CONVEYOR (English сonveyer, from сonvey - to advance, transport) (conveyor), a continuous machine used for moving bulk, lumpy, piece and other cargo. K. is widely used in areas of internal or external transport, as part of reloading devices (for example, bridge loaders, spreaders); in loading and unloading complexes together with other machines; for moving cargo-products in production line by position, performing in some cases the functions of storage units (mobile warehouses) and distributors of products according to other technological processes. lines.

Conveyor and its history

When considering what a conveyor is, you should pay attention to its history. Today, the meaning of the word conveyor may differ slightly, but in most cases it means a continuous machine that is designed to transport various goods. Recently, the base has been used as a basis for installing parts at the time of processing.

Conveyors have become most widespread recently due to the fact that production lines often resemble areas with several processing zones in continuous production.

If we consider the history of the use of such a mechanism, we note that it appeared quite a long time ago. An example is the following:

- Continuous water-lifting devices were used for a long period in ancient Egypt to transport liquids.

- The first screw devices in their classical form began to appear in the 16th century. They were installed in a room where flour-grinding production was being established.

- In the second half of the 19th century, devices of this type began to be installed to ensure the transportation of heavy loads.

- In the period from 1869 to 1914, the main types of conveyors were created, most of which are only being improved today.

The proliferation of such equipment can be associated primarily with the fact that it significantly increases labor productivity and increases the efficiency of operations.

Henry Ford - inventor of the assembly line?

Statement:

Henry Ford invented the assembly line.

The surname of Henry Ford is forever entrenched in human history. First of all, thanks to the brand of the same name: Ford was famous for its desire to make a cheap car accessible to the masses, which it really achieved. Also, his name went down in history in the form of the economic term “Fordism”. The essence of Fordism is the new organization of continuous production, which became possible with the help of the assembly line. So history has included the conveyor belt itself among Ford's inventions.

Why this is not true:

Ford did not invent the assembly line, but was the first to organize continuous production.

Before this, Ford had already assembled his first car, but he did it manually, like all automakers of that time. That is why the car was a piece goods and extremely expensive, and vehicle repair turned into a technical puzzle. The automotive industry had to be brought under uniform standards.

The first step towards conveyor production was the assembly line, which appeared in 1901 at the Oldsmobile company, founded by Ransom Olds, who can be called the inventor of the conveyor in the modern sense. Parts and components of the future car were moved on special carts from one work point to another. The prototype of the conveyor increased the production of cars from 400 to 5,000 units per year. Henry Ford understood the potential of Olds' invention and put all his resources to work around it, adapting and improving the system he had developed.

In 1903, Ford, while studying flow production technology, visited the plant, where he observed how animal carcasses, moving under the influence of gravity, fell under the knives of cutters. By adding belts to the assembly line, Ford introduced improved technology into its factories. Thus, Ford, obsessed with the idea of making his cars accessible, successfully used the experience accumulated before him. As a result, the Ford Model T cost approximately $400 and was produced in less than 2 hours. This made Henry Ford a millionaire and a recognized engineering genius of the 20th century, but he did not invent the assembly line itself.

images via Shutterstock

www.lookatme.ru

Conveyor device

The simplicity of the operating principle of the device in question largely determines its distribution. In most cases, the main purpose is to move material or products from one point to another. Moreover, in some cases it is possible to automate the entire process, which is why the device is popular. The general structure of conveyors is characterized by the following features:

- The engine serves as a drive. The conveyor motor is practically no different from the conventional version, except for how the drive is connected.

- Another important design element is the drive. It can be represented by a chain or a combination of gears, it all depends on the specific case.

- The working surface is designed for direct placement of the load. It is often represented by tape or special containers, it all depends on the area of application and many other points.

The classic principle of operation is to transmit rotation from the motor to the working surface through an intermediate element. There are also more complex mechanisms that are used in certain cases.

Varieties

Conveyor belts come in many types. They are usually divided by area of application, materials of manufacture and shape.

Let's start with the material and shape, they are:

rubber-fabric

Most conveyor belts made from rubber compounds include two types of design features. Most often, rubber-fabric tape is used in industry; it contains textile cord. The cord itself is made from a small number of pads, including cotton fabric. The number of such layers can include up to 12 pieces.

rubber rope

Unlike products with fabric cord, it has good strength. This type transports coal, ore, as well as salt, clay and many other types of mineral rocks.

chevron

These belts are usually used to deliver loads at an angle of no more than 45 degrees. The operational efficiency of this type is achieved due to the fact that a chevron is installed on their surface, which resists the spilling of cargo.

Conveyor belts are divided into six types according to application:

- general purpose

- mine type

- heat resistant

- frost-resistant

- oil and petrol resistant

- food

General purpose

It is used when several types of cargo need to be transported in production. This type of conveyor belt can be made from three grades of rubber, and have differences in the number and type of layers.

Mine type

This type of tape includes ordinary fabric and rubber. Such materials are used at great depths, where conditions are harsh. They are also constantly loaded with various items.

Heat resistant

Heat-resistant tape is most often used in the metallurgical industry. This can be explained by the fact that in this area it is necessary to use products that can withstand high temperatures.

Frost-resistant

Frost-resistant conveyor belt is necessary for working at low temperatures, up to - 60°C. The product itself can be divided into several operating modes: light, medium, heavy.

Oil and petrol resistant

MBS tape is resistant to working with various oils and fuels. It is intended for the chemical industry and is used in an aggressive environment.

Conveyor classification

As previously noted, there are quite a large number of different devices designed for transporting goods. Conveyors are classified in most cases according to their design characteristics. The most widely used versions are:

- Tape devices are more common than others due to their versatility in use and relatively low cost. Their purpose is to transport lump and other materials over a fairly long distance. The key feature is that the working surface is represented by a stretched multi-layer tape, on which various loads are placed. Today, due to the huge number of positive signs, this group is extremely common, but is not considered a universal option.

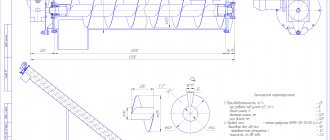

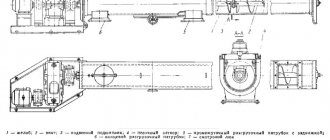

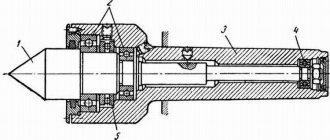

- Screw devices are based on the principle of using an Archimedean screw and are often installed to transport bulk materials over a fairly long distance. This group is also divided into several classes, the main distinguishing feature being the type of auger installed. The screw conveyor is also very common due to its high efficiency and relatively low cost.

- The inertial group of equipment is designed to move bulk and, in some cases, piece goods over a short distance. In this case, the line of movement can be exclusively horizontal or inclined. The principle of operation is to create vibration, due to which lightweight materials shift their position.

- The plate device is most often installed in production shops, since the main working surface can withstand significant impact, for example, high temperature. The purpose is to transport sharp, hot or abrasive parts. Such an automobile conveyor can overcome fairly sharp slopes, since special ribs are often created on the surface to ensure reliable fixation. However, this proposal has one significant drawback - the movement speed is too low.

- Scraper conveyors are characterized by the fact that the movement of material is ensured by dragging it along a special chute. This type of design is widely used in the mining and manufacturing industries. Installation of this design option is not possible if the product loses its attractive appearance during drawing. An advantage can be called fairly high efficiency in use, but there is also a significant drawback, which is associated with the complexity of the design and the inability to use it in the case of transporting fragile goods.

- Elevators are a separate group of conveyors, the purpose of which is to continuously transport goods. The device is often used for vertical movement of materials. This type of bucket conveyor is widely used in agriculture and the mining industry; it is a rather complex device that requires timely and professional maintenance.

The above information indicates that there are simply a huge number of different conveyor options, the choice is made depending on the application and other factors.

Criteria for selecting a conveyor chain

Effective practical use of a conveyor chain is only possible if it is correctly selected taking into account the most important operational parameters. The first selection criterion is the load level. It is determined based on the load being moved and the speed of the conveyor.

The second important selection parameter is the length of the chain, as well as the dimensions of the individual links and their number. It is obvious that these characteristics directly affect the operation of the entire chain conveyor. Do not forget about such criteria as material of manufacture, type of fastening of scrapers, buckets or other devices for transporting cargo

When purchasing a conveyor chain, the cost of manufacturing is also important, so in this matter it is advisable to cooperate directly with the manufacturer

Application and operating principle of belt conveyor

In the modern world, belt conveyors are the most widespread. Their purpose is to move piece parts or bulk materials over a fairly large distance. The design features of this version are as follows:

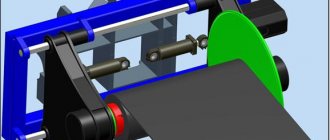

- The main part is represented by a continuous movement belt that goes around the guide drums. It is worth considering that it has quite high flexibility.

- To reduce the degree of belt deflection, special rollers are installed. They are located with a certain step relative to each other.

- The main element is the electric motor. It transmits rotation to the drive drum through a gearbox.

The peculiarity of the device is that the tape is constantly in tension. Otherwise, the movement will not be transmitted. The industrial use of conveyors is due to the fact that they are easy to operate, are characterized by increased versatility in use, and can also be serviced with your own hands if necessary.

Types of Belt Conveyors

There are quite a large number of different options for belt type conveyors. When choosing conveyors, attention is paid to a variety of parameters. The following types of conveyors are installed:

- Direct.

- Gutters.

- Inclined.

- Mixed type.

- Rotary.

- Telescopic.

When considering the types of belt conveyors, attention is also paid to the power of the installed motor and many other parameters. Some types of conveyors are not widely used due to the complexity of their design.

Conveyors are straight

The most widely used version is the direct type. There are models of various performance levels on sale. Among the features we note the following:

- A closed tape is used as a base.

- The working and idle branches are supported by special rollers. This ensures the required degree of tension.

- Drums are installed as a drive.

There are models that have a productivity of 20 thousand t/h. Moreover, the length can reach 10 km, which can be called a very impressive indicator. This universal type design is installed in many industrial premises.

Troughed Conveyors

This type of conveyor is characterized by the fact that the transport belt is located on a grooved roller support, which is made using a steel or aluminum profile.

The scope of application of the device is quite extensive. Examples include the engineering field, construction, energy, woodworking industry, coal mining and others. Due to the deflection that forms in the central part, the material is fixed with greater reliability.

Installing Docker

Docker is a platform for running applications in "containers"; The container includes all the necessary dependencies and ensures that the application will work the same regardless of the underlying operating system - all you need to do is install docker on your system, and run a few commands.

For Ubuntu you need to install some prerequisites:

sudo apt install apt-transport-https ca-certificates curl software-properties-common

Then add the GPG key to Docker:

curl -fsSL https://download.docker.com/linux/ubuntu/gpg | sudo apt-key add -

And add the repo itself:

sudo add-apt-repository "deb [arch=amd64] https://download.docker.com/linux/ubuntu bionic stable"

Update your sources:

apt update

And finally install Docker from apt:

sudo apt install docker-ce

Your system should now be running Docker, which you can check using systemctl.

Inclined conveyors

A distinctive feature of this version is the location of the transport belt at an angle to the horizontal. The features are as follows:

- The operating principle of the design is practically unchanged.

- Distinctive features are the frame, which allows you to adjust the angle of inclination.

- Most models are characterized by the presence of a certain limitation regarding the angle of inclination allowed during transportation. This is due to the fact that there are no elements on the surface of the tape that the products could catch on.

Inclined products are characterized by versatility in use. It can be installed indoors and outdoors, it all depends on the type of material used in manufacturing.

Who invented the conveyor anyway? - Do you know that? — Interesting facts for you.

Did you know that Henry Ford did not invent the conveyor belt at all and was not even the first to use it in the automotive industry. In general, inventions that resemble a conveyor belt have been used by mankind since the times of Ancient Egypt. In 1901, the conveyor belt was first used for the production of cars. And Ransom Eli Olds, the founder of the Oldsmobile manufacturing company, did it. In 1901, Olds pioneered the use of an assembly line in his factory. This allowed him to increase car production by more than 5 times in one year.

Naturally, Henry Ford was terribly dissatisfied with this turn of affairs, since with such a competitive advantage Olds could not even think about getting around him. The best minds working for Ford were thrown into studying Olds' technology and improving it. As a result, belts were added to Olds' assembly line, and the technology was introduced into Ford plants. Apparently it is Ford who is so often remembered in connection with the conveyor belt, because he used it wherever he could. If Olds used innovation only when assembling the car, then Ford used the conveyor at intermediate stages - to assemble individual components.

Knowing this fact will help you when taking quizzes about various prominent personalities.

Sources: Wikipedia (Ransom E. Olds, Oldsmobile); https://www.ideafinder.com.

Next

Kim, Lee, Park, Choi and Chung

Previous

Superstitions associated with flying

Comments are closed.

znaeteli.ru

Mixed conveyors

In some cases, complex configurations of conveyor lines are required that can transport material in straight and inclined lines. The following versions have become quite widespread:

- L-shaped.

- Z-shaped.

The second type of device is considered the most complex device and is installed in a limited space.

Recently, manufacturers have been creating sectional devices that can be assembled into a single system for transporting material from one point to another

Installing Jenkins

Jenkin binaries are available for several operating systems, but usually not from the default package managers. If you are using Ubuntu, you can download and install it using the following few commands:

wget -q -O - https://pkg.jenkins.io/debian/jenkins.io.key | sudo apt-key add - sudo sh -c 'echo deb https://pkg.jenkins.io/debian-stable binary/ > /etc/apt/sources.list.d/jenkins.list' sudo apt-get update sudo apt-get install jenkins

To make the platform independent, we will run Jenkins using Docker, which recommends Jenkins anyway.

Rotary conveyors

If it is not possible to use trolley platforms, and the room has a complex layout, a rotary structure is often installed. Among the features of this option, we note the following:

- A distinctive feature is the movement of segments along guides.

- The rotary version is often used as an additional element when connecting straight sections.

Such a mechanism is characterized by increased complexity, as it is designed to redirect the path of cargo movement.

Telescopic conveyors

In sea and river ports you can often find telescopic conveyors. They have become very widespread due to the possibility of changing the angle of inclination and length of the device. The key points of this proposal are:

- The loading and unloading efficiency is high. That is why the device is installed when it is necessary to speed up the loading and unloading procedure.

- Relatively high degree of mobility. It is often necessary to change the position of the transport element, for which wheels are attached to it.

- The low weight of the device greatly simplifies the task of transportation. For this purpose, a certain metal is used, the strength is increased due to the stiffening rib.

Telescopic devices are very common today in a wide variety of industries.

Selection order

Such a wide variety means that quite a lot of difficulties arise with the direct selection of the most suitable mechanism for specific operating conditions. The main criteria are the following:

- Required length of transportation route.

- Engine power.

- Type of cargo being moved.

- Terms of Use.

As a rule, as the length of the transport belt increases, a more powerful motor is installed. It is worth considering that some operate on 220V, others 380V. The scope of application determines what materials are used in the manufacture of the main part. An example is the use of steel with increased corrosion resistance.