Russia is a land that nature has generously endowed with such mineral wealth as iron ore. To at least roughly appreciate this luck, it is enough to imagine the role of metal objects in our lives and build a logical bridge to the categories of production.

It is not for nothing that when they first entered the lives of people hundreds of centuries ago, the changes in the way of life and consciousness of mankind turned out to be so great that this era began to be called the “Iron Age”.

What is iron ore and what does it look like?

Formations in the earth's crust containing iron in more or less pure form or its compounds with other substances: oxygen, sulfur, silicon, etc.

Such deposits are called ore when the extraction of a valuable substance on an industrial scale is economically profitable.

There are many types of such mineral formations. The species leader of the geological rock is red iron ore or hematite in Greek. The name translated from Greek means “blood red” and has the chemical formula – Fe2O3.

Iron oxide has a complex color ranging from black to cherry and red. Opaque, can be dusty and dense (in the second case it has a surface sheen).

Diverse in shape - found in the form of grains, scales, crystals and even a pink bud.

Iron Ore Formation

Based on their origin in nature, iron-containing minerals useful for humans can be classified into several main groups:

- Magmatogenic formations are formed under the influence of high temperatures.

- Exogenous - originated in river valleys as a result of precipitation and weathering of rocks.

- Metamorphogenic - formed on the basis of old sedimentary deposits from high pressure and heat.

These groups are in turn divided into numerous subspecies.

Types of iron ores and their characteristics

From an economic point of view, they are classified primarily by their iron content:

- High – more than 55%. These are not natural formations, but already an industrial semi-finished product.

- Average. An example is sinter ore. Obtained from iron-rich natural raw materials through mechanical action.

- Low – less than 20%. These are obtained as a result of magnetic separation.

The location of ore mining is also economically important:

- Linear - lie in places of depressions in the earth's surface, the richest in iron, with a low content of sulfur and phosphorus.

- Flat-like - in nature they form on the surface of iron-containing quartzites.

According to geological parameters, in addition to hematites, the following are widespread and actively used:

- Brown iron ore (nFe2O3 + nH2O) is a metal oxide with the participation of water, usually based on limonites. Characteristic dirty yellowish color, loose, porous. Valuable metal contains from a quarter to fifty percent. Not much - but the substance is well restored. It is enriched for further production of good cast iron.

- Magnetic iron ore, magnetite is a natural iron oxide (Fe3O4). Hematite species are less common, but they contain more than 70% iron. They are dense and granular, in the form of crystals embedded in the rock, black and blue in color. Initially, the compound has magnetic properties; exposure to high temperatures neutralizes them.

- Spar iron ore containing siderite FeCO3.

- There is a large proportion of clay in the ore, then it is clay iron ore. A rare species with relatively low iron content and voids.

Chemical composition

The properties of iron ore, its value and characteristics directly depend on its chemical composition. Iron ore may contain varying amounts of iron and other impurities. Depending on this, there are several types:

- very rich, when the iron content in the ores exceeds 65%;

- rich, the percentage of iron in which varies from 60% to 65%;

- average, from 45% and above;

- poor, in which the percentage of useful elements does not exceed 45%.

The more by-products there are in iron ore, the more energy is needed to process it, and the less efficient the production of finished products is.

The composition of a rock can be a combination of various minerals, waste rock and other by-products, the ratio of which depends on its deposit.

Chemical composition of iron ores

Composition of iron ores of large deposits

Gap rock may also contain iron, but recycling it is not economically feasible. The most commonly found minerals are iron oxides, carbonates and silicates.

It should be noted that ferruginous rocks may contain a huge amount of harmful substances, among which are sulfur, arsenic, phosphorus and others.

Iron ore deposits in Russia

The largest deposit in the world is the Kursk Magnetic Anomaly. This natural creation is so grandiose that people have been trying to understand it since the end of the 16th century. Navigation instruments went crazy from the power of the electric field acting from underground over more than 150 square kilometers. Ore reserves amount to billions of tons.

Deposits of magnetite quartzites are being developed in the Olenegorsk deposit near Muromsk.

On the Kola Peninsula, magnetite, olivine, apatite and magnesioferrite are mined from the Eisko-Kovdor accumulation, and there are many mines in Karelia on the territory of the Kostomuksha deposit.

One of the oldest ore mining sites that can be found on the map of Russia is located in the Sverdlovsk region. It has been supplying material since the end of the 18th century and is called the Kachkanar group of deposits.

The legacy of the Demidov family of entrepreneurs from the Petrine era is actively being transformed. At the end of the 20th century, the Gusevogorsk ore accumulation began to be developed here.

Metallurgy

"Metallurgical complex of Russia" - Development of new technologies. Combination of raw materials and energy. Ore mining. 1. Open pit method 2. Mine method. Features of the ore used. Lithosphere pollution: Solid waste Waste rock dumps. Pollution of the biosphere: Destruction of natural complexes Biological mutations. Copper ore. Type of energy.

“Ferrous metallurgy of Russia” - Combining production - combining all stages of metallurgical production. Ore beneficiation. Get acquainted with the features and problems of ferrous metallurgy. Metal is one of the main construction materials. Production of ferroalloys. Russia's share in the world in iron ore reserves and production. Full cycle metallurgical enterprise.

“Ferrous metallurgy” - 4th group of reactions - formation of cast iron 3 fe + 2CO = fe3c + CO2. Ore mining. Products of metallurgical plants. Iron ore deposits. Types of ferrous metallurgy enterprises. Iron pyrite FeS2. What is metallurgy? Repetition. Chemistry of the blast furnace process. Environmental problems of ferrous metallurgy.

“Non-ferrous metallurgy” - Aluminum tin copper tungsten nickel molybdenum magnesium silver. Main countries (regions) for importing products. The importance of Russia in the non-ferrous metallurgy of the world. Sayan Aluminum Plant. Heavy non-ferrous metals: Main producing countries. Non-ferrous metals: heat-resistant, conduct electricity well, do not rust.

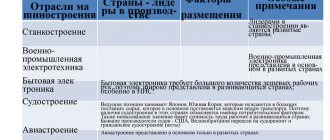

“Ferrous metallurgy of the world” - Leading countries in steel production 2004 (million tons). Steel production methods (%). Types of ferrous metallurgy enterprises. Factors influencing the location of ferrous metallurgy enterprises. Technological stages in the production of ferrous metals. The largest exporters: 1. Brazil 2. Australia 3. Canada 4. Russia.

“Aluminium Production” – ALUMINUM PRICING MECHANISM – London Metal Exchange (LME). Production chain of the merged company. -. 6. 9. 12. Transaction to create a united company. World Aluminum Flows (2005). Alumina – raw material supply. Impact on the aluminum market.

Iron ore reserves in the world

After the grandiose accumulation near Kursk, the largest phenomenon among similar ones on the world geographical map is the strip of iron deposits of the Krivoy Rog deposit in Ukraine.

Next in descending order is the resource of magnetites in the area around the Swedish city of Kiruna - a gift from volcanoes that lived in ancient times.

The wealth of the Lorraine iron ore basin is shared by three European countries - France, Luxembourg and Belgium.

In North America, large mines operate in Newfoundland, Belle Island and near Labrador City. In the South, places rich in ore were called Itabira and Karazhas.

Northeast India also has impressive ore reserves, and on the African continent it is mined in the Guinean city of Conakry.

The list of distribution by country looks like this:

Iron ore mining

The first criterion for mining methods is where the work is carried out:

- On the ground: when fossils occur no more than half a kilometer from the surface. In this case, it is more economically profitable (and more expensive for the environment) to dig giant quarries using blasting operations and special equipment. This is an open source mining method.

- Underground: a large immersion of ore in the bowels of the earth requires the creation of a mine. The closed mining method is not so traumatic for the ecological system, but more labor-intensive and dangerous for humans.

The extracted ore is transported to the plant, where the raw material is crushed for subsequent enrichment. Iron is drawn away from chemical compounds with other elements.

Sometimes to do this you have to go through not one, but several processes:

- Gravity separation (ore particles, due to different physical densities, disintegrate due to mechanical effects on the material - crushing, vibration, rotation and screening).

- Flotation (oxidation of evenly crushed raw materials with air, which attaches metal to itself).

- Magnetic separation:

- the impurity is washed off with a stream of water, and the metal is pulled away with a magnet - an ore concentrate is obtained;

- the product of magnetic separation undergoes flotation - the raw material reveals another half of the iron in its pure form.

- Complex method: using all the above processes, sometimes several times.

The resulting hot briquetted iron is sent to an electrometallurgical plant, where it takes the form of a metal billet of standard shapes or custom-made up to 12 meters. And the cast iron is sent to blast furnace production.

Origin

Native iron

Origin telluric (terrestrial) iron is rarely found in basalt lavas (Uifak, Disko Island, off the western coast of Greenland, near Kassel, Germany). At both locations, pyrrhotite (Fe1-xS) and cohenite (Fe3C) are associated with it, which is explained by both the reduction by carbon (including from the host rocks) and the decomposition of carbonyl complexes such as Fe(CO)n. In microscopic grains, it has more than once been established in altered (serpentinized) ultrabasic rocks, also in paragenesis with pyrrhotite, sometimes with magnetite, due to which it arises during reduction reactions. Very rarely found in the oxidation zone of ore deposits, during the formation of swamp ores. Findings have been recorded in sedimentary rocks associated with the reduction of iron compounds with hydrogen and hydrocarbons. Almost pure iron was found in lunar soil, which is associated with both meteorite falls and magmatic processes. Finally, two classes of meteorites - stony-iron and iron - contain natural iron alloys as a rock-forming component.