Aluminum products, due to their plasticity, are malleable to any mechanical stress. It is quite easy to bend an aluminum pipe even at home, and it will remain safe and sound. It is enough just to observe some features of this operation.

What is the difficulty of bending profile pipes?

Regardless of the shape of the pipe profile, the essence of the bending process is to give the product a partial or full bend. This can only be achieved by applying a certain external influence - exclusively pressure or a combination of heat and pressure.

From the point of view of physics, during the bending process, two multidirectional forces simultaneously act on the profile pipe:

- Tensile force. Appears on the outside of the bend.

- Compression force. Directed towards the inside of the bending area.

The opposite direction of these forces is precisely responsible for some of the difficulties that often arise in the process of bending pipes:

- Different sections of the pipe in the bending zone may change shape differently, which will inevitably lead to a violation of their alignment.

- The pipe wall on the outside of the bend may lose strength or even burst under strong tension.

- On the inside of the bend, on the contrary, folds often form during compression.

To avoid these troubles and not get a crumpled metal surface instead of a smoothly curved pipe, you should definitely take into account the type of material and numerous geometric parameters of the product: wall thickness, cross-section diameter, bending radius. Knowing these characteristics will allow you to choose the optimal bending method.

Note! Experts say that it is better not to bend profile pipes with a wall thickness of less than 2 mm. The strength at the bend points will be quite low, even with perfect adherence to the technology. For such pipes it is better to prefer welded joints.

Profile preparation

Preparing a profile for bending depends on the length of the workpiece and takes an average of 15 to 20 minutes, and the bending process itself takes 7 to 8 minutes. First, the profile blank is marked taking into account the technological segments. To avoid flattening of the profile walls, cracks and bruises during the bending process, the profile chambers are tightly packed with quartz sand. To ensure that the packing is not loose and does not lead to flattening in the bend area, as the chambers are filled, the walls of the profile are tapped from top to bottom, thus compacting the sand. Then the profile must be closed at both ends with plugs so that sand does not spill out of the profile during the bending process. Sand is not thrown away after use, because... after the next use, the quality of the sand only improves (sand fractions become smaller during the bending process) and it can be used repeatedly. Before bending, profiles and rollers must be lubricated with thick oil to reduce friction between the surfaces of the rollers and the outer walls of the profile.

The principle of using a pipe bender

It is not always possible to bend a profile pipe (especially for large-diameter products) with your own hands. For these purposes, there are special devices - pipe benders. A standard pipe bender is equipped with a drive wheel, which, moving along one of the edges, carefully bends the pipe section in the required direction.

There are two types of pipe benders:

- Manual. The wheel of the device is operated manually using a special handle. Well suited for pipes with a small cross-sectional area.

- Electrical. The use of such devices is justified in cases where the volume of work is quite large, and the pipes themselves have substantial dimensions. The device is connected to a standard power supply, and the wheel moves by means of an electric drive. Allows you to obtain smoother products with significant time savings.

If the work is one-time, purchasing your own pipe bender may not be profitable. In this case, you should consider renting the device, or consider one of the alternative bending methods.

Installation features

When installing a profile with dowels and nails to the walls, certain difficulties may arise. To avoid this, you should familiarize yourself with certain nuances:

- When installing into a brick wall, you should determine the location of the dowel-nail. If the fastener gets on the boundary (in the mortar) between the brick, then there is a high probability that it will pop out. Because the solution may crumble.

- Before drilling into the wall, you should know for sure that there are no electrical wires going through there. Otherwise, a short circuit will occur.

- If there is metal reinforcement running through the wall, this will also have a negative effect on making the hole.

- To properly install the dowel-nail, you need to make holes with the same diameter as the dowel (6mm).

- You need to drill the wall at low speed so that the material does not come out from the surface in one piece, which will create a large hole.

- When driving the dowel, the limiting collar will prevent the fastener from falling into the hole. Therefore, the dowel should be driven in carefully.

Useful tips

If the hole turns out to be large and the dowel does not hold, this can be corrected in the following ways:

- tighten the self-tapping screw next to it;

- if possible, drill with a larger diameter and select the appropriate dowel;

- insert a plastic dowel and drop a little foam there. Overnight it will expand, press against the plastic part and harden. Only after this can a nail be screwed in and excess foam removed;

- squeeze liquid nails into the hole;

- insert the plastic part of the dowel-nail into the hole, apply plaster. It will dry overnight, then screw in the nail.

On a ceiling structure for a suspended ceiling, it is better to use an iron wedge anchor, because in the event of a fire it does not melt, but holds the metal structure. And for reliable fastening of direct ceiling suspensions, this is the best option for holding the structure.

But, if the ceiling is being leveled with plasterboard in an old panel house, then a plastic dowel-nail can be used. It wedges better and holds the metal frame.

In addition, familiarize yourself with the types of dowels for fastening directly into a gypsum board sheet.

https://youtube.com/watch?v=IpkNvkmhz-Y

Video:

Video:

Video:

Is it possible to bend a pipe at home?

If the pipe does not have the largest dimensions, and bending accuracy is not a critical parameter, it is possible to carry out the necessary work at home.

Of course, it will be better if there is a separate room for this work, equipped with a workbench, a vice and other necessary tools. In addition, during the work you will most likely have to use an angle grinder, a welding machine or an open flame source. Agree, a private house or apartment is not suitable for this.

Another important tip. Metal is a fairly elastic material that, after any deformation, will strive to regain its previous shape. For this reason, the pipe should be bent at a slightly larger angle than the design provides. The metal will return a few degrees back, and we will get exactly the bend radius that we originally expected.

Read also: How to check a triac on a board

To facilitate the bending procedure, the corresponding section of the pipe can be preheated. The hot metal becomes more ductile and pliable, which greatly facilitates the process. For warming up, they most often use:

The pipe is thoroughly heated at the site of the future bend (the length of the heating site is taken to be equal to six pipe diameters).

It is worth remembering that repeated cycles of intense heating and cooling inevitably make the metal more brittle.

How to bend a profile for drywall

Working with durable sheets requires the necessary set of accessories. In order to correctly bend metal parts, make the necessary cut on one of them, and also ensure their high-quality installation, we use the following accessories: How to correctly bend a drywall profile? The guide profile can be bent, since the rack-mount ones are designed to support the main weight of the future structure. When creating an opening for an arch, you need to use a special arch profile. Any of the listed cases assumes that it is necessary to bend the plasterboard profile so that the structure is installed based on a given diagram.

If you perform all the steps correctly, the profile will be easy to install. Drywall (gypsum plasterboard) is used to create various shaped elements. Modern installation of suspended ceilings is not complete without the use of this material. When creating a ceiling design, the following elements are used:

- If a high arch is formed, the profile can be bent into an arc

- When the ceiling is formed as a single composition with the transition of individual shaped components to the walls

- When installing a niche that has a curved element

- When creating an arched partition with a complex bend

Alternative bending methods

Fortunately, you don't need any special equipment to bend pipes. People's ingenuity has long invented more than one way to achieve the desired result without using a pipe bender.

We use an angle grinder

In the area where it is necessary to bend the pipe using a grinder, several cross cuts are made. The smaller the bend radius, the more cuts will be needed. In most cases, three is enough. Next, the profile pipe is bent without much effort, and the cut points are sealed using welding.

If the welded areas are carefully sanded, the resulting product will look very decent . There will be no folds or significant loss of strength at the bend. But this method will not give ideal roundness, because the bend will consist of several straight sections located at an angle to each other.

Spring method

To make a spring you will need steel wire with a cross section of 2 mm. The wire is bent to the shape of the profile so that the side of each segment is several millimeters smaller than the corresponding side of the pipe profile and can move freely along its internal length.

Next, the spring is simply inserted into the pipe and bent to the required radius. To facilitate the bending procedure, the pipe section can be heated.

Note! To avoid problems with removing the spring from the cavity of the profile pipe after the bending procedure, a piece of wire should be securely attached to its nearest end.

Filling the pipe with sand

This method is striking in its simplicity and efficiency, because all the necessary materials are literally under your feet:

- We first prepare two wooden wedges that can tightly close the pipe cavity.

- We hammer the wooden wedge tightly into the end of the pipe.

- We fill the pipe with sand, previously sifted and dried.

- We drive in the second wedge.

Next, one of the ends of the pipe is fixed and bent. To facilitate the procedure, the pipe section can also be heated. At the end of the work, the wedges are removed and the sand is poured out.

Using a dense sand bed will help prevent warping by ensuring an even and strong bend.

Plain water will help

One end of the profile pipe is closed with a plug, after which water is poured into the cavity. An indispensable condition is the presence of a negative temperature sufficient to freeze the liquid. After the water freezes, the pipe will bend without any problems, and the bend will be beautiful and durable.

It is important! The method is suitable for pipes made of non-ferrous metals that are not subject to corrosion.

How to bend drywall and drywall profile

Professionals recommend using a special brand of plasterboard for the construction of semicircular structures, which is designed for these purposes - GKLA, that is, arched plasterboard sheet. This type of building material has less thickness and increased elasticity. Thanks to this, it bends very well and takes the desired shape.

The cuts are made every 1 - 5 cm. Moreover, the greater the curvature, the more often the cuts need to be made. The cuts are made, leaving only 1-3 mm to the opposite part of the drywall. In order to fix the plasterboard sheet with slots, use putty that is suitable for this material. Thanks to putty, the entire structure is more durable.

When thinking about the interior of an apartment, we often need to smooth out the corners or make rounded arches in the bays - this looks modern and stylish. However, many people starting renovations do not know how to bend drywall and its profile in order to make curved structures on the ceiling or walls. Don't forget to make the radius of the template smaller by the thickness of the sheet than the radius of the final bend.

Once the template is ready, we move on to the drywall. So, the concave side of the drywall needs to be slightly wetted with water. It is necessary for water to penetrate inside the material and soak its gypsum part. To do this, treat the entire surface of the sheet with a needle roller - this will make small punctures and allow water to penetrate inside. It is used if it is necessary to make a strongly rounded decorative element.

This method is called the “notch method”. To do this, slits are made on one side of the sheet. They can be made using a milling cutter or a sharp construction knife.

Necessary equipment

To perform work on bending a profile pipe without using a special pipe bender, you will need one of these simple devices:

- Elementary lever with a template.

- A horizontal plate with several holes in which metal stops of the appropriate diameter are arranged. The device is well suited for pipes made of soft metals, or products with a low profile height (no more than 10 mm). Filigree precision cannot be achieved here. In addition, significant physical effort may be required.

- Roller devices. One end is securely fixed in a vice, and a roller is applied to the bend, which, with appropriate physical impact, will ensure an even bend of the required radius.

- Special mandrel. The device is a kind of template made of thick plywood or wood. With some effort, the pipe can be placed on the mandrel, giving it its bending radius. The device will be useful if it is necessary to frequently perform work on bending profile pipes.

Read also: Unipolar digital hall sensor

Today, many DIYers use aluminum for almost everything. Its characteristics allow it to be used without any problems for furniture, for creating garage accessories, etc.

Tsvetprokat aluminum corner offers to purchase on the most favorable terms. This publication will describe various techniques that will make it possible to bend aluminum without damaging it. If you start bending an aluminum part mechanically, cracks may appear in the metal and the part will simply break at the bending point.

Opening arched sash windows:

When producing a window with an opening arched sash, it is difficult to match the bending radius of the frame profile and the sash. Since curved profiles cannot be reinforced, there are difficulties in operating such a window due to thermal deformations of unreinforced PVC. It is difficult to ensure reliable sealing in the unreinforced arched part. In addition, this design is much more expensive due to the use of a non-standard set of fittings. Therefore, experienced manufacturers try to make the arched parts of windows blank whenever possible.

Using a homemade rolling machine

A homemade machine can be made from everything you have at hand:

Everything, of course, depends on the dimensions of the aluminum profile itself, as well as on the required bending radius. Such homemade machines allow you to achieve very positive results, in principle, without heating the part.

Success is achieved through gradual, slow bending over a large area. As a result, local stresses do not arise in the metal. You can be sure that cracks will not appear.

However, there is an easier way. All you need is a gas burner and large pieces of wood. Initially, it should be noted that you will not get the expected result the first time. To understand the technique, it is recommended to practice cutting the profile.

Different profile systems:

Different profile systems and even different batches of the same system may have differences:

- profile geometry,

- changes in the use of PVC-S or the preparation of the mixture,

- violations of profile extrusion technology

All this significantly affects the quality of profile bending. The temperature in the production room and the profile temperature must be at least 17-18°C (the profile heats up in the room by 1°C in 1 hour). Therefore, a profile delivered in the cold season must be warmed up so that there is no stress inside the profile.

Profile bending with a gas torch

Using a gas torch, it is necessary to heat the aluminum profile exactly at the bending point and next to it. The main heat of the flame should be concentrated at the point of bending.

After the required temperature has been reached and the profile has become noticeably more plastic, a steel metal pipe of suitable diameter is applied to the bending metal. Strictly speaking, its outer diameter will be equal to the bending diameter of the aluminum profile.

It is necessary to work with thick gloves, as the metal becomes very hot. Leaning the pipe against the profile, we begin to carefully bend it. Apply jerky, soft movements (you don’t have to constantly pull the profile to bend).

We watch the place of bending. If we see a change in color, continue heating with a gas burner. The final result will be achieved much faster than using homemade rolling machines.

The video demonstrates how you can bend an aluminum profile at home:

Aluminum is a lightweight and practical material that is often used to install various structures at home. If it is necessary to obtain a bent workpiece, this is easy to do, which is facilitated by the low melting point and ductility. How aluminum profiles are bent at enterprises and at home is described in detail below.

Do-it-yourself greenhouse structures based on aluminum pipes or profiles

| 7401 | 0 | Print Click Print or CTRL+P to print the page |

Greenhouses made of aluminum are especially popular. Greenhouse structures have become widespread in recent years. Despite the significant amount of modern materials for the manufacture of such structures, aluminum greenhouses are especially popular.

A modern greenhouse made of aluminum profiles compares favorably with similar structures with a large number of advantages. It is precisely this kind of greenhouse or greenhouse that can be seen on many personal plots in our country, and the ability to assemble a frame based on an aluminum pipe at home and with your own hands makes them very promising.

The concrete version of the foundation depends on the dimensions of the greenhouse structure and can be shallow or shallow

general characteristics

The modern market for frame greenhouse structures offers gardeners and summer residents in abundance structures made on the basis of a frame made of galvanized or painted steel and profiles, as well as those made using aluminum profiles or pipes. Aluminum profiles for modern greenhouses have good quality characteristics.

A high-quality greenhouse should not only be characterized by maximum functionality, but also have a completely modern and aesthetic appearance.

Greenhouses made of high-quality aluminum are a stylish element that can decorate a modern country estate. This design is characterized not only by the variety of shapes of the greenhouse frame, but also by the covering material.

In addition, greenhouses with an aluminum frame have design installation features and operational characteristics. Most aluminum frames based on pipes are easy to assemble with your own hands.

An aluminum country greenhouse can have several frame shapes:

- with the installation of a pitched roof, which is easy to install with your own hands and has an insufficient degree of illumination;

- with the arrangement of a gable roof, which is characterized by practicality and versatility, as well as the ability to use the lightest possible pipes;

- arched type of aluminum greenhouse, which has increased resistance to snow loads and a good degree of illumination;

- multifaceted aluminum greenhouses made of pipes, very popular among gardeners;

- luxury aluminum greenhouses;

- aluminum greenhouses with domed roof.

The most popular aluminum structures are arched and gable greenhouses

In addition to these forms, there are other, but less common options. The most popular aluminum structures are arched and gable, the height of which depends on the type of vegetable, berry or flower crops grown. The shape of an aluminum greenhouse affects the appearance and aesthetics of the entire garden plot, which should be taken into account when installing it yourself.

Advantages and disadvantages

Greenhouse structures made of aluminum pipes have a large number of obvious advantages, the most important of which are the following:

- an aluminum greenhouse can be installed as easily as possible with your own hands and can be made at home;

- the low weight of the aluminum pipe facilitates all stages of installation;

- aluminum profile type belongs to the category of ergonomic structures that can withstand fairly heavy loads, including high temperatures, high humidity and severe frost;

- aluminum structures allow the use of not only polycarbonate sheets, but also ordinary glass as a coating;

- The aluminum type of greenhouse can be used as a glazed winter garden, since the pipes that such a greenhouse has are resistant to rust, and the glass retains heat well and has excellent light transmittance.

In addition, the high quality and characteristics of the aluminum pipe allow this design to be used for several decades, and models from the “Lux” series have maximum durability. You may also be interested in an article about the advantages and disadvantages of glass and aluminum greenhouses.

To bend an aluminum profile correctly and efficiently, you will need to use a ruler, bending machine, profile pipe, grinder, marker and welding

Tools, materials and drawings

Setting up a greenhouse at home involves using the following tools and materials:

- aluminum pipes in the quantity required for DIY installation;

- covering material, which can be represented by sheets of translucent polycarbonate, traditional glass or polyethylene;

- galvanized fasteners;

- cement mixture or wooden beams treated with special antiseptics;

- grinder with a cutting wheel;

- a wrench used at home to secure an aluminum profile using hex bolts;

- the execution of a concrete base requires the use of a concrete mixer and containers;

- a tool suitable for cutting the coating material;

- drill for drilling holes.

Work specifics

There is only one difficulty when deforming an aluminum workpiece. Although the material is very plastic, cracks may appear at the bend, and the profile itself may not bend as smoothly as we would like. But this does not always happen, and more often due to a person’s lack of experience. If you use modern equipment (which is available not only for large enterprises), the problem will not even manifest itself.

For work at home, you will not need the cheapest equipment. It is recommended to purchase it only if bending aluminum is part of regularly performed work. Now - about methods of bending a profile with and without machines.

How to bend drywall: using different methods

At one time, gypsum board revolutionized the interior decoration of premises, significantly simplifying the work and making it easier.

Some people, when they see intricate figures on the ceiling or in partitions, ask the question: “Is there a machine for bending profiles for drywall?” Such a device does not exist in nature, but, nevertheless, both sheets and guides are successfully bent and the most intricate elements are obtained from them.

This is how you can bend drywall for arches

Equipment classification

It is possible to obtain a curved aluminum part with the most accurate required radius and minimal material loss by using roll forming devices. Conventionally, they are divided into 2 groups depending on their dimensions:

- on a fixed frame (large);

- portable (small).

Another classification criterion is the fold itself. So, the machine can bend the workpiece:

- along a given radius;

- at a given or right angle.

Read more about representatives of certain groups below.

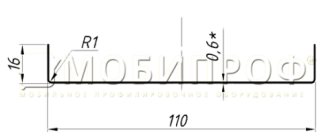

Bending process

To set up a roll forming machine, regardless of quantity, 2-3 profiles are usually required. Wall thickness, shelf life of the aluminum profile, the state of its delivery and the geometric characteristics of the profile - all these indicators affect the possibility of bending the profile with a particular radius and the subsequent quality of the arc. The minimum radius also depends on the profile width. For a quality system profile with a width of 45 to 50 mm, a minimum radius of 150 to 175 mm can be achieved. The rollers must slide freely along the profile flanges, otherwise the profile may curl; this fact is taken into account when installing the clamp. The surface of the rollers must be clean to avoid scoring and scratches on the profile being processed. Due to the fact that the profile blank is coated with oil, along with the lubricant, dust and grains of sand fall on the walls of the rollers, which scratch the surface of the profile. Also, during bending of an unpainted profile, particles of aluminum oxide can be torn off by the force of friction from the cladding layer of aluminum (a thin layer of pure aluminum), which are smeared over the deformed surface and scratch the walls of the profile and rollers. Therefore, during the bending process, periodically wipe the rollers with a clean rag and remove accumulated dirt from them. The main indicator of the quality of a bent profile is the preservation of a constant cross-section, the absence of metal corrugations on the inner edge of the profile, the parallelism of the front walls of the profile, undeformed grooves for installing glazing beads and seals.

Stationary equipment

An example of a large machine whose task is to bend an aluminum profile along a radius is a profile bending machine. The main working parts of the equipment are stationary and movable rollers, the geometry of which follows the contour of the workpiece in cross section. Based on the number of videos, they are divided into groups:

Read also: Nozzle for a stove for heating a house

The first two rollers rotate in the same direction and are on the same line, feeding the profile to the third roller, rotating in the opposite direction. By adjusting the distance between two co-directed elements, the master changes the bend radius of the aluminum workpiece. If a very small radius is required, several passes are made through the rollers.

Four-roller machines are used for bending profiles of complex shapes (circles, spirals, etc.). Two rollers are also stationary and co-directed, while the other two bend the non-standard product. The radius can be adjusted with your own hands, or on a computer if there is electronic control.

The position of the rollers may vary on machines. It happens:

The former are suitable for elements with a large cross-section (up to 300 mm in height), the latter - for small workpieces (rolled products) or particularly complex materials (window profiles). Now a few words about angle bending devices.

What is a metal wedge dowel?

This fastener is commonly called a metal wedge anchor. It is made from metal. The word "anchor" is translated as "anchor".

The metal dowel for drywall has a different installation technology. The moving part of the fastener is driven in with a hammer, due to which the dowel is wedged into the surface.

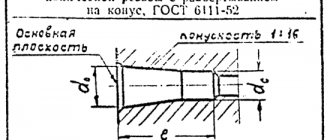

According to GOST, 2 types of metal dowels for drywall are produced: 6/40 and 6/60, where 6 is the diameter in mm, 40(60) is the length in mm. Wedge anchors are available for sale in packages of 100 and 200 pcs.

How to hammer a metal dowel wedge quickly with a hammer drill, watch the video.

Video:

Features of using a wedge anchor

The wedge anchor is made of galvanized steel or stainless steel. Carbon steel is used and coated with white or yellow zinc. On the head of the anchor there is a manufacturer's mark indicating the density of the metal used.

The wedge anchor is produced in the form of a metal rod. There is a locking cap at one end, and a wedge-shaped spacer end at the other. When mounting, an anchor is placed in the hole made and the moving part is driven in with a hammer. In this case, the wedges diverge in different directions, thereby fixing the fastening element in the ceiling. The wedge anchor is particularly reliable when attached to the base.

Factors affecting structural strength

In order for the wedge anchor to have a long shelf life and also maintain strength, there are some factors that influence these indicators:

- The wedge anchor is driven into the base, which has no voids. This ensures fastening strength.

- With high humidity, the concrete base will constantly absorb moisture, which can cause premature corrosion of the metal.

- If there is constant pressure (movement, vibration) on the base into which the wedge anchor is mounted, the wedge will soon break out.

- If there is a moving part left above the surface - the rod, this means that the anchor has not fully opened. However, the service life is limited.

- Chemical solutions should not be allowed to come into contact with the fasteners. They will destroy the fastener.

We advise you to study - How to choose the right built-in electric oven

Comparative table with which you can determine the strength of the anchor wedge:

| Name | 6/40 | 6/60 |

| Diameter of wedge anchor, mm. | 6 | 6 |

| Wedge anchor length, mm. | 40 | 60 |

| Max thickness of fixed material, mm. | 5 | 8 |

| Drill diameter for hole, mm. | 6 | 6 |

| Min depth of hole for anchor, mm. | 45 | 65 |

| Pull-out force minKN from concrete B25 | 3.60 | 5 |

| Weight 1000 pcs, kg. | 10.70 | 16.05 |

Separately, it should be noted that for fire safety reasons, all suspended structures must be secured with metal wedge anchors.

Portable equipment

An example of such a unit is the ALS profile bending machine. Its task is to bend strips and metal profiles of complex shapes up to 160 mm wide and up to 2 mm thick. It is most often used for bending wide profiles (for example, when installing outdoor advertising - volumetric letters), but it is also suitable for small ones.

Distinctive features of the ALS machine:

- there is no need to attach to a workbench - the built-in support is sufficient;

- ease of transportation due to small dimensions and weight;

- the action takes one second.

The most popular devices of this format are “ALS-A 90” and “ALS-A 60”. The first bend the workpiece by 90 degrees, the second by 60. The cost of “ALS” is about 6,000 rubles.

The correct way to bend a profile for a plasterboard product

Therefore, the question “how to bend a profile?” remains very relevant. If everything is done correctly, then in the end you can get exactly what you wanted. In order for the procedure for giving the elements of the metal frame the required shape to go correctly, you must adhere to some rules and recommendations, because only in such a situation will you be satisfied with the end result: Drywall has already become an integral part of a modern renovation. From this finishing material you can create various complex shaped elements for walls and ceilings, as well as assemble beautiful partitions.

And everywhere you will need to bend profiles, which are an integral part of the frame necessary for installing plasterboard sheets.

- a cut at a right angle of 90 degrees is made on both side parts of the profile. The base of the element remains intact, which allows the stiffeners to be preserved intact. This method is great for making arches, semicircular elements or a circle;

Note! Self-tapping screws are installed whenever a bend needs to be made. This will give the final design more fluidity.

Profile bending at home

Surely those who regularly carry out repairs have wondered how to bend an aluminum profile without expensive equipment. Below are several ways to do the job yourself.

Method 1. Vise and bars

For open profiles (for example, U-shaped), it will be necessary to prevent the loss of stability of the walls. To do this, you need to use a block-liner, preferably metal, that fits exactly into the groove of the groove. The sequence of actions of the wizard is as follows:

- put the liner inside the profile;

- clamp the workpiece in a vice so that the edges of the liner and the lips of the vice coincide;

- bend the profile slightly;

- Unclench the vice and extend the profile half a millimeter;

- repeat the two steps described above until the required bent profile is obtained.

The method is simple, but far from accurate - it is difficult to get an even product the first time, but an experienced craftsman will be able to correct the geometry.

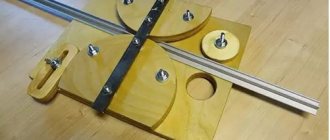

Method 2. Homemade videos

The simplest way to create an analogue of a roll forming machine involves the following steps:

- buy 2-4 rollers of small diameter with a width slightly exceeding the height of the blank profile;

- fix the product on a flat horizontal surface so that they can rotate freely, and the distance between them is sufficient for the passage of the profile.

That's all. To bend the workpiece into a circle, two rollers will be enough; to obtain a product of a certain radius - at least three, and it is better to make one of them adjustable, by analogy with profile bending machines. A metal product is inserted between the rollers and carefully scrolled. The user controls the applied force, the progress of work and holds the workpiece.

The DIY methods described above are an alternative to expensive methods of working with equipment. If it is possible, and bending of metal blanks is carried out regularly, you should think about purchasing at least a compact device at a price of 10 thousand rubles. If you can give recommendations on ways to bend aluminum profiles of various shapes, please share the information in the discussion for the article.

Drywall figures

How to bend a metal profile

The UD profile has smooth sides

- If you want to understand how to bend drywall with your own hands, then first of all you need to learn how to bend metal profiles on which circles and waves from gypsum plasterboard will be mounted . First of all, you should pay attention that for figures in frames, mainly two types of guides are used, these are UD and UW, where the sides are not profiled and they are quite easy to cut. But this does not mean at all that the CD or CW type cannot be used for this purpose - in practice it is quite possible, it’s just technically more difficult.

The principle of bending a metal profile

- So, how do you bend a metal L-shaped support to make a circle or a wavy line? Yes, it’s very simple and there is even an unwritten instruction about this - you need to trim the shelves on both sides to the very base. The cuts themselves must be at the same distance so that the bend is smooth, without sudden changes.

Installation of an arch, 90 cm wide

- Let's say you need to bend a circle with a diameter of no more than one meter or a narrow arch with a sharp bend (see also how to make an arch from plasterboard), which means that the cuts will be more frequent and in this situation 5 cm is quite acceptable. The cuts must be made strictly opposite friend and monitor the uniformity of the step. You can get additional information on this issue by watching the video clip on this page.

The profile was bent to one side, cutting off the shelf and sole

Advice. The profile does not always bend with the sole inward; sometimes you need it to be on the outside, then cut each petal into a cone so that they do not pile up on each other. And if you need a bend to the side, then cut the side on the convex side and the sole, as in the photo above.

How to wet bend drywall

Before soaking, drywall is treated with a spiked roller

- Let's look at how to bend drywall using the wet method, that is, by soaking it with rags soaked in water. To do this, you need to cut the panel to the required size and treat the supposed convex side with a spiked roller.

- The gypsum board pierced with spikes is covered on both sides with wet rags and left overnight. After this, the material can be used to bend the shapes on a metal frame for drywall. But this method takes a lot of time and this, of course, increases the price of the issue, because the master spends the whole day on the process instead of several hours.

How to dry bend drywall

Curved plasterboard ceilings

- Pay attention to the photo above, namely, to the lower tiers of the ceiling - the vertical strips were neither soaked nor cut during installation, since it is possible to bend drywall of such a width and into such a large circle without any preparation. Special processing requires steeper bends, when, when tensioned, the paper on the material will burst on the convex side.

A classic example of bending a plasterboard sheet

- Any gypsum plasterboard (wall, moisture-resistant, ceiling, fire-resistant) can be formed in the same way as bending a profile for drywall, that is, making cuts in the area of greatest resistance. To do this, the required piece is cut out and uniform cuts are made on the side of the intended convexity, and the steeper the bend, the finer the pitch of the cut strips.

- The distance for cuts on paper should be determined by analogy with the profile on which the figure will be mounted. If the UW or UD shelves turn out to be 7 cm long petals, then the drywall should be cut in the same step. But this does not mean at all that whole and broken parts of two materials should coincide with each other, especially when cutting frequently.

Advice. If you need to bend the plasterboard strip to cover the lower horizontal part of the arch, you should not install it entirely. In such cases, it is very convenient to install gypsum boards in pieces of 30-40 cm.

How to dry bend drywall without seams

Drywall can be bent with cuts inward

- How to bend drywall so that the cuts are on the inside and the convex side is smooth? If you need a figure made in this particular way, then you will spend a little more time on it than on regular trimming, but only a little.

- The marking occurs in exactly the same way as with a conventional section, but the slurry, that is, the body of the sheet (the filler between the paper) will not allow the strip to be bent in the desired direction, but only in the opposite direction. Therefore, we need to use the same cone method as when bending the metal profile inward.

- Each cut needs to be widened by making grooves there, and the wider the cut, the steeper the bend can be allowed. It is very convenient to make such furrows with a grinder, but you can only do this on the street, but in an apartment you will have to make do with a knife.