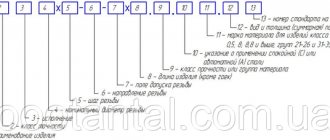

Marking and designation of channel in accordance with GOST 8240

The height of the channel profile is approximately 1.5-3.5 times greater than the width.

The shape of its cross-section provides it with high levels of rigidity. This allows this type of rolled steel to be used in heavy engineering and construction, mainly for the manufacture of critical metal structures, as load-bearing elements of floors, frames of buildings and structures. In addition, many brands of channels are used in the automotive industry, carriage building, for the manufacture of supports, fences, gates, and for decorative purposes. The geometric parameters and dimensions of the channels of the P series (with parallel edges) and the U series (with a slope of internal edges) are the same, the main difference is only in the radii of curvature of the shelves.

The key parameter in marking and designation is height. Channel number = Height in mm / 10, or, in other words, equal to the height of the channel in cm.

| Channel number | Channel height | Shelf width | Wall thickness | Shelf thickness |

| 5P, 5U | 50 | 32 | 4,4 | 7,0 |

| 6.5P, 6.5U | 65 | 36 | 4,4 | 7,2 |

| 8P, 8U | 80 | 40 | 4,5 | 7,4 |

| 10P, 10U | 100 | 46 | 4,5 | 7,6 |

| 12P, 12U | 120 | 52 | 4,8 | 7,8 |

| 14P, 14U | 140 | 58 | 4,9 | 8,1 |

| 16P, 16U | 160 | 64 | 5,0 | 8,4 |

| 18P, 18U | 180 | 70 | 5,1 | 8,7 |

| 20P, 20U | 200 | 76 | 5,2 | 9,0 |

| 22P, 22U | 220 | 82 | 5,4 | 9,5 |

| 24P, 24U | 240 | 90 | 5,6 | 10,0 |

| 27P, 27U | 270 | 95 | 6,0 | 10,5 |

| 30P, 30U | 300 | 100 | 6,5 | 11,0 |

| 40P, 40U | 400 | 115 | 8,0 | 13,5 |

Channel with inclined edges of shelves

The shelf of the construction channel is designed to take part of the load and distribute it. The features of this version include the following points:

- During manufacturing, GOST 8240-97 is used as a standard.

- The slope of opposite shelves can be from 4% to 10%.

- When marking, the letter “U” is indicated.

Assortment of channels with inclined edges of shelves

An important parameter that a construction channel with a slope of the internal edges of the shelves has is the distance between the shelves, indicated in centimeters.

Types of channels - classification, standards

According to the production method, the channel is divided into bent and hot-rolled profiles. A bent profile is obtained by cold profiling from a steel sheet blank (strip). In turn, a bent channel can be equal-flanged or unequal-flanged.

GOST 8278-83 regulates the range and maximum deviations of bent steel equal-flange channel. According to the requirements of this document, channel dimensions can be in the range from 25x26 to 410x65 with a thickness of 2 to 20 mm. The length of the bent profile, which is made from carbon, low-alloy steels, can range from 3 to 12 m.

GOST 8281-80 contains the range and value of maximum deviations of bent steel unequal-flange channel, which is made from ordinary quality grades and high-quality carbon steels, as well as low-alloy grades. Profile dimensions according to this document range from 32x22x12 to 300x80x40, thickness from 2 to 10 mm. The measured length of this profile is 4-11.8 meters.

GOST 8240-97 contains the range, classification and maximum deviations of the dimensions of hot-rolled channels for general and special purposes. The profile of this group can be 50 - 400 mm high. The channel number reflects the section height expressed in centimeters. According to this standard, the cross-section of a channel can have 2 types of profile: 1) with sloped edges (U and C series), 2) with parallel edges (P, E and L series). The width of the profile corresponds to the width of the shelf and can take a value of 32-115 mm. The marking of a channel, for example 10P, reflects its height and type of profile.

There are also highly specialized types of channels. Their shape and size are regulated by relevant standards.

GOST 21026-75 standardizes rolled products with bent flanges, which are used for the production of trolleys. They have only 2 standard sizes SP-10 and SP-12. GOST 5267.1-90 contains dimensions and reference characteristics of hot-rolled channels for railcar construction. The channel number according to the requirements of this standard can take values from 8V to 30V-2. GOST 5422-73 contains the dimensions of hot-rolled profiles intended for tractors. According to the standard, profile No. 5 corresponds to a 24T channel, and profile No. 6 corresponds to 18T.

Assortment of steel channels: tables, GOST

When creating load-bearing structures, a channel is quite often used. This material is represented by a U-shaped profile, which is made from various steels. Classification is carried out according to a fairly large number of different characteristics. The range of channels is presented in a table of the ratio of the main characteristics.

Channel assortment

State assortment standard (GOST 8240-97 or GOST 8240-89) allows you to control the quality of supplied building materials. It is worth considering that such a material, made from various grades of steel, is used to create critical load-bearing structures, which means its declared characteristics must correspond to real ones.

Main characteristics of channels

When choosing the building material in question, you should pay attention to special tables that significantly simplify the task. Channels, the dimensions of which in tables are often indicated in millimeters, are characterized by:

- The length of the material is often not indicated in the tables. This is due to the fact that such an indicator can vary over a fairly large range.

- Most attention is paid to the slope of the internal faces and other indicators. Examples include the thickness of walls and shelves, the radius of internal curvature, and the cross-sectional surface area. In order to understand the main tabular data, you should consider the cross section, along which the width of the channel is indicated.

- An important characteristic is the weight of one linear meter. The steel channel is designed to create a load-bearing structure, but the load will also be placed on the base. In order to calculate the load, the weight of one linear meter is taken into account.

- The steel grade is also indicated. Many physical and mechanical qualities depend on the type of material used: surface hardness, load resistance, corrosion resistance and many others.

How to correctly decipher the channel symbol

The type of channel symbol depends on its type (GOST) and the material from which it is made. For example, a 30P channel of normal rolling precision B, made of steel St3, fourth category, first group, has the following designation:

- Channel 30P-V GOST 8240-97/St3sp4-1 GOST 535-88

The same profile made of steel 09G2S with increased rolling precision, strength class 345 is designated:

- Channel 30P-B GOST 8240-97/345 GOST 19281-89

A bent equal-flange channel with dimensions 300x80x6 of profiling accuracy A (high), from a strip of increased rolling accuracy B, of the second category, made of St3sp steel is designated:

- Channel A 300x80x6 B GOST 8278-83/2-St3sp GOST 11474-76

Price list for galvanized and black square section profile pipe according to GOST 8639, 30245, steel 09G2S and art. 3.

Prices for equal-flange, galvanized, unequal-flange steel angles with flange widths from 20 mm to 200 mm, wall widths from 3 mm to 20 mm.

Source: apex-metal.ru

What it is?

A channel is a type of shaped metal product with a cross-section in the shape of the letter “P”.

Two technologies are used for its production, as a result of which the entire assortment is divided into two large groups:

The profile produced by hot rolling has excellent strength, bending resistance and resistance to mechanical damage. Due to this, this type is used in the construction of critical parts and load-bearing structures.

Rolled steel has less strength and is therefore not used in load-bearing elements. Otherwise, its characteristics are practically the same as the hot-rolled version, and lower weight and lower price often play a decisive role in use.

However, the differences don't end there. When choosing for specific needs, the following are taken into account: material, design, dimensions and other parameters. They are worth considering in more detail.

Application area

The main indicator that characterizes a construction channel can be considered high axial bending strength. In addition, the angle channel has a relatively low mass and a high strength index. These qualities have determined the widespread use of building materials in a variety of areas:

- Automotive industry. When creating trucks, the material in question is often used to strengthen the supporting structure.

- Production sites for the production of frames and portable supporting structures.

- When constructing a structure to obtain a frame, ramps or floors. The beam copes well with the resulting transverse or axial load and can significantly increase the strength of the floors.

- When creating floors of large spans, creating walls.

- As an element that strengthens a concrete structure.

The material in question is characterized by the fact that it copes well with axial and load-bearing loads; when certain alloys are used, it does not react to environmental influences and has a relatively low weight.

Channel and material

Depending on the required characteristics of the finished product, steel of various grades can be used for its production.

With the hot-rolled method, the main raw materials are steel St3 (semi-quiet and calm), 09G2S, 17G1S, 10ХСНД and 15ХСНД. The last two are characterized by increased corrosion resistance and lower weight.

Bent rolled products are made from steel St3ps5, 09G2S, 08ps, 1ps, 2ps and others.

Since almost all of the above alloys are susceptible to corrosion, galvanizing can be done if necessary. This significantly extends their service life, especially if they are used outdoors or in high humidity conditions.

Design

The metal products and shelves differ, specifically in their sizes and the position of the internal edges.

The sizes of the edges are:

- equal,

- unequal when the length of one of the shelves is greater.

The first option is the most popular.

As for the location of the internal edges, they can be perpendicular to the wall (parallel to each other) or located at an angle. The corresponding parameters can also be found after decoding the markings.

- The letter “P” denotes rolled products with parallel edges.

- The letter “U” is applied to products whose edges are located at an angle.

Channel with parallel flange edges

The channel shelf can be located at right angles to the base. A channel with parallel flange edges is found quite often, as it is easy to manufacture. Let's call the following features:

- The edges are parallel.

- There is a curvature radius, but it is significantly lower than that of the version with parallel edges.

Assortment of channels with parallel flange edges

Construction channels with parallel flange edges can be of normal or high precision.

Other brands

We have already considered the main parameters and the two most popular options, but there are three more brands of channel:

- Economical (“E”) - characterized by thinner shelves and walls, as well as lighter weight, which makes it much cheaper. Available exclusively with parallel shelf edges. Without the need to hold massive structures, it saves on construction costs.

- Lightweight (“L”) – similar in shape to economical. It is produced in accordance with GOST, but lighter materials, such as aluminum, are used as raw materials.

- Special (“S”) - has its own dimensional grid and is used in specific industries: automobile and carriage building (GOST 19425-74 and GOST 5267.1-90, respectively).

Recommendations for selection

When choosing, you should take into account the parameters of the construction channel, as well as the type of metal used in manufacturing. Other recommendations include the following:

- You should purchase material only from a trusted manufacturer who complies with established standards in GOST.

- The surface of the material must not have any defects.

- Minor surface corrosion is acceptable. However, it is worth considering that when using the material you will have to remove it and cover the surface with a protective substance.

- As the size increases, the volume of material used increases, as well as its weight.

The channel can have a variety of sizes. Using markings and special tables, you can determine the main characteristics of the material. The range provides simply a huge selection of the building material in question.

If you find an error, please select a piece of text and press Ctrl+Enter.

Subscribe to our articles

To determine the brand of channel, especially if you have a finished product in front of you, you need to know what varieties are produced, and also be able to read the markings. This material will be devoted to these issues.

Channel - decoding of markings

Now that we have examined all the main parameters and characteristics, we can begin to get acquainted with the labeling.

Depending on the height of the wall, it can be located on a tag attached to the bundle (for products up to 22 millimeters) or directly on the rental itself. According to the standard, it is applied no closer than 30 centimeters from the end.

The conditions of storage, packaging, transportation and labeling are regulated by special GOST 7566-94.

According to the standard, the brand is indicated in the form of a fraction, to the left of which the name of the product is applied.

The upper part of the fraction contains (in order):

- shelf size (in centimeters) according to the assortment table in the relevant GOST,

- indication of the position of the edges of the shelves,

- rolling accuracy,

- standard regulating the production of this product.

The lower part informs about what material was used. It states from left to right:

- steel grade,

- GOST, according to which the alloy was produced.

So the decoding of our example suggests that we have a channel with parallel flange edges of ordinary accuracy. The wall has a height of 30 centimeters. The rental product complies with state standard 8240-97.

The raw material for its production was steel grade St3, semi-quiet, fourth category, first group, produced in accordance with GOST 535-88.

The designation for bent channel is slightly different. Firstly, the dimensions are indicated in the format “height * width * thickness”. Secondly, after them there is an indication of the accuracy of the workpiece.

Main characteristics of channels

When choosing the building material in question, you should pay attention to special tables that significantly simplify the task. Channels, the dimensions of which in tables are often indicated in millimeters, are characterized by:

- The length of the material is often not indicated in the tables. This is due to the fact that such an indicator can vary over a fairly large range.

- Most attention is paid to the slope of the internal faces and other indicators. Examples include the thickness of walls and shelves, the radius of internal curvature, and the cross-sectional surface area. In order to understand the main tabular data, you should consider the cross section, along which the width of the channel is indicated.

- An important characteristic is the weight of one linear meter. The steel channel is designed to create a load-bearing structure, but the load will also be placed on the base. In order to calculate the load, the weight of one linear meter is taken into account.

- The steel grade is also indicated. Many physical and mechanical qualities depend on the type of material used: surface hardness, load resistance, corrosion resistance and many others.

The main technical characteristics allow you to select the most suitable building material. Standard sizes significantly simplify the design process, since you can calculate the required number of load-bearing elements, the maximum permissible load and many other parameters. The creation of the assortment was carried out due to the fact that metal channels are widely used and are used in many industries. Almost all manufacturers comply with channel dimensions according to GOST, which greatly simplifies the selection process.

Designations on kmd drawings

Symbols on the drawings that correspond to one or another parameter help make the project more compact, without compromising its capacity.

These designations, along with other aspects of an architect’s work, are determined by generally accepted norms and rules of use.

Earlier, in our materials, we talked about how important the clarity of drafting and readability of a project is.

We considered many theoretical aspects of drawing.

Today, we have selected graphic illustrations for our readers and colleagues that will help to correctly create drawings for various designs.

The materials we collected cover all the key points of project development. You will see examples from division into design elements to document forms.

We have made a selection of symbols, both individual structural elements, and presented complete examples of correctly compiled design instructions.

We sincerely hope that, along with the previously discussed topics, these materials will help you in your work.

In turn, we are also always happy to come to your aid.

Our specialists will develop a high-quality KMD project of any complexity in the shortest possible time and at the best prices.

They just don’t work any differently at Lukarinvest.

You can familiarize yourself with our selection of symbols using the links below.