SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

A belt grinder is a tabletop machine that is commonly used for grinding various flat surfaces. A device of this type has many advantages and is distinguished by its versatility, which makes it very popular among home craftsmen. The cost of such drive devices is quite high, so it is recommended to approach the choice of a grinder with the utmost seriousness.

Belt grinder - a device that is used for sharpening and grinding

Grinder: what is it and for what purposes is it used

This term refers to a grinding device used for processing metal (and other) parts. Machines that belong to this category are stationary. Their design includes an electric drive, due to which the working element is set in motion. This device is most often used for the following types of work:

Most often, the grinder is used for metal processing, but can also be used for grinding wood and glass.

- grinding;

- sharpening;

- rust removal;

- elimination of burrs.

Many home craftsmen use similar equipment to sharpen knives. The efficiency of this device is very high, so for such a simple task you can take an inexpensive model of the unit. Many experts do not advise buying a machine of this type to perform one task, since it is extremely unprofitable. Before purchasing a specific model, it is recommended to study reviews about it. Grinders located in the lower price segment may be ineffective, so it is not recommended to save much on such a purchase.

Using a grinder, you can bring a metal surface to the desired state: polish it, eliminate various defects, and also remove unnecessary sharp edges. The cost of such devices averages 17 thousand rubles, which is quite expensive. As a result, many people decide to assemble such a device with their own hands. The design of a belt grinder is very similar to a manual sander. The drive, which is a key element of the device, drives a pulley, which is equipped with an abrasive belt.

What else can this type of machine be used for? In addition to processing metal cutting tools, such a unit can be used to grind products made from other materials. For example, it is often used to process parts made of stone and glass. If desired, you can use a grinder to smooth the edge of glass or sand wood.

The device is suitable for sharpening, grinding, removing rust and burrs

This tabletop machine allows you to remove a layer of rust, paint or varnish, which is also considered a very useful property. In addition, you can do it yourself. A drawing of a homemade grinder can be found on any specialized forum. Such a machine is the most effective solution if there is a need to grind a metal pipe, align the edges of parts, and also sharpen them.

Problems that arise when sharpening claws

Learning to use an electric grinder takes some time, and the dog may have its own characteristics:

- You will have to accustom her to the sound if she is afraid of it. Reward your pet every time, creating an association of sound with a reward.

- The grinder heats up the paw, which sometimes scares the dog. When you use an electric nail clipper, take your time and give your animal a rest. Over time, the pet will get used to it. You can also do a little work on each claw to keep the heat to a minimum.

- If your grinder comes with different sized stones and sanding belts, as well as different holes in the attachment, then you'll have to experiment to find a combination that works for you.

Belt grinder: main advantages and disadvantages

Any equipment used in home or professional workshops has its pros and cons. Such machines are also no exception to the rule. The first and perhaps most significant advantage of the grinder is its versatility. Some models can be used for a large number of tasks, for example, like the grinder from Chapai.

Another advantage of such equipment is a consequence of its design. The point is that during grinding the working area does not overheat. An increase in temperature is a drawback common to most grinding units. Moderate heating is achieved due to the dimensions of the working element (pulley). The dimensions of the circle contribute to its cooling when moving outside the operating point.

All surfaces of such a tabletop machine are polished, which is also considered a serious advantage. This characteristic makes its operation as simple and convenient as possible. Belt grinders have a smooth operation, which allows you to evenly process metal parts and products made from other materials.

The main advantage of a belt grinder is its versatility

Industrially manufactured equipment is distinguished by high precision in the location of the rollers. Due to this, the likelihood of distortion of the abrasive belt as the pulley moves around its axis is reduced.

The downside of any factory grinder, of course, is its cost, which is far from affordable. However, today it is possible to purchase a prefabricated kit, which includes all the necessary parts (except the engine). One of the most popular sets is the Mastak belt grinder, the price of which is only 7 thousand rubles.

And finally, it is worth noting the special design of the pressure pad. Tabletop machines of this type are designed for processing parts that differ not only in material, but also in shape.

Is the purchase worth the money?

Everything here is very individual. You will never know the answer without trying. Working with a mechanical nail clipper is more familiar and faster, but its disadvantages outweigh its advantages. Therefore, many livestock breeders like the grinder much more. If you doubt the advisability of a purchase, sign up your pet at a grooming salon and watch how the treatment process takes place.

What types of grinders are on sale?

Grinding devices equipped with a drive are widespread on the modern market. The range of different models is quite wide. They differ from each other in their design, power, and cost. When choosing a specific model, you need to pay attention to these criteria.

Belt grinders are available for industrial use and for home use.

It is also worth considering the operational affiliation of such units. Some of them are used for highly complex work that is not possible to perform with manual grinding equipment.

Simpler options are ideal for sharpening knives. A grinder for this purpose can be purchased in an online store, which is very convenient. Purchasing such equipment on the Internet also has one disadvantage - the impossibility of consulting with the seller. Thus, depending on the operational accessory, the units are distinguished:

- industrial;

- homemade.

All devices of this type have a drive mechanism. However, drive power may vary. This is another criterion by which belt grinders are differentiated. It is also worth noting that the belt equipped with abrasive material can have different lengths. The width of this element also varies.

The units differ in design, power, cost

When choosing a specific device, you should pay attention to its brand. The most popular brands combine reasonable prices and good quality. The tape grinders “Levsha” and “Mustak” have the largest number of positive reviews.

The number of revolutions is a characteristic that affects the speed of movement of the abrasive belt. The lower this parameter, the lower the efficiency of the device. During operation, this indicator often needs to be reduced to eliminate the possibility of overheating of the belt, as well as the workpiece being processed.

How to do it yourself:

It is almost impossible to make a good grinder with your own hands, capable of grinding a smoking mixture of herbs or tobacco, without turning skills.

Let's consider the option of purchasing devices that can replace the grinder:

The most common garlic cutter (garlic chopper) can be an excellent replacement; it can be purchased at any hardware store for a symbolic 30-40 rubles.

Another device is a pepper grinder, but it is a little less convenient, because it will be impossible to get the dust remaining in it, and its price is comparatively higher.

Now let's look at homemade options:

The simplest grinder you can make is a grinder card. It is enough to cut a blank from a sheet of stainless steel, the size of a credit card. Then take a drill, an F3 drill and mark 0.5 cm between each hole, make 4-5 rows, 5-7 holes each.

Another option could be a wooden grinder; you can use a round wooden box as a base. After cutting off the heads of the nails, hammer them along the diameter in several rows (depending on the size of the box) on both sides. The main thing is not to make the distance between the rows of nails too small, otherwise cutting tobacco will be very difficult.

Just as you can use a matryoshka doll as a base, in this case the nails will be driven into wooden blanks with a diameter the size of the inside of the doll. After which the blanks should be secured inside the nesting doll itself.

What is a grinder: design features of the unit

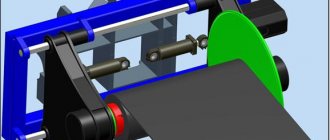

This machine has a simple device. The configuration may vary depending on the model, but the basic design elements remain the same. The simplicity of such units is the main reason that they are often performed independently using improvised means. At home, such a unit can be made using a conventional electric motor from an old washing machine. A standard grinder includes the following structural elements (in addition to the engine):

- frame;

- leading roller;

- mechanism for tensioning the abrasive belt;

- pressure pad;

- back stop.

A standard grinder consists of a device for tensioning the belt, rollers, frame, stop and pressure pad

The last detail is very important, as it eliminates the possibility of belt rupture, which can occur under the influence of excessive pressure during processing of the workpiece. Photos of grinders allow you to visually evaluate their simplicity and advantages, as well as quickly understand the design of such units.

The simplest versions of such equipment include only one drive roller in their structure. Professional models, which can be found in small industries, may have 2 or 3 rollers. In this case, a certain pattern can be traced: the more rollers the device has, the longer its abrasive belt.

The length of the tape is an important criterion, since the service life of this consumable depends on it. Short tapes need to be changed frequently, which is not very convenient. In turn, the use of a longer consumable allows not only to reduce the frequency of friction, which affects the shelf life, but also to reduce overheating. In any case, this indicator is selected depending on the operational purpose of the device. If you rarely use the device for sharpening knives, axes and scissors, there is no need for a long belt.

Such equipment is indispensable for knife makers. Belt grinders can handle a lot of work. During operation of the factory unit, the workpiece rests against a table fixed on the frame, which allows for more precise grinding. It is also worth noting that industrial versions are equipped with special glass, which performs protective functions, protecting the master’s face from sparks.

Often, tape grinders are made by hand due to the simplicity of their design.

Note! Over time, the grinder belt loses its previous technical characteristics and stretches. To solve this problem, the factory equipment contains a tension mechanism, through which the consumables are adjusted.

Separately, it should be said that on sale you can find universal equipment that combines the characteristics of not only a grinder, but also other sharpening units. A sharpener with a grinder does not provide the ability to turn off a separate mechanism. Its main disadvantage is its high cost.

The principle of operation of the grinder: how grinding is done

The operating principle of such units is quite simple. Any person who does not have special knowledge and skills can understand it. The operation of this device is based on an electronic motor. When you turn it on, the videos are activated. It is important to remember that there can only be one leading video. The rest are followers.

The resulting thrust is transmitted to the abrasive belt, which sets the latter in motion. The design of such equipment provides the ability to regulate and control the driven rollers. This greatly simplifies the work at the machine. The belt grinder produces a lot of dust during use. This is especially noticeable when processing workpieces made of wood. This problem can be solved simply: just use a hand-held vacuum cleaner or any blowing equipment.

Operating principle of a belt grinder for grinding and sharpening

Users note the ease of use of such a desktop machine. Reviews about it are mostly positive. When operating a homemade device, it is recommended to adhere to all necessary safety rules. The operator must be aware that the absence of a screen on a home-made unit may result in dust or sparks getting into the eyes. Therefore, when using a homemade sanding machine, you should prepare safety glasses in advance.

Over time, the abrasive belt, as mentioned above, wears out and stretches. There are several tension mechanisms that eliminate this problem. Such a system may be based on a spring or a special locking element.

What to look for when choosing a sanding grinder

The selection of the necessary device depends on many factors. Experts recommend assessing the dimensions of the workpieces and focusing on these indicators when choosing a unit. It is also very important to consider which parts will be processed using such equipment. Special models of grinders are used for various types of surfaces. An example is devices that grind convex workpieces.

The next selection criterion is purely individual. We are talking about the frequency of use of the grinding machine. Inexpensive models are suitable for rare use. It is worth noting that there are special grinder attachments that are installed on angle grinders (grinders). Their price is much lower than the cost of a full-fledged machine, and their efficiency is quite high.

First of all, you need to choose a unit based on the size of the workpieces that will be processed on it

The power of the unit is one of the most important parameters that affects the speed and efficiency of work. Today you can find devices on sale whose power ranges from 0.5 to 1.5 kW. For home use, as a rule, a model with a power of 0.5-0.8 kW is sufficient. If the device is purchased for frequent use, then you should pay attention to modifications, the same indicator of which is 0.8-1.2 kW.

You can learn about the operational characteristics of specific models and the features of working with them from thematic videos. Grinders made from scrap materials can have different powers. It all depends on what kind of electronic motor was taken for this purpose.

Related article:

Metal lathe for home: types and technical characteristics

Features and benefits, device. Review of TV-4, TV-6 and TV-7 machines. CNC machine. Recommendations for selection and prices. Working on the machine.

When choosing a belt drive machine used for grinding, it is also worth paying attention to the speed of the belt. This technical specification can be seen in the product passport. The performance of the unit depends on it. The price of a belt grinder indicates the degree of its effectiveness. Depending on the speed indicator, three types of grinders can be distinguished:

- 200-360 m/min;

- 360-500 m/min;

- 500-1000 m/min.

For home use, you need to purchase devices with a power of 0.5 to 0.8 kW

The last two options are not used at home. Craftsmen also recommend paying attention to the weight of the device if it is used for processing vertical surfaces. This is due to the fact that such work involves holding the machine in weight. There are two categories of grinders:

- from 2.5 to 4 kg;

- from 4 to 7 kg.

Lastly, you need to familiarize yourself with the additional functionality of the unit. It should be remembered that the number of additional modifications affects the final price of the grinder. For example, a device equipped with a soft start is much more efficient and convenient. Another useful feature is the alignment system. For home use, it is recommended to choose models equipped with stationary fasteners and auxiliary handles.

Homemade pulley

This structural element is the most difficult to manufacture. A ready-made pulley for a grinder is quite an expensive part. To make it yourself, you need certain knowledge in the field of mechanics and turning. You can get a high-quality pulley from steel or duralumin. In this case, the workpiece must be processed on metal-cutting machines. In a simplified version, it can be made from plywood. It must be FSF or FB. The thickness is selected based on the width of the tape used.

The diameter of the drive shaft is calculated based on the characteristics of the selected motor and the required belt speed. You can make this calculation yourself or use existing tables.

The main types of grinder rollers

In the design of modern stationary electrically driven devices, an important place is given to rollers or rollers. They are driven by a motor. A belt with an abrasive layer for grinding workpieces is passed through them. As a result, the belt moves, which makes it possible to work with such a machine.

Rollers or rollers for grinders are primary and secondary

The output shaft, which is a structural element of the electronic motor, is connected to the drive roller of the drive device. All this is indicated in detail in the grinder drawings, which can be found on the Internet. The rotation created by the engine passes to the driving and then to the auxiliary (driven) rollers. Thus, there are only two types of rollers: primary and secondary.

The position of the auxiliary rollers can be adjusted, which allows you to control the grinding depth. The tension mechanism, which is a compensatory system, is located on one of the rollers. It is because of this that this roller is called a tension roller. If one such element fails, you can make it yourself. Do-it-yourself grinder rollers can be made from available materials, but the cost of replacing them is not so high.

The rollers of the drive table unit used for grinding and sharpening are important design elements. Their function is to hold and evenly distribute the tension of the abrasive belt.

Grinder selection: belt size for grinding workpieces

The dimensions of the abrasive strip must necessarily correspond to the operational purpose. It is important to understand that the dimensions of the products that will be processed on the machine are the most important factor when choosing a belt. There are three main characteristics of such bands:

The tape must be selected depending on what products will be processed on the machine

- grain;

- length;

- width.

The length of the tapes that can be found on sale today ranges from 610 to 1830 mm. In turn, there are only two width options, namely: 50 and 100 mm. The smallest abrasive strips are found in grinders for an angle grinder. Products of minimum length wear out very quickly, which is worth keeping in mind when choosing the required tape.

Note! The abrasive strip for grinding must have an elastic base. The relative percentage of material elongation without breaking in a quality product is at least 10%. When choosing a grain size, you should also focus on what purpose the strip will be used for. This product can be made at home, but often such tapes do not have a long service life.

When choosing a grain size, you should also focus on what purpose the strip will be used for. This product can be made at home, but often such tapes do not have a long service life.

The width of the belts for the belt grinder is available in two versions - 50 and 100 mm