Mechanical properties of metals and alloys

The main mechanical properties of metals include strength , toughness , ductility , hardness , endurance, creep, wear resistance. They are the main characteristics of a metal or alloy .

Let's consider some terms used to characterize mechanical properties. Changes in size and shape that occur in a solid under the influence of external forces are called deformations, and the process that causes them is called deformation. Deformations that disappear upon unloading are called elastic, and those that do not disappear after the load is removed are called residual or plastic.

Voltage

is the magnitude of the internal forces that arise in a solid body under the influence of external forces.

The strength of a material is understood as its ability to resist deformation or destruction under the influence of static or dynamic loads. Strength is judged by the characteristics of mechanical properties obtained during mechanical tests. Static strength tests include tension, compression, bending, torsion, and indentation. Dynamic tests include tests for impact strength, endurance and wear resistance. Elasticity is the ability of materials to deform elastically, and plasticity is the ability to deform plastically without destruction.

Viscosity

- this is a property of a material that determines its ability to absorb mechanical energy with a gradual increase in plastic deformation until the destruction of the material. Materials must be both durable and ductile.

Hardness

is the ability of a material to resist the penetration of other bodies into it.

Endurance

- this is the ability of a material to withstand, without collapsing, a large number of repeatedly variable loads.

Wear resistance

is the ability of a material to resist surface destruction under the influence of external friction.

Creep

- this is the ability of a material to slowly and continuously plastically deform (crawl) under constant stress (especially at high temperatures).

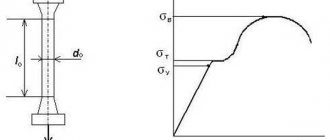

The behavior of some metals (for example, annealed steel) under tensile testing is shown in Fig. 3

. As the load increases, processes of elastic deformation first develop in the metal, and the elongation of the sample is insignificant. Then plastic flow of the metal is observed without increasing stress; this period is called fluidity. The stress at which the sample continues to deform without a noticeable increase in load is called the yield strength. With a further increase in load, hardening processes (hardening under load) develop in the metal. The highest stress preceding failure of the sample is called the tensile strength.

Rice. 3. Diagram of deformation during tensile testing of metals.

Tense state

- this is the state of a body under the influence of balanced forces, with established elastic equilibrium of all its particles. Residual stresses are stresses that remain in the body after the cessation of external forces, or that arise during rapid heating and cooling if the linear expansion or shrinkage of metal layers and body parts occurs unevenly.

Internal stresses are formed during rapid cooling or heating in temperature zones of transition from the plastic to elastic state of the metal. These temperatures for steel correspond to 400-600°. If the resulting internal stresses exceed the tensile strength, then cracks form in the parts; if they exceed the elastic limit, then warping of the part occurs.

Tensile strength in kg/mm2

is determined on a tensile testing machine as the ratio of the load P in kg required to destroy a standard sample (

Fig. 4, a

) to the cross-sectional area of the sample in mm2.

Rice. 4. Methods for testing the strength of materials: a - tensile; b - bending; c - impact strength; g - for hardness

Bending strength in kg/mm2

is determined by the destruction of the sample, which is installed on two supports (

Fig. 4, b

), loaded in the middle with a concentrated load P.

To establish the plasticity of a material, the relative elongation δ during tension or the deflection ƒ during bending is determined.

Relative elongation δ in %

determined on samples tested for tension. Divisions are applied to the sample (Fig. 4, a) and the distance between them is measured before testing (l0) and after destruction (l) and the elongation is determined

δ = l-lo / lo 100%

The bending deflection in mm is determined using a machine deflection meter, indicating the deflection ƒ formed on the sample at the moment of its destruction (Fig. 4, b).

Impact strength in kgm/cm2 is determined on samples ( Fig. 4, c

), subjected to destruction on a piledriver by the blow of a pendulum retracted to the side. To do this, the work of deformation in kGm is divided by the cross-sectional area of the sample in cm 2.

Brinell hardness (HH) is determined on the cleaned surface of the sample, into which a steel ball is pressed ( Fig. 4, d

) with a diameter of 5 or 10 mm under a corresponding load of 750 or 3000 kg and measure the diameter d of the resulting hole. The ratio of the load in kg to the hole area πd2 / 4 in mm2 gives the hardness number.

Indicators for mechanical properties for the main alloys are given in table. 1

.

Hardness concept

The hardness of a material is its resistance to destruction when a harder material is introduced into the outer layer. In other words, the ability to resist deforming forces (elastic or plastic deformation).

The hardness of metals is determined by introducing a solid body called an indenter into a sample. The role of the indenter is performed by: a metal ball of high hardness; diamond cone or pyramid.

After exposure to the indenter, an imprint remains on the surface of the test sample or part, the size of which determines the hardness. In practice, kinematic, dynamic, and static methods of measuring hardness are used.

The kinematic method is based on the compilation of a diagram based on continuously recorded readings that change as the tool is pressed into the sample. Here the kinematics of the entire process is traced, and not just the final result.

The dynamic method is as follows. The measuring tool acts on the part. The reverse reaction allows you to calculate the expended kinetic energy. This method allows you to test the hardness of not only the surface, but also a certain volume of metal.

Static methods are non-destructive methods that allow you to determine the properties of metals. The methods are based on smooth indentation and subsequent holding for some time. The parameters are regulated by methods and standards.

The applied load can be applied:

- pressing;

- scratching;

- cutting;

- rebound

Machine-building enterprises currently use the Brinell, Rockwell, Vickers methods, as well as the microhardness method, to determine the hardness of materials.

Based on the tests carried out, a table is compiled indicating the materials, the applied loads and the results obtained.

Strengthening Mechanisms - Materials Science Questions and Answers

go to content Menu

- House

- branched MCQ Programming

- CS - IT - IS CS

- IT

- IS

- ECE

- Sanfoundry Tests

Menu

- House

- branched MCQs

.

Mechanical Understanding Test

- Numerical thinking

- Verbal thinking

- Assessment Centers Tray Exercises

- Exercises with an electronic tray

- What to expect

- Role-playing games

- Group exercises

- Presentations

- Assessment Center Tips

- Interview

- How to prepare for an interview

- How to behave during an interview

- Hope to cope with nerves

- PwC Assessment Center

- KPMG Assessment Center

- EY Assessment Center

- BDO Assessment Center and Online Test Guide

- IBM Assessment Center

- GSK Assessment Center

- First Training Assessment Center

- MI5 Assessment Center

- Network Rail Assessment Center

- Fast Stream Assessment Center

- PSNI Assessment Center

- Psychometric tests

.

How to Prepare for a Mechanical Aptitude Test or Reasoning Test

Mechanical aptitude tests or mechanical reasoning tests are usually conducted for technical and engineering positions. The Mechanical Aptitude Test measures your ability to understand and apply mechanical concepts and principles to solve problems.

You may need to take a mechanical fitness test?

Candidates applying for technical and mechanical roles will likely be asked to take a mechanical reasoning test. Positions for which a mechanical reasoning test is typically applied include: fire brigade (CFA, MFB), train operators, laborers, laborers and assembly line workers . The level of difficulty and complexity of the test questions depends on the skills required.

Examples of mechanical skills test questions

What to Expect from a Mechanical Aptitude Test?

- The mechanical fitness test involves a set of mechanical challenges that must be completed at a predetermined time.

- The time limit is designed so that only 1% to 5% of the population can correctly solve all the test questions within the allowed time period.

- There is only one correct answer for each test question.

- Each test question presents you with a mechanical scenario that may include acceleration, gravity, friction, pressure, moments, energy conversion, kinetic and potential energy, work and power, levers, pulleys, screws, gears, springs, etc.

- You should have about 30 seconds to answer each question on the test.

- The level of difficulty and complexity of the test questions depends on the position you are applying for. For example, test questions for candidates applying for management positions will have a higher level of difficulty and complexity than questions for candidates applying for entry-level positions.

Improving mechanical aptitude test scores can be achieved by developing simple factors to solve test problems, such as proper methods and frameworks.

How We Prepare You for the Mechanical Aptitude Test

Online IPC Mechanical Reasoning Tests:

- The largest pool of questions for testing mechanical aptitude.

- All test questions and answers were developed by experienced psychometric test authors.

- Immediate, complete test reports that include your total score, a list of your correct and incorrect answers, and detailed answer explanations. This will allow you to quickly recognize your strengths and areas that need improvement.

- Immediate and practical recommendations to improve your results.

- Powerful solutions to train your mind to quickly recognize patterns and solve problems correctly.

IPC Internet courses Mechanical skills testing courses :

- Know the dos and don'ts of a mechanical fitness test.

- All course materials are developed by experienced test writers.

- Learn effective aptitude test-taking strategies to ensure you answer more questions in the allotted time.

- Learn how to prepare for the Mechanical Aptitude Test.

- View sample Mechanical Aptitude Test questions and learn how to solve each one.

Personal coaching IPC:

- Individual sessions with an IPC psychologist so you can improve your results.

- Contact an expert who can tell you about your strengths and weaknesses.

- Get personalized advice on how to improve your aptitude test-taking skills.

- Coaching is provided over the phone and after hours to ensure you get the most out of it.

The IPC preparatory service operates:

- All of our preparatory material is written by experienced Australian psychologists and psychometric test developers.

- Contrary to popular belief, you can prepare for an aptitude test and improve your score significantly. We've worked with over 200,000 satisfied clients who have improved their test scores.

- We don't just give you the chance to take any aptitude test - we ensure that it matches the level of difficulty you'll find in your actual test.

- We don't just give you a list of aptitude test questions (which is NOT an effective preparation strategy), but we give you detailed explanations of the answers to make sure you learn the correct problem-solving techniques.

.