Corrugated sheets have been actively used in construction and in many other areas for several decades. This reliable material, the production of which requires a special machine for the production of corrugated sheets, is used as the main element of enclosing structures, it covers the roofs of building structures, cladding walls, and also solves a whole list of other problems associated with both capital and private construction.

Corrugated sheets are produced by cold rolling

The production of profiled sheets can be carried out using both mechanized and manual equipment, which, if desired, can be made with your own hands. Knowing all the nuances of such production, you can organize a profitable business for the production of profiled sheets that are in demand on the market or produce such material for your own needs at minimal cost.

Passivation and priming

The strip of now galvanized steel is then coated with a chromate conversion coating and preservative oil. This is a type of coating used to passivate steel products. It is needed to make the steel last even longer.

Steel is coated with a special layer of salts and oxides that prevent it from deteriorating.

Next, a primer coating is applied using a special painting machine.

It additionally protects the steel from destruction, providing strong adhesion between the polymer coating and the metal, leveling out defects on it.

The final stage is the application of the polymer.

Application of polymer

The polymer coating is applied using a U-shaped painting machine. It plays an important role for everyone who organizes their own production of corrugated sheets. This machine has two heads (A and B) for front coating and a lower head (C) for back coating.

The presence of two pairs of paint heads allows you to transition from one paint color to another without stopping the line. While one painting head is in operation, the second one can be prepared for subsequent painting with a different color.

After coating, the products are dried in a convector gas oven. This is necessary to achieve a metal temperature that will allow the solvent to evaporate, providing the necessary polymerization. The drying mode is set by the technologist.

The dried, painted metal is placed in an air-cooling chamber. This is done to reduce the temperature of the strip. Then it (the strip) is placed in a water cooling section, which will avoid temperature shock and deformation of the metal.

After applying the polymer layer, the colored strip passes through the belt feeding mechanism onto the winder mandrel to wind the strip into a roll.

Using a hydraulic trolley, the roll is removed from the winder and fed to storage stands. The dyed roll is then transported by overhead crane to a special area for packaging.

Protective layers of corrugated sheeting, ranging from passivating to polymer, are designed to prevent the occurrence of corrosion on steel.

The polymer coating provides the profiled sheet with the desired color, attractive appearance, and protects the steel from fading in the sun and from mechanical damage.

Quality checking

Next comes the quality control stage. This is what is needed to produce reliable corrugated sheets. has its own laboratory. Here they check the impact and bending strength, the hardness of the polymer coating, the adhesion of the coating to steel, the color difference in comparison with the standard, the gloss and thickness of the coating. The work is carried out by experienced and highly qualified employees. Thanks to constant monitoring, our customers can be confident in the quality of our products.

Workplace of a process engineer for conducting tests.

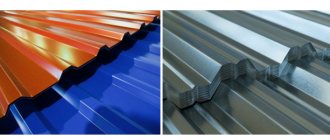

produces profiled sheets with polymer coating (painted and galvanized) and without it (galvanized only). Painted corrugated sheeting is a more aesthetically pleasing material than galvanized sheeting. It is used in various fields of application: from cladding facades to the construction of durable permanent fencing. The decorative layer of coated corrugated sheets protects from external natural influences - sun, rain and snow.

Profiling

The automated process of manufacturing corrugated sheet steel can be described in a few phrases. The roll is installed on an unwinder, which ensures correct and uniform feeding of the sheet. The end of the sheet is inserted into the forming machine of the rolling mill. The main parameters are entered into the automatic control system, which include the rolling speed and the number of corrugated sheets. After adjusting the parameters, the equipment starts up. The profile on the sheet appears gradually, passing through many shafts. By the end of the rolling line it turns into a full-fledged profiled sheet. After profiling, the product is cut with hydraulic shears according to the required parameters. Produced on high-tech lines and having gone through all stages of strict control, corrugated sheets meet the highest quality standards.

How is corrugated sheet made?

To obtain high-quality material, you need appropriate equipment for corrugated sheeting, so organizing the production of this roofing requires a large initial investment, but its payback time is minimal.

A production line is only possible if the workshops:

- there is a gantry crane or any similar equipment;

- the temperature regime is observed (not lower than +4 degrees);

- Spacious warehouses are equipped for storing steel coils and other finished products.

Depending on the purpose of use, corrugated sheeting may have a special coating, or it may be produced without it. The starting material can be metal for the manufacture of corrugated sheets, which is coated with polymers for external work, and without coating is successfully used in the construction of concrete formwork.

The use of first-grade steel is common - in this case, a zinc coating of 20-26 microns is applied over the profile. If the coating thickness is noticeably reduced, the service life of the material is reduced several times.

Based on this, the production of corrugated sheets requires the use of high-quality raw materials with additional spraying and production equipment from a large company reputable in the mechanical engineering industry.

Slicing and packaging

Lastly, the sheets are cut to the required length. All dimensions of corrugated sheets depend on the type of profile; the required length of sheets is indicated by the customer.

Our equipment allows us to make sheets of any size in the range from 0.5 to 12 meters.

Modern high-precision equipment allows us to eliminate the “human factor” from production. All necessary parameters for the manufacture of the product are set by the operator in the automatic control system. Highly qualified personnel work in the workshops for the production of corrugated sheets.

The quality of finished products is controlled by quality control department. Before production begins and at the end of the finished product, samples are taken. The input section operator (using electric scissors) takes a sample from the first roll of a new batch and passes it to the quality control inspector. Quality control is also carried out according to GOST.

Modern equipment allows us to eliminate the “human factor” from production.

The finished corrugated sheet is placed on pallets, covered with bubble wrap and secured with metal ties.

After packaging, orders are placed in a warehouse, from where they are then sent to the end consumer.

Corrugated sheets are well suited for roofs, facades and fences.

Prices for profiled sheets (per m2)

Galvanized corrugated sheetingColored corrugated sheets

Color card

- Profiled sheet C8

Full width: 1200 mm, working 1150 mm

Profile height: 8 mm

Metal thickness: 0.25-0.7 mm

Application: wall

Price from 290 rubles per m2, 696 rubles per sheet

- Profiled sheet C21

Full width: 1051 mm, working 1000 mm

Profile height: 21 mm

Metal thickness: 0.30-0.7 mm

Application: wall, roof

Price from 330 rubles per m2

- Profiled sheet N60

Full width: 902 mm, working 845 mm

Profile height: 60 mm

Metal thickness: 0.5-1.0 mm

Application: wall, roof, load-bearing

Price from 590 rubles per m2

- Profiled sheet C10

Full width: 1180 mm, working 1150 mm

Profile height: 10 mm

Metal thickness: 0.25-0.7 mm

Application: wall

Price from 290 rubles per m2, 696 rubles per sheet

- Profiled sheeting NS35, MP35

Full width: 1060 mm, working 1000 mm

Profile height: 35 mm

Metal thickness: 0.35-0.9 mm

Application: wall, roof, load-bearing

Price from 400 rubles per m2

- Profiled sheet N75

Full width: 800 mm, working 750 mm

Profile height: 75 mm

Metal thickness: 0.5-1.0 mm

Application: wall, roof, load-bearing

Price from 640 rubles per m2

- Profiled sheet S20, MP20

Full width: 1150 mm, working 1100 mm

Profile height: 18 mm

Metal thickness: 0.25-0.8 mm

Application: wall, roof

Price from 300 rubles per m2, 690 rubles per sheet

- Profiled sheeting NS44, C44

Full width: 1070 mm, working 1000 mm

Profile height: 44 mm

Metal thickness: 0.4-0.9 mm

Application: wall, roof, load-bearing

Price from 390 rubles per m2

- Profiled sheet N114

Full width: 807 mm, working 750 mm

Profile height: 114 mm

Metal thickness: 0.75-1.0 mm

Application: roofing, load-bearing

Price from 1090 rubles per m2

*The price indicated is for a sheet 2 m long

Result:

Since the 19th century, corrugated sheets have become one of the most popular building materials. We have everything you need to produce profiled sheets. We make reliable profiled sheets for roofs, facades and fences. Qualified employees and the presence of our own laboratory guarantee quality control of corrugated sheets at every stage of its production. Thanks to our own production, we are able to provide affordable prices for corrugated sheets. Select the desired profiled sheet and order it in our online store.

* Detailed information about warranty periods for products can be obtained on the website metallprofil.ru in the “Documents” section.

Organizational aspects

The first step is to register an individual entrepreneur or LLC. At the initial stage, it is enough to obtain the status of an individual entrepreneur. This takes from 1 to 3 days. Documents can be submitted directly to the tax service or through the MFC.

This form of business is easier in terms of paying taxes and keeping records. For tax purposes, a simplified regime is chosen, in which only income is taken into account. The amount of tax paid is 15% of profit.

Registration of production

When choosing a type of activity, they rely on the all-Russian classifier. In this case, you need to select “Processing of metal products using basic mechanical engineering processes.”

Search for premises for a workshop

The production of profiled sheets requires a large space. Therefore, the minimum area of the room will be 150 m2. The requirements for communications are minimal, only electricity and heating are sufficient. If the workshop will operate only during the season (spring-summer), then you can rent a cold one, without heating.

It will be important to have ventilation and storage space for finished products.

The location for the workshop is chosen in an industrial zone, with access roads or a site for loading and unloading operations.

Formation of staff

Equipment for the production of profiled sheets does not require special qualifications; it can be operated by one employee working one shift of 8 hours. An experienced manager is needed to organize sales.

Loading and unloading operations are performed by two employees. Keeping accounting records for individual entrepreneurs using the simplified tax system is not required; tax calculations can be done by the entrepreneur himself using a special program. At first, it is also better to carry out general guidance yourself.

The monthly wage fund will be (rub.):

- automatic line operator (1 person) – 15,000;

- general workers (2 people) – 30,000;

- sales manager – 15,000 +% of sales, average – 25,000.

Total monthly labor costs – 70,000 rubles, per year – 840,000 rubles. At the same time, the individual entrepreneur will pay taxes to the treasury for employees - 30% of the payroll, which in monetary terms will be 252,000 rubles. In addition, the entrepreneur pays contributions “for himself” - 40,874 rubles. Thus, the total cost of labor with taxes will be 1,132,874 rubles.