Science does not stand still, but is constantly evolving, resulting in the emergence of new high-tech materials that have found their application in various industries. Today, some polymers are capable of not only successfully competing with metals and their alloys, but in some cases, their characteristics are considered better than them.

One of the most common high-tech materials that appeared relatively recently is caprolon, which has properties superior to metal in various respects, including corrosion resistance and strength.

Characteristic

Caprolon is a polymer material that is white with a slight yellowish tint and odorless. Its shade often changes due to various dyes or additives added to the polymer during the production process. One of the main properties of caprolon is its strength, which is not inferior to steel, and a wide operating temperature range from -40 to +80 degrees. This allows it to be used in different climate zones or in extreme conditions.

Quite often, such a polymer is associated with a substitute for alloys and metals in parts that are subject to severe wear due to friction. Due to its antifriction properties, this material is used as bearings and gaskets.

Caprolon is absolutely waterproof and has a high level of corrosion resistance . Can work for quite a long time in the following aggressive environments:

- sea water;

- alkaline solutions and dilute acids;

- fuel (kerosene, gasoline, diesel);

- alcohols.

Having dielectric properties, caprolon is successfully used in the manufacture of insulating components and electric motors.

The polymer weighs 6 times less than steel, which significantly increases its popularity. Structures with parts made of caprolon instead of iron are lightweight, which is sometimes a critical indicator. The material is subjected to all types of mechanical processing, which makes it possible to produce such a part from it with a fairly high class of surface accuracy.

Receipt

To obtain high-density caprolon, it is necessary to carry out a low-temperature polymerization reaction, in which aminocaproic acid, alkaline catalysts and activators will take part.

The resulting material can be diluted in phenolic and cresol solutions. This material is considered an excellent dielectric.

According to the state standard, this polyamide must be manufactured in accordance with the requirements of GOST 7850-86. “Caprolon. Technical conditions".

Advantages

Parts made of caprolon are durable and remarkably absorb shock loads , due to which they are used for the manufacture of trolleys, housings of various mechanisms, gearbox drives, conveyors, hubs, gears, sprockets and many other units in which there are shock loads on the product body or elements. Polyamide rods and sheets are resistant to:

- alcohol;

- alkalis;

- oils;

- ether;

- weak acid.

Parts made from this material are used in friction units and even without lubrication. The advantage of sheet and rod caprolon is that it is an excellent dielectric, its qualities are not inferior to materials such as polyvinyl chloride and polystyrene.

With a low coefficient of friction, Polyamide 6 products are quickly and easily installed in place of steel and bronze parts. In addition, they are much lighter in weight than metal products.

Sheet or rod caprolon is perfectly processed on sharpening, milling and grinding machines. Products made from such material guarantee more reliable and long-lasting service in friction and sliding units. Caprolon rods can withstand various loads and impacts, and are also characterized by a long service life.

Processing Features

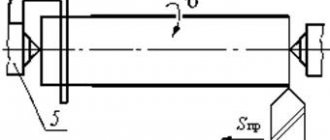

Caprolon processing is possible on milling, turning, drilling and grinding machines. During turning work, it must be remembered that this material has a low melting level.

During long-term machining, it is recommended to use carbon steel tools and tungsten tips.

Caprolon sheets or bushings stored for a long time in the cold cannot be immediately processed on machines. They must be moved indoors for 5 days so that the temperature in the material becomes the same.

Read also: Styles of cocktail dresses (60 photos)

It is worth noting that parts made from caprolon have a service life 1.5 times longer compared to parts made from other materials. The cost of producing parts from such polyamide is significantly lower compared to metal parts. Caprolon from polyamide 6 allows the production of parts with low cost, high strength and low labor intensity.

Application area

Having remarkable properties and technical characteristics, caprolon is successfully used in various industries. most in demand in the following areas:

- Electrical engineering. Possessing dielectric properties, this material is excellent for insulating power cables. It is also used to make protective casings for electrical equipment operating outdoors. In addition, due to the fact that this polymer is subject to low galvanoelectric corrosion, it is used to make coils, connectors, terminals and switches. High resistance to alkaline solutions allows this material to be used in contact with a variety of electrolytes.

- Mechanical engineering, shipbuilding, mining. Due to its light weight, the use of polymer makes the structure several times lighter and significantly reduces costs without loss of quality due to the fact that the material has the lowest cost compared to similar polymers. Caprolon is used to make hubs, rock crusher drums, cuffs, plain bearings, etc.

Application of caprolon in industry and construction

Design and manufacture of non-standard equipment in accordance with drawings and the customer, including repair work. Repair work, maintenance during warranty and post-warranty service. Design and manufacture of rigging. . The capabilities of the Topaz enterprise allow us to perform the following types of industrial work. Design of models of molds, dies, tools, cutting tools and their manufacture. Examples of parts manufactured in molds from our plant. Production of non-standard equipment. Design and manufacture of special equipment for various purposes. Formatting machines, smoke generators, presses, test benches, fitness equipment, etc.

General information

Kaprolon represents the Russian name for the famous polyamide - polycaproamide. There are also analogues of this material on the market.

The product belongs to the category of fairly new products, which have been produced since the end of the last century. The technical characteristics and properties of caprolon are unique, including increased strength and wear resistance. A product made from caprolon, left in an open space for up to several years, will have its original properties absolutely unchanged.

Created in the recent past, the material has a white tint with a yellowish tint and is odorless. It is prone to changeability due to additives during the production of all kinds of coloring preparations. In terms of strength, the polymer resembles steel.

The extended range of temperatures used makes it possible to work in areas with varied climates, including extreme conditions. Anti-friction properties favor its use for bearings or gaskets.

Products made from caprolon

On top of that, caprolon can absorb noise and significantly reduce vibration and dynamic loads. Taken together, all these technical characteristics have made it one of the most sought-after and popular polymers. Moreover, this material can be easily processed by various mechanical methods. For example, processing of caprolon is carried out by milling, turning, cutting, drilling, and grinding. Thus, using ordinary factory equipment, it is possible to make various products from caprolon instead of heavier and less reliable metal ones.

What is caprolon made from?

| Sphere | Products |

| Shipbuilding and ship repair | Propeller and sternshaft bearings |

| Fan rollers and valve covers | |

| Valves, pistons, gears, impellers | |

| Energy and electrical engineering | Turbine liners and ball mills |

| Feed augers, gold and dust removal | |

| Bearings for pumps and equipment | |

| Mining industry | Bearings for stone crushing systems |

| Seat bearing shells | |

| Bushings for the central pin and aiming unit | |

| Oil and gas production | Bearings for pumps |

| Sucker Rod Scrapers | |

| Grids for vacuum filters | |

| Mechanical engineering | Rolling and sliding bearings |

| Guides and bearings for friction units | |

| Bushings, gears, sprockets, pistons | |

| Crane and transport equipment | Pulleys, blocks, rollers of wheel mechanisms |

| Housings, brackets, wheel hubs | |

| Axle supports, bushings, bearings | |

| Food equipment | Separators, pumps, rollers, gears |

| Bearings, guides, bushings | |

| Nipples, strips, pads, augers |

And this is not a complete list of possible products made from this polymer. Since the processing of caprolon is 35% easier and faster than the processing of other steel analogues, and the final cost of such products will be much lower with high technical characteristics, many enterprises choose this particular material for the production of new products. In turn, many engineers are trying to replace old worn steel parts in industrial or private civil engineering with highly reliable and efficient parts made of caprolon or its polymer analogues.

Analogues of caprolon

It is important to understand that the word “ caprolon”

"is a purely domestic designation for polycapromide.

Another common name for this material is polyamide

.

By the way, in some cases this name is shortened to the abbreviation PA

.

In general, caprolon

has a large number of patented names, which are trademarks of various companies around the world.

Very often this polymer is designated as Tecamid, Ertalon, Tecast, Ultralon, Neylon and many other different names, but all of them are analogues of caprolon .

Foreign analogues of caprolon

| Polyamide 6 (PA-6) | Akulon | Akzo | Holland |

| Maranyl | ICI | Great Britain | |

| Capron | Allied Chem. Corp. | Canada, USA, Belgium | |

| Zytel | Du Pont E.I. | Canada, USA, Switzerland | |

| Nylene | Service Color Corp. | USA | |

| Adell | Adell Ptastics Inc. | ||

| Grilon | Emser Werke | Switzerland, USA | |

| Nypel | Nypel Inc. | Japan, USA, Germany, Thailand | |

| Amilan SM | Toray Ind | Japan, USA | |

| Duretan B | Bayer AG | Germany | |

| Ultramid D | BASF | ||

| Technyl C | Rhone Poulenc | France | |

| Polyamide 66 (PA-66) | Akulon | Akzo | Holland |

| Maranyl | ICI | Great Britain | |

| Minlon, Zytel | Du Pont E.I. | Canada, USA, Switzerland | |

| Gelanese | Gelanese Plastics | Canada, USA, Denmark, England | |

| Adell | Adell Ptastics Inc. | USA | |

| Nypel | Nypel Inc. | Japan, USA, Germany, Thailand | |

| Amilan | Toray Ind | Japan | |

| Nylon 66 | Ube Ind. | ||

| Ultramid A | BASF | Germany, USA | |

| Technyl | Rhone Poulenc | France | |

| Polyamide 610 (PA-610) | Thermocomp Q | LNP Corp. | USA |

| Vydyn | Monsanto Co. | ||

| Amilan SM | Toray Ind | Japan, USA | |

| Ultramid S | BASF | Germany | |

| Technyl D | Rhone Poulenc | France |

In addition, in the post-Soviet space, caprolon is often designated as block polyamide PA-6 . This name was given due to the fact that this material was produced in the form of blocks. However, for a long time the main forms of its release have been rod, sleeve, sheet or granules. The unprofitability of the block form is due to the fact that during the manufacture of parts from caprolon, a significant part of the material was ground off, turned into chips and wasted. Of course, this was extremely unprofitable. However, this name has remained in common use and is still used today, and some companies continue to produce this form.

It is noteworthy that caprolon has several structural modifications that differ in the degree of resistance to loads and other technical characteristics. Depending on the purpose and operating conditions, polyamide PA-6 , as well as polyamide PA-6 oil-filled , that is, containing a special lubricant. In this case, oil-filled caprolon will no longer have a light color, but black. In addition, polyamide PA-6 MDM with molybdenum disulfide , and another special type of this polymer - polyamide PA-6 MG graphite-filled, .

In addition, there is also glass fiber polyamide PA-6 , which contains glass fiber in its structure, which gives it the greatest rigidity and strength. This is where the products with the prefix “6” end, but other modifications are already underway. For example, there is polyamide-11, which is practically not subject to aging. polyamide-12, similar to it . In addition, polyamide-46 , polyamide-66 and polyamide-610 . Each of them has slightly better technical indicators than the material with the prefix “6”. But here it is important to take into account that these are not analogues of caprolon, these are its structural modifications.

Comparison with fluoroplastic

Caprolon is one of many polymers used to replace metals. Of all analogues, it is most often compared with fluoroplastic and polyurethane. Technical characteristics of fluoroplastic and polyamide in comparison:

- Thermal resistance is better with fluoroplastic. It can withstand temperatures up to 200 °C.

- Both materials are slightly susceptible to chemical corrosion. The difference is that fluoroplastic parts are more often used in diluted acids, and caprolon parts are used in alkalis.

- The specific density of caprolon is significantly less than that of fluoroplastic. They can be distinguished by their weight. Fluoroplastic is almost twice as heavy

. In places where the weight of the product plays an important role, polyamide-6 is more often used. - In terms of compressive strength and deformation upon impact, fluoroplastic is superior to caprolon.

Fluoroplastic is a soft and flowable polymer, not suitable for use under high loads. The service life of fluoroplastic is higher than that of polyamide-6, and in terms of strength characteristics, fluoroplastic has better performance

However, caprolon is more affordable, and this often determines the choice of manufacturers in its favor.

. More information about fluoroplastic F4 can be found here.

Polyurethane is used to replace rubber, traditional plastics, and sometimes metals. It is indispensable in the manufacture of various gaskets and seals.

Thanks to the use of new polymer materials, manufacturers of various types of mechanisms have the opportunity to significantly lighten and reduce the cost of structures. This brings significant economic benefits and often increases the service life of products.

Among the wide variety of modern polymer materials, fluoroplastic and caprolon stand out, and this is not surprising, because both of them are widely used in almost all industries. What properties do both materials have, how do they differ, and in what areas are fluoroplastic and caprolon used?

Differences

As can be seen from the table, caprolon or fluoroplastic have practically no differences in appearance , but in physical and mechanical properties they have quite significant differences. Therefore, when choosing a polymer, you should pay attention to the following criteria:

- Mechanical strength and hardness;

- Electrical insulating properties;

- Resistance to abrasion and wear;

- The magnitude of the sliding friction coefficient.

In terms of strength characteristics, caprolon is stronger than fluoroplastic , but is somewhat inferior to it in hardness and workability. Caprolon is more resistant to abrasion and wear and works better under long-term loads. The electrical insulating properties of the materials differ slightly.

It is also worth paying attention to the cost of materials. The price of caprolon is from 250 rubles. for 1 kg, and fluoroplastic - from 500 rubles. Thus, when comparing caprolon and fluoroplastic and choosing which material is better, we start from the following criteria: for working in difficult conditions and mechanisms with increased wear of parts, it is preferable to use caprolon, and in conditions of exposure to chemically aggressive environments and elevated temperatures, fluoroplastic performs better.

Caprolon is a polymer material

Caprolon is a polymer material (polyamide 6 PA-6) with high technical characteristics, has been used in modern industry for more than 30 years and actively replaces parts made of metal, bronze, and other alloys.

Kaprolon is the Russian name; another name is often found - polyamide 6 or PA6 (PA6). Other countries produce the same material under their patented names: Tecamid, Ertalon, Tecast, Ultralon, Nylon and so on, all these polymers are analogues of caprolon. Here you can still find the old name - polyamide PA6 block, due to the form of release. At the moment, it is not relevant; when processing a block, a large amount of waste and shavings remain. Caprolon is produced in the form of plates, sheets, rods, circles. These forms are convenient for processing and obtaining the final product. Caprolon PA6 polyamide 6, manufactured according to TU 2224-001-78534599-2006, does not require preliminary preparation before mechanical processing. Heat treated in production to reduce internal stress and increase strength and chemical resistance; Delivered already trimmed, this greatly reduces the cost of working time. Operating temperature from -60°С to +120°С.

Caprolon PA6 polyamide 6, manufactured according to TU 2224-036-00203803-2012, requires heat treatment to relieve the internal stress of the material that arises during production to prevent warping, deformation and cracking. Operating temperature from -40°С to +70°С.

Caprolon is produced in two grades: grade “A” - the highest grade, and grade “B” - the first grade, the physical and mechanical properties of these grades are excellent and are presented in the table:

Caprolon (polyamide 6 block) grade “A” and grade “B” main parameters according to TU 2224-001-78534599-2006:

| The name of indicators | Caprolon rods, circles, sheets, plates | |||

| PA 6, unfilled | PA 6 HS, filler CM025, heat stabilizer | PA 6 OFN, filler CM015, low temperature oil | ||

| Brand "A" | Brand "B" | |||

| Appearance | Smooth surface without shells, cracks, white to cream color | Smooth surface, from white to cream color, shells, chips no more than 2 pieces per 10% of the entire surface | Sheets, rods with a smooth surface without shells, cracks, blue color | Sheets, rods with a smooth surface without shells, cracks, from gray to black |

| Number of pores ranging in size from 0.8mm to 1.5mm on the surface of the product, pcs, no more | No | No more than 1 | 2 | |

| Bending stress at a deflection value equal to 1.5 sample thickness, MPa, not less | 90 | 80 | — | — |

| Shock resistance | Does not collapse | Does not collapse | Withstands testing | |

Caprolon (polyamide 6 block) grade “A” and grade “B” main parameters according to TU 2224-036-00203803-2012:

| The name of indicators | Caprolon rods, circles, sheets, plates | |||

| PA 6 | PA 6-MG, graphite | PA 6-MDM, molybdenum disulfide | ||

| Brand "A" | Brand "B" | |||

| Appearance | Sheets, rods with a smooth surface without shells, cracks, from white to cream color | Sheets, rods with a smooth surface without shells, cracks, from gray to black | ||

| Number of pores ranging in size from 0.8mm to 1.5mm on the surface of the product, pcs, no more | No | 2 | 2 | |

| Bending stress at a deflection value equal to 1.5 sample thickness, MPa, not less | 90 | 80 | 95 | 85 |

| Shock resistance | Does not collapse | Withstands testing | Withstands testing | |

Caprolon PA6 production

Caprolon PA6 is produced using anionic polymerization of liquid or granular caprolactam (GOST 7850-86); it has a synthetic base.

Polyamide 6 construction material, color from white-beige to cream. It is possible to paint in production in other colors at the request of the customer. Also, to change and improve its properties and increase performance in various environments, additives are used and oil-filled, graphite-filled and other types of modified caprolon are obtained. When producing polyamide, manufacturers are guided by GOST, but use different technical conditions, while caprolon has slightly different physical and mechanical properties. Caprolon TU 2224-001-78534599-2006 TU 2224-036-00203803-2012 comparison of properties:

| Physical and mechanical indicators | Caprolon manufactured according to TU 2224-001-78534599-2006 | Caprolon manufactured according to TU 2224-036-00203803-2012 |

| Density | 1.145 g/cm3 | 1.150 - 1.160 g/cm3 |

| Melting temperature | + 220°C | from + 220°C to + 225°C |

| Operable at temperatures | -60°C to +120°C | — |

| Tensile strength | 80 MPa | 70 - 80 MPa |

| Relative extension | >20 % | >20 % |

| Stress at relative strain equal to 25% | 95 MPa | 120 - 130 MPa |

| Bending temperature under load 1.8 MPa | — | from + 80°C to + 100°C |

| Water absorption in 24 hours | 0,3 % | 1,5 — 2 % |

| Water absorption is maximum until saturation in water | 7 % | 6 — 7 % |

| Coefficient of thermal conductivity | 0.26 W/m °C | 0.30 - 0.35 W/m °C |

| Average coefficient of thermal expansion | 8*10-3 °C | 6.6*10-5 - 9.8*10-5 °C |

| Specific surface resistance | 1*1012 Ohm | 1*1012 - 1*1013 Ohm |

| Specific volumetric electrical resistivity | 1*1013 Ohm*m | 1*1013 - 1*1014 Ohm*m |

| The dielectric constant | at a frequency of 103 Hz - 3.7 | at a frequency of 106 Hz - 3.3-3.5 |

| Electric strength | 25 kV/mm | 20 - 25 kV/mm |

| Friction coefficient on steel without lubrication | 0,39 | 0,23 — 0,33 |

| Hardness Shore D | 84 | — |

| Impact strength | — | 120 kJ/m2 without notch 3 kJ/m2 with notch |

| Impact strength | 5.6 kJ/m | — |

| Flexural strength | 105 MPa | — |

| Flexural modulus | 330 MPa | — |

Extruded and cast caprolon

Extruded and cast caprolon differ in the manufacturing method:

✔

Cast raw materials are poured into a mold and then kept under certain conditions of temperature and time.

✔

Extrusion - the raw material is squeezed out through a hole, thereby obtaining a certain shape; the density of the workpieces is more uniform along the entire length.

Technical characteristics for different production methods are dependent. Extrusion and casting make it possible to obtain polyamide of different densities; impact strength, rigidity, water absorption, hardness, operating temperature limits, and color differ. These characteristics are important when choosing caprolon as blanks for the manufacture of parts, spare parts for aircraft construction, mechanical engineering, shipbuilding and similar high-tech industries.

Caprolon properties and advantages

- Incredibly light specific gravity - 6-7 times lighter than bronze, steel and other metals and successfully replaces them.

- Resistance to corrosion.

- Resistance to aggressive environments - sea water, hydrocarbons, oils, alcohol, ketones, ethers, alkalis and weak acids. Caprolon can only be dissolved by concentrated acids, phenols, fluorinated and chlorinated alcohols.

- High level of wear resistance - lasts 5 times longer than non-ferrous metals; on the other hand, caprolon is viscous and can absorb abrasive particles during operation without losing its properties. Polyamide 6 is well suited for the production of parts for conveyor lines.

- Self-lubricating ability - can work without lubrication in friction pairs.

- Operation in a wide temperature range from -40°С to +100°С, short-term from -100°С to +170°С.

- Complete environmental safety - non-toxic and safe for humans.

- Excellent strength qualities, easy to process.

Basic properties

We present average values for various characteristics. Exact numbers may vary depending on the brand of material, modifiers used and other conditions.

| Characteristics | Meaning |

| Density | 1.15–1.16 g/cm3 |

| Frost resistance | -50 °C |

| Working temperature | -40…+80 °С |

| Maximum permissible operating temperature (constant) | 90 °C |

| Maximum permissible operating temperature (short-term) | 150 °C |

| Heat resistance according to Martens | 75 °C |

| Thermal conductivity coefficient at 20 °C | 0.29 W/mK |

| Melting temperature | 220–225°С |

| Tensile modulus | 2000–2300 MPa |

| Compressive modulus of elasticity | 3500–4000 MPa |

| Compressive strength | From 90 MPa |

| Bending strength | From 80 MPa |

| Elongation at break | 10 % |

| Brinell hardness | 130–140 kg s/cm2 |

| Work intensity РхV | 15 MPa m/s |

| Electric strength | 30–35 kV/mm |

| Coefficients of linear thermal expansion when heated by 1 °C: | |

| — at a temperature of -50…0 °С | 6,6×10-5 |

| — at a temperature of 0...+50 °C | 9,8×10-5 |

| Friction coefficients on metal surfaces (steel, bronze): | |

| - without lubrication | 0,1-0,2 |

| - water lubricant | 0,006 |

| - oil | 0,008 |

Caprolon sheets

Sheet caprolon – polyamide PA-6 in the form of a plate with a rectangular cross-section. Widely used in industry for the production of bearings, shafts, rollers, liners, bushings and other equipment elements. The sheets vary in thickness, weight, and dimensions. You can buy sheet caprolon with a thickness from 6 to 250 millimeters, sheet size 1000*1000 mm, 1000*2000 mm, 500*700 mm, and other sizes. The weight of the sheet depends on its dimensions and thickness, for example, the weight of one sheet of polyamide 6, 10 mm thick, 1000*1000 mm in size is about 11.7 kg, and 40 mm thick with the same size is about 49.3 kg.

You should not strike sheet caprolon with a hammer or other objects, because the surface is slippery and smooth, elastic. You should only handle the sheets with gloves; the sharp edges can damage your skin. Mechanical processing is carried out on standard metalworking machines with tools made of carbon steel or, during long-term work, with special tips made of tungsten carbide or diamond-coated. When producing complex parts, it is advisable to distribute the scope of work into several simple operations in order to avoid damage and cracking of the semi-finished product.

When storing sheet caprolon in the cold (cold rooms) before putting it into production, it is necessary to keep the sheets for about 5 - 7 days at a higher temperature (warm rooms).

Technical specifications

Despite the relative youth of the material and recent use (no more than 30 years), its scope of application is expanding, and its popularity is growing , largely due to its properties and characteristics.

Caprolon, technical characteristics:

- density (g/cm3) from 1.135 to 1.16 depending on the brand and modification;

- tensile strength (MPa) from 70 to 100;

- the maximum permissible temperature range for long-term operation is +110 degrees, and for short-term operation it can reach +150 degrees;

- subject to melting at a temperature of 225 degrees.

Just a small part of the technical parameters shows the high strength and wear resistance of caprolon.

Application

Due to the unique properties and technical characteristics of PA-6 polyamide, many different types of products are made from it for a wide variety of industries and human activities. These are rollers, pulleys, liners, caprolon bushings, elements of sliding and rolling bearings.

The ability to absorb dynamic loads, noise and vibration makes this type of plastic in demand for covering guides, wheels, blocks, as well as in the manufacture of gears (for example, in a household electrical appliance such as an electric meat grinder).

PA-6 is also used for the manufacture of parts for lifting mechanisms, high-pressure gearboxes, friction units subject to high loads, etc. It is used to produce impellers, pump blades, gears, rollers for conveyor belts, and housings. At food industry enterprises you can often find cutting boards made of PA-6.

Scope of use

Caprolon, whose technical characteristics are quite unique, is used instead of metals. The material is 6 or even 7 times lighter than steel, which indicates that the products are light in weight and have high strength. Caprolon is used for the manufacture of bearings that are resistant to corrosion, are wear-resistant, have a low coefficient of friction, among other things, these parts have a self-lubricating effect.

Caprolon is used to produce gears, pump blades, impellers, various housings, as well as rollers that form the basis of conveyor belts. Sometimes cutting boards are also made from this material, which are convenient for use in the meat industry.