Blowing glass at temperatures just above glass transition

Material thermoplastic

it is a material that tends to soften (sometimes we see a fusion frankly) when it is sufficiently heated, but which becomes hard when cooled.

Therefore, such a material always retains its original thermoplasticity in a reversible

.

The softening state allows them to undergo mechanical deformation, while this deformation is frozen upon cooling.

This quality makes the material recyclable

provided that the material is not subject to thermal decomposition and that the mechanical stresses of the shearing process and possible formatting do not change the molecular structure.

This is the case of a glass, made of metals and generally macromolecules, one-dimensional

(issues of divalent monomers), linear structure or branched, belonging to Organic chemistry (For example, PVC as well).

Thermoplastic polymers

General

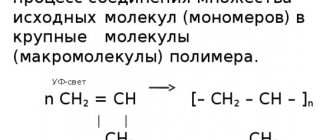

to degree of polymerization

(DP or

not

, directly proportional to the molar mass of the polymer), on the one hand, determines the ability to implement on machines (which depends on the viscosity), and on the other hand, the mechanical and thermal properties of the final product[1].

The molecular structure of solid thermoplastic polymers is either amorphous (unorganized) (formerly:, PMMA and also), that is, crystalline (organized, in which the lines are aligned). In the second case, the mechanical and thermal properties are better. These two structures can coexist in varying proportions; the corresponding polymer is called semicrystalline

and characterized by the degree of crystallinity.

The presence of crystallinity in materials capable of crystallizing (such as PE, and PA) depends largely on their thermal history

and, therefore, the implementation conditions used to manufacture the mussel object.

Some thermoplastic plastics may have a partial three-dimensional structure (formerly: PS weak mesh); then the semi-thermoplastic polymer will be hard, less soluble, more slug resistant, but more brittle.

Temperature dependence

Variation of elastic modulus of polypropylene with temperature obtained by DMA

An increase in temperature causes the separation of long molecular chains. The transition of a material from a solid state to a viscous liquid state occurs when thermal mixing breaks the “weak bonds” ( physical

For example, interactions of low molecular weight (van der Waals) or medium energy (hydrogen bonds) between two adjacent segments of macromolecules without affecting the covalent bonding contact networks[2].

This mechanism is reversible

(the viscous liquid solidifies upon cooling, when the chains converge, forming a more or less pronounced removal): the material

is thermoplastic

. Semi-crystalline materials exhibit overall shrinkage[3] superior to amorphous[4].

The glass transition temperature (Tv) corresponds to the breaking of (few) weak interchain bonds in the amorphous phase. It is always lower than the melting temperature (Tm), which corresponds to the disappearance of (many) weak interchain bonds in the crystalline phase.

Applications

Formula of some large industrial polymers[5]

Extrusion cords putty polymer

Softening (for sampling) plates made of injected polymer material

The cycle of heating-softening and cooling-hardening can be repeated more or less indefinitely. This cycle represents a significant advantage since it is the basis of most techniques for converting these materials. However, this phenomenon is a disadvantage because it means that the properties of thermoplastics are temperature dependent. In calendering, extrusion and injection molding methods the transformation of typically polymers into thermoplastics. The main method of processing thermoplastic materials technology

This is an injection. Polymers with an amorphous structure and high molecular weight are preferred for extrusion. In contrast, low molecular weight amorphous polymers are good candidates for injection.

THE 'cellulose acetate, abbreviated CA, is the result of chemical modification (by acetylation) of cellulose[6]. This artificial polymer has been known since the 1920s, with a certain economic significance. The main application of this thermoplastic cellulose derivative is the production of textile fibers and films.

In the production of son and synthetic fibers, we can, after extrusion through the Faculty of spinning, perform mechanical stretching uniaxial

polymer in the solid state at a temperature below the melting point of the crystalline zones.

The stretching of the monofilament creates crystallization. The fibers are continuously drawn by rollers from 300 to 500% of the original length. This operation helps strengthen the cohesion of the macromolecular system, which increases mechanical resistance tenfold. The main polymers that use this process are polyolefins (PE and PP), polyamides (PA) and polyethylene terephthalate (PET) (“polyester”). This phenomenon is also used in film making. Biaxial

stretching (usually orthogonal in two directions) is carried out in such a way as to orient the polymer chains, which improves mechanical properties in two dimensions.

Thermoplastic polymers are soluble if the solvent is able to disrupt the molecular interactions, allowing them to adhere. They can then be used as coatings and adhesives.

B copolymerization

is an operation very often used in the field of thermoplastics to improve certain properties. For example, in the styrene family:

- block copolymer ( block

) styrene-butadiene (SBR) or "polystyrene-choc" was developed to increase the stability of the PS homopolymer "Crystal"; - statistical copolymer styrene-acrylonitrile (SAN), increases the rigidity of PS (application areas: battery boxes, household appliances, etc.);

- Styrene-butadiene (SBS), a triblock copolymer, is a thermoplastic elastomer (TPE, in English) and is therefore recyclable. It is used in all applications of elastomers. The formatting is performed using methods typically used for thermoplastic polymers. SBS is also used as a "pressure sensitive" adhesive.

In polymer mixtures thermoplastics (“polymer-polymer” mixtures) - /ABS, PPO/ PS (Noril), PP /EPDM, etc. — are mechanical mixtures of polymers (amorphous or semi-crystalline). Binding agents are used. The combination of polymers produces a mixture whose characteristics are hybrid with its constituent polymers.

Economy

Production of plastic products in France in 2007 was approximately 3.5 million tons.

The consumption of thermoplastic polymers is approximately four times higher than that of thermoset materials in Western Europe[7].

The production of synthetic fibers accounts for more than half of the production of textile fibers of any kind.

LDPE[8], HDPE, PVC, PP and PS are thermoplastic polymers. consumer goods very low price. These five members represent more than half of total plastic consumption.

Poly(phenylene ether ketone) (PEEK) is a thermostable (Tj ~335°C) that arrived on the market rather late. a special talk about this polymer

: has a very high price.

Classification of thermoplastics.

Thermoplastics are classified according to several criteria. According to their physical state, they are divided into amorphous and crystallizing. The former, depending on the temperature of exposure, can be in three states (in increasing order): glassy, highly elastic and viscous. The first state is characterized by small elastic deformations, the second state is characterized by the possibility of large reversible deformations; a further increase in temperature leads to irreversible changes appearing in the thermoplastic.

Depending on the chemical structure, thermoplastics can be divided into polyolefins (polyethylene, polypropylene), polyesters, polyamides, styrene plastics, polymers (acrylic and based on cellulose and fluoroplastic).

Based on their performance characteristics, thermoplastics are divided into general technical, engineering and heat-resistant thermoplastics.

To improve the technological and operational characteristics of thermoplastics, fillers can be used. Based on their type, polymers are divided into fiberglass (glass filler), carbon fiber (carbon fiber) and special thermoplastics (with electrically conductive materials, anti-friction and wear resistance-increasing additives, etc.).

All these polymers have a number of very useful and unique properties that allow them to be widely used in a wide variety of fields. They have good heat resistance, elasticity, softness, are practically non-toxic, very elastic even at low temperatures, and are resistant to chemical influences. In addition, they are very technologically advanced and last a long time.

Thermoplastic polymers are often used in the production of pipes, electrical wiring, and furniture fittings. They are used in agriculture and construction work. Thermoplastics have also taken their place in medicine (dentistry, prosthetics).

Today, thermoplastic materials are essential in the footwear industry (high-quality soles are made from them), mechanical engineering (various gears, couplings, bearings, shock absorbers, etc. are made), and the production of sports equipment.

Since secondary thermoplastics still have slightly worse characteristics, only primary materials are currently used for the production of products that are subject to increased requirements for quality and hygienic characteristics (for example, things for children, packaging for products).

A specific thermoplastic polymer is selected based on the conditions and characteristics of the finished product. For example, polycarbonate has very good strength, and it can be used in a very wide temperature range (from approximately - 100 to + 140 ° C), so it is used for glazing various transparent structures (greenhouses, public transport stops, etc.) .

Thermoset polymers

Polymers thermosetting materials

become hardened

irrevocably

, most often after heating. The transformation is carried out using a chemical reaction (polymerization). Their thermomechanical properties are very different from thermoplastic polymers; The three-dimensional network consists of covalent nodes (including high-energy bonds), the breaking of which is irreversible by nature.

Unlike thermoplastics, thermoset plastics can only be shaped once; finished products can no longer be melted (without decomposition) by possible heat. Therefore, thermoset materials cannot be recycled.

Examples of thermosetting materials: obtained by copolymerizing styrene in the presence of an unsaturated polyester reagent, aminoplast resins and epoxy resins, vulcanized elastomers, etc.

After processing, thermoset materials are typically rigid.[9] and their mechanical properties depend little on temperature.

Polyethylene.

Polyethylene is most often used where high resistance to chemical influences is required, therefore it is used to produce containers for storing and transporting chemically aggressive liquid substances (acid, alkali, etc.). When high structural strength with a large number of bends and turns is required, polypropylene is used. In addition to strength, this material is characterized by high wear resistance, inertness to various chemical compounds (for example, alcohols and acids), it does not allow gas and steam to pass through.

Notes and links

- THE 'Tensile test is the simplest way to characterize the mechanical resistance of a polymer.

- Catenary: relating to the main chain of a macromolecule.

- Shrinkage ("immediate", occurring during molding and continuing for (approximately) the next two hours) plus subsequent shrinkage (delayed, occurring over several months).

- Reinforcements (eg, fiberglass) and charges (chalk, talc, etc.) improve thermal resistance and reduce shrinkage (ie, improve dimensional stability).

- PA-6 (polycaprolactam) belongs to the family of technical thermoplastic polymers (they have high mechanical characteristics and are very expensive).

- The molecular chains are not destroyed during transformation.

- Review by Plast Europe

, 2001. - A typical example of a branched design refers to LDPE ("low density") produced by high pressure polymerization.

- The three-dimensional structure, which allows virtually no rotation around the bonds, increases molecular rigidity.