This is a type of rolled metal that has a U-shaped cross section. This structure is formed from a wall and two shelves. Modern construction is unthinkable without such elements, which, with a relatively low weight, can easily withstand significant loads. If you need a channel, the dimensions of which must be strictly defined, then you need to remember that there are equal and unequal flange products. In the second case, the dimensions of the shelves forming the U-shaped section will be different.

The following types of channels are used in construction:

- shelves having an internal slope;

- with parallel internal edges;

- bent equal-strength and unequal-strength;

- special;

- cold rolled.

WHAT IS A CHWELLER?

.

The very word “channel” in German is translated as “skirt”; these two items have some distant similarities. The channel is a structure made of non-ferrous or ferrous metal, in cross section resembling the letter P in various variations, since the edges can be either parallel to each other or located at an angle. A distinctive feature of this product is strength, so most often channels are made of steel and its alloys, and are used to strengthen any supports, components, surfaces made of fragile materials, frames.

The production of channels is strictly regulated, which means that the products produced by a metalworking enterprise must comply with state standards, that is, be universal in use. Each type of channel has its own GOST.

Classification of channels by size

The use of a channel, a U-shaped beam of long products, fully justifies its name. “Skirt” translated from German (Schweller) evenly distributes the load, which determines its use as load-bearing and supporting structures in conjunction with other types of basic elements.

The constant demand for various channels determines the production of products in a wide range of standard sizes, purposes and classifications. GOSTs, which regulate the chemical composition of raw materials, production technology, sizes and shapes, indicate all the basic requirements that directly affect the performance characteristics of rolled products.

Application of channels

Metal, as one of the building materials, has been known since ancient times, when its quality was not sufficient for the construction of serious structures. Technologies have developed, new types of steel and product shapes have appeared, and their scope has expanded.

Channels are one of the types of structural elements that cannot be dispensed with in the manufacture of oil rigs, power line supports, and when reinforcing concrete for high-rise buildings. The channel is resistant to various types of loads, which is due to its special shape.

What types of channels are there?

Why do channels have a complex cross-section? Firstly, when constructing buildings and structures, the weight of the structure and the load on the foundation are of great importance. All things being equal, all-metal beams with the ability to withstand the loads that the channel can withstand are much heavier.

That is why various types of channels are used for reinforcement, the dimensions of which are regulated according to the relevant GOST documents. Thus, significant savings in metal are achieved and construction costs are reduced.

The most common are channels with a cross-section resembling the Russian letter “P”. Products are divided into cold and hot rolled products. Varieties of hot-rolled profiles are manufactured with shelves that are located parallel to the planes of the internal shelves or at a certain slope.

This profile is easy to identify by its appearance - sharp corners. There are three categories of channel manufacturing accuracy (to a given size): “A”; "B"; "IN". Accordingly, the first category is highly accurate, the second is increased and the last is normal.

Production of channels

Hot rolled channels are made of a certain steel grade regulated by GOST. A sheet of metal of various widths is cut into strips and rolled under high temperatures. The output results in sharp corners, which distinguishes the channel from its analogue, made by bending blanks.

Channel assortment

The listed products have a range that allows you to choose the desired product option. To determine which channel is suitable in your case, you need to decipher the letter and numerical markings that determine the properties of the products. There is nothing complicated here and the letter designations are intuitive.

So, if a hot-rolled profile is marked “P”, therefore, the flanges are parallel (their internal surfaces). The letter "U" directly indicates that the parallel shelves are on a slope. Letters “accompany” digital designations. For example, marking 24 indicates the distance between the shelves, or rather between their outer surfaces.

If the letter designations “P” and “U” refer to standard types of products, then for a specialized product other meanings are provided. Oddly enough, the letter “C” denotes a product outside the standard, manufactured to order according to specified parameters. Further it is more clear: “L” - light for reinforcement; “E” - economical, with less metal consumption for the product.

The requirements for channel length are not so strict. There are limits, but they are within a certain range and have some variation.

Standards for measured and multiple lengths allow deviations in length of no more than 40 mm for products from two to eight meters.

According to the curvature of the channel, distortion from the specified dimensions is allowed by no more than 0.2% of the entire length of the product. There are no such strict requirements for channels of unmeasured length.

Where and what channels are used

The rolled metal in question is used in many areas and its application is determined not only by its size, but also by the metal alloy. “Black” alloys are not able to withstand extreme loads and may be subject to deformation, so hot-rolled steel channels with high performance characteristics are used for walls and ceilings.

Table of approximate prices for channels in Moscow

| Channel | According to GOSTSize | Steel grade (st) | Cost in rubles |

| GOST 8240 P | 5P | 3 | 39700 |

| GOST 8240 P | 6.5P | 3 | 36450 |

| GOST 8240 P | 8P | 3 | 36450 |

| GOST 8240 P | 10P | 3 | 36450 |

| GOST 8240 P | 12P | 3 | 36450 |

| GOST 8240 P | 14P | 3 | 36450 |

| GOST 8240 P | 16P | 3 | 36450 |

| GOST 8240 P | 18P | 3 | 36450 |

| GOST 8240 P | 20P | 3 | 41900 |

| GOST 8240 P | 22P | 3 | 44450 |

| GOST 8240 P | 8P | 09G2S | 40900 |

| GOST 8240 P | 10P | 09G2S | 39900 |

| GOST 8240 P | 12P | 09G2S | 34450 |

| GOST 8240 P | 14P | 09G2S | 34400 |

| GOST 8240 P | 16P | 09G2S | 34450 |

| GOST 8240 P | 18P | 09G2S | 40940 |

| GOST 8240 P | 20P | 09G2S | 52500 |

| GOST 8240 P | 22P | 09G2S | 52500 |

Channels marked 10P are produced by hot rolling of steel in special mills; heat treatment is not carried out as an additional operation.

Marking 12P - used for reinforcing structures and increasing the load-bearing capacity of various structures.

Grade 14P is produced in rolling mills. It is used to create structures of increased strength and has increased rigidity.

Table for channels with slope

Table for channels with parallel edges

Table for channels economical

If you have questions about the current cost of products or the order of shipment of products, please contact the company manager at the phone numbers listed on the website.

Channel

Switch to mobile version

Channel (Schweller) is a rolled metal product with a U-shaped cross-section, length from 4 to 12 m and thickness from 4 to 15 mm. Steel channels are produced by hot rolling or bending steel on section machines. Due to its high load-bearing capacity, it increases the reliability of the structure and its service life. The main criteria for a channel are strength and resistance to corrosion.

For the production of channels, different materials are used, but most often structural steel. As a rule, load-bearing structures are erected from steel channels, so the reliability of the structure depends on its strength.

Channel markings

The channel brand usually includes a number and a letter in the designation, for example: 10 P or 18 C. The number in the product designation means the distance between the outer edges of the channel in centimeters; the letter designations indicate the properties of the shelves and edges of the channel:

- “U” - channel with a slope of the internal edges of the shelves

- “P” - channel with parallel flange edges

- “L” - lightweight model with parallel edges of shelves

- “E” - economical model with parallel edges of shelves

- "C" - special channel

Product designation

To make choosing the right product easier, the distance between shelves is used. This is the number that appears after the designation of the element, but there are also differences in length: it varies from 4 to 12 meters.

From the point of view of counteracting large loads directed vertically downward, the channel is second only to the I-beam. The width of the shelves varies and starts from 32 mm, and can reach 115 mm, therefore the load capacity varies within a wide range. The situation is similar with height, which ranges from 5 to 40 cm.

It must be remembered that the standard channel 10, the dimensions of which can be different, will be the cross-section that is required in a particular case and depends on the place of application. The letter found after the number indicating the distance between the shelves will tell the specialist about the type of product. If a product with the “U” index is used, then we are talking about inclined internal edges. When the shelves are located parallel, this is a “P” series channel. There are also “L” - light, “S” - light varieties.

channel 20: dimensions, description, characteristics, parameters, manufacturing, photo

Dimensions of bent unequal channels 20, GOST 8281-80 Number h (mm) bxb1 (mm) s (mm)

| 20 | 200 (mm) | 50x30 (mm) | 4 (mm) |

Following GOST 8240-97, 20mm channel is produced only at enterprises. However, when purchasing, you should personally verify this and check the product for a certificate of conformity. Otherwise, huge defects may arise during the operation of buildings or the structure may completely collapse.

The production is mainly based on alloys with the addition of structural carbon and low-alloy steel. Such alloys have special grades st2ps and st3sp, respectively. Alloys have many different metals in their chemical composition (for example, aluminum).

Manufacturers of 20P channel of this type use the hot-rolled method to produce materials. The essence of the technology is that raw materials undergo several stages of mechanical deformation, which is carried out on a special mill.

The equipment is equipped with a number of rolling units, which successively change the geometry of the metal until it acquires the required profile.

When setting up systems, they are guided by the final dimensional indicators, with the exception of the values of the radii of curvature of the shelves on the inside, the edges of the shelves and the angle between their surfaces. These parameters are set taking into account the correct construction of the calibers.

The difference between this technology and alternatives is that before profiling begins, the 20P channel blank goes through a stage of heating to a high temperature.

The exact indicators depend on the selected metal, that is, the level at which it is heated to a state of increased ductility.

At this stage, the raw material is given a quality that allows the manufacturer of the 20P channel to eliminate the occurrence of internal stresses in the structure, as well as reduce the wear of the working elements of the systems and the number of profiling stages.

After reaching the specified mark, processing of the metal workpiece begins. It passes successively through rollers, which with each step give a geometry closer to the required result. When leaving the rollers, the steel part takes on a standard size shape.

Due to heating, the metal structure becomes uniform, and such materials withstand the load better than alternatives. No additional temperature treatment is required to reduce internal stresses of the product. However, in comparison with analogues, the prices of 20P channel are higher, since the production stages, in particular, heating to the required level, require the expenditure of significant resources.

Channel assortment 20

The range of channels is large and has special letter designations in order not to be confused and to easily recognize the production method:

- “P” - channel 20P has parallel edges of the shelves.

- “U” - the internal edges of the shelves are located at an angle.

- “C” is a special channel. GOST does not define the parameters of this product. Since such channels are made to order, and the client himself sets the parameters he needs.

- "L" - light. Manufacturing is carried out in accordance with GOST, but only light metals will be added during the production process.

- “E” is an economical channel. Less metal is used in production.

- “B” - such a channel is used only for the construction of cars or cars.

- “T” is a metal product that has found its application for tractors.

All channels are produced in several ways:

- Hot rolling method.

- Cold rolled or bent channel.

- Special method.

The channel 20 can be produced by hot rolling. The production process is described in more detail in GOST 8240-97.

Channel dimensions 20

Based on the above, the manufacture of channel 20 occurs in compliance with GOST. The standard size of channel 20 is 20 meters. But you can always order a channel with the required parameters. Such a channel is indicated by a special marking in the form of the letter “C”.

Technical characteristics of channel 20

The product under consideration is heavier than the 16P channel, for example, because the parameters are higher in terms of strength characteristics, but the mass of the components has also increased. The production is carried out based on the requirements of the state-level regulatory document for channel 20P GOST 8240, which came into force in 1997 and has not undergone major revisions since then.

The width of the rolled product corresponds to 200 mm and is indicated in the marking in centimeters, that is, divided by 10. The height of the shelves is 76 mm, while the elements have a thickness of 9.0 mm. The thickness of the wall, on the contrary, is uniform along its entire length, with the exception of the rounded bases at the transitions to the shelves, is equal to 5.2 mm.

The external corners of the profile are straight, and the internal ones are rounded, due to this the product receives greater rigidity and strength, in comparison with such an analogue as a bent channel, in which both corners are rounded. The radius value from the inside is equal to 9.5 mm.

The edges of the product shelves are also rounded on the inside of the part, the radius is 5.5 mm.

There are other aspects for channel 20 GOST 8240, which are assessed rather during the design process and are more important for the expert community of the metallurgical sector and engineers purchasing materials:

- cross-sectional area of the component in the transverse direction corresponds to 23.4 cm²

- moments of inertia along the X and Y axes are equal to 1530 cm4, respectively; and 134 cm4;

- moments of resistance in the same directions are equal to 153 cm³ and 25.2 cm³;

- the radius of gyration is 8.08 and 2.39 cm for the X and Y axis;

- the static half-section moment is equal to 88 cm³.

Before buying a 20P channel, it is worth considering two more aspects that are appropriate to know, both for ordinary builders when implementing household projects, and for representatives of the professional community. The first of them is the mass of a linear meter, and the second is the price of a 20P channel.

In the second case, we are talking about a significant spread, which depends on the region and product parameters related to the capabilities of the manufacturing company.

It is important to take into account that the cost is affected by a fairly pronounced seasonality, that is, at the end of the construction season, the prices of channel 20 fall slightly, and with its beginning they rise, usually within 10 percent.

Channel 20 is a U-shaped metal product. Thanks to this, the channel is able to withstand enormous loads, despite its low weight.

Channel 20 has the following technical parameters:

- Shelf height 200mm.

- Width 76mm.

- The wall thickness of the channel is 5.2mm.

- The thickness of the shelves is 9mm.

- Cross section 24mm2.

- The radius of internal curves is 9.5mm.

In the photo you can see a 20mm channel.

Channel weight 20

Despite the fact that the channel contains an alloy, the part is durable and weighs little. Channel 20 has a small mass per linear meter. This is the main advantage, thanks to which the channel is in great demand among builders. The weight of 1 meter of channel 20 is 18.40 kg.

Advantages of channel 20

- The material meets all strength requirements.

- Channel 20 gives greater rigidity.

- Not subject to deformation and corrosion.

- Light weight, making working with the part easy, even at height.

Channel 20 GOST is a standard instruction for the proposed assortment. Each enterprise must comply with GOST.

In this case, the result is an ideal channel that can be safely used in any production area.

Channel dimensions 20P

You can buy channel 20 of various types, which apply to the entire range of products as a whole. Common groups are as follows:

- products characterized by the presence of a slope between the shelves. Such materials are marked with the letter U, for example, channel 20U, and are distinguished by the presence of an angle between the structural elements and the vertical. It is convenient to use such products as guides, since the geometry provides reliable support for rollers and similar systems;

- the second group is designated P, and the product in question is included in it. Manufacturers of 20P channel create materials of this class with parallel flanges. Such products have greater rigidity if force is applied to the site, since the shelves interfere with deformation, therefore the products have found wide application in the construction industry and mechanical engineering, including in the form of load-bearing elements;

- the third class is marked E, that is, economical products whose edges are parallel. The series got its name due to the fact that the prices of channel 20 of this class are more affordable than analogues. This factor is achieved by reducing metal costs when producing a profile; it is obvious that the load-bearing characteristics suffer from this first of all, therefore the rolled product is guaranteed to work in conditions with less constant/variable influences. For serious loads it is worth buying a 20P channel;

- category L, that is, light profiles, can be called similar in characteristics. The components of the structures are lightweight, which makes them a reasonable solution when it is necessary to give the system high strength while saving weight;

- Manufacturers of channel 20 also produce materials marked C, that is, special products. These components have a slope of internal edges, which makes them similar to the U class. For this reason, the cross-section in the transverse direction of the marked groups is similar, similarly, the P, E and L profiles have common features. The slope of the shelves for a special type and U corresponds to a spread from 4 to 10 percent.

In addition to the above classes, there is a division according to rolling accuracy. You can buy channel 20 with high profiling accuracy and increased accuracy, group A and B, respectively.

The severity of permissible deviations from the table parameters, and therefore reliability during operation, depends on the indicator. The material is better able to calculate the load-bearing capacity during design, since there is a higher probability of maintaining the optimal level.

You have to pay for the characteristics by increasing the price of the channel by 20 P.

The range of rolled products deserves special attention; according to the standard, you can buy a 20 P channel, as well as various standard sizes from 50 to 400 mm wide with flanges from 32 to 115 mm.

Application of channels

Today, the demand for such products is quite high, which is due to the widespread use of concrete and metal structures. The attractiveness of the channel lies in the fact that it is light in weight and can withstand quite a significant load. The channel owes this feature to its U-shaped profile, which provides the necessary combination of structural properties and reliability. Metal structures of this type can be used both for construction and for repair work. They are used in a wide variety of fields, from mechanical engineering to the creation of various shelving.

Various metal structures that are erected for advertising purposes or for laying communications are also places where such elements are in demand. Channel 20, whose dimensions vary widely, is excellent for this purpose.

Its type depends on where the metal structure will be used. For example, to work under heavy loads, it is better to use a design with inclined shelves. In fact, the outer contour of the product still remains U-shaped, but the inner one already has some deviations from this shape, because the slope of the inner walls can be large. This results in increased wall thickness and higher reliability.

The type of channel and its parameters are selected only after calculations have been carried out, and they must be performed by a specialist. Otherwise, problems may arise due to the wrong choice of thickness or other characteristics of the product, which means the reliability of the structure will decrease.

WHY DO YOU NEED A CHWELLER

As mentioned earlier, this rolled metal product is found everywhere.

Steel channels, especially strong and reliable, thanks to these qualities, they are used to strengthen walls, reinforce concrete structures, build power lines, and make floors. This ensures the durability of these structures. If the channel is perforated, that is, it has holes for fastening, it can be used in installation work without welding. Also, pipes made of less durable materials can be laid inside the channel, this gives the pipeline high wear resistance.

Aluminum channels are used in lighter structures, in the manufacture of office partitions, shop windows, shelving, in everyday life, in repair, finishing and construction work, and in mechanical engineering.

Channel: dimensions affecting the scope of application

Summarizing the above, the conclusion suggests itself that a channel is a rolled metal product that is used for reinforcing reinforced concrete structures, for the production of crane products, electrical supports, bridges, oil rigs and other large-scale structures. The wide range of uses is due to the high level of strength and stability with a relatively small weight of the product. At the same time, different sizes of channels are applicable in specific areas or have a special purpose.

Thus, due to its compact dimensions, channel 8 is widely used in individual construction as concrete lintels, and is also used for making foundations for the construction of door and window openings. Channel 10, made by hot rolling, is widely used due to its universal size and strength.

The scope of use of the channel directly depends on its size and steel thickness.

Channel 12 is also produced in the same way. Its main positive feature is excellent weldability. It is used to increase the load-bearing capacity of a structure and as reinforcement for structures. Channel 14 is produced using rolling machines. Increased rigidity suggests its use as load-bearing beams in floors during the construction of high-rise buildings, as well as in carriage building.

On a note! When choosing rolled metal products, you should remember that there are different series of channels. Profiles in which the edges of the shelves are placed parallel are marked with the letter “P”; special channels are marked “C”. Models with inclined inner edges of the shelves are designated by the letter “U”; economical profiles correspond to; the sign “L” implies lightweight versions of the channels.

Channel 16, made by hot rolling, is widely used in the construction of high-rise buildings, as well as in the construction of metal supports for bridges. The dimensions of channel 18 allow it to be used as reinforcement in high-rise buildings and in structures with a high degree of load.

Profiles marked 20 and above can be used for the construction of bridges and other large objects with high loads.

Profiles marked 20, 22, 24 belong to the high-strength category. They are used in the construction of highly loaded buildings and structures that move. For example, the dimensions of a channel 24 suggest its use in the construction of sliding bridges, as well as cranes with high lifting capacity.

Channel 40, having maximum rigidity, is used in heavy industry, where enormous loads are required, in shipbuilding, as well as for the construction of oil platforms.

Rolled metal assortment: popular types of products and algorithms for calculating weight (read more)

Thus, channels are of great importance in construction, and therefore are widely used in various fields. When choosing products, you need to navigate the range of sizes and know the main characteristics of each type of channel. This will allow you to select the desired series and use this type of rolled metal products as efficiently as possible.

Types of channel

The special channel is intended for use in the automotive industry (GOST 19425-74) and in carriage building (GOST 5267.1-90).

They are manufactured in lengths from 4 to 13 m, but on special order they can be longer than 13 m. The lengths of special channels are:

- channel of measured length;

- multiple measured length;

- measured length with a remainder of up to 5% of the batch weight (residue of at least 3 mm);

- multiple measured length with a remainder of up to 5% of the batch weight;

- of unmeasured length.

Depending on the rolling accuracy, the special channel is divided into: high strength - A, normal strength - B.

Steel bent equal-flange channels in accordance with GOST 8278-93 are manufactured on pipe mills from coiled steel of ordinary quality and high-quality carbon structural steel. The height of the equal-flange channel ranges from 50 to 400 mm, width from 32 to 115 mm.

The different lengths of bent equal-flange channel are:

- channel of measured length;

- measured and unmeasured lengths in an amount of no more than 5% of the batch weight;

- multiple measured length;

- multiple measured lengths from unmeasured lengths in an amount of no more than 5% of the lot weight;

- unmeasured length;

- limited length within unmeasured.

Steel bent unequal-flange channels are manufactured on roll forming mills from rolled cold-rolled and hot-rolled steel of ordinary quality, high-quality carbon structural and low-alloy steel in accordance with GOST 8281-80. They are also divided by numbers, which indicate the distance between the shelves (in mm). The length varieties are the same as for equal-flange channels.

Depending on the rolling accuracy, bent channels are divided into: high precision - A, increased precision - B, normal precision - B.

The highest category of quality for bent unequal and equal flange channels corresponds to channels with categories A and B.

Forms of bent channel: U - with a slope of the internal edges of the shelves, P - with parallel edges of the shelves, L - light series with parallel edges of the shelves, S - special.

Characteristics of channel 10: dimensions, weight, cost

The range of channel 10, as a fairly popular rolled metal product, is quite wide. The characteristics of its varieties and types are regulated by GOST No. 8240, developed back in 1989. The properties of products include the parameters of shelves and walls, in particular their height and width, and also the radii of curvature of channels marked 10U are taken into account.

Channel 10 has three subtypes with corresponding markings:

- U – a profile in which the internal shelves are made with a slope;

- P – channel, where the edges of the flanges are parallel;

- E - economical products with parallel placement of shelves.

On a note! Each type of channel has its own designation, for example, 10P, 10U or 10E. The corresponding values are contained in a separate table. Despite the same numerical data, these are different types of products.

The range of channels includes products of various sizes and configurations.

The most used in various industries is, due to its size, the 10P channel. It is widely used in individual construction for the construction of load-bearing structures. The number 10 in the marking, in fact, indicates its height, equal to 100 mm, and the letter P indicates the type of profile, while emphasizing the parallel arrangement of the shelves.

This type of channel has the following parameters:

- width is 46 mm;

- wall thickness – 4.5 mm;

- shelf thickness – 7.6 mm;

- radius of curvature – 7 mm;

- The radius of curvature at the edge of the shelf is 4 mm.

To determine the weight of channel 10, it is necessary to know the cross-sectional area. This figure corresponds to 10.9 cm². This type of channel is produced in lengths from 4 to 12 m. Longer products are made to order. The weight of 1 meter of channel 10 with a steel density of 7.85 g/cm³, according to calculations, is 8.59 kg. The error in the indicated mass values may be 3-5%. The average price of channel 10 per meter is 356 rubles.

Channels are made by hot-rolled, cold-rolled and by bending metal sheets.

Some features of choice

The range of channels, of course, is significantly inferior in variety to the range of angles, but this does not prevent the selection of a product of the required dimensions and characteristics to solve a specific design problem. When choosing a specific brand from the assortment, you should be guided by the following rule, which is relevant for products of any profile: having decided on the type of channel that meets your requirements, you should include in the specification for the drawing the brand that is located closer to the beginning of the table.

The assortment, in which various types of channels are presented in table form, allows you to determine not only their sizes, but also a number of other important parameters:

- linear meter weight;

- cross-sectional area;

- axial moment of inertia;

- axial moment of resistance;

- radii of inertia.

The last three parameters are calculated relative to the central axis of the channel section.

It is very important to choose those brands of channels whose mechanical characteristics are not lower than the calculated ones by more than 5%. If this condition is not met for the selected brand of product, then it is better to take a channel one number higher.

Determining the weight and price of a channel per meter: table of sizes, cost of profiles

Complex calculations of specific gravity, in addition to mathematical skills, also require updating the school course in physics and geometry. Therefore, it is better to use ready-made calculations given in special tables, or use an online calculator. To do this, just enter the necessary data and get an accurate result.

The cost of channels is determined in accordance with linear meters. The price formation is influenced by the profile height, which determines the product number, as well as the grade of steel from which the product is made. For example, a channel made from low-alloy steel will cost an order of magnitude more than similar products made from carbon steel. This is due to the fact that the first type of raw material has increased strength characteristics.

The current average prices for channels on the Russian rolled metal market are shown in the table:

| Channel number | Weight per linear meter, kg | Length in ton, m | Price per linear meter, rub. |

| 5 | 4,8 | 207 | 200 |

| 6,5 | 5,9 | 169 | 240 |

| 8 | 7,1 | 142 | 265 |

| 10 | 8,6 | 115 | 350 |

| 12 | 10,4 | 97 | 420 |

| 14 | 12,3 | 82 | 480 |

| 16 | 14,2 | 71 | 520 |

| 18 | 16,3 | 60 | 600 |

| 20 | 18,4 | 55 | 760 |

| 22 | 21,0 | 48 | 870 |

| 24 | 24,0 | 42 | 1020 |

| 27 | 27,7 | 35 | 1150 |

| 30 | 31,8 | 32 | 1400 |

| 40 | 48,3 | 21 | 4250 |

Above is a general table. In order to have an idea about each type of channel, its individual features, sizes and characteristics, it is worth getting to know each type in more detail. Below, as an example, we will consider the most popular types and sizes of channels that are in high demand and widely used.

Marking

If you look at the range of channels, you can see that it includes metal profiles with a wide range of sizes. With such a variety of options offered, it is very difficult to choose exactly the brand of channel that will be optimally suited for solving a particular problem. Naturally, the manufacturers took this point into account. To designate their products, they use markings, which can be used to get a fairly complete picture of the characteristics and dimensions of the U-shaped profile.

Markings that comply with GOST 8240-97 include both digital and alphabetic designations. The first number in the designation is the main characteristic; it corresponds to the size of the channel, that is, the distance between its flanges. By the letter in the marking you can determine what type the channel is. These can be products in which the internal edges of the shelves are made with a slope or are parallel to each other (“U” and “P”, respectively), metal profiles of economical (“E”) or light (“L”) type, special purpose (“S” ).

If you need to know all the other dimensions of a channel of a certain brand from the assortment, then for this there is a special table in which they are indicated. The choice of a product of a certain brand is made depending on what kind of loads the structure for which it is planned to be used will be subjected to.

Weight of channels, their markings and symbols

To designate different types of channels, special markings are used.

The letter indicates the type of profile, characterizing the structural features and arrangement of the edges:

- “P” – indicates parallelism;

- “U” – indicates the presence of a slope on the edges;

- “E” – indicates efficiency;

- “L” – implies lightness;

- “C” indicates the special purpose of the profile.

On a note! The numerical indicator next to the letter indicates the size of the product; it corresponds to the height given in the GOST table. It should be noted that channels are usually marked with numerical values in centimeters, and their height in the table is indicated in millimeters. Visually it looks like this: channel 8, channel weight 12 or channel dimensions 16P.

To determine the types of channels, as well as their characteristics, special symbols are used.

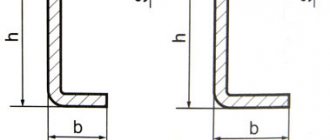

In addition to the height of the product, other size indicators are also used. In the tables they have special designations:

- h is the profile height, which is the main quantity that determines the size of rolled metal products;

- b – indicates the width of the shelves;

- S – indicator of the thickness of the main wall;

- R – determines the radius of the rounded inner part of the shelf;

- t – indicates the thickness of the shelves;

- r is the value of the total radius of curvature of the shelves.

An important indicator in the choice of material (when designing construction) is the weight of the channel. Correct calculation of data allows you to accurately calculate the quantity of required products and, thus, save on their purchase. There are several methods for calculating the weight of a linear meter. They depend on the method of production of rolled products. For example, to determine the specific gravity of a hot-rolled channel, the indicators of the radii of internal curvature and flange curvature are taken into account.

Drawing of a hot-rolled steel channel with a slope and parallel flanges.

Aluminum channel

The classic U-shaped structure made of steel not only has greater resistance to bending, but also has good resistance to torsional deformation, so the scope of application of such products is very wide. The use of aluminum has further expanded the scope where these metal structures are used today.

Channel 16, the dimensions of which are ideal for those structures that experience light loads, is used no less often than its steel variety. Aluminum structures are well suited for applications where it is necessary to contain elements in contact with the environment. Aluminum itself differs favorably from steel in that it does not interact with air or water, therefore the reliability of the future structure does not depend on such random factors as bad weather or improper care of painted elements.

In conclusion, we note that one of the main advantages of most types of channels is the ability to construct metal structures without the use of welding. This allows you to create collapsible structures that can be moved to another location in whole or in part. For example, this technology is used to create a variety of seasonal structures, temporary buildings or warehouses. A channel, the dimensions of which are proportional to its weight, is a modern building material that is in no hurry to give up its position to plastic or concrete. In general, an aluminum channel is much more profitable than a profile pipe of the same size, since it allows you to further reduce the weight of the future structure.

“Hot-rolled steel channels. Assortment" - GOST 8240 97: description of the document

The main difference between a hot-rolled channel and a bent one is that it is produced by the hot rolling method. It is manufactured in accordance with several GOSTs, in accordance with the needs of a particular industry. The range of channels GOST 8240 97 was approved by Gosstandart back in 1997 and subsequently approved by almost all post-Soviet countries. On April 5, 2001, by decree of the State Committee of the Russian Federation for Standardization and Metrology, the document was put into effect on the territory of Russia.

Drawing of a standard 80 mm metal channel with dimensions

As a direct State Standard in the Russian Federation, it began to operate with some changes from the beginning of 2002, replacing the previously valid GOST 8240 89 “Hot-rolled steel channels. Assortment". The document indicates all the quality characteristics of rolled metal building materials produced by the hot-rolled method.

The current document indicates the scope of application of the products, establishes a range of hot-rolled steel channels with a height of 5-40 cm and a flange width of 32-115 mm. GOST includes various parameters of shapes and sizes, dividing products into different series:

- with sloped edges inside;

- with the edges of the shelves located parallel;

- economical models with parallel edges;

- lightweight products with shelf edges located parallel.

Each specific series, in accordance with the dimensions and qualities of the steel from which rolled metal is produced, provides its own extended table for the assortment of channels GOST 8240-97. In total, the document contains 7 tables, thanks to which you can choose the most suitable material for construction.

For each type of channel there is its own table of state standards, which indicates the main characteristics of the material

Channels 10P, 12P and 10U, corresponding to GOST 8240‒97

In the list of products that meet the requirements of GOST 8240-97, the most popular are channels with dimensions of 10 and 12 cm. All of them are produced by hot rolling. In this case, the number of rolling depends on the initial dimensions of the workpiece and the required accuracy of the product. The workpiece is subjected to heat treatment reaching 1250 °C.

Helpful advice! Considering that GOST tables indicate dimensions in millimeters, you can often find markings like channel 120, although this indicator indicates a U-shaped rolled metal product marked 12P or 12U.

Channel 10P has the following characteristics:

- the weight of a linear meter is 8.59 kg;

- 1 ton holds 116.4 m of channel;

- the height of the profile corresponds to its main dimension and is equal to 100 mm;

- channel width – 46 mm;

- profile walls have a thickness of 4.5 mm;

- The thickness of the channel shelves reaches 7 mm.

Depending on their purpose, channels are divided into light and reinforced profiles

Channel 10U, like 10P, has similar characteristics of a nominal height of 100 mm, a linear meter weight of 8.59 kg, a width of 46 mm and a thickness of 4.5 mm. One ton of material contains 116.4 m. The differences lie in the characteristics of the rounded shelves. In particular, the radius of the rounded side of the shelf is 7 mm, and the radius of the curvature of the shelves is no more than 3 mm.

Taking into account the differences in the main size, that is, in the height of the rolled metal, the 12P channel has significant differences in parameters. Its characteristics are as follows:

- the weight of a linear meter is 10.40 kg;

- 1 ton holds 96.15 m of channel;

- product height – 120 mm;

- channel width – 52 mm;

- profile walls have a thickness of 4.8 mm;

- The thickness of the channel flanges should not exceed 7.8 mm.

Table with dimensions of channels with parallel flange edges.

| Series P channel number | h | b | s | t | R | r | Cross-sectional area F cm2 | Weight 1m/kg | Reference values for axes | X0 cm | ||||||

| no more | XX | YY | ||||||||||||||

| mm | Ix cm4 | Wx cm3 | Ix cm | Sx cm3 | Iy cm4 | Wy cm3 | Iy cm | |||||||||

| 5P | 50 | 32 | 4.4 | 7.0 | 6.0 | 3.5 | 6.16 | 4.84 | 22.8 | 9.1 | 1.92 | 5.61 | 5.95 | 2.99 | 0.98 | 1.21 |

| 6.5P | 65 | 36 | 4.4 | 7.2 | 6.0 | 3.5 | 7.51 | 5.90 | 48.8 | 15.0 | 2.55 | 9.02 | 9.35 | 4.06 | 1.12 | 1.29 |

| 8P | 80 | 40 | 4.5 | 7.4 | 6.5 | 3.5 | 8.98 | 7.05 | 89.8 | 22.5 | 3.16 | 13.30 | 13.90 | 5.31 | 1.24 | 1.38 |

| 10P | 100 | 46 | 4.5 | 7.6 | 7.0 | 4.0 | 10.90 | 8.59 | 175.0 | 34.9 | 3.99 | 20.50 | 22.60 | 7.37 | 1.44 | 1.53 |

| 12P | 120 | 52 | 4.8 | 7.8 | 7.5 | 4.5 | 13.30 | 10.40 | 305.0 | 50.8 | 4.79 | 29.70 | 34.90 | 9.84 | 1.62 | 1.66 |

| 14P | 140 | 58 | 4.9 | 8.1 | 8.0 | 4.5 | 15.60 | 12.30 | 493.0 | 70.4 | 5.61 | 40.90 | 51.50 | 12.90 | 1.81 | 1.82 |

| 16P | 160 | 64 | 5.0 | 8.4 | 8.5 | 5.0 | 18.10 | 14.20 | 750.0 | 93.8 | 6.44 | 54.30 | 72.80 | 16.40 | 2.00 | 1.97 |

| 16aP | 160 | 68 | 5.0 | 9.0 | 8.5 | 5.0 | 19.50 | 15.30 | 827.0 | 103.0 | 6.51 | 59.50 | 90.50 | 19.60 | 2.15 | 2.19 |

| 18P | 180 | 70 | 5.1 | 8.7 | 9.0 | 5.0 | 20.70 | 16.30 | 1090.0 | 121.0 | 7.26 | 70.00 | 100.00 | 20.60 | 2.20 | 2.14 |

| 18aP | 180 | 74 | 5.1 | 9.3 | 9.0 | 5.0 | 22.20 | 17.40 | 1200.0 | 133.0 | 7.34 | 76.30 | 123.00 | 24.30 | 2.35 | 2.36 |

| 20P | 200 | 76 | 5.2 | 9.0 | 9.5 | 5.5 | 23.40 | 18.40 | 1530.0 | 153.0 | 8.08 | 88.00 | 134.00 | 25.20 | 2.39 | 2.30 |

| 22P | 220 | 82 | 5.4 | 9.5 | 10.0 | 6.0 | 26.70 | 21.00 | 2120.0 | 193.0 | 8.90 | 111.00 | 178.00 | 31.00 | 2.58 | 2.47 |

| 24P | 240 | 90 | 5.6 | 10.0 | 10.5 | 6.0 | 30.60 | 24.00 | 2910.0 | 243.0 | 9.75 | 139.00 | 248.00 | 39.50 | 2.85 | 2.72 |

| 27P | 270 | 95 | 6.0 | 10.5 | 11.0 | 6.5 | 35.20 | 27.70 | 4180.0 | 310.0 | 10.90 | 178.00 | 314.00 | 46.70 | 2.99 | 2.78 |

| 30P | 300 | 100 | 6.5 | 11.0 | 12.0 | 7.0 | 40.50 | 31.80 | 5830.0 | 389.0 | 12.00 | 224.00 | 393.00 | 54.80 | 3.12 | 2.83 |

| 33P | 330 | 105 | 7.0 | 11.7 | 13.0 | 7.5 | 46.50 | 36.50 | 8010.0 | 486.0 | 13.10 | 281.00 | 491.00 | 64.60 | 3.25 | 2.90 |

| 36P | 360 | 110 | 7.5 | 12.6 | 14.0 | 8.5 | 53.40 | 41.90 | 10850.0 | 603.0 | 14.30 | 350.00 | 611.00 | 76.30 | 3.38 | 2.99 |

| 40P | 400 | 115 | 8.0 | 13.5 | 15.0 | 9.0 | 61.50 | 48.30 | 15260.0 | 763.0 | 15.80 | 445.00 | 760.00 | 89.90 | 3.51 | 3.05 |

For channels of the U and P series there is a size that is not subject to control - this is the maximum deviation in wall thickness.

Classification

Channels differ in their scope of application, manufacturing method, overall dimensions, rolling accuracy, and other technical features.

Depending on the purpose, these products are:

- ordinary;

- universal;

- special (for example, for machine or carriage building).

A regular channel is used most often. The overall dimensions of all these types are described in state standards.

Types of channels by production methods:

- obtained by hot rolling;

- special;

- equal flange bent;

- mixed-shelf bent;

- not equal bent.

In terms of rolling accuracy, channels can be high-precision or standard-precision products. The edges of the shelves are located at an angle, parallel. There are also special channels, as well as lightweight and economical products with parallel arrangement of shelf edges.

Table with dimensions of channels for economical shelves with parallel edges.

| Series E channel number | h | b | s | t | R | r | Cross-sectional area F cm2 | Weight 1m/kg | Reference values for axes | X0 cm | ||||||

| no more | XX | YY | ||||||||||||||

| mm | Ix cm4 | Wx cm3 | Ix cm | Sx cm3 | Iy cm4 | Wy cm3 | Iy cm | |||||||||

| 5E | 50 | 32 | 4.2 | 7.0 | 6.5 | 2.5 | 6.10 | 4.79 | 22.9 | 9.17 | 1.94 | 5.62 | 6.02 | 3.05 | 0.993 | 1.23 |

| 6.5E | 65 | 36 | 4.2 | 7.2 | 6.5 | 2.5 | 7.41 | 5.82 | 48.9 | 15.05 | 2.57 | 9.02 | 9.42 | 4.13 | 1.127 | 1.32 |

| 8E | 80 | 40 | 4.2 | 7.4 | 7.5 | 2.5 | 8.82 | 6.92 | 90.0 | 22.50 | 3.19 | 13.31 | 13.93 | 5.38 | 1.257 | 1.41 |

| 10E | 100 | 46 | 4.2 | 7.6 | 9.0 | 3.0 | 10.79 | 8.47 | 175.9 | 35.17 | 4.04 | 20.55 | 22.68 | 7.47 | 1.450 | 1.56 |

| 12E | 120 | 52 | 4.5 | 7.8 | 9.5 | 3.0 | 13.09 | 10.24 | 307.0 | 51.17 | 4.84 | 29.75 | 35.12 | 10.03 | 1.638 | 1.70 |

| 14E | 140 | 58 | 4.6 | 8.1 | 10.0 | 3.0 | 15.41 | 12.15 | 495.7 | 70.81 | 5.67 | 40.96 | 51.76 | 13.13 | 1.833 | 1.86 |

| 16E | 160 | 64 | 4.7 | 8.4 | 11.0 | 3.5 | 17.85 | 14.01 | 755.5 | 94.43 | 6.50 | 54.41 | 73.17 | 16.70 | 2.024 | 2.02 |

| 18E | 180 | 70 | 4.8 | 8.7 | 11.5 | 3.5 | 20.40 | 16.01 | 1097.9 | 121.99 | 7.34 | 70.05 | 100.51 | 20.87 | 2.219 | 2.18 |

| 20E | 200 | 76 | 4.9 | 9.0 | 12.0 | 4.0 | 23.02 | 18.07 | 1537.1 | 153.71 | 8.17 | 88.03 | 134.07 | 25.54 | 2.413 | 2.35 |

| 22E | 220 | 82 | 5.1 | 9.5 | 13.0 | 4.0 | 26.36 | 20.69 | 2134.2 | 194.02 | 9.00 | 111.00 | 179.05 | 31.54 | 2.606 | 2.52 |

| 24E | 240 | 90 | 5.3 | 10.0 | 13.0 | 4.0 | 30.19 | 23.69 | 2927.0 | 243.92 | 9.85 | 139.08 | 249.03 | 40.07 | 2.872 | 2.78 |

| 27E | 270 | 95 | 5.8 | 10.5 | 13.0 | 4.5 | 34.87 | 27.37 | 4200.2 | 311.12 | 10.97 | 178.25 | 316.24 | 47.43 | 3.011 | 2.83 |

| 30E | 300 | 100 | 6.3 | 11.0 | 13.0 | 5.0 | 39.94 | 31.35 | 5837.1 | 389.14 | 12.09 | 224.00 | 395.57 | 55.58 | 3.147 | 2.88 |

| 33E | 330 | 105 | 6.9 | 11.7 | 13.0 | 5.0 | 46.15 | 36.14 | 8021.8 | 488.17 | 13.18 | 281.23 | 497.02 | 65.78 | 3.282 | 2.94 |

| 36E | 360 | 110 | 7.4 | 12.6 | 14.0 | 6.0 | 52.90 | 41.53 | 10864.5 | 603.58 | 14.33 | 350.05 | 618.92 | 77.76 | 3.420 | 3.04 |

| 40E | 400 | 115 | 7.9 | 13.5 | 15.5 | 6.0 | 61.11 | 47.97 | 15307.9 | 765.40 | 15.83 | 445.41 | 770.89 | 91.80 | 3.552 | 3.10 |

The dimensions of the economical channel (E series) are controlled according to GOST 8240-97 (the data in the tables corresponds).

Table with dimensions of light series channels with parallel flange edges.

| Series L channel number | h | b | s | t | R | r | Cross-sectional area F cm2 | Weight 1m/kg | Reference values for axes | X0cm | ||||||

| no more | X–X | Y–Y | ||||||||||||||

| mm | Ix cm4 | Wx cm3 | Ix cm | Sx cm3 | Iy cm4 | Wy cm3 | i0 cm | |||||||||

| 12L | 120 | 30 | 3.0 | 4.8 | 7 | – | 6.39 | 5.02 | 135.26 | 22.54 | 4.60 | 13.43 | 5.02 | 2.24 | 0.89 | 0.76 |

| 14L | 140 | 32 | 3.2 | 5.6 | 7 | – | 7.57 | 5.94 | 212.94 | 30.42 | 5.31 | 18.23 | 6.55 | 2.70 | 0.93 | 0.78 |

| 16L | 160 | 35 | 3.4 | 5.3 | 8 | – | 9.04 | 7.10 | 331.96 | 41.49 | 6.06 | 24.84 | 9.23 | 3.46 | 1.01 | 0.83 |

| 18L | 180 | 40 | 3.6 | 5.6 | 8 | – | 10.81 | 8.49 | 503.87 | 55.98 | 6.83 | 33.49 | 14.64 | 4.10 | 1.16 | 0.94 |

| 20L | 200 | 45 | 3.8 | 6.0 | 9 | – | 12.89 | 10.12 | 748.17 | 74.82 | 7.62 | 44.59 | 22.37 | 6.51 | 1.32 | 1.06 |

| 22L | 220 | 50 | 4.0 | 6.4 | 10 | – | 15.11 | 11.86 | 1070.97 | 97.36 | 8.42 | 57.82 | 32.85 | 8.61 | 1.47 | 1.19 |

| 24L | 240 | 55 | 4.2 | 6.8 | 10 | – | 17.41 | 13.66 | 1476.39 | 123.03 | 9.21 | 72.90 | 46.25 | 11.04 | 1.63 | 1.31 |

| 27L | 270 | 60 | 4.5 | 7.3 | 11 | – | 20.77 | 16.30 | 2218.16 | 164.31 | 10.33 | 97.48 | 65.10 | 14.17 | 1.77 | 1.40 |

| 30L | 300 | 65 | 4.8 | 7.8 | 11 | – | 24.30 | 19.07 | 3186.74 | 212.45 | 11.45 | 126.24 | 89.08 | 17.84 | 1.91 | 1.51 |

Series L channels must have a wall deflection size of no more than 0.15s.

Using a channel

Thanks to the shape of the channel, metal consumption during its production is greatly reduced, and the product has increased tensile strength. Therefore, this rolled metal is used mainly in construction and in the assembly of various structures as a frame reinforcement. In particular, with the help of channels they reinforce wall and interfloor ceilings. Due to its significant strength, this rolled metal very well strengthens any structures, giving them additional rigidity and even earthquake resistance.

In the construction of almost any objects, different types of metal channels are used. They often act as reinforcement to strengthen concrete structures. This rolled metal is also used in the car and automobile industries. Frames, frames, and supporting structures are assembled from channels. Therefore, to order a channel, you need to know exactly its parameters.

Table with sizes of special channels.

| Series C channel number | h | b | s | t | R | r | Shelf slope % | Cross-sectional area F cm2 | Weight 1m/kg | Reference values for axes | X0 cm | |||||

| no more | X–X | Y–Y | ||||||||||||||

| mm | Ix cm4 | Wx cm3 | ix cm | Iy cm4 | Wy cm3 | Iy cm | ||||||||||

| 8C | 80 | 45 | 5.5 | 9.0 | 9.0 | 1.5 | 6 | 11.80 | 9.26 | 115.82 | 28.95 | 3.13 | 22.24 | 7.63 | 1.38 | 1.57 |

| 14C | 140 | 58 | 6.0 | 9.5 | 9.5 | 4.75 | – | 18.51 | 14.53 | 563.70 | 80.50 | 5.52 | 53.20 | 13.01 | 1.70 | 1.71 |

| 14Ca | 140 | 60 | 8.0 | 9.5 | 9.5 | 5.0 | 10 | 21.30 | 16.72 | 609.10 | 87.01 | 5.35 | 61.02 | 14.09 | 1.69 | 1.67 |

| 16C | 160 | 63 | 6.5 | 10.0 | 10.0 | 5.0 | – | 21.95 | 17.53 | 866.20 | 108.30 | 6.28 | 73.30 | 16.30 | 1.83 | 1.80 |

| 16Ca | 160 | 65 | 8.5 | 10.0 | 10.0 | 5.0 | – | 25.15 | 19.74 | 934.50 | 116.80 | 6.10 | 83.40 | 17.55 | 1.82 | 1.75 |

| 18C | 180 | 68 | 7.0 | 10.5 | 10.5 | 5.3 | – | 25.70 | 20.20 | 1272.00 | 141.00 | 7.04 | 98.50 | 20.10 | 1.96 | 1.88 |

| 18Ca | 180 | 70 | 9.0 | 10.5 | 10.5 | 5.3 | – | 29.30 | 23.00 | 1370.00 | 152.00 | 6.84 | 111.00 | 21.30 | 1.95 | 1.84 |

| 18Sat | 180 | 100 | 8.0 | 10.5 | 10.5 | 5.0 | 6 | 34.04 | 26.72 | 1791.01 | 199.00 | 7.25 | 305.48 | 43.58 | 3.00 | 2.99 |

| 20C | 200 | 73 | 7.0 | 11.0 | 11.0 | 5.5 | 10 | 28.83 | 22.63 | 1780.37 | 178.04 | 7.86 | 128.04 | 24.19 | 2.11 | 2.02 |

| 20Ca | 200 | 75 | 9.0 | 11.0 | 11.0 | 5.5 | 10 | 32.83 | 25.77 | 1913.71 | 191.37 | 7.64 | 143.63 | 25.88 | 2.09 | 1.95 |

| 20Sat | 200 | 100 | 8.0 | 11.0 | 11.0 | 5.5 | 6 | 36.58 | 28.71 | 2360.88 | 236.09 | 8.03 | 327.23 | 46.30 | 2.99 | 2.93 |

| 24C | 240 | 85 | 9.5 | 14.0 | 14.0 | 7.0 | – | 44.46 | 34.90 | 3841.35 | 320.11 | 9.29 | 268.89 | 43.70 | 2.46 | 2.35 |

| 26C | 260 | 65 | 10.0 | 16.0 | 15.0 | 3.0 | – | 44.09 | 34.61 | 4088.00 | 314.50 | 9.63 | 1115.60 | 171.60 | 5.03 | 3.91 |

| 26Ca | 260 | 90 | 10.0 | 15.0 | 15.0 | 7.5 | 8 | 50.60 | 39.72 | 5130.83 | 394.68 | 10.07 | 343.15 | 52.62 | 2.60 | 2.48 |

| 30C | 300 | 85 | 7.5 | 13.5 | 13.5 | 7.0 | 10 | 43.88 | 34.44 | 6045.43 | 403.03 | 11.74 | 260.74 | 41.41 | 2.44 | 2.20 |

| 30Ca | 300 | 87 | 9.5 | 13.5 | 13.5 | 7.0 | 10 | 49.88 | 39.15 | 6495.43 | 433.03 | 11.41 | 288.78 | 43.93 | 2.41 | 2.13 |

| 30Sat | 300 | 89 | 11.5 | 13.5 | 13.5 | 7.0 | 10 | 55.88 | 43.86 | 6945.43 | 463.03 | 11.15 | 315.35 | 46.29 | 2.38 | 2.09 |

Series C channels are hot-rolled steel channels, which come in general and special purposes and can have the following dimensions: height 50 - 400 mm, shelf width 32 - 15 mm. The dimensions of the C series channel are controlled according to GOST 8240-97.

Recommendations for selection

When choosing, you should take into account the parameters of the construction channel, as well as the type of metal used in manufacturing. Other recommendations include the following:

- You should purchase material only from a trusted manufacturer who complies with established standards in GOST.

- The surface of the material must not have any defects.

- Minor surface corrosion is acceptable. However, it is worth considering that when using the material you will have to remove it and cover the surface with a protective substance.

- As the size increases, the volume of material used increases, as well as its weight.

The channel can have a variety of sizes. Using markings and special tables, you can determine the main characteristics of the material. The range provides simply a huge selection of the building material in question.

Maximum deviations of parameters (channel sizes) in the table.

| Parameter | Parameter value range | Maximum deviation |

| Height h | Up to 80 | ±1.5 |

| Over 80 to 200 | ±2.0 | |

| Over 200 to 400 | ±3.0 | |

| Shelf width b | Up to 40 | ±1.5 |

| Over 40 to 89 | ±2.0 | |

| Over 89 | ±3.0 | |

| Shelf thickness t | To 10 | -0.5 |

| Over 10 to 11 | -0.8 | |

| Over 11 | -1.0 | |

| Wall thickness s | Up to 5.1 | ±0.5 |

| Over 5.1 to 6.0 | ±0.6 | |

| Over 6.0 | ±0.7 | |

| Warp of shelf D with shelf width b, no more | Up to 95 | 1.0 |

| Over 95 | 0.015b | |

| Wall deflection ƒ along the height h of the profile section, no more | Up to 100 | 0.5 |

| Over 100 to 200 | 1.0 | |

| Over 200 to 400 | 1.5 |

Advantages of hot rolled channel

The main advantage of this product is its shape. Thanks to this, it is used where high rigidity values are needed. Advantages of this type of rolled metal:

- Ability to withstand heavy loads.

- Resistance to deformation.

- Resistance to mechanical damage.

But this metal product has another advantage - the channel is resistant to corrosion.

But there are also disadvantages. Hot-rolled channel is difficult to weld. Therefore, in prefabricated structures, where elements are connected by welding, a product produced by cold rolling is used.

Advantages of bent channel

The production of this type of rolled metal takes place on a special profile bending machine. Paired pressing rollers act on the sheet metal workpiece on both sides, giving it a U-shape. With the help of modern equipment, this process occurs automatically and has a number of advantages: speed, the ability to create a profile of any shape, etc.

Unlike hot-rolled channel, its bent version has low weight. This makes it possible to use this type of channel in lightweight metal structures. The low weight of this product reduces the time for its installation and reduces the complexity of this process.

Bent profile is used:

- In the construction of buildings.

- During the reconstruction of buildings.

- During major repairs.

Lightweight versions of bent profiles can be used to assemble greenhouse frames and erect temporary structures. The scope of use of this product is not only construction, but also carriage building, machine tool building, shipbuilding, automotive industry, etc. It can be used to produce products that have high load resistance, but are light in weight.

Assortment of channels - table, dimensions, GOST

Along with rod, angle and sheet, channel is one of the most popular rolled profiles. Construction, automobile and carriage building, manufacturing of metal structural elements - this is an incomplete list of applications in production. The demand for it continues to grow, and the range of channels is varied.

General concepts and types

A channel is a U-shaped metal profile. The assortments are completely unified. Their dimensions and mechanical properties are described by state standards GOST 8540-92 and GOST 8278-83. The blanks are various bars, rods and sheet metal.

The channel has a cross-sectional shape that is quite advantageous from the point of view of material resistance.

In terms of its ability to withstand bending loads, it is comparable to a solid bar, but the channel has a significantly lower mass.

The material utilization rate in this case increases by 5-8 times. This is the main reason for such active demand for the profile in the construction industry.

Types of channels, by analogy with assortments of angles, are divided according to the following principles:

- Manufacturing method: rolled and bent.

- Type of metal used: steel, aluminum and magnesium alloys.

Let us now dwell on each point in more detail.

Bent channels

The range of standard sizes of bent channel is described in the state standard GOST 8278-83. Its manufacturing technology consists of giving the workpiece, which is a metal sheet, a U-shaped profile. This is done using special industrial presses and stamps.

This process is distinguished by its versatility, i.e. the ability to quickly change over equipment to a different range of channels. As a rule, this does not take a relatively long amount of time. At the same time, the pressing equipment itself does not require large areas. Another important fact is the cost of such equipment, which is significantly lower compared to rental equipment.

Peculiarities:

- The shelves and the wall are approximately comparable in length. Otherwise, there is a high probability of cracks forming at the bend of the sheet when bending it with a press.

- They are distinguished by high surface cleanliness. The reason for this lies in the absence of heating of the workpiece and the fact that bending is carried out by applying pressure to two points of the sheet.

- The length of the channel is limited by the dimensions of the die molding matrix.

- The thickness does not exceed 4-5 mm. With large blank sheet sizes, the smoothness of the process is disrupted, which causes microcracks to appear on the surface.

Rolled channels

The main advantage of obtaining a profile by rolling is its continuity. This greatly increases the productivity of the profile manufacturing process.

The number of meters per minute of a finished channel increases by 8-10 times compared to a flexible one.

The downside of this technology is the difficult conversion to another type of profile and the higher cost of the equipment.

Rolling technology allows the use of more massive workpieces, which makes it possible to obtain U-shaped products with large wall thickness. In addition, preheating the metal bar promotes grain refinement, which has a beneficial effect on the mechanical properties of the channel. Although, on the other hand, this causes a decrease in surface quality and deterioration in appearance.

Dimensions are regulated by GOST 8240-92. According to it, they are divided into the following categories:

- With inclined edges of shelves. The tilt angle is 8-12 degrees. It is designated in the technical literature by the letter “U”.

- With parallel edges of shelves. This range is similar in size to a channel with inclined shelves, but is inferior to it in its strength characteristics. This happens due to less smooth transitions between the wall and the flanges, which increases the stress concentration coefficient of the section. Marked with the letter "P".

- Special purpose channel. In another way it is called reinforced. It has thicker walls and larger shelves. For this reason, the profile has greater strength and rigidity. As a rule, it is used in units that require increased resistance to cyclic loads. Conventionally, it is designated by the letter “C”.

- Light series channel. Significantly inferior to all of the above types both in wall thickness and shelf width. It has a lower resistance to deformation, and for this reason it is used in structures that do not require increased rigidity. Denoted by the letter "L".

- Economical - in size and shape it occupies an intermediate position between the profile with inclined shelves and the light series. Marked with the letter "E".

Types of materials

State standards allow the use of the following range of metals and alloys:

- Carbon steel of ordinary quality GOST 380-2005.

- Construction steel GOST 27772-88.

- High strength rolling steel GOST 619281-89.

- Low-alloy steel for bridge construction GOST 6713-89.

- Aluminum alloys GOST 4884-76 and GOST 4784-76.

Characteristics

As mentioned earlier, channels differ from each other in size and parameters of the strength properties of the profile. Among them, it is worth noting the following most important characteristics of the channel:

- Profile height.

- Shelf width.

- Wall thickness.

- Radius of internal rounding.

- The moment of inertia and the moment of resistance are quantities that characterize the ability of a channel to resist deformation and destruction, respectively.

The higher the value of each of these parameters, the higher the strength of the product.

Marking

Let's look at the designation in the technical documentation using an example:

Channel (20P GOST 8240-97)/(St3sp GOST 535-2005), where

- 20 – channel height in centimeters;

- P - indicates that the channel has parallel flange edges;

- GOST 8240-97 – regulates its geometric dimensions;

- St3sp – brand of material from which the profile is made;

- GOST 535-2005 - characterizes the chemical composition and mechanical properties of this steel.

I-beam or channel?

The choice in favor of one or another rolled metal product is based on the scope of its application. In terms of strength, the I-beam is significantly superior to the channel. Shelves protruding from both sides better distribute weight and are able to withstand significant loads. When heavy loads are placed on the channel, forces arise that tend to twist it. Which cannot happen when using an I-beam.

When comparing these types of rolled metal of the same standard size, wall thickness and shelf dimensions, with a load acting perpendicular to their axis, the U-shaped profile will be stronger. This is due to its shape. The shelves located in one direction make it so that the center of gravity extends beyond its cross section and is shifted towards the ends. While in an I-beam it is located exactly in the middle.

GOST standards

Weight, dimensions, profile configuration are regulated by GOST. Since products are produced for different industries, each type has its own standard for the manufacture.

GOST 8240-97 describes the assortment of hot-rolled channels, both general - for the construction and strengthening of floors and walls, and special. The profile obtained for automotive production is regulated by GOST 19425-74. Products for carriage building are described by GOST 5267.0-90 and 5267.1-90. Each of the standards describes not only the classic type of channel - equal-flange and with parallel flanges, but also wide-flange, bent, with different accuracy classes - GOST 8278-83B GOST 8281-80, GOST 5422-73. The U-shaped profile is made of both hot-rolled and cold-rolled steel. The material for the beams must also comply with GOST.

Channel 14 variations: dimensions, weight, scope of application

U-shaped products marked 14, due to their high strength characteristics, are widely used in strengthening reinforced concrete products, used for reinforcing metal structures, as well as in various construction and restoration works. This type of product has its own series:

- 14P is a channel produced by the hot-rolled method and has a general purpose. It is produced in accordance with GOST 8240-97.

- 14U is a special-purpose profile that is widely used in mechanical engineering.

- Bent steel channel with equal flanges is produced using specialized machines.

- A bent steel profile with unequal flanges is produced using roll forming equipment.

Channel 14, like other types of rolled metal, can be either with parallel flanges (marked “P”) or with inclined flanges (marked “U”).

For both series there are common characteristics of the channel:

- height – 140 mm;

- width – 58 mm;

- shelf thickness – 8.1 mm;

- wall thickness – 4.9 mm;

- weight of 1 meter of channel 14 – 12.3 kg;

- There are 81.3 m of product in 1 ton.

Channel 14 - section diagram with symbols.

It should be noted that the weight of channel 14 is strictly regulated by the requirements of a certain GOST. The maximum error cannot exceed 4.5% of the weight of all purchased products. Channels of this type are produced in lengths from 2 to 12 m. The cost of products depends on the series.