High molecular weight compounds. Polymerization and polycondensation reactions. Polymers. Plastics, fibers, rubbers.

| High-molecular substances consisting of large molecules of a chain structure are called polymers (from the Greek “poly” - many, “meros” - part). |

For example , polyethylene obtained by polymerization of ethylene CH2=CH2 :

…-CH2-CH2-CH2-CH2-CH2-CH2-CH2-… or (- CH 2 - CH 2 -) n

A polymer molecule is called a macromolecule (from the Greek “macro” - large, long). The molecular mass of macromolecules reaches tens - hundreds of thousands (and even millions) of atomic units.

The compounds from which polymers are formed are called monomers .

For example , propylene (propene) CH2=CH–CH3 is a monomer of polypropylene

A group of atoms repeated many times in a chain macromolecule is called its structural unit .

| Monomers are low molecular weight substances from which polymers are formed. |

The degree of polymerization is a number indicating the number of elementary units in a polymer molecule.

The degree of polymerization is usually indicated by the index “n” behind brackets that include the structural (monomer) unit: (– CH2–CH2–)n.

Polymers whose macromolecules are built in a strictly defined way are called regular .

A polymer is called stereoregular if the R substituents in the main chain of macromolecules (–CH2–CHR–)n are arranged in an orderly manner.

Stereoregular polymers have much better properties - plasticity, strength and heat resistance; they are capable of crystallizing, unlike irregular ones.

What are polymers

Synthetic polymers are petroleum derivatives. Most of them are obtained through two main reactions - polymerization and polycondensation.

Substances that have multiple monomer bonds enter into the polymerization reaction. As a result, one product is obtained.

The polycondensation reaction involves substances that have functional groups of monomers in the chain. In this case, the output is a high molecular weight polymer and a low molecular weight substance (water).

Polymers are not only artificially created substances by man, but also natural building materials for all living things.

These include:

- complex carbohydrates

– polymers of elemental sugars;

- squirrels

– polymers of amino acids;

- cellulose

– polymer found in wood;

- keratin

– is a polymer and is found in the hair, nails and feathers of birds;

- chitin

– a polymer that holds together the shells of arthropods;

- nucleic acid derivatives

– DNA heteropolymers.

Polymerization

The degree of polymerization is a number showing how many monomer molecules are combined into a macromolecule.

The degree of polymerization is usually indicated by the index “n” outside the brackets, which include the structural (monomeric) unit: (– CH 2 – CH 2 –) n

Characteristic signs of polymerization.

|

Polymerization catalysts can be: sodium metal, peroxides, oxygen, organometallic compounds, complex compounds.

The process of formation of high molecular weight compounds by the joint polymerization of two or more different monomers is called copolymerization .

For example , a scheme for the copolymerization of ethylene with propylene:

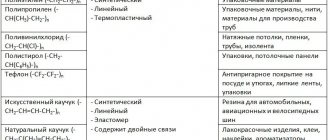

The most important synthetic polymers

Image from the portal orgchem.ru

The most important synthetic polymers obtained by the polymerization reaction and their areas of application:

| Polymer | Monomer | Polymer characteristics | Application of polymer |

| Polyethylene (–CH2–CH2–)n | Ethylene CH2=CH2 | Synthetic, linear, thermoplastic, chemical resistant | Packaging, container |

| Polypropylene | Propylene CH2=CH–CH3 | Synthetic, linear, thermoplastic, chemical resistant | Pipes, packaging, fabric (non-woven material) |

| Polyvinyl chloride | Vinyl chloride CH2=CH–Cl | Synthetic linear polymer, thermoplastic | Stretch ceilings, windows, film, pipes, floors, electrical tape, etc. |

| Polystyrene | Styrene | Synthetic linear polymer, thermoplastic | Packaging, dishes, ceiling panels |

| Polymethyl methacrylate Methacrylic acid methyl ester | Synthetic linear polymer, thermoplastic | Glasses, headlight and lamp housings, shower cabins, furniture, etc. | |

| Teflon (polytetrafluoroethylene) | Tetrafluoroethylene | Synthetic linear polymer. Thermoplastic (t = 260-3200C) Has very high chemical resistance | Dishes, iron plates, tapes and tape, packaging, insulation |

| Artificial rubber Monomer: butadiene-1,3 (divinyl) | Synthetic, linear, elastomer, contains double bonds | Rubber, insulation, various materials, rocket fuel | |

| Natural rubber Monomer: 2-methylbutadiene-1,3 | Natural, linear, elastomer, contains double bonds | Rubber, insulation, various materials, rocket fuel | |

| Chloroprene rubber Monomer: 2-chlorobutadiene-1,3 | Synthetic, linear, elastomer, contains double bonds | Rubber, insulation, various materials, rocket fuel | |

| Styrene-butadiene rubber Monomers: 1,3-butadiene and styrene | Synthetic, elastomer | Rubber, insulation, various materials, rocket fuel | |

| Polyacrylonitrile | Acrylonitrile | Synthetic, linear | Fibers, plastics |

Discovery of polymers

The 20th century can rightfully be called the century of polymers. Their discovery was not a deliberate study. They were originally a byproduct of various experiments and chemical reactions.

Chemist Leo Baekeland eventually turned his attention to these useless materials, and his experimental work resulted in plastic, a polymer that can take on different shapes when temperature and pressure change. With the invention of Bakelite (the original name of plastic), the era of polymer production began.

During World War II, synthetic rubber was developed for the production of rubber to meet the needs of the American army. During unsuccessful experiments, a new polymer was also discovered in the form of a mastic with increased elasticity. This was the time of the creation of hardboard glass and phenol-formaldehyde-based resins. A separate branch has emerged in chemistry – polymers.

Classification by chemical character

According to the chemical nature and composition, polymers and chemical fibers are : polyester, polyamide, organoelement (for example, organosilicon polymers).

| Polyester polymers | Polyamide polymers | Organoelement |

| Contains the -COO- Lavsan group (polyethylene terephthalate) | Contains the group -СО-NH2— Nylon, nylon | Contain atoms of other chemicals. elements (silicon, etc.). Organosilicon polymers |

Polyester polymers - contain the group of esters -COO-.

Polyamide polymers - contain a peptide bond -CO-NH2-.

Organoelement polymers contain atoms of other chemical elements (in addition to C, H, O, N).

Classification of polymers

Polymers have several classifications.

First of all, they are divided by origin:

- natural

– rubber, proteins, potato and corn starch, wood cellulose;

- artificial

– viscose;

- synthetic

- nylon, polyurethanes.

Next by molecular weight. It indicates how homogeneous a molecule is in its chemical composition. The percentage of its reaction and polymerization depends on the number of repetitions of one structural unit of monomers in their construction. Therefore, additional properties play an important role in classification.

Thermosets and their abbreviations

- BF is a phenol-formaldehyde oligomer combined with polyvinyl butyral.

- KS – silicon resins.

- MAS – melamine aldehyde resins.

- NPS – unsaturated polyester resins.

- PI – polyimides.

- PEEK – polyetheretherketone.

- PU – polyurethanes.

- PPU - polyurethane foam .

- FS – furan resins.

- FFS – phenol-formaldehyde resins.

- ES – epoxy resins.

Branching of the molecule

Depending on their structure, polymers have different properties.

Their formulas reflect the different types and structures of molecules:

- linear

– a macromolecule consists of one chain of monomers;

- branched

– there are branches in the linear chain;

- mesh

– branched macromolecules have connecting links among themselves.

Reaction to heat treatment

There are two types:

- Thermoplastic

– after heating they return to their original shape. Can be recycled many times.

- Thermoset

– They are destroyed under the influence of high temperatures.

As a result of various processing processes, the resulting polymers are divided into 4 main groups:

- plastics

– polypropylene, polystyrene, polyvinyl chloride, polyurethane;

- fibers

– acetate silk, viscose;

- elastomers

– rubber, rubber (vulcanized rubber);

- biopolymers

- carbohydrates, proteins, nucleic acids.

Properties of polymers

Depending on whether polymers have an organic composition or are derivatives of inorganic compounds, their basic properties appear:

- have high strength under mechanical stress;

- there is no precisely defined melting point;

- the main part is insoluble in water;

- retain the ability to viscous flows;

- do not change their qualities after heating and cooling;

- dielectrics;

- plastic, easy to form;

- waterproof.

They can be soft, hard, flexible, rigid or strong.

Difference between natural and synthetic polymers

Main difference

The main difference between natural polymers and synthetic polymers is that natural polymers are polymer compounds available in our environment, whereas synthetic polymers are polymer compounds that we produce artificially and cannot be obtained from nature .

Natural polymers vs synthetic polymers

Polymers are macromolecules made up of small units known as monomers. Polymers contain a wide range of compounds that are very valuable in our daily lives. These polymers are classified in different ways; for example, they are classified according to structure and physical or chemical properties. The main classification of polymers includes two groups called natural polymers and synthetic polymers.

Natural polymers are polymer compounds that are found in our environment, while synthetic polymers are polymer compounds that are not found in nature and are manufactured artificially. Natural polymers are mainly found in three types: polyamides, polysaccharides and polynucleotides. Synthetic polymers are formed through numerous chemical reactions. Thus, polymers are further classified by the type of chemical reaction that was used to form them. Additionally, synthetic polymers are classified as inorganic polymers or organic polymers. Rubber occurs naturally and is also synthesized by humans. It can be collected as a milky liquid (latex) from various types of trees.

Natural rubber, which we obtain from tree latex, is basically called a polymer, which contains a small percentage of impurities and is made up of isoprene units. On the other hand, synthetic rubber can be obtained by polymerizing several monomers, which also include isoprene.

comparison table

| Natural polymers | Synthetic polymers |

| Natural polymers are polymeric compounds available in our environment. | Synthetic polymers are polymer compounds that we create artificially and cannot be produced by nature. . |

| Examples | |

| The most common examples of natural polymers are DNA, cellulose, silk, wool and proteins. | The most common examples of synthetic polymers are polyethylene, polyester, nylon, Teflon and epoxy. |

| Types | |

| Natural polymers generally come in three types: polyamides, polysaccharides, and polynucleotides. | Synthetic polymers are generally classified as inorganic polymers or organic polymers. Because they are formed using numerous chemical reactions, they are further classified by the type of chemical reaction that was used to form them. |

| Entry | |

| Natural polymers occur in nature. | Synthetic polymers are not found in nature. |

| Production | |

| Natural polymers are obtained through biological processes. | Synthetic polymers are produced by chemical processes. |

| Degradation | |

| Almost all natural polymers found in our environment can be easily broken down by biological processes. | Most synthetic polymers are difficult to degrade naturally through biological processes. |

| Rubber | |

| Natural rubber, which we obtain from tree latex, is basically called a polymer, which contains a small percentage of impurities and is made up of isoprene units. | Synthetic rubber is produced by polymerizing several monomers, which also include isoprene. |

What are natural polymers?

Natural polymers are polymeric compounds available in our environment. These polymers are often water-based. The most common examples of natural polymers are DNA, cellulose, silk, wool and proteins. Natural polymers are polymeric compounds that are commonly found in three types: polyamides, polysaccharides, and polynucleotides. Polysaccharides contain polymers consisting of monosaccharide units.

The most common types of monosaccharides are fructose, glucose, galactose, etc. Polysaccharides are found in both plants and animals. For example, starch is a polysaccharide that is found in plants as a storage carbohydrate. Glycogen is another polysaccharide that is found in animals in the form of storage carbohydrate. Polyamides contain proteins and all other naturally occurring polymers that are made up of peptide bonds. Polynucleotides contain DNA and RNA, and they are made up of monomers called nucleotides.

What are synthetic polymers?

Synthetic polymers are polymer compounds artificially created by humans. Their production is carried out in factories or laboratories, depending on the need. Natural polymers served as inspiration for the production of synthetic polymers. After studying the chemical structure of natural polymers, people created synthetic polymers. These polymers are usually derived from petroleum oil.

Synthetic polymers are further classified into categories which depend on the production method and the components that are used in production, etc. For example, some polymers are formed by condensation polymerization and some other polymers are formed by addition polymerization. In addition, synthetic polymers can also be classified into organic or inorganic polymers. Organic polymers are composed of hydrocarbons, whereas inorganic polymers do not contain hydrocarbons.

Key differences

- Natural polymers are polymer compounds that are available in our environment, whereas synthetic polymers are polymer compounds that we create artificially and cannot be obtained from nature.

- The most common examples of natural polymers are DNA, cellulose, silk, wool and proteins, on the other hand, the most common examples of synthetic polymers are polyethylene, polyester, nylon, Teflon and epoxy.

- Natural polymers are generally of three types: polyamides, polysaccharides and polynucleotides; On the other hand, synthetic polymers are generally classified as inorganic polymers or organic polymers. Because they are formed using numerous chemical reactions, they are further classified by the type of chemical reaction that was used to form them.

- Natural polymers occur in nature; on the other hand, synthetic polymers do not occur in nature.

- Natural polymers are produced through biological processes, while synthetic polymers are produced through chemical processes.

- Almost all natural polymers present in our environment can be easily degraded by biological processes; on the other hand, most synthetic polymers are difficult to degrade naturally through biological processes.

- Natural rubber, which we obtain from tree latex, is mainly a polymer consisting of isoprene units, which also contains a small percentage of impurities. Conversely, synthetic rubber is obtained when a process of polymerization of several monomers occurs, which also includes isoprene.

Conclusion

The above discussion summarizes that natural polymers and synthetic polymers are the two main categories of polymers. The former contains polymer compounds that occur naturally, while the latter contains compounds that are produced by humans and are not found in nature.

Application of polymers

Without these compounds, modern civilization cannot develop and exist. Products based on raw materials with various monomer compounds are necessary both in everyday life and for the operation of high-tech industries.

The proposed table only to a small extent reflects examples of their application.

| Name of polymer compounds | Scope of application |

| Polyethylene | Packaging materials, insulation of electrical wires, machine parts, containers for storing acids and alkalis, corrosion protection of oil pipelines. |

| Polystyrene | Toys, parts of household appliances, interior lining of cars and airplanes, fittings, electronics cases, dishes. |

| Polyvinyl chloride | Machine parts, equipment for the chemical industry, artificial leather, PVC window frames. |

| Polymethyl methacrylate | Plexiglas, lighting components, cladding of aircraft and cars. |

| Polycarbonates | Particularly precise parts of machines and electronics, replacement of metal structures, building materials. |

| Epoxy resins | Varnishes, glue, laminate. |

| Polyesters | Lamps, masts, fishing rods, protective equipment, aircraft and machine bodies. |

Thermoplastics and their abbreviations

- ABS is a graft copolymer of acrylonitrile, styrene with butadiene or styrene-butadiene rubber.

- AC – cellulose acetate.

- LLDPE – linear low density polyethylene.

- MS is a copolymer of styrene with methyl methacrylate .

- MSN is a copolymer of styrene with methyl methacrylate and acrylonitrile .

- PAN – polyacrylonitrile.

- PA – polyamides.

- PAA – polyamide acid.

- PAR – polyarylates.

- PAS – polyalkylsulfone.

- PBT – polybutylene terephthalate.

- PVA – polyvinyl acetate.

- PVA – polyvinyl alcohol.

- PVF, fluoroplastic-1 – polyvinyl fluoride .

- PVC – polyvinyl chloride .

- PVDF, fluoroplastic-2 – polyvinylidene fluoride .

- PVDC – polyvinylidene chloride .

- PI – polyimides.

- PC – polycarbonates.

- PMMA – polymethyl methacrylate .

- PO – polyolefins.

- PP – polypropylene .

- PS – polystyrene .

- EPS – expanded polystyrene .

- PSF – polysulfone.

- PTP – pentaplast .

- PTFE, fluoroplastic-4, fluorlon-4, teflon - polytetrafluoroethylene

- PTFCE, fluoroplastic-3. fluorlon-3 – polytrifluorochloroethylene .

- PU - polyurethanes .

- PF – polyformaldehyde .

- PPO – polyphenylene oxide.

- PE – polyethylene .

- PEI – polyetherimide.

- HDPE, HDPE, HDPE – high-density polyethylene (low pressure) .

- LDPE, LDPE, LDPE – low density polyethylene (high pressure).

- PEO – polyethylene oxide.

- PESD – medium pressure polyethylene.

- PET – polyethylene terephthalate .

- CAM is a copolymer of styrene with α-methylstyrene.

- SAN is a copolymer of styrene and acrylonitrile.

- STD is a copolymer of trioxane with dioxolane.

- SFD is a copolymer of formaldehyde with dioxalane.

- TAC – cellulose triacetate.

- FN – phenylone.

- CPE – chlorinated polyethylene.

- CSPE – chlorosulfonated polyethylene.