How is strength testing performed?

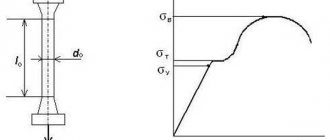

Strength testing of metals is carried out using specialized mechanisms that allow you to set the required power during tensile testing. Such machines consist of a special loading element, with the help of which the necessary force is created.

Equipment for testing metals for strength makes it possible to stretch the materials being tested and set certain values of force that are applied to the sample. Today, there are hydraulic and mechanical types of mechanisms for testing materials.

Consequences of exceeding values

In fact, the tensile strength parameter is used to solve special engineering problems and in non-standard heating, water supply, and filtration systems. This value is determined in the laboratory during product certification to obtain evidence of compliance with state and international standards.

For the average person, the value of the nominal pressure (PN) is more important - Pressure Nominal, that is, the operating pressure for the pipeline at a temperature of 20 ° C. This value also guarantees that, subject to the manufacturer's recommendations and acceptable environmental conditions, the pipeline will last at least 50 years with a minimum durability MRS of 6.3 MPa. Simply put, when you buy a PN20 pipe, it will last for at least 50 years at a pressure of at least 6.3 MPa and a temperature of 20 ° C. Also, when calculating MRS (Minimum Continuous Strength), a safety factor of 1.25 is included, so the actual service life may be 25% longer. The need to calculate the tensile strength of a pipe for the average person, engineer, heating engineer, and designer has almost completely disappeared.

Formation of the concept of the ultimate strength of metals

Galileo once spoke about the ultimate strength, who determined that the maximum permissible limit of compression and tension of materials depends on their cross-section. Thanks to the scientist's research, a previously unknown quantity arose - fracture stress.

The modern doctrine of the strength of metals was formed in the middle of the 20th century, which was necessary based on the need to develop a scientific approach to prevent possible destruction of industrial structures and machines during their operation. Until this point, when determining the strength of a material, only the degree of its plasticity and elasticity was taken into account and the internal structure was not taken into account at all.

Temporary resistance and fatigue

There is a direct connection between PP and temporary resistance to various loads. The second indicator in the documentation and technical literature is designated by the symbol T. It shows how long the deformation of the sample lasts when it is subjected to a constant load. When temporary resistance ceases, the crystal lattice of the substance is rearranged. This is typical for solid materials. As a result, the substance becomes stronger than it was before. This phenomenon is called self-strengthening.

Another important characteristic is metal fatigue. When talking about steel, the expression “endurance limit” is used. The symbol R is used for designation. This characteristic shows the impact of what force the material can withstand constantly, and not just once. During the experiment, pressure of a given force is applied to the sample. The number of impacts is 107. During testing, the material should not deform or lose its original characteristics.

Conducting such experiments takes a lot of time, so they are not always carried out. They often make do with mathematical calculations, calculating all the important coefficients.

The limit of proportionality is the maximum load at which the ratio determined by Hooke's law is maintained. According to him, the body is deformed in direct proportion to the magnitude of the impact exerted on it. Each material has a certain degree of elasticity. It can be classic and absolute. Changes can be reversible or irreversible. An example of the first type is a spring: while it is being acted upon, it compresses, and when the pressure stops, it expands.

Tensile strength of steel

Steel is the main raw material in most industrial applications. It is widely used in construction. That is why it is very important to select in advance a high-quality, truly suitable type of steel to perform specific tasks. The result and quality of the work performed directly depends on the correct calculation of the tensile strength of a certain steel grade.

As an example, we can cite several values of the ultimate strength indicators of steels. These values are based on government standards and are recommended parameters. Thus, for products cast from structural non-alloy steel, the GOST 977-88 standard is provided, according to which the limiting strength value during tensile testing is about 50-60 kg/mm 2, which is approximately 400-550 MPa. A similar grade of steel, after undergoing the hardening procedure, acquires a tensile strength value of more than 700 MPa.

The objective tensile strength of steel 45 (or any other grade of material, just like iron or cast iron, as well as other metal alloys) depends on a number of factors that must be determined based on the tasks assigned to the material during its use.

Main classes

A bolt is a cylindrical fastener with a thread on the outside. Usually has a hex head made to fit a wrench. The connection occurs using a nut or other threaded hole. Before the creation of screw fasteners, bolts were any products in the form of a rod.

The bolt design is as follows.

Head

With its help, torque is transmitted to the rest of the fastener . It can be hexagonal, semicircular, semicircular with a screw, cylindrical, cylindrical with a hexagonal recess, countersunk and countersunk with a screw.

Cylindrical rod

Divided into several types:

- standard;

- for installation in a hole with a gap;

- for installation in a reamed hole;

- with a rod of reduced diameter without thread.

screw

May have the following forms:

- round;

- wing nut;

- hexagonal (with low/high/normal chamfers, crown and slotted).

There are many types of bolts, it all depends on what qualities the manufactured structure should have during operation. The strength class of bolts describes their mechanical properties.

Based on the most popular tables, you can understand that this class is the main one.

Strength is a property of a product characterized by resistance to destruction from external factors. Any manufacturer must indicate the strength of the product so that during installation or assembly it is clear whether the fasteners are suitable for certain cases. Strength is measured by two numbers separated by a dot, or by a two-digit and a single-digit number also separated by a dot:

- 3.6 — connecting elements made of unalloyed steel, additional hardening is not used;

- 4.6 — carbon steel was used for production;

- 5.6 — made of steel without final tempering;

- 6.6, 6.8 — hardware made of carbon steel, without impurities;

- 8.8 — components such as chromium, manganese or boron are added to the steel, and the finished metal is additionally tempered at temperatures above 400°C;

- 9.8 — has a minimum of differences from the previous class and higher strength;

- 10.9 — for the production of such bolts, steel is taken with additional additives and tempered at 340-425 ° C;

- 12.9 — stainless or alloy steel is used.

The first number means the tensile strength (1/100 N/mm2 or 1/10 kg/mm2), that is, 1 millimeter of a 3.6 square bolt will withstand 30 kilograms of tensile strength. The second number is the ratio of yield strength to tensile strength as a percentage. That is, the 3.6 bolt will not deform to a force of 180 N/mm2 or 18 kg/mm2 (60% of the tensile strength).

Based on strength values, connecting bolts are divided into the following options.

- Functioning in tension-rupture along the inner diameter of the bolt. The higher the strength of the fastener, the more likely it is that the bolt will deform under load, that is, stretch.

- Functioning to shear the bolt along two planes. The lower the strength, the higher the likelihood that the fastening will fail.

- Functioning in tension and shear - the bolt head is cut off.

- Frictional - here the material is crushed under the fasteners, that is, they function for shear, but with a high tension of the fasteners.

The yield strength is the greatest load, when increased, deformation occurs that cannot be restored in the future, that is, the screw connection will increase in length after certain actions. The greater the weight the structure can withstand, the higher the fluidity rate. When calculating the load, they usually take 1/2 or 1/3 of the yield strength. As an example, consider a kitchen spoon - if you bend it in one direction, you get a different object. The fluidity was broken - this led to deformation, but the material itself did not break. It can be concluded that the elasticity of steel is higher than its fluidity.

Another item, a knife, will break when bent. Therefore, the strength of strength and fluidity are the same. Products with such characteristics are also called fragile. Tensile limit is a change in the size and shape of a material under the influence of external factors, without the product being destroyed. In other words, this is the percentage of elongation of the material compared to the original sample. This characteristic shows the length of the bolt before failure. Classification by size - the larger the area, the greater the resistance to torsion.

The length of the bolt is selected in accordance with the thickness of the parts being connected.

Fasteners are also divided according to such an indicator as accuracy. Various thread cutting and surface treatment methods are used in production. It can be elevated, normal and rough.

- C – rough accuracy. These fasteners are suitable for holes 2-3 millimeters larger than the rod itself. With such a difference in diameters, the connections may move.

- B – normal accuracy. The connecting elements are installed in holes 1-1.5 millimeters wider than the rod. Amenable to less deformation compared to the previous class.

- A – high accuracy . The holes for this group of bolts can be 0.25-0.3 millimeters wider. Fasteners have a fairly high cost, as they are produced by turning.

For fasteners made of stainless steel, they indicate not the class, but the tensile strength; they have a different designation - A2 and A4, where:

- A is the austenitic structure of steel (high-temperature iron with a crystalline fcc lattice);

- numbers 2 and 4 indicate the chemical composition of the material.

Stainless steel bolts have 3 strength ratings - 50, 70, 80. In the production of high-strength bolts, alloys with greater hardness and strength are used. Such materials are more expensive than carbon steel. The strength class varies - 6.6, 8.8, 9.8, 10.9, 12.9. Also, to improve performance, a heat treatment stage is carried out, which changes the chemical composition and structure of the material. Possible operation at temperatures below 40°C is designated U. 40-65°C is marked as HL.

The hardness of bolts is the ability of a material to resist penetration of another body into its surface. The hardness characteristics of bolts are measured by Brinell, Rockwell and Vickers. Brinell hardness tests are carried out using a hardness tester; the indenter (pressed object) is a hardened ball with a diameter of 2.5, 5 or 10 millimeters. The size depends on the thickness of the material being tested. Indentation occurs within 10-30 seconds, the time also depends on the material being tested. The resulting print is then measured in two directions using a Brinell magnifying glass. The ratio of the applied load to the surface of the print is the definition of hardness.

The Rockwell method is also based on indentation. A diamond cone acts as an inderator for hard alloys; for softer alloys, a steel ball with a diameter of 1.6 millimeters is used. In this method, the test is carried out in two phases. First, a preload is applied to ensure firm contact between the material and the tip. Then the main load comes for a short time. After the working load is removed, the hardness is measured. That is, the calculations will take place at the depth at which the indeter remains, with an applied preload. This method distinguishes 3 hardness groups:

- HRA - for particularly hard metals;

- HRB - for relatively soft metals;

- HRC - for relatively hard metals.

Vickers hardness is determined by the width of the indentation. The pressed tip is a diamond pyramid with four edges. It is measured by calculating the ratio of the load to the area of the resulting mark. Measurements are made under a microscope installed on the equipment. This method is characterized by increased accuracy and super sensitivity. The measurement methods used according to GOST in Soviet times did not allow determining all the maximum permissible loads on fasteners, so the materials produced were of low quality.

Copper strength

Under normal conditions at room temperature, annealed commercial copper has a tensile strength of about 23 kg/mm 2. With significant temperature loads on the material, its ultimate strength is significantly reduced. The indicators of the ultimate strength of copper are reflected by the presence of various impurities in the metal, which can both increase this indicator and lead to its decrease.

Aluminum strength

The annealed fraction of technical aluminum at room temperature has a tensile strength of up to 8 kg/mm 2. Increasing the purity of the material increases its ductility, but is reflected in a decrease in strength. An example is aluminum, which has a purity of 99.99%. In this case, the ultimate strength of the material reaches about 5 kg/mm 2.

A decrease in the tensile strength of an aluminum dough piece is observed when it is heated during tensile testing. In turn, lowering the metal temperature in the range from +27 to -260 o C temporarily increases the test indicator by 4 times, and when testing the highest purity aluminum fraction - by as much as 7 times. At the same time, the strength of aluminum can be slightly increased by alloying it.