DIAMETER OF STEEL PIPES

The diameter of the steel pipe is determined by:

- — external diameter for electric-welded and seamless pipes;

- — nominal diameter for VGP pipes.

- — Nominal diameter (DN or Dу) — internal diameter of pipes.

- — Conditional bore is a conditional value representing the value of the actual internal diatreme, rounded to the nearest standard range, and serves as a reference point for selecting the dimensions of other parts and equipment. Its value is standardized according to GOST 28338-89. Measured in inches or mm.

- — Internal diameter - the actual value of the parameter obtained by direct measurement, as a rule, indicated in mm;

- - Outer diameter of pipes (Dn or Dn) - the actual diameter of the pipe taking into account the wall thickness, indicated in mm;.

- — Thread diameter (G).

Pipe sizes are indicated in millimeters, but for VGP pipes they are often indicated in inches (“”).

The relevance of using pipes of this category

The high popularity enjoyed by VGP pipes made from steel alloys can be explained very simply. No matter how exceptional the characteristics of today's popular pipes made of polymeric materials may be, their use in many cases is simply not possible. Such cases, in particular, include installation of a pipeline in the open air, where it will be affected by a lot of negative factors.

The demand for such products is also explained by the fact that, according to generally accepted requirements, pipelines for transporting gas and supplying it to consumers can only be made of steel pipes. That is why VGP pipes are simply an irreplaceable material in any gas industry.

Gas supply to a private home is a typical example of using VGP pipes

This is interesting: How to attach an anchor bolt: video, photos, nuances, tips

TABLE OF CORRESPONDENCE OF PIPE DIAMETERS IN MM AND INCHES

| Nominal diameter of the pipe (Dy), mm | Thread diameter (G), inch | Pipe outer diameter (Dн), mm | ||

| Steel water and gas pipe | Seamless steel pipe | Polymer | ||

| 10 | 3/8″ | 17 | 16 | 16 |

| 15 | 1/2″ | 21,3 | 20 | 20 |

| 20 | 3/4″ | 26,8 | 26 | 25 |

| 25 | 1″ | 33,5 | 32 | 32 |

| 32 | 1 1/4″ | 42,3 | 42 | 40 |

| 40 | 1 1/2″ | 48 | 45 | 50 |

| 50 | 2″ | 60 | 57 | 63 |

| 65 | 2 1/2″ | 75,5 | 76 | 75 |

| 80 | 3″ | 88,5 | 89 | 90 |

| 90 | 3 1/2″ | 101,3 | 102 | 110 |

| 100 | 4″ | 114 | 108 | 125 |

| 125 | 5″ | 140 | 133 | 140 |

| 150 | 6″ | 165 | 159 | 160 |

Steel grades and tolerances

The classification given above is quite incomplete. It can be continued almost endlessly. Such a huge range is due to the large number of applications for steel pipes.

Among other classifications, there is another one - by diameter. Naturally, thinner or thicker pipes are used for different purposes. Today, the industry produces steel products with a diameter from 17 to 114 mm. In this case, the following indicators are considered normal error:

- For products with diameters from 17 mm to 48 mm, the normal error (tolerance) can be considered 0.4-0.5 mm;

- For materials with diameters from 60 to 114 mm, the normal error is considered to be 0.8-1% of the diameter.

On the wall this figure is 15%.

Water and gas pipes of various diameters

It must also be said that these tolerances are typical only for the following grades of steel:

- 0.8ps and 0.8kp;

- 10;

- 15, 15ps, 15kp;

- 20, 20ps, 20kp;

- St1ps;

- St2ps;

- St3ps and St3kp.

DIMENSIONS OF VGP-PIPES ACCORDING TO GOST 3262-75

Main dimensions of the VGP pipe: 15 mm (1/2″ inch); 20 mm (3/4″); 25 mm (1″); 32 mm (1 1/4″ inches and a quarter); 40 mm (1 1/2″); 50 mm (2″). There are also the following DNs: 10 mm, 65 mm, 80 mm, 90 mm, 100 mm and even 125 mm - but they are rarely used and, as a rule, are replaced by other types of steel pipes (for example, electric welded). Most often, 3/4″ pipes are used for risers, and 1/2″ for internal wiring.

Some technical requirements

All steel water and gas supply materials are manufactured according to technical standards and have GOST 3262-75, as noted earlier. Production is carried out from types of steel (GOST 380 and GOST 1050) without standardization of the chemical composition and all mechanical qualities.

If necessary, the ends of the pipes can be chamfered at an angle of 40 degrees at the manufacturer's factory. With this type of work, an end ring is left, the width of which lies in the range from 1 to 3 mm.

It must be said that chamfers are removed from products whose wall thickness is more than 5 mm.

In addition, at the customer's request, threads can be applied to both ends. The condition is a conditional passage, which should not be less than 1 cm.

Among other things, individual water and gas supply elements can be equipped with couplings (GOST 8944,8954,8965 or 8966). In this case, each water and gas steel pipe must be equipped with one coupling.

The surface of the products must not have cracks, blisters or dents. There should be no delamination, chips or burrs at the ends.

The following defects are allowed:

- Risks;

- Individual dents;

- Traces of stripping;

- A layer of scale that does not interfere with inspection;

- Some manufacturing defects, but only if they do not reduce the wall thickness to the minimum value in some places.

Below is a table of correspondence of some parameters of water and gas products.

DIMENSIONS OF ELECTRIC WELDED PIPES ACCORDING TO GOST 10704-91

Straight-seam electric welded pipes come in the following outer diameters (in millimeters): 10; 12; 13; 14; 16; 17; 17.5; 18; 19; 20; 21.3; 22; 24; 25; 26; 28; thirty; 32; 33; 33.7; 36; 38; 40; 42; 43; 45; 48; 51. For diameters up to 57 mm, a VGP pipe of the appropriate size is used. The most popular are straight-seam pipes in accordance with GOST 10704-91 with sizes of 57 mm and above. Their main diameters: 57; 60; 63.5; 76; 89; 102; 108; 114; 127; 133; 140; 146; 159; 168; 178; 193; 219; 245; 273; 325; 377; 426; 530.

Scope of application

The primary purpose of VGP pipes is to transport water (both hot and cold) and household gas to the end consumer. When installing a network of water and gas steel pipes, either welding, threaded adapters, or other additional parts and segments are used for connection. Most often, these products are present in household communications. A huge percentage of modern and private housing constructions and high-rises built in the past are equipped with VGP steel pipes for consumers to receive gas, heat and water.

In addition to their direct purpose, pipes are widely used for the construction of metal structures of various types and sizes: shelving and cabinets, scaffolding, fences and small architectural forms. But this is already a separate area of their application, into which we will not delve too deeply.

For gas pipeline

TEST METHODS

4.1. For quality control, one sample is cut from each selected pipe for each type of test.

The tensile test is carried out in accordance with GOST 10006. Instead of the tensile test, it is allowed to control the mechanical properties by non-destructive methods.

(Changed edition, Amendment No. 3, 6).

4.2. The surface of the pipes is inspected visually.

4.3. Hydraulic testing is carried out in accordance with GOST 3845 with exposure to test pressure for at least 5 s.

4.4. The bend test is carried out according to GOST 3728. Galvanized pipes are tested before coating.

(Changed edition, Amendment No. 3).

4.4a. The expansion test is carried out according to GOST 8694 on a conical mandrel with a cone angle of 6°.

Testing on a mandrel with a taper angle of 30° is allowed.

(Changed edition, Amendment No. 3, 4).

4.4b. The flattening test is carried out according to GOST 8695.

(Changed edition, Amendment No. 3).

4.4v. Weld inspection is carried out using non-destructive methods according to regulatory and technical documentation.

(Introduced

additionally, Amendment No. 3 ).

4.5. The thickness of the zinc coating on the outer surface and in accessible places on the inner surface is controlled according to GOST 9.301 and GOST 9.302, as well as with devices of the MT-41NTs, MTZON or Impulse type according to the normative and technical documentation.

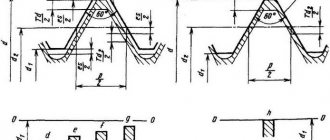

4.6. The thread is checked using thread ring gauges in accordance with GOST 2533 (third accuracy class).

In this case, the screw-in of the no-go ring gauge onto the thread should be no more than three turns.

(Changed edition, Amendment No. 3, 4).

4.7. The curvature of the pipes is controlled using a straight edge in accordance with GOST 8026 and a set of probes in accordance with NTD.

(Changed edition, Amendment No. 3, 5).

4.8. The right angle of the pipe ends is controlled with a 90° square measuring 160´100 mm, class 3 GOST 3749, plate probes set 4 according to NTD or an inclinometer GOST 5378. The bevel angle of the chamfer is controlled with an inclinometer according to GOST 5378.

(Changed edition, Amendment No. 3, 6).

4.9. The outer diameter is checked using smooth micrometers in accordance with GOST 6507, clamp gauges in accordance with GOST 2216 or GOST 18360.

The wall thickness, the height of the internal burr and the height of the burrs are measured with a micrometer according to GOST 6507 or a wall gauge according to GOST 11358 at both ends of the pipe.

The length of the pipes is measured with a tape measure in accordance with GOST 7502. The threads are controlled with gauges in accordance with GOST 2533.

The mass of a batch of pipes is controlled on scales of no more than 10 tons with a division value of no more than 20 kg.

(Changed edition, Amendment No. 3, 4, 5, 6).

4.10. Weld inspection is carried out using non-destructive methods according to technical documentation.

(Introduced

additionally, Amendment No. 4 ).

Product varieties

Different pipeline laying methods and different operating conditions require different technical characteristics. The rental company produces several modifications.

Classification by material

The raw material for the manufacture of water and gas pipes is carbon steel of various grades. At the same time, GOST 3262-75 regulates two types of products:

- water pipelines made of steel of ordinary precision - only the mechanical qualities of the product are controlled. The chemical composition of steel is not studied. The products are used for household communication systems;

- pipeline made of high-precision steel - galvanized steel is used in manufacturing, mechanical properties are standardized by GOST 3262-75. The products are used in the construction of large highways, where high pressure resistance is important.

In fact, both types of water and gas pipes are made of steel, but undergo different levels of control. As a result you get:

- black – without galvanizing, more often used when laying gas lines;

- galvanized - finished products are galvanized - immersed in molten zinc. A protective layer is formed on the internal and external surfaces of the product, protecting against corrosion. Large water mains are constructed from galvanized VGP.

Release form

Water and gas pipes GOST 3262-75 are produced:

- with threads at the ends (knurling or cutting) - it is worth noting that the protective layer is damaged during welding, and therefore galvanized products are mounted only by the threaded method;

- without thread - a welded connection is assumed.

Duration of operation

The list of important technical characteristics includes the service life of the finished structure. This indicator largely depends on the conditions in which the pipeline is located.

Non-galvanized structures that are constantly in contact with cold water fail over several decades, as the walls under the threads gradually become thinner and the clearance decreases.

Galvanized products, even in contact with humidity, can last 50-80 years without repair.

The absence of humidity (gas pipeline) allows the facility to be operated for more than 80 years.

Rules for storing and transporting steel pipes

Requirements for storage and transportation of steel products are specified in detail in GOST 10692-80.

According to the stipulated standards, rolled steel products must be stored in a ventilated area, under a tented canopy, or on an area equipped with restrictive structures.

There should be no direct contact with the ground.

A distance of 1.5 m is required between shelves or racks. This is necessary to comply with safety regulations and ensure unimpeded access for special equipment.

Loading and unloading of products should be carried out using special types of equipment and mechanisms.

Advantages and disadvantages

The water and gas pipe is characterized by high strength and good wear resistance.

The rigidity indicators of such products are equal to the quality characteristics of solid metal timber with similar diameter parameters.

The use of VGP pipes is in demand when constructing not only main lines, but also household pipelines, for example, when replacing polypropylene water supply pipes reinforced with fiberglass (the characteristics are written here), where gas or water is used as the working medium.

The main advantages of water and gas pipelines are presented:

- low coefficient of linear expansion, which prevents deformation of the structure under the influence of high temperatures and as a result of freezing of the working environment;

- high strength compared to polypropylene and other materials, as well as the possibility of use in creating pressure-type structures;

- good thermal conductivity , which has a positive effect on the long-term preservation of temperature indicators of the transported working medium (read reviews about a hot water meter with a temperature sensor on this page);

- tightness , allowing the delivery of gaseous and volatile substances, as well as acids and other chemically active components.

It is important to remember that high thermal conductivity can cause cooling of the transported working medium, therefore the use of VGP pipelines with the additional use of thermal insulation materials is considered optimal.

What do you know about the design and repair of a water ball valve? Read this useful article for instructions on how to disassemble and restore the tightness of shut-off valves for water supply inside buildings.

Watch a video on how to make a heat accumulator for heating boilers with your own hands on this page.

Extra options

For the convenience of those who are going to purchase water and gas pipes and use them for certain purposes, the length of such products is also standardized and may correspond to one of the following categories:

- interval 4–12 meters - measured length;

- length of pipes, a multiple of their measured value;

- unmeasured length, which, nevertheless, must be within the limits of the measured value.

Consumers of such products should keep in mind that the price is set not per unit of pipe length, but per unit of its weight. It is also important to take into account that the weight of galvanized pipes is 3% higher than the weight of products made from unprotected steel.

Steels from which high-precision galvanized and non-galvanized pipe products are produced must comply with the requirements of GOST 1050, while the chemical composition and mechanical characteristics of the manufacturing material are not subject to standardization. The welds with which water and gas pipe products are connected after they are formed must be of a reinforced type.

Mechanical properties of rolled products used for pipe production

The range of water and gas pipe products made of black steel involves their production with several options for wall thickness. Depending on this parameter, such products are:

- light class;

- ordinary category;

- reinforced type.

The wall thickness of such products, which can be selected according to the assortment according to the table, is standardized by the requirements of GOST 3262-75. Based on this regulatory document, a range of pipe products is formed; it also stipulates a number of other parameters that such products must comply with: nominal diameter, outer diameter, theoretical weight of one linear meter.

Dimensions of light series pipes intended for thread rolling

Pipes of various classes are designed for operation under different operating pressures. Thus, pipes corresponding to the light category can be operated at a pressure not exceeding 25 kgf/cm2, and reinforced type products - 32 kgf/cm2.

At the request of the customer of a batch of water and gas pipes, long or short threads can be applied to their ends. Galvanized pipe products can be supplied to customers not only with threads, but also equipped with couplings for their installation.

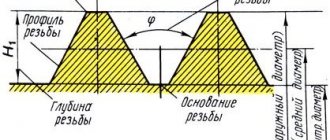

Thread Requirements

Characteristics of VGP

Water and gas pipes are made from steel blanks - strips, using the molding method. The edges of the workpiece are welded. The seam used is reinforced. Examination of the seam is the first task of quality control, since it represents a high-risk area. According to GOST 3262-75, radiography is used to determine quality.

Water and gas pipes, as a rule, are made straight-seam, since for these products the more important quality is resistance to internal pressure rather than resistance to external loads. The photo shows a gas pipeline.

Advantages:

- high strength, which allows the product to be used with any installation method and in any area;

- oxygen and gas impermeability are precisely those properties due to which gas pipelines are and will be constructed only from steel products;

- low coefficient of expansion - temperature and moisture changes do not affect the material. The pipeline does not expand, which allows the use of rigid fastening and does not require the installation of compensation devices;

- durability - with proper maintenance it is 50 years;

- affordable price.

Flaws:

- quite heavy, which makes installation difficult and requires a large amount of fasteners;

- the need for preventive maintenance - metal accumulates electricity;

- the need for thermal insulation when laying in the ground - the freezing liquid expands, while the parameters of the water pipeline remain unchanged. This leads to damage and ruptures.