm. They are attached to the walk-behind tractor using an additional hub.

Method 2: based on a used gas cylinder.

- We cut out 2 disks from the cylinder, 6–10 cm wide and 30 cm high, they will also be the rims.

- We install metal plates on the resulting rims.

- We attach the teeth to the plate (they must be at least 15 cm).

In principle, these are not the only ways to create such a canopy. This equipment can be made from absolutely any round-shaped metal. It is important to simply choose the correct width and diameter, stick to the diagram, and be able to use welding and a grinder.

Thanks to such attachments, your walk-behind tractor will become a full-fledged agricultural machine. It will cope with work on sites even more efficiently and will significantly increase its cross-country ability and functionality. A motor unit with such equipment will make your work easier on sites and will delight you with quality work done.

Purpose

The most common uses of lugs (iron wheels) are walk-behind tractors, mini-tractors and motor-cultivators. Despite the fact that some modern mechanisms and devices have these attachments in their own basic configuration, more often they still need to be purchased separately from the unit or made with your own hands.

Iron wheels are used in situations where it is necessary to increase the coupling of equipment with the ground, thus increasing traction force and the ability to overcome obstacles. Thus, motor vehicles equipped with iron wheels behave much more stably on loose and loamy soils. This allows the unit to thoroughly till the soil without the danger of getting stuck or buried in it. The use of iron wheels for cars and mini-tractors significantly increases their maneuverability in muddy conditions.

However, the possibilities for using lugs with road and agricultural machinery do not end there. In a slightly different form, these devices are used to more firmly fix greenhouses on the soil, and also additionally to tie a wooden foundation to the ground. The design of construction lugs is somewhat different than that of wheeled lugs. They are rods of iron reinforcement up to a meter long with a plate welded at one end.

Design of the Neva MB 2 walk-behind tractor

Like any other special equipment, a walk-behind tractor consists of a number of components that work together. Let's look at the main parts that make up this equipment:

- engine (due to this unit, torque is generated, which is transferred to the axle);

- transmission (this component allows you to determine the direction of application of torque, as well as the number of engine revolutions);

- gearbox (this unit allows you to evenly distribute torque to the driving parallel axis);

- transmission mechanisms (allow you to redirect torque from the engine to the gearbox and to the axle);

- wheelbase (the axle moves the device along the surface; there are two-wheel and four-wheel models);

- steering mechanism (due to this mechanism, it is possible to control a motor-cultivator or Neva walk-behind tractor).

In this case, the main components of the walk-behind tractor were considered, but its structure also contains a number of additional mechanisms and parts.

Important! In order for this soil cultivation device to work properly, it is necessary to constantly monitor the performance of the power units, as well as auxiliary mechanisms; in addition, maintenance (replacement of consumables) is carried out in a timely manner.

general information

- By design, these devices are wheels with spikes. Today there are many different device transformations, and you should choose them wisely. To a large extent, the quality of work is determined by the weight of the unit. The most functional awnings can only be hung on heavy walk-behind tractors or medium-weight units. If the unit is of high quality and does not give the desired result, you need to additionally purchase wheels with lugs for it.

- Standard devices are metal wheels with spikes that dig into the ground and engage the walk-behind tractor with it. To make devices yourself, you will need to know their structure, which drawings and diagrams will greatly help with. You will need to determine the diameter of the canopy, select the material of manufacture, and, of course, select the necessary tools. The first thing you need is a welding machine and an angle grinder.

- First of all, we decide on the size of the devices. Their height and width depend on the tasks for which the hooks are mounted on the walk-behind tractor. You also need to take into account the requirements for the weight of the devices, because the wheels are put on with them to improve the traction of the walk-behind tractor with the ground. This requires wheels of considerable weight, which a walk-behind tractor may lack. The minimum weight of wheels is 20 kg. If necessary, weights are hung on the soil hooks. This is necessary to achieve better results, or is used when the weight does not reach the norm.

What third-party wheels are suitable for the Neva walk-behind tractor?

Wheels from Muscovites and Lada are best suited for installation on the Neva walk-behind tractor. There is no need to change anything in them, since their diameter is ideal for installation on a walk-behind tractor. They only need to be slightly modernized by welding.

Factory options will cost much more.

The main task when modernizing Zhiguli wheels is to make them heavier, since in the factory configuration they are very light.

Listed below are the main stages of manufacturing wheels for a walk-behind tractor from car tires:

- An axle shaft is installed inside the wheels;

- To make it easier to change wheels, square plates are installed on the axle and holes are made in them. And then the wheels from Zhiguei are attached to these plates;

- A cap is placed on the outside to protect against external factors;

- The tubes should be removed, and only the tires should be left (to improve the quality of traction, winter tires should be used).

Using tires from other cars is problematic because they have a larger diameter or width, so they need to be additionally adjusted using an axle extension or some other method, and this is not always possible for everyone.

To improve the lug-holding properties, some people additionally cover the wheels with a chain. When driving, the chain digs into the ground and provides additional traction. The effect of it is especially noticeable when driving after rain or snow.

The video demonstrates how to install Zhiguli wheels on a Neva walk-behind tractor:

Independent production of the simplest elements

There are several technologies for creating homemade iron wheels. Let's talk about different options that differ in the degree of complexity and the scale of the necessary activities.

The simplest method to make something similar to industrial iron wheels is to modernize ready-made factory elements. For this purpose, “anti-slip strips” are made, which are put on the wheels.

Let's consider the process of their creation.

- A 2-3 mm sheet of iron is taken.

- Using an angle grinder, a rectangle is cut out, which should be several centimeters wider than the tire contour and coincide with the length of its circumference.

- The edges of the strips are bent inward to prevent them from slipping to the side and causing injury to the operator of the unit.

- They begin preparing the lug component (for this purpose, sheet iron with a thickness of at least 0.04 centimeters is required, which is bent at an angle of 120° and cut into identical pieces).

- Using a welding installation, the resulting elements are welded to the strips, maintaining the same distance between them.

The same operations are performed for the second wheel. To tighten the structure you will need bolt ties, which are also welded. A violation of the dimensional relationships between the spikes (plates) on different wheels can cause the unit to skew to the right or left when moving forward.

Attachments for Oka walk-behind tractors

The attachments produced by the plant significantly expand the capabilities of this type of motor vehicle. The following is an overview of all factory additional elements for the Oka walk-behind tractor, their characteristics and a description of the principle of operation.

All Kadvi attachments combined with the Oka walk-behind tractor are also suitable for the Ugra.

Potato planter

A potato planter is a device that is used to automate the process of planting potato tubers.

The planter embeds root crops into the ground, forming a soil ridge on the surface of the earth.

| Weight | 34 kg |

| Planting hopper capacity | 33 l |

| Distance between tubers | from 30 cm to 50 cm |

| Track width | 0.7 m. |

Cultivator cutter

This equipment is designed to loosen the earth. The cutters crush the weeds, and when throwing fertilizers into the ground, they mix them thoroughly. Installation is carried out on the output shaft.

The cutters with a diameter of 34 cm produced by Kadvi are designed for a cultivation depth of up to 20 cm, and the gripping track width is 10.5 cm. The total weight of the two cutters is 17.2 kg.

Please note that the Ugra walk-behind tractor has hexagonal cutters without connecting pins - this prevents grass fibers from wrapping around the part during the cultivation process. Such equipment is additionally equipped with protective disks.

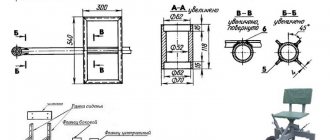

The diagram below shows the assembly diagram of the cutter for the Oka walk-behind tractor.

Plowing with cutters - video review:

Lugs

The use of lugs gives the walk-behind tractor the opportunity to grip more with the top layer of soil, automatically stabilizing the unit and providing more powerful force for plowing or hilling.

Equipment of this type is attached to the location of the wheels or cutters. Some walk-behind tractors require additional long hubs for installation.

The diameter of factory lugs from Kadvi for Oka walk-behind tractors is 350-500 mm and depends on the modification of the motorcycle. Maximum weight - 18.8 kg.

The figure demonstrates the process of installing lugs on a walk-behind tractor.

Weighting weights

Oka walk-behind tractors are classified as heavy equipment; the name itself speaks for itself - a walk-behind tractor is always heavier than a cultivator. However, even when working with heavy equipment, additional weight may be required. It is for these purposes that weights are intended.

The weight of such cargo can reach 5-17 kg. Homemade attachments may weigh more than the factory standard.

The plow for "Oka" is suitable, like other types of attachments, for the "Ugra" walk-behind tractor. It is used for plowing and fertilizing the soil.

Some implement stores sell plows with or without a hitch. The plow is attached to the walk-behind tractor using a set of fasteners, a hitch and a wrench.

The dimensions of the factory product are 535x310x410 mm. The width of the layer of earth that the plow can capture reaches 21.5 cm. Weight - 7.8 kg.

Raspashnik, hiller

A hiller or tiller is an attachment that is used to add fresh soil to the beds, as well as loosen it.

The hiller can be single-row or double-row, disk, or propeller. The simplest and cheapest is single-row.

These devices are also divided by working width (fixed or adjustable).

The figure below shows a diagram of the installation of a two-row hiller on the Oka walk-behind tractor.

Standard differential

A differential is a device that performs several functions.

- The first task is to lock the rotary extension.

- The second is to reduce the radius of movement of the walk-behind tractor when turning.

- The third is to increase the maneuverability of equipment.

With the help of a differential, one wheel is locked, which is why the walk-behind tractor can turn a total of 240 degrees. The differential can be used as an independent part to lengthen the axles, for example, to hang cutters, or in combination with other attachments.

Harrow

The classic version of the harrow for the Oka walk-behind tractor, produced by the Kaluga Motor Vehicle Plant, is used for a whole range of actions on a plot of land: with its help you can level the surface of the earth after plowing, cultivate the soil between sowing rows, and also remove debris from the rows after harvesting.

Standard dimensions of the implement: width of the captured soil 80-90 cm, weight 12 kg.

Root digger

A simple digger is used to extract crops from the ground, for example, beets, potatoes. There are many devices of this nature, the simplest ones are aggregated with the Oka walk-behind tractor and mounted on the agricultural machine using simple fasteners. You can make this connection manually.

Larger diggers are more expensive, but the yield of root crops when using them will, of course, be higher.

The working principle of the digger is shown in the figure below.

A short review of the converted potato digger for the OKA walk-behind tractor:

Hitch

Additional equipment, without which it would be impossible to attach many auxiliary units to the Oka walk-behind tractor. A coupling device is necessary to connect a mini-tractor with implements such as a potato digger, plow, hiller and others.

Product weight - 5.2 kg, dimensions 435x130x175mm.

Cargo trolleys

Trailed-type equipment necessary for transporting cargo, collecting garbage and other operations for moving something on a walk-behind tractor. A single-axle trolley can be loaded with a maximum of 300-350 kg.

Carts from many manufacturers are mounted with an Oka walk-behind tractor; when choosing such equipment, you should take into account the weight of the walk-behind tractor or cultivator, and also purchase an additional hitch.

Motoblock Oka with trolley TM 500:

Rotary snow blowers

This is a device for “Oka”, also suitable for “Ugra”. With its help, you can clear the territory of your dacha, yard, or garden plot from snow. On the Oka walk-behind tractor, the drive is carried out by a V-belt drive, on the Ugra - by a power take-off shaft.

A rotary snow blower can throw snow 15 meters, and it is quite acceptable to work with it in a high layer of snow (up to 75 cm).

Motoblock shovel

Used either instead of or after a snow blower. Main purpose: leveling snow cover or a layer of dug up earth, etc.

Dimensions: 1000x280x370 mm, weight - 13 kg.

Adapters

The AMPK-500 all-wheel drive walk-behind tractor adapter can be used with heavy walk-behind tractors, including Ugra, and not just Oka. This model is equipped with rear wheel drive. The body can be easily removed.

Thanks to the use of such a device, the operator can transport loads weighing up to 500 kg.

Mower "Zarya"

Rotary mower with a productivity of 0.2 ha per hour. Works in combination with many heavy walk-behind tractors, including Oka, Ugra and others.

It mows the grass and at the same time folds it to the sides, as after using a simple scythe. It is put on a special pin at the front of the machine. It is equipped with two discs with four knives. Supplied complete with tension device.

General characteristicsWeight: 24 kg. Dimensions: 810 mm/930 mm/780 mm. Body material: steel. Cutting width: 800 mm. Mulching: no. Grass catcher: no.Production of lugs with a more complex design

In addition to methods that allow you to make the simplest lugs, there are also ways to make more complex structures. To work on the manufacture of the latter you need to prepare:

- Steel sheet, thickness from 3 to 5 mm - you need to make a central disk from it;

- A steel strip, 5 mm thick and 50 mm wide - it will be needed to make the outer hoop. You will need 6 hoops - they will weigh the wheel down and make it more durable;

- Another steel plate, 8 to 10 mm thick - you need to make a hook from it;

- Bulgarian;

- Drilling machine or drill;

- Welding machine.

All parts should be connected to each other using arc welding, since a gas torch will not be able to heat metal of this thickness. The manufacturing algorithm is as follows:

- First, lengthen the axles of the walk-behind tractor - this is required due to the fact that the width and diameter of the lugs are larger than the mounting location of the standard wheels;

- Be sure to provide the ability to adjust the position of the track, since in the future you will cultivate the garden with rows of different widths. When moving the lug wheels, you will be able to adjust the position of the attachment used and the width at which the lugs will be located. Since the mass of each wheel is about 10 kg, reliable grip and high stability of the walk-behind tractor on the ground will be ensured;

- Next, proceed to making the lugs themselves. To do this, make 2 spoke-shaped central disks from profiled steel sheet;

- After this, weld 3 external hoops and hooks to the end parts of the structures;

- Weld steel plates to the hoops. They should be placed diagonally on the hoops in the form of a snake;

- Sharpen each plate for better traction.

The lugs made will ensure maximum adhesion to the ground and will help you easily remove even the thickest weeds.

When using lugs, never forget that they are intended only for work in the garden. Do not use devices to move the walk-behind tractor on concrete or asphalt, as the teeth of the product will bend and quickly become unusable.

Both the simplest and more complex designs are suitable for use on walk-behind tractors Salyut, Agat, as well as Neva MB-1 and MB-2.

What we call wheels are lugs in the case of a walk-behind tractor. In the vast majority of factory designs, the equipment is equipped with conventional wheels with textured off-road tires.

This is done so that traction power can be used to transport goods along ordinary dirt roads.

Important! The use of a walk-behind tractor (even a factory-made one) on public roads is prohibited. Even if it has high-quality factory wheels installed

Therefore, many owners of small agricultural machinery make lugs for walk-behind tractors with their own hands. In this case, you only need to adjust the mounting socket to the hubs of the factory motor plow. When changing the mode of use, simply mount the necessary wheels.

If the walk-behind tractor is used only in the field, ordinary rubber tires are not needed. And for a mini-tractor of your own production, you don’t have to make ordinary wheels at all. In this case, homemade lugs for a walk-behind tractor will be the only set.

The design is not new; the first tractors were produced without rubber tires. The wheels were metal, and powerful transverse or diagonal plates made of thick steel were installed on the driving rollers.

Options for wheel design drawings for a walk-behind tractor

Factory configurations of wheels for a motor cultivator are classified according to the number of axles, as well as the principle of traction. Manufacturers produce home mini tractors, the design of which involves the movement of the unit due to:

- two wheelsets;

- paired wheel structure on one axle;

- one drive wheel;

- on three wheels.

Single-wheel mechanisms are often equipped with additional devices on the axle, which also serve as support for the structure. Analyze the model of your home cultivator to improve its functionality. Choose a durable, reliable material or a suitable base for making homemade chassis elements.

Four wheel option

Small-sized agricultural tractors on four wheels are a miniature of a similar vehicle without a cabin. The configuration of the models allows the user to move on a walk-behind tractor.

To improve the factory configuration, you can replace only the drive pair or change all the disks. Choose one of the options to improve the performance of home agricultural equipment:

- equipping factory tires with additional protectors;

- putting new tires with a textured pattern on the wheels;

- installation of wheelsets of different radii on the axles - larger ones under the mechanisms, smaller ones under the driven part;

- installation of car wheels.

Important! Designing wheels is an important stage in improving a walk-behind tractor, at which it is necessary to make accurate calculations of the optimal dimensions, arrangement of elements, and locations for drilling fasteners.

Four-wheeled walk-behind tractors are classified as heavy-duty models. A number of machines are configured with non-removable wheel elements. Before modifying a mini tractor, make a drawing according to which you plan to improve.

On one wheel set

Two-wheeled motor cultivators are equipped with one axle with a pair of wheel elements. The platform with the installed engine is controlled by the user using handles. Installing a passable wheelset will solve the problem with:

- slippage;

- slippage;

- filling the poorly expressed tread pattern with earth;

- poor handling;

- insufficient plowing depth, etc.

Draw a sketch of one element on paper yourself or make a drawing in a computer program. In the figure, indicate the diameter of the disk, the location of the holes for the axle, fastenings, and their dimensions.

With one driving wheel

Single-wheeled cultivators are devices in the form of a wheel element in a tire with a pronounced tread. The speed of work and efficiency when performing farming work depend on the permeability of the disk.

When preparing a drawing for replacing the drive wheel, use the following recommendations:

- select the diameter of the wheel element similar to the factory configuration;

- choose materials with greater weight when making a wheel yourself;

- replace the rubber with a more textured and wider one.

The walk-behind tractor on one wheel is controlled by manual manipulation. It will be easier for you to drive a design with a wide wheel and a powerful tread.

Three-wheeled models

On small-sized agricultural tractors for cultivating a summer cottage with three wheels, the front element performs the function of following a given trajectory. The rear wheel pair is supplied with torque from the unit engine. In most models, the chassis located at the front is made of a larger diameter.

To design the replacement of wheels on a single-axle small-sized tractor, use the following recommendations:

- calculate the same radius of the wheel and tire that is provided in the factory configuration. Installing a smaller or larger wheel in diameter will make the mechanisms work incorrectly;

- make identical wheel elements. Replacing wheels with different tread patterns or different weights will complicate the use of the mini tractor.

When making a drawing with your own hands, take as a basis the model designed by the manufacturer. Consider the full radius of the elements. You can design a disc with a smaller diameter, but install thick tires on it, and vice versa.

Combined design

If the equipment is homemade and the soil is not too difficult, the wheels should be appropriate. You can make hooks using tractor protectors.

We take halves of wheel rims from a Zhiguli car. We choose tires with good tread from the tractor. We cut off the sides, we get a rubber closed ring with a good protector. We open the halves of the wheel rims and, after laying the tires, twist them firmly. With such lugs, you will be able to move along a compacted dirt road without fear of loosening it. On the soft soil of a plowed field, the wheels will not fail, but the traction force will be less than in the case of the metal version.

If it is necessary not only for the wheels to be grippy, but also to additionally loosen the soil in the rut, knife-type hooks are made. You can create a homemade rim to mount them or weld them to the rims. The only drawback of the blade design is that it does not allow you to move the walk-behind tractor in the usual way.

When loosening in spring together with traditional attachments, the width of the soil processed per pass will double, which will save a lot of time.

Functions

The lug lugs are produced both as universal ones, suitable for all brands of walk-behind tractors, and as specially tailored for a specific model. Some manage to make such attachments on their own, using old disks from a car as a basis, however, the cost of such a unit turns out to be more expensive than if it were purchased ready-made. Lugs are necessary, first of all, to:

- improve the quality of traction of the walk-behind tractor with the soil on which you have to move;

- increasing the weight of the equipment, due to which it becomes more stable and can be used without fear on uneven surfaces, even when using other heavy attachments;

- The lug provides additional soil treatment;

- The walk-behind tractor can easily move uphill on soft soil.

It becomes clear that without such attachments, most standard tasks would become inaccessible to the walk-behind tractor. It is impossible to talk about the versatility of such equipment without lugs.

To make the walk-behind tractor as functional as possible, you need to purchase a model of attachment specifically for it. In this case, the unit becomes more productive and economical. Sometimes lugs that are made of light alloy are supplied for sale; their use on a light-weight walk-behind tractor is impractical, since the total weight should be above average. Higher quality, heavier ones cost the consumer more, but they fully perform the assigned tasks.

How to make from Zhiguli wheels?

1 way

You can create more complex elements based on metal sheets or car wheels. Precise fixtures can only be made in accordance with the drawing. Some make the drawing themselves, others use a ready-made version.

To create such products take:

- 4 mm steel, which will serve as the disks of future iron wheels;

- 8 mm metal sheet, which is necessary for the area immersed in the ground;

- electrical tools (welding machine, angle grinder, electric drill).

The manufacturing process is quite simple:

- Using an angle grinder, 2 pieces of equal size are cut out in the shape of a circle, in the center of which holes are drilled for the studs and the hub.

- A jagged frame is made along the outer edge (no more than 100 millimeters in height).

- The second sheet of metal unfolds into triangles with rounded corners.

- The triangles are welded to the gear frame.

Method 2

In this case, you will need a full set of disks. You can install tires on one pair and use it for driving on asphalt, while the other can be made like classic lugs.

Let's look at the order of operations.

- We dissolve a metal corner with a 5-6 cm shelf into pieces wider than the available disks.

- In the middle of one side, use an angle grinder to cut out a triangle-shaped area. It is this part that they will touch on iron wheels. Using a gas burner, heat the corner and bend it slightly. We “grab” it with electric welding to strengthen the workpiece.

- Along the outer rim of the car rim, we weld the spikes from the corners at regular intervals (a step of 15 centimeters would be ideal), directing the pointed part in the direction of movement of the motorcycle.

- Similar actions are repeated for the other disk.

Do-it-yourself lug lugs for a walk-behind tractor: the optimal design option

To make more complex factory analogues, lugs are made from steel sheets or car wheels. An exact design can only be created from a drawing, which you either make yourself or take a ready-made one.

For lugs in the first case, take:

- 4 mm steel – it will serve for the rims of future wheels;

- steel sheet 8 mm - for the part immersed in the soil;

- power tools - welding, angle grinder, drill.

Work progress:

- Using an angle grinder, we cut out two identical round-shaped blanks, in the middle of which we drill fasteners for the hub and studs;

- along their outer edge we make a jagged edge with a height of no more than 100 mm;

- we unravel the second sheet of steel into triangles with blunted corners;

- We weld the latter to the serrated edge, as shown in the figure.

The second option based on Zhiguli wheels

A complete set of disks will be needed, since tires can be placed on one pair and used for transportation on asphalt roads, and the second pair can be used as traditional lugs.

Sequencing:

- cut a steel corner with a side of 5-6 cm into pieces wider than the existing disks;

- In the center of one side, use a grinder to cut out a triangular area. It is this part that they will touch on the lug;

- Heat the corner with a burner and bend it slightly. Additionally, we tack by welding to strengthen the workpiece;

- We weld the spikes from the corners along the outer rim of the machine disk at equal intervals (a step of 15 cm would be optimal, directing the pointed part as the walk-behind tractor moves).

Similar operations are repeated for the second disk, as shown in the video.

“Using our recommendations, you can make homemade lugs for any brand and model of walk-behind tractors: Agat, Salyut or Neva. The dimensional differences between the models of these cultivators are insignificant, so the lugs from the Neva MB-1 series are also suitable for later versions - MB-2, MB-21, etc., expanding the scope of their application.

Auto mechanic, specializes in agricultural equipment

In modern life, various devices are used that are designed to significantly reduce physical stress when performing certain work. For agriculture and gardening, appropriate special equipment is used, which increases productivity

In practice, special attention is paid to small and multifunctional devices

One of these devices is a walk-behind tractor. Of course, the device itself does not have a certain value without additional attachments. However, due to the high cost, lugs for the walk-behind tractor and other devices can be made independently. In this case, it is necessary to consider exactly how homemade lugs are made for a device such as the Mole walk-behind tractor or other models.

Save time and effort with walk-behind tractor lugs

How to make lugs with existing factory wheels

The easiest way is to put the structure on the tire, like snow chains.

It is enough to take sheet iron 2-3 mm thick and cut a strip that will be slightly wider than the tire profile. The tension is ensured by a simple tie rod made of bolts. The edges of the strip should be folded to prevent slipping under lateral loads.

The lugs themselves are cut from thicker sheet steel (4-5 mm). They must be bent in the middle at an angle of 120°. The blanks are then welded to the strips at regular intervals.

Important! The distance between the lugs should be the same on both wheels. Otherwise, the equipment will be pulled to the side during work. Therefore, before starting work, you should use ready-made drawings, or develop a layout yourself

Therefore, before starting work, you should use ready-made drawings, or develop a layout yourself.

You can make such lugs with your own hands in a couple of evenings. If you use a regular smooth tread on a homemade walk-behind tractor, the device will turn the equipment into a real SUV.

We will introduce small mechanization lovers to various types of structures and varying degrees of complexity.

Owner reviews

Ilya, 31 years old:

I don’t have an Oka walk-behind tractor, but a mini-tractor! I bought a front Forza 2 years ago and moved on to high-speed work. My 1.5 hectares of potatoes are processed quickly and efficiently. Savings in human resources, time and fuel. I felt the difference in the first week. The attachment is fully equipped. The technology is excellent.

Peter, 52 years old:

Hello. My old lady Oka is already 8 years old. Still works fine. Over the years, I have collected all the attachments I have and tested them under different loads. What can I say: in the spring I only mill the soil, in the fall I pull with a plow, I pull a 300 kg trailer, I take a disk hiller, I have a simple, inexpensive potato digger. There is other equipment, everything is simple, without bells and whistles - everything works great. In winter I also use it, plant it on a tracked attachment and complete it with a blade - that’s it! The car, of course, is periodically repaired, parts are freely available, belts too.