array(3) { [0]=> array(40) { [0]=> string(113) «

" [1]=> string(113) "

" [2]=> string(113) "

" [3]=> string(113) "

" [4]=> string(113) "

" [5]=> string(113) "

" [6]=> string(113) "

" [7]=> string(113) "

" [8]=> string(115) "

" [9]=> string(115) "

" [10]=> string(115) "

" [11]=> string(113) "" [12]=> string(115) "

" [13]=> string(113) "

" [14]=> string(115) "

" [15]=> string(113) "

" [16]=> string(115) "

" [17]=> string(115) "

" [18]=> string(113) "

" [19]=> string(115) "

" [20]=> string(115) "

" [21]=> string(115) "

" [22]=> string(113) "

" [23]=> string(113) "

" [24]=> string(113) "

" [25]=> string(115) "

" [26]=> string(115) "

" [27]=> string(113) "

" [28]=> string(115) "

" [29]=> string(115) "

" [30]=> string(115) "

" [31]=> string(115) "

" [32]=> string(115) "

" [33]=> string(113) "

" [34]=> string(113) "" [35]=> string(115) "

" [36]=> string(113) "

" [37]=> string(115) "

" [38]=> string(115) "

" [39]=> string(115) "

" } [1]=> array(40) { [0]=> string(62) "/wp-content/uploads/2/b/7/2b719512d631c9043c6885df52d09d74.jpg" [1]=> string(62) "/ wp-content/uploads/f/9/f/f9f3ba0e17bb437f2d48a6cdbf2fc03b.jpg" [2]=> string(62) "/wp-content/uploads/2/a/8/2a8efdb67cc4212e5e5081764e4fa511.jpg" [3]=> string( 62) “/wp-content/uploads/b/a/0/ba007bf53cf7d77849c958f4a2ddad98.jpg” [4]=> string(62) “/wp-content/uploads/7/3/4/73418da8c51f67eb8484b4b7da3040ff.jpg” [5] => string(62) "/wp-content/uploads/9/d/4/9d45287be99eb473b6b3efa89a4f792a.jpg" [6]=> string(62) "/wp-content/uploads/6/d/c/6dc84483aa6ac5a2f98e3570636da9d0.jpg " [7]=> string(62) "/wp-content/uploads/0/b/4/0b4d97975dfb9bb81597cea60a57ed2a.gif" [8]=> string(63) "/wp-content/uploads/5/d/d /5dd3cedb638371f461313ee862993d86.jpeg" [9]=> string(63) "/wp-content/uploads/6/d/c/6dc6be1343bd7db992d7582f6b850ede.jpeg" [10]=> string(63) "/wp-content/uploads/9 /c/2/9c2e8a7d0a438573082204e78d8c77e7.jpeg" [11]=> string(62) "/wp-content/uploads/e/4/a/e4ab68a4e6a36d98732a953e302a1498.png" [12]=> string(63) "/wp-content /uploads/c/4/b/c4b2411fcf065288ba5eb8669583c5a4.jpeg" [13]=> string(62) "/wp-content/uploads/8/1/a/81a155ec3cd4887dd1ba44f3c2bbfb5d.gif" [14]=> string(63) " /wp-content/uploads/d/2/8/d289a76f3a346ee253e491438f3729a0.jpeg" [15]=> string(62) "/wp-content/uploads/1/5/6/156ba76d07024adb99943c93b948b32d.png" [16]=> string (63) “/wp-content/uploads/d/2/1/d21e37da4265b734cf5068767c896e30.jpeg” [17]=> string(63) “/wp-content/uploads/2/6/1/261ef98de020511d898c6ed8b5495c1b.jpeg” [18 ]=> string(62) "/wp-content/uploads/a/f/f/affea957ac4b1a64045d931ab4347c50.png" [19]=> string(63) "/wp-content/uploads/b/b/c/bbc70329be7ae54275ca6b8558831d04. jpeg" [20]=> string(63) "/wp-content/uploads/b/d/f/bdf95fb06f08dc48b94793becca17114.jpeg" [21]=> string(63) "/wp-content/uploads/0/8/ 5/085b52fb94f40c0232af197630cb8f74.jpeg" [22]=> string(62) "/wp-content/uploads/2/7/f/27fe42549785d060b9aece4ec2c6e04f.png" [23]=> string(62) "/wp-content/uploads/ 4/e/7/4e77a946db570c9b1743ff0a0baa33d2.png" [24]=> string(62) "/wp-content/uploads/d/d/4/dd4b813822cd9b27456379f9887b011e.png" [25]=> string(63) "/wp- content/uploads/9/2/e/92ecb92ccbe088ec3f8e98149819f931.jpeg" [26]=> string(63) "/wp-content/uploads/3/0/d/30d2d8f7bd0f35f55e8c7e1f770a28f6.jpeg" [27]=> string(62) "/wp-content/uploads/1/3/2/132cb9732176b7ef26e2a20284e32cb1.png" [28]=> string(63) "/wp-content/uploads/4/d/1/4d1a33435134726f03c96c842437bad0.jpeg" [29]=> string(63) "/wp-content/uploads/c/c/b/ccb2131ac5f2ab4c9f16b67f9143e7d2.jpeg" [30]=> string(63) "/wp-content/uploads/5/2/a/52ac4e68173459c2929542eede207029.jpeg" [ 31]=> string(63) "/wp-content/uploads/7/a/6/7a64b0c19c2bfdff762781c98cd046a9.jpeg" [32]=> string(63) "/wp-content/uploads/c/9/6/c961d325e3a30b180fa600409901c237 .jpeg" [33]=> string(62) "/wp-content/uploads/2/7/1/2719a86405fe7cdea2c6c0439c0d2033.png" [34]=> string(62) "/wp-content/uploads/7/5 /7/757e12cf237804f7a4befcfa7bcfd8c1.png" [35]=> string(63) "/wp-content/uploads/c/a/2/ca24f312e6bfea60b231bc33b47013ab.jpeg" [36]=> string(62) "/wp-content/uploads /9/9/0/990faaf64380c8c255b0593e9c14e4ef.png" [37]=> string(63) "/wp-content/uploads/f/b/c/fbcf373443e87a4e150b5cd7f432cd5b.jpeg" [38]=> string(63) "/wp -content/uploads/f/f/9/ff9a2e8f17457509e62a6fb7b277c919.jpeg" [39]=> string(63) "/wp-content/uploads/e/0/d/e0d906b8fafad84a6d1a84804b63f464.jpeg" } [2]=> array( 40) { [0]=> string(36) "2b719512d631c9043c6885df52d09d74.jpg" [1]=> string(36) "f9f3ba0e17bb437f2d48a6cdbf2fc03b.jpg" [2]=> string(36) "2a8efdb67cc4212e 5e5081764e4fa511.jpg" [3]=> string(36) "ba007bf53cf7d77849c958f4a2ddad98.jpg" [4]=> string(36) "73418da8c51f67eb8484b4b7da3040ff.jpg" [5]=> string(36) "9d45287be99eb473b6b3efa89a4f792a .jpg" [6]=> string(36) "6dc84483aa6ac5a2f98e3570636da9d0.jpg " [7]=> string(36) "0b4d97975dfb9bb81597cea60a57ed2a.gif" [8]=> string(37) "5dd3cedb638371f461313ee862993d86.jpeg" [9]=> string(37) "6dc6be1343bd7db992d7582f 6b850ede.jpeg" [10]=> string( 37) "9c2e8a7d0a438573082204e78d8c77e7.jpeg" [11]=> string(36) "e4ab68a4e6a36d98732a953e302a1498.png" [12]=> string(37) "c4b2411fcf065288ba5eb8669 583c5a4.jpeg" [13]=> string(36) "81a155ec3cd4887dd1ba44f3c2bbfb5d.gif" [ 14]=> string(37) "d289a76f3a346ee253e491438f3729a0.jpeg" [15]=> string(36) "156ba76d07024adb99943c93b948b32d.png" [16]=> string(37) "d21e37da4265b734cf5 068767c896e30.jpeg" [17]=> string(37) "261ef98de020511d898c6ed8b5495c1b.jpeg" [18]=> string(36) "affea957ac4b1a64045d931ab4347c50.png" [19]=> string(37) "bbc70329be7ae54275ca6b8558831d04.jpeg" [ 20]=> string(37) “bdf95fb06f08dc48b94793becca17114.jpeg” [21] => string(37) "085b52fb94f40c0232af197630cb8f74.jpeg" [22]=> string(36) "27fe42549785d060b9aece4ec2c6e04f.png" [23]=> string(36) "4e77a946db570c9b1743ff0a0 baa33d2.png" [24]=> string(36) "dd4b813822cd9b27456379f9887b011e .png" [25]=> string(37) "92ecb92ccbe088ec3f8e98149819f931.jpeg" [26]=> string(37) "30d2d8f7bd0f35f55e8c7e1f770a28f6.jpeg" [27]=> string(36) "132cb9732176b 7ef26e2a20284e32cb1.png" [28]=> string(37) "4d1a33435134726f03c96c842437bad0.jpeg" [29]=> string(37) "ccb2131ac5f2ab4c9f16b67f9143e7d2.jpeg" [30]=> string(37) "52ac4e68173459c2929542eede2 07029.jpeg" [31]=> string(37) "7a64b0c19c2bfdff762781c98cd046a9.jpeg " [32]=> string(37) "c961d325e3a30b180fa600409901c237.jpeg" [33]=> string(36) "2719a86405fe7cdea2c6c0439c0d2033.png" [34]=> string(36) "757e12cf237804f7 a4befcfa7bcfd8c1.png" [35]=> string( 37) "ca24f312e6bfea60b231bc33b47013ab.jpeg" [36]=> string(36) "990faaf64380c8c255b0593e9c14e4ef.png" [37]=> string(37) "fbcf373443e87a4e150b5cd7f432 cd5b.jpeg" [38]=> string(37) "ff9a2e8f17457509e62a6fb7b277c919.jpeg" [ 39]=> string(37) “e0d906b8fafad84a6d1a84804b63f464.jpeg” } }

Copper deposits

Metals in the copper subgroup are characterized by low chemical activity, for this reason they are found in the form of chemical compounds, as well as nuggets. Many centuries ago, copper could only be found in the form of sulfur compounds - chalcopyrite and chalcocite. This is because copper has a high chemical affinity for sulfur. Most primary ores contain copper in sulfide form - CuS. Over time, especially under conditions of volcanic activity, under the influence of large amounts of oxygen, copper sulfides became oxides. Copper nuggets were formed in nature during the strong heating of oxidized sulfur ore. For example, if oxidized copper minerals and sulfur ores lay under a thick layer of rock, they were heated by natural disasters and earthly heat. In such natural “metallurgical shops” colossal volumes of copper were smelted. A nugget weighing 420 tons was found in North America. However, this is rare; native copper on the planet is approximately 1%.

Sredneuralsky plant: characteristics.

As mentioned above, the Sredneuralsk Copper Plant (SUMZ) is one of the main copper smelting centers in our country. This plant is located in the city of Revda, in the Sverdlovsk region. SUMZ belongs to the Ural Mining and Metallurgical Company, and is also a member of the regional industrial chamber.

Copper deposits and mining

But before you start mining, the substrate will need to be examined more closely. With further drilling and sound waves, the best production sites should be explored by next year. According to von der Linden, 700 million euros will be invested in the construction of the mine. The operating company hopes to promote copper worth at least €300 million per year for 20 years. Shiny metal plates emerge from the black rubble. The copper sheets from the dining table, each weighing more than 100 kilograms, are eventually sold to industry. It is much more common in jewelry making than copper. Often you think about magnetic bracelets made of copper, which are supposed to have a healing effect. However, many people know that copper is also used as a material.

At SUMZ, copper is smelted from primary raw materials, which are taken from the Degtyarskoye deposit.

The Sredneuralsk Copper Smelter has a large copper smelting workshop, an enrichment plant, as well as xanthate and sulfuric acid workshops. The plant also has a number of auxiliary enterprises that serve the needs of the copper smelter.

When did people start winning copper?

But nowadays copper has been brought out of the flood and is used mainly for its beautiful color for jewelry. What properties make the material a suitable raw material for jewelry? The history of copper is long because copper is very easy to work with, people really enjoy making objects from this material at an early stage. In addition to gold, silver and tin, copper was the first metal that people recognized and appreciated. Copper finds a date as far back as a thousand years ago. It was even referred to as the Copper Age, when copper was used and processed excessively. SUMZ produces about one hundred tons of blister copper annually. Copper concentrates at this plant are processed by firing in fluidized bed furnaces, and the method of converting and reflective smelting of the cinder is also used.

The products of the Serdneuralsk plant are supplied to all large Russian enterprises operating in the metallurgical, mining and chemical industries and located in different regions of the country, as well as abroad.

Almost everything at that time was made of copper. At that time, copper mining strongholds were found in Jordan and the former Roman Empire, where up to 000 tons of copper were produced annually. Copper is what is called a semi-precious metal, so it does not have the value of the precious metals gold and silver. However, copper has very good properties that are in no way inferior to silver and gold. Since copper has always been mass produced, its reputation is of course not as good as precious metals, which cannot be won as easily or in harsh quantities.

World copper deposits

A lot of copper, like other minerals, is located at the bottom of the oceans. At the bottom there are clusters of round stones containing approximately 0.5% copper. According to the analysis of geologists, the reserves of copper ore in the ocean reach 5 billion tons. There are almost 250 copper minerals, but only 20 are used industrially. The main copper ores include:

- chalcocite - Cu2S, which contains 79.8% copper

- chalcopyrite - CuFeS2, which contains 30% copper. This ore accounts for almost 50% of all copper deposits

- bornite - Cu5FeS4, contains from 52 to 65% copper

- covellite – CuS, contains 64% copper.

According to genetic and industrial-geological parameters, copper deposits are:

- stratiform, which include copper shales and sandstones

- pyrites. This group includes native and vein copper

- hydrothermal

- igneous, including the most common ores of the copper-nickel type

- carbonate. This group includes iron-copper and carbonatite ores.

Natural compounds containing copper

Pure copper, which is what its nuggets represent, is found in nature in very small quantities. Copper is mainly found in nature in the form of various compounds, the most common of which are the following.

- Bornite is a mineral that got its name in honor of the Czech scientist I. Born. This is a sulfide ore, the chemical composition of which is characterized by its formula - Cu5FeS4. Bornite has other names: variegated pyrite, copper purple. In nature, this ore is presented in two polymorphic forms: low-temperature tetragonal-scalenohedral (temperature less than 228 degrees) and high-temperature cubic-hexaoctahedral (more than 228 degrees). This mineral can have different types depending on its origin. Thus, exogenous bornite is a secondary early sulfide, which is very unstable and is easily destroyed by weathering. The second type, endogenous bornite, is characterized by variable chemical composition, which may contain chalcocite, galena, sphalerite, pyrite and chalcopyrite. Theoretically, minerals of these types can contain from 25.5% sulfur, more than 11.2% iron and over 63.3% copper, but in practice this content of these elements is never maintained.

- Chalcopyrite is a mineral whose chemical composition is characterized by the formula CuFeS2. Chalcopyrite, which is of hydrothermal origin, was previously called copper pyrite. Along with sphalerite and galena, it is included in the category of polymetallic ores. This mineral, which, in addition to copper, contains iron and sulfur, is formed as a result of metamorphic processes and can be present in two types of copper ores: contact-metasomatic type (skarns) and mountain metasomatic (greisens).

- Chalcocite is a sulfide ore, the chemical composition of which is characterized by the formula Cu2S. This ore contains a significant amount of copper (79.8%) and sulfur (20.2%). This ore is often referred to as “copper lustre”, due to the fact that its surface appears as a shiny metal, ranging in shades from lead-gray to completely black. In copper-bearing ores, chalcocite appears as dense or fine-grained inclusions.

Chalcopyrite

In nature, there are also rarer minerals that contain copper.

- Cuprite (Cu2O), a member of the oxide group of minerals, can often be found in places where there is malachite and native copper.

- Covelline is a sulfide rock formed metasomatically. This mineral, whose copper content is 66.5%, was first discovered at the beginning of the last century in the vicinity of Vesuvius. Now covellite is actively mined in deposits in countries such as the USA, Serbia, Italy, and Chile.

- Malachite is a mineral well known to everyone as an ornamental stone. Surely everyone has seen products made from this beautiful mineral in the photo or even owns them. Malachite, which is very popular in Russia, is copper carbonate or copper dihydrocoxcarbonate, which belongs to the category of polymetallic copper-containing ores. The malachite found indicates that there are deposits of other minerals containing copper nearby. In our country, a large deposit of this mineral is located in the Nizhny Tagil region; previously it was mined in the Urals, but now its reserves there are significantly depleted and are not being developed.

- Azurite is a mineral that is also called “copper blue” due to its blue color. It is characterized by a hardness of 3.5–4 units; its main deposits are developed in Morocco, Namibia, Congo, England, Australia, France and Greece. Azurite is often intergrown with malachite and occurs in places where deposits of sulfide-type copper-bearing ores are located nearby.

Malachite

Copper reserves in the world

The largest amount of copper, approximately 65%, occurs in North and South America. European states have 15% of resources, Asian states - 11%, African states - 4.5%. The largest confirmed copper reserves are recorded in Chile. Almost 20% of the world's reserves are located there. And in the USA - 12.7%. In addition to these countries, there is a lot of copper in Poland, Indonesia, Iran, Kazakhstan, China, Uzbekistan, the Philippines, as well as in Zaire, Zambia, Brazil, Canada, Mexico, Panama, Peru and Australia. In each of these states, according to experts, there are about 10 million tons.

Bauxite ore is the basis of global aluminum production

The silver metal itself is directly obtained from alumina. This raw material is aluminum oxide (Al2O3), obtained from ores:

- Bauxite;

- Alunitov;

- Nepheline syenites.

The most common source of starting material is bauxite, which is considered the main aluminum ore.

Despite the more than 130-year history of discovery, it has still not been possible to understand the origin of aluminum ore. It is possible that simply in each region the raw materials were formed under the influence of certain conditions. And this makes it difficult to derive one universal theory about the formation of bauxite. There are three main hypotheses about the origin of aluminum raw materials:

- They were formed due to the dissolution of certain types of limestone as a residual product.

- Bauxite was obtained as a result of weathering of ancient rocks with their further transport and deposition.

- The ore is the result of chemical processes of decomposition of iron, aluminum and titanium salts, and fell as sediment.

However, alunite and nepheline ores were formed under different conditions from bauxite. The former were formed under conditions of active hydrothermal and volcanic activity. The second - at high temperatures of magma.

Bauxite

As a result, alunites generally have a crumbly porous structure. They contain up to 40% of various aluminum oxide compounds. But, in addition to the aluminum-bearing ore itself, the deposits, as a rule, contain additives, which affects the profitability of their mining. It is considered profitable to develop a deposit with a 50 percent ratio of alunites to additives.

Nephelines are usually represented by crystalline samples, which, in addition to aluminum oxide, contain additives in the form of various impurities. Depending on the composition, this type of ore is classified into types. The richest contain up to 90% nephelines, second-rate 40-50%; if the minerals are poorer than these indicators, then it is not considered necessary to develop them.

Having an idea of the origin of minerals, geological exploration can quite accurately determine the location of aluminum ore deposits. Also, the formation conditions, which influence the composition and structure of minerals, determine the extraction methods. If the deposit is considered profitable, its development is established.

Copper ore mining

Due to the low copper content in the ore, its extraction involves processing large volumes of rock. In order to smelt 1 ton of copper, over 200 tons of ore must be processed. Copper mining methods:

- open method. If ore deposits are located close to the earth's surface, then they are developed in this way; the depth of open-pit mining is 150-300 m. The method is characterized by lower losses

- underground method. Using this method, ore is mined from a depth of 500 m, and sometimes from 800-1000 m.

There are five technological systems for field development:

- using self-propelled equipment. This technology is widely used

- using continuous vibration mechanisms

- using hardening goaf backfill. In this case, there is a continuous excavation of reserves of powerful deposits with minimal losses. With the use of such systems, losses are reduced by 3-4 times

- method of extracting ore in horizontal layers. When filling goafs (in underground mines) with hardening compounds, pipes lined with rubber or basalt are used, the service life of which is 50-100 times higher than that of steel

- cyclic-flow technology for the implementation of mining operations.

Table 1. Copper mining in the world

| A country | Ore mining (thousand tons per year) | Reserves (million tons) |

| Chile | 5,38 | 140 |

| USA | 1,16 | 35 |

| Peru | 1 | 30 |

| Indonesia | 0,8 | 35 |

| Australia | 0,85 | 24 |

| Russia | 0,84 | 20 |

| China | 0,62 | 26 |

| World | 14,49 | 467 |

Leading countries in aluminum ore production

The main deposits of aluminum are concentrated in regions with a tropical climate, and most of the 73% of deposits are found in just 5 countries: Guinea, Brazil, Jamaica, Australia and India. Of these, Guinea has the richest reserves, more than 5 billion tons (28% of the world share).

If we divide reserves and production volumes, we can get the following picture:

- 1st place – Africa (Guinea).

- 2nd place - America.

- 3rd place – Asia.

- 4th place – Australia.

- 5th – Europe.

The top five countries in aluminum ore production are presented in the table

| A country | Production volumes million tons |

| China | 86,5 |

| Australia | 81,7 |

| Brazil | 30,7 |

| Guinea | 19,7 |

| India | 14,9 |

Also, the main producers of aluminum ores include: Jamaica (9.7 million tons), Russia (6.6), Kazakhstan (4.2), Guyana (1.6).

Copper production centers

Copper production centers are present in different regions of Russia. Kazakhstan boasts the richest ore deposits. There are also deposits in the Urals. According to the latest data, Russia ranks first in the world in copper ore mining. Copper plants are being built in close proximity to the mines. The raw material factor is the determining component, due to the low content of concentrates in the feedstock. There are 11 copper complexes in the Urals, producing 43% of the country’s copper. In addition to our own raw materials, production also uses those imported from Kazakhstan. There are also waste recycling plants. For example, sulfur dioxide gases, as a byproduct of copper mining, are used to create sulfuric acid, which is then used to make fertilizers.

Source

Applications of Aluminum Ore

Basically, up to 60% of ore raw materials are used to produce aluminum. However, the rich composition makes it possible to extract from it other chemical elements: titanium, chromium, vanadium and other non-ferrous metals, which are necessary primarily as alloying additives to improve the quality of steel.

As mentioned above, the technological chain for producing aluminum necessarily passes through the stage of formation of alumina, which is also used as fluxes in ferrous metallurgy.

The rich composition of elements in aluminum ore is also used to produce mineral paint. Also, the smelting method produces alumina cement - a quickly hardening, strong mass.

Another material obtained from bauxite is electrocorundum. It is obtained by smelting ore in electric furnaces. It is a very hard substance, second only to diamond, making it popular as an abrasive.

Also, in the process of obtaining pure metal, waste is formed - red mud. The element scandium is extracted from it, which is used in the production of aluminum-scandium alloys, which are in demand in the automotive industry, rocket science, production of electric drives, and sports equipment.

review

In 2022, global copper production was 20.4 million tonnes (2017: 20.0 million tonnes). By far the largest producing country was Chile (5.8 million tons), followed by Peru (2.4 million tons), People's Republic of China (1.6 million tons), USA (1.2 million tons) and DR Congo . (1.2 million tons). The share of these five countries in world production was 60.3%. In Europe, mention should be made of Russia, Poland, Bulgaria, Portugal and Sweden.

Copper smelting and refining is only partially carried out in the respective producing countries. In particular, China now smelts and refines a significant portion of the world's copper production. The following table provides an overview of the four countries with the largest volumes of refined copper.

Figures in millions of tons

| classify | a country | Funding (2017) | Melting (2016) | Recycling (2016) | |

| 1. | People's Republic of China People's Republic of China | 1,7 | 5.5 | 8.0 | |

| 2. | Chile Chile | 5.5 | 1.5 | 2,7 | |

| 3. | Japan Japan | USA USA | 1.3 | 0,5 | 1.2 |

Suitable reserves were estimated by the United States Geological Survey (USGS) in January 2022 at 870 million tons worldwide. Chile accounts for 200 million tons, Australia 87 million tons, Peru also 87 million tons, Russia 61 million tons and Mexico 53 million tons. These five countries together accounted for 56.1 percent of the world's reserves. The range of static reserves is approximately 43 years.

Copper mines on the Keweenaw Peninsula of Lake Superior/USA were historically significant (the world's largest deposit of native copper; mining dates back to pre-Columbian times). In Germany, copper slate was mined in the Mansfeld area until 1990.

TOP 10 leading countries in the world of copper producers

The metal received its Latin name Cuprum due to its location on the island of Cyprus. Most of it is found in soil (mines) than in water. Element 29 of the periodic table is found, both in pure form and with impurities.

Poland

Perhaps in 2022 Poland will break all production records in history. In 2022, huge deposits of the fossil were discovered. So far, according to analytical data, Poland refined 630 thousand tons of copper ore last year.

Japan

According to Bloomberg, copper production has fallen sharply. Such trends were noticed due to the exhaustion of mines. The material that can be obtained is of poor quality. State investment in such projects will lead to an increase in prices for fossil fuels. According to agency statistics, only 740 thousand tons were smelted in Japan in 2022.

Canada

Canada is one of the countries with the largest amount of non-ferrous metal deposits in the world. This feature is observed due to the peculiar tectonic location of the territory of the state. Despite the large number of reserves, Canada cannot boast of high numbers due to the presence of ore deep underground. It takes a long time to obtain copper ore and process it. At the same time, the quality of ore is getting worse every year. Last year, 890 thousand tons were produced.

Russia

According to the deputy director of the Ural Metallurgical Company, 2019-2021 may become the starting point for a shortage of minerals in the world. This announcement was made due to the increasing need for copper in the electricity and automotive industries. The production of environmentally friendly cars requires several times more material than the production of conventional vehicles. Last year, 920 thousand tons of minerals were mined in Russia.

South Korea

Over the past 20 years, South Korea has seen changes in the non-ferrous metals industry. Today, some industries are gradually moving to a fully automatic process for processing copper ore. Now, instead of 20 workers, only two mechanization supervisors are needed. In 2022, South Korea produced 1.3 million tons of fossil fuels.

USA

According to analysts at Dow Jones, the United States invests more money in the development of the non-ferrous industry than in the extraction of precious metals. Since the demand for copper is growing every year. It is expected that the cost of the fossil will increase in 2022. Last year, 1.9 million tons were produced in the United States.

Peru

The indigenous population of Peru again staged protests in the first quarter of 2022 over the export of copper outside the state. For several months, factories practically did not work, which will most likely affect the statistics at the end of 2022. According to analysts at Morgan Stanley, 2.4 million tons of minerals were produced in 2022.

India

According to analysts, copper production in India in 2022 will reach about 2.1 million tons. In 2022, the figures were equal to 2.6 million tons. Every year, the need for the use of copper increases in various industries in India. Over the past few years, the need has doubled. Thanks to new infrastructure projects, according to the director of the Indian company Birla Copper, Jagdish Chandra Laddha, the plants will be able to produce the required amount of metal.

China

According to the National Bureau of Statistics of China, last year showed strong results for domestic production. Thanks to this, the need to purchase metal from other countries has decreased. According to general estimates of the PRC, 3.1 million tons were produced.

Chile

6.2 million tons of copper were obtained by ore processing. This is slightly more than ¼ of the world's global production. Due to the strike of some Chilean factories and the flooding of some mines, production figures fell slightly.

Source

Reserves

The USGS distinguishes the following two categories:

- A reserve base is that portion of an identified resource that meets specific minimum physical and chemical criteria for current extraction and production methods, including grade, quality, thickness and depth. Publication of data on the storage base was stopped by the USGS in 2009.

- Inventories are that portion of the supply base that can be economically produced or produced at a given time. This term does not necessarily mean that the exhaust systems are installed and operating. Reserves contain only substances suitable for use.

The reserves of the countries with the largest production are listed here.

Figures in thousands of tons (2018)

| classify | a country | promotion | Reserves | Share base (2009) |

| 1. | Chile Chile | 5 830 | 200 000 | 360 000 |

| 2. | Peru Peru | 2,440 | 87 000 | 120 000 |

| 3. | Australia Australia | 920 | 87 000 | 88 000 |

| 4th | Russia, Russia | 751 | 61 000 | 30 000 |

| 5. | Mexico Mexico | 751 | 53 000 | 50 000 |

| Sixth | USA USA | 1,220 | 51 000 | 70 000 |

| 7th | Indonesia Indonesia | 651 | 28 000 | 38 000 |

| 8th. | People's Republic of China People's Republic of China | 1,590 | 26 000 | 63 000 |

| 9. | Democratic Republic of the Congo DR Congo | 1,230 | 19 000 | k. A. |

| 10. | Zambia Zambia | 854 | 19 000 | 35 000 |

| Other countries | 3 540 | 220 000 | 110 000 | |

| World | 20 400 | 870 000 | 1,000,000 |

Copper exporters

The country with the largest volume of metal production does not always lead the ranking in raw material exports. The picture on the world market for the sale of refined copper is somewhat different than in terms of production volumes.

Leading countries for red metal exports:

Export of refined copper by leading exporting countries in 2007, thousand tons

- Chile - 2,547,000 tons per year;

- Russia – 633,000 tons;

- Peru - 415,000 tons;

- Kazakhstan – 354,000 tons.

The leading countries in production in Africa are not far behind:

- Zambia;

- Democratic Republic of the Congo;

- Republic of South Africa.

The main importers of copper products are the European Union countries, as well as:

Copper smelting volumes by region

- USA;

- Japan;

- Taiwan;

- China;

- Korea;

- Türkiye.

The total volume of imports is 5805.4 thousand tons per year.

China buys raw materials mainly from Chile. Türkiye, the USA and Japan are in Africa, Korea is near Australia.

promotion

Around the country

The following table shows all countries whose annual production in 2022 was more than 10,000 tons. The copper content in ores and concentrates is given. Copper has not been mined in Germany since the early 1990s. All figures refer to states within their current borders.

Figures in thousands of tons

| Rank (2018) | a country | 1970 | 1980 | 1990 | 2000 | 2010 | 2015 | 2016 | 2017 | 2018 |

| 1. | Chile Chile | 686 | 1,068 | 1,588 | 4 602 | 5 419 | 5772 | 5,553 | 5 504 | 5 832 |

| 2. | Peru Peru | 220 | 367 | 323 | 554 | 1,247 | 1,701 | 2354 | 2,446 | 2,437 |

| 3. | People's Republic of China People's Republic of China | 120 | 165 | 285 | 889 | 1,156 | 1,712 | 1 900 | 1,706 | 1,591 |

| 4th | USA USA | 1,560 | 1,181 | 1,588 | 1,444 | 1,110 | 1,416 | 1,462 | 1,290 | 1,250 |

| 5. | Democratic Republic of the Congo DR Congo | 386 | 462 | 352 | 33 | 378 | 1,039 | 1,024 | 1,095 | 1,225 |

| Sixth | Australia Australia | 158 | 244 | 330 | 832 | 871 | 996 | 948 | 849 | 913 |

| 7th | Zambia Zambia | 684 | 610 | 546 | 249 | 767 | 711 | 725 | 797 | 851 |

| 8th. | Russia, Russia | 387 | 400 | 643 | 530 | 703 | 711 | 702 | 762 | 785 |

| 9. | Mexico Mexico | 61 | 175 | 299 | 365 | 270 | 594 | 766 | 742 | 697 |

| 10. | Indonesia Indonesia | 59 | 162 | 1.012 | 863 | 579 | 728 | 622 | 651 | |

| 11. | Kazakhstan Kazakhstan | 138 | 143 | 230 | 430 | 381 | 474 | 475 | 558 | 636 |

| 12th | Canada Canada | 610 | 716 | 794 | 634 | 522 | 715 | 693 | 597 | 539 |

| 13th | Mongolia Mongolia | 44 year | 124 | 126 | 128 | 318 | 516 | 475 | 459 | |

| 14th | Poland Poland | 83 | 343 | 370 | 454 | 426 | 426 | 424 | 419 | 401 |

| 15th | Brazil Brazil | 4th | 34 | 32 | 214 | 359 | 338 | 385 | 381 | |

| 16. | Iran Iran | 1 | 67 | 147 | 257 | 246 | 289 | 296 | 317 | |

| 17th | Spain Spain | 10 | 49 | 13th | 25th | 54 | 113 | 168 | 198 | 185 |

| 18th | Myanmar Myanmar | 10 | 71 | 95 | 116 | 154 | ||||

| 19th | Laos Laos | 132 | 168 | 178 | 153 | 147 | ||||

| 20th | Bulgaria Bulgaria | 42 | 62 | 33 | 93 | 113 | 112 | 110 | 109 | 109 |

| 21st | Sweden Sweden | 26th | 43 years old | 74 | 78 | 77 | 75 | 79 | 104 | 106 |

| 22nd | Uzbekistan Uzbekistan | 42 | 43 years old | 69 | 70 | 80 | 100 | 100 | 100 | 100 |

| 23 | Papua New Guinea Papua New Guinea | 147 | 170 | 203 | 160 | 45 | 80 | 105 | 96 | |

| 24 | Armenia Armenia | 1 | 1 | 1 | 12th | 31 year | 84 | 103 | 114 | 84 |

| 25th | turkey turkey | 31 year | 21 years old | 40 | 76 | 80 | 108 | 100 | 83 | 80 |

| 26th | Philippines Philippines | 160 | 305 | 181 | 32 | 58 | 84 | 84 | 68 | 70 |

| 27 | Saudi Arabia Saudi Arabia | 2 | 12th | 28 | 36 | 68 | ||||

| 28. | Portugal Portugal | 4th | 4th | 160 | 76 | 74 | 83 | 74 | 64 | 49 |

| 29 | South Africa South Africa | 144 | 201 | 188 | 148 | 103 | 77 | 65 | 66 | 47 |

| 30's | Finland Finland | 31 year | 53 | 18th | 12th | 15th | 41 years old | 47 | 53 | 47 |

| 31. | Serbia Serbia | 85 | 107 | 129 | 46 | 23 | 30's | 41 years old | 45 | 44 year |

| 32. | India India | 10 | 27 | 52 | 38 | 32 | 32 | 32 | 34 | 37 |

| 33. | Mauritania Mauritania | 37 | 45 | 33 | 29 | 28 | ||||

| 34. | Morocco Morocco | 15th | 20th | 24 | 25th | 24 | ||||

| 35. | Vietnam Vietnam | 12th | 23 | 23 | 21 years old | 23 | ||||

| 36. | Argentina Argentina | 1 | 145 | 140 | 62 | 82 | 33 | 17th | ||

| 37. | Eritrea Eritrea | 62 | 25th | 8th | 17th | |||||

| 38. | Pakistan Pakistan | 20th | 16 | 14th | 15th | 17th | ||||

| 39. | Namibia Namibia | 23 | 39 | 28 | 5 | 14th | 17th | 16 | 15th | |

| 40. | Georgia Georgia | 3 | 3 | 4th | 9 | 11 | 13th | 14th | 15th | 13th |

| 41. | Colombia Colombia | 2 | 1 | 5 | 8th | 9 | 10 |

By company

The company, the country in which it is located, the volume of production and the share of world production are listed.

Figures in thousands of tons (2017)

| classify | Companies | a country | quantity | Ownership % |

| 1. | Codelco | Chile Chile | 1840 | 9.1 |

| 2. | Freeport-McMoRan | USA USA | 1436 | 7.1 |

| 3. | Glencore | Switzerland Switzerland | 1247 | 6.2 |

| 4th | Grupo Mexico | Mexico Mexico | 883 | 4.4 |

| 5. | BHP Billiton | Australia Australia United Kingdom United Kingdom | 796 | 3.9 |

| Sixth | KGHM Polska Mied | Poland Poland | 553 | 2,7 |

| 7th | The first quantum minerals | Canada Canada | 513 | 2,5 |

| 8th. | Rio Tinto Group | Australia Australia United Kingdom United Kingdom | 499 | 2,5 |

| 9. | Antofagasta plc | United Kingdom United Kingdom | 486 | 2.4 |

| 10. | Group of Minerals and Metals | Australia Australia | 445 | 2.2 |

Global funding

The following table shows global production in thousands of tons.

Figures in thousands of tons

| 495 | |

| 1901 | 526 |

| 1902 | 555 |

| 1903 | 596 |

| 1904 | 660 |

| 1905 | 713 |

| 1906 | 724 |

| 1907 | 721 |

| 1908 | 744 |

| 1909 | 828 |

| 1910 | 858 |

| 1911 | 890 |

| 1912 | 1,000 |

| 1913 | 996 |

| 1914 | 938 |

| 1,060 | |

| 1916 | 1,420 |

| 1917 | 1,430 |

| 1918 | 1,430 |

| 1919 | 994 |

| 1920 | 959 |

| 1921 | 558 |

| 1922 | 884 |

| 1923 | 1,270 |

| 1924 | 1,360 |

| 1925 | 1,530 |

| 1926 | 1,510 |

| 1927 | 1,520 |

| 1928 | 1,730 |

| 1929 | 1,950 |

| 1,610 | |

| 1931 | 1,400 |

| 1932 | 909 |

| 1933 | 1,050 |

| 1934 | 1,280 |

| 1935 | 1,500 |

| 1936 | 1,720 |

| 1937 | 2290 |

| 1938 | 1,990 |

| 1939 | 2,130 |

| 1940 | 2400 |

| 1941 | 2,480 |

| 1942 | 2,590 |

| 1943 | 2 620 |

| 1944 | 2,460 |

| 2,110 | |

| 1946 | 1,780 |

| 1947 | 2,130 |

| 1948 | 2,210 |

| 1949 | 2,140 |

| 1950 | 2380 |

| 1951 | 2,490 |

| 1952 | 2,570 |

| 1953 | 2600 |

| 1954 | 2640 |

| 1955 | 2 900 |

| 1956 | 3 200 |

| 1957 | 3 300 |

| 1958 | 3 190 |

| 1959 | 3 430 |

| 3 940 | |

| 1961 | 4 090 |

| 1962 | 4220 |

| 1963 | 4290 |

| 1964 | 4 450 |

| 1965 | 4 660 |

| 1966 | 4,580 |

| 1967 | 4 630 |

| 1968 | 5,010 |

| 1969 | 5 520 |

| 1970 | 5 900 |

| 1971 | 5 940 |

| 1972 | 6 540 |

| 1973 | 6 920 |

| 1974 | 7 100 |

| 6 740 | |

| 1976 | 7 260 |

| 1977 | 7 420 |

| 1978 | 7 280 |

| 1979 | 7,350 |

| 1980 | 7 200 |

| 1981 | 7 690 |

| 1982 | 7 580 |

| 1983 | 7 610 |

| 1984 | 7 810 |

| 1985 | 7 990 |

| 1986 | 7 940 |

| 1987 | 8 240 |

| 1988 | 8 720 |

| 1989 | 9 040 |

| 9 200 | |

| 1991 | 9 330 |

| 1992 | 9 470 |

| 1993 | 9 490 |

| 1994 | 9 500 |

| 1995 | 10 000 |

| 1996 | 11 000 |

| 1997 | 11 500 |

| 1998 | 12 100 |

| 1999 | 12 800 |

| 2000 | 13 200 |

| 2001 | 13 700 |

| 2002 | 13 600 |

| 2003 | 13 800 |

| 2004 | 14 700 |

| 2006 | 15 100 |

| 2007 | 15 500 |

| 2008 | 15 600 |

| 2009 | 16 000 |

| 2010 | 16 100 |

| 2011 | 16 300 |

| 2012 | 16 900 |

| 2013 | 18 300 |

| 2014 | 18 500 |

| 2015 | 19 100 |

| 2016 | 20 100 |

| 2017 | 20 000 |

| 2018 | 20 400 |

| 2019 e | 20 000 |

Copper production

After mining the ore, the next problem arises: how to extract the necessary material from it? There are several ways.

One of the oldest technologies involved burning malachite ores with limited air access. The mass placed in pots, mixed with coal, burned, releasing carbon monoxide. Which led to achieving the desired result - obtaining copper that was sufficiently pure for its time.

It is clear that over the past centuries, methods and methods of ore processing have undergone major changes, driven by the goal of achieving the most optimal results for any type of primary raw material. That is why modern metallurgy is based on three main methods for producing copper.

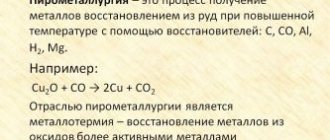

Pyrometallurgical method

Based on high-temperature processes, the pyrometallurgical method is ideally suited for sulfide ores, which are sometimes quite poor in copper concentration. It allows you to extract metal even with a content of 0.5%.

But first of all, the feedstock is enriched during the flotation process. Its essence lies in thoroughly grinding the ore, filling it with water, and adding complex organic flotation reagents. They envelop mineral particles containing copper alloys, giving them non-wetting.

At the second stage of this process, foam is created in the solution, the bubbles of which pick up particles coated with organic matter. This happens under the influence of air flow, as a result of which the formations float to the surface, from where they are later taken up. The foam saturated with copper compounds is collected, squeezed out and dried.

After which the resulting concentrate is fired at a temperature of 14,000 C. This is necessary to remove sulfur and oxidize sulfides. Then high-temperature (14,0000 - 15,0000C) smelting is carried out in shaft furnaces to produce an alloy of iron and copper - matte. Next, in the process of Bessemer smelting in a converter under the influence of oxygen, the oxide is obtained, and then the blister copper itself, containing 90.95% of the metal. In this case, sulfur turns into an acid residue, and iron into silicate slag.

You can obtain pure copper from a rough substance using:

- fire refining,

- electrolysis,

- exothermic reduction reaction under the influence of hydrogen.

Hydrometallurgical method

To extract copper and a number of other metals from polymetallic ores containing less than 0.5% of the desired mineral, the hydrometallurgical method is used.

The extracted minerals are dissolved using non-concentrated sulfuric acid or ammonia. Copper is obtained from the resulting liquids during the displacement reaction. Metallic iron is used to carry out the reaction.

Electrolysis method

The method is designed to obtain pure copper through an electrolytic reaction.

Its technology is to produce pure copper thin sheet cathodes and thick plate anodes from blister copper. Placed then in a bath filled with copper sulfate, they react under the influence of electric current. Copper dissolves on the anodes and is deposited on the cathodes. Released impurities are removed by chemical methods.

Copper pipes

Production and export

Smelting by country

All figures refer to states within their current borders.

Figures in thousands of tons

| Rank (2018) | a country | 1970 | 1980 | 1990 | 2000 | 2010 | 2016 | 2017 | 2018 |

| 1. | People's Republic of China People's Republic of China | 120 | 175 | 358 | 1.014 | 2 826 | 6,115 | 5 966 | 6 357 |

| 2. | Japan Japan | 603 | 929 | 1,041 | 1,331 | 1,356 | 1,290 | 1,192 | 1,263 |

| 3. | Chile Chile | 647 | 953 | 1,329 | 1,460 | 1,560 | 1,365 | 1,265 | 1,246 |

| 4th | Zambia Zambia | 683 | 601 | 355 | 180 | 535 | 698 | 788 | 829 |

| 5. | Russia, Russia | 368 | 516 | 954 | 550 | 647 | 665 | 730 | 754 |

| Sixth | USA USA | 1,489 | 1,008 | 1,158 | 862 | 601 | 563 | 470 | 536 |

| 7th | Korea, South South Korea | 5 | 64 | 161 | 371 | 476 | 510 | 510 | 530 |

| 8th. | India India | 9 | 28 | 41 years old | 256 | 654 | 773 | 823 | 492 |

| 9. | Poland Poland | 69 | 367 | 430 | 463 | 470 | 447 | 458 | 462 |

| 10. | Australia Australia | 112 | 175 | 192 | 391 | 410 | 445 | 360 | 378 |

| 11. | Peru Peru | 177 | 349 | 261 | 340 | 313 | 309 | 317 | 328 |

| 12th | Bulgaria Bulgaria | 40 | 59 | 30's | 163 | 247 | 245 | 323 | 317 |

| 13th | Germany Germany | 134 | 170 | 198 | 211 | 379 | 343 | 333 | 311 |

| 14th | Iran Iran | 79 | 156 | 188 | 153 | 114 | 304 | ||

| 15th | Kazakhstan Kazakhstan | 165 | 230 | 426 | 414 | 354 | 294 | 296 | 295 |

| 16. | Canada Canada | 465 | 493 | 476 | 544 | 318 | 304 | 289 | 290 |

| 17th | Mexico Mexico | 60 | 86 | 210 | 308 | 169 | 268 | 270 | 286 |

| 18th | Spain Spain | 55 | 103 | 121 | 290 | 259 | 292 | 272 | 285 |

| 19th | Indonesia Indonesia | 174 | 263 | 256 | 246 | 259 | |||

| 20th | Philippines Philippines | 153 | 150 | 216 | 215 | 240 | 171 | ||

| 21st | Sweden Sweden | 37 | 46 | 76 | 105 | 142 | 132 | 150 | 150 |

Oil refinery production

Around the country

All figures refer to states within their current borders.

Figures in thousands of tons

| Rank (2018) | a country | 1970 | 1980 | 1990 | 2000 | 2010 | 2016 | 2017 | 2018 |

| 1. | People's Republic of China People's Republic of China | 120 | 295 | 558 | 1,371 | 4,540 | 8 436 | 8 970 | 9 029 |

| 2. | Chile Chile | 452 | 811 | 1,192 | 2668 | 3 244 | 2 613 | 2,430 | 2,461 |

| 3. | Japan Japan | 713 | 1.014 | 1,008 | 1,437 | 1,549 | 1,553 | 1,488 | 1,595 |

| 4th | USA USA | 1444 | 1,730 | 2,017 | 1 802 | 1,095 | 1,220 | 1,080 | 1,070 |

| 5. | Russia, Russia | 346 | 502 | 722 | 842 | 900 | 860 | 949 | 1,039 |

| Sixth | Democratic Republic of the Congo DR Congo | 29 | 259 | 819 | 825 | 1,000 | |||

| 7th | Germany Germany | 440 | 425 | 532 | 709 | 704 | 671 | 694 | 672 |

| 8th. | Korea, South South Korea | 7th | 88 | 192 | 471 | 565 | 645 | 663 | 665 |

| 9. | Poland Poland | 93 | 357 | 346 | 486 | 547 | 536 | 522 | 502 |

| 10. | Zambia Zambia | 534 | 608 | 426 | 226 | 767 | 426 | 466 | 458 |

| 11. | India India | 10 | 23 | 46 | 260 | 512 | 788 | 831 | 450 |

| 12th | Kazakhstan Kazakhstan | 199 | 288 | 414 | 395 | 323 | 408 | 426 | 438 |

| 13th | Mexico Mexico | 53 | 97 | 157 | 343 | 247 | 462 | 446 | 437 |

| 14th | Spain Spain | 111 | 154 | 171 | 316 | 348 | 429 | 415 | 424 |

| 15th | Australia Australia | 127 | 182 | 274 | 509 | 424 | 475 | 386 | 408 |

| 16. | Belgium Belgium | 326 | 526 | 332 | 423 | 381 | 367 | 399 | 390 |

| 17th | Peru Peru | 33 | 224 | 182 | 452 | 394 | 331 | 335 | 337 |

| 18th | Canada Canada | 478 | 505 | 516 | 551 | 320 | 314 | 330 | 291 |

| 19th | Indonesia Indonesia | 158 | 279 | 253 | 271 | 275 | |||

| 20th | Iran Iran | 1 | 48 | 181 | 220 | 193 | 161 | 239 | |

| 21st | Sweden Sweden | 35 year | 56 | 97 | 133 | 190 | 207 | 219 | 224 |

By company

The list includes company, headquarters, refinery, and share of global production.

Figures in thousands of tons (2009)

| classify | Companies | a country | quantity | Ownership % |

| 1. | Codelco | Chile Chile | 1881 | 10,4 |

| 2. | Aurubis AG | Germany Germany | 1092 | 6.0 |

| 3. | Freeport-McMoRan | USA USA | 1028 | 5,7 |

| 4th | Jiangxi Copper | People's Republic of China People's Republic of China | 804 | 4.4 |

| 5. | Xstrata | Switzerland Switzerland | 761 | 4.2 |

| Sixth | Nippon Mining & Metals Company | Japan Japan | 666 | 3,7 |

| 7th | BHP Billiton | Australia Australia United Kingdom United Kingdom | 587 | 3.2 |

| 8th. | Sumitomo mining industry | Japan Japan | 529 | 2,9 |

| 9. | LS-Nikko Copper | Korea, South South Korea | 519 | 2,9 |

| 10. | Mitsubishi materials | Japan Japan | 506 | 2,8 |

| 11. | KGHM Polska Mied | Poland Poland | 503 | 2,8 |

Copper exports by country

The following table shows countries according to their copper exports. 2012 data in millions of dollars, as reported by the Observatory of Economic Complexity. The top ten countries are listed.

| # | a country | Cost in millions of US dollars |

| 1 | Chile Chile | 21 962 |

| 2 | Japan Japan | 4,542 |

| 3 | Kazakhstan Kazakhstan | 3 637 |

| 4th | Australia Australia | 2 904 |

| 5 | Poland Poland | 2 672 |

| Sixth | Russia, Russia | 2,528 |

| 7th | Zambia Zambia | 2 349 |

| 8th | India India | 2,248 |

| 9 | Germany Germany | 2,106 |

| 10 | Peru Peru | 1 989 |