For reference, table 10 (coarse thread pitch) and table 11 (fine thread pitch) show the breaking loads for nuts and bolts of various strength classes. For bolts of low strength classes, the expected failure will be stripping of the bolt threads, while for bolts of high strength classes, stripping of the nut threads can be expected.

Table 10 - Breaking loads for nuts with a nominal height of 0.5 d

up to 0.8

d

(large thread pitch)

| Nut strength class | Test load voltage nuts, N/mm2 | Minimum stress in the bolt shaft when the thread breaks, N/mm2, for bolts of strength class | |||

| 6.8 | 8.8 | 10.9 | 12.9 | ||

| 04 | 380 | 260 | 300 | 330 | 350 |

| 05 | 500 | 290 | 370 | 410 | 480 |

Table 11 - Breaking loads for nuts with a nominal height of 0.5 d

up to 0.8

d

(fine thread pitch)

| Nut strength class | Minimum stress in the bolt shaft when the thread is broken, %, stress from the test load of bolts of strength class | |||

| 6.8 | 8.8 | 10.9 | 12.9 | |

| 04 | 85 | 65 | 45 | 40 |

| 05 | 100 | 85 | 60 | 50 |

8.1 Proof load test

A proof load test should be carried out whenever the testing equipment used allows, and this test is decisive for nuts with a thread diameter of M5 and larger.

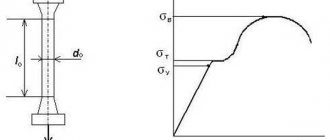

The nut is screwed onto a hardened mandrel, as shown in Figures 1 and 2. In cases of dispute, the tensile test is decisive (see Figure 1).

1) D11 - according to GOST

25346

Figure 1 - Axial tensile test

Figure 2 - Axial compression test

The test load is applied to the nut in the axial direction and held for 15 s. The nut must withstand the load without breaking or stripping the thread and can be unscrewed by hand after the load is removed. If the thread of the mandrel is damaged during the test, the test is considered invalid. When unscrewing a nut, it is permissible to use a wrench to turn the nut 1/2 turn, and then it must be unscrewed by hand.

The hardness of the test mandrel must be at least 45 HRC.

The tolerance field of the mandrel thread is 5h6g, with the exception of the tolerance of the outer diameter of the thread, which should be 1/4 of the tolerance field 6g in its lower part.

Marking of bolt strength class

For a long time in our country, all hardware was produced in accordance with GOST 22353-77, but today its rules are no longer relevant. All technical characteristics of bolts comply with GOST R 52644-2006. However, in the bins of grandfather's balconies, as well as in warehouses and workshops, bolts with the old markings are still found. And they are sometimes found on an industrial scale. Therefore, let's say a few words about the Soviet GOST and what the old markings meant.

It is represented in two parts: letters at the top and numbers at the bottom. The letters indicate the mark of the factory where the hardware was manufactured, for example, WT, Ch, L, OC, D and others. This is usually followed by numbers reflecting the temporary resistance of the hardware in MPa, divided by ten. Next are the letters again, by which we can determine the level of resistance of the fastener to aggressive environmental conditions. For example, HL would indicate that the bolt is designed for cold climates. The numbers below indicate the heat number.

Sometimes you can see an arrow on the bolts pointing in a counterclockwise direction. This means that you are holding hardware with a left-hand thread. If the thread is right-handed, then the designation is simply missing.

8.2 Hardness test

When inspecting nuts, the hardness test is carried out on one of the supporting surfaces of the nut at three points shifted relative to each other by 120°, and the hardness values are determined as the arithmetic mean of three measurements.

In controversial cases, hardness is checked on a longitudinal section passing through the axis of the nut, at points located as close as possible to the outer diameter of the nut thread.

The Vickers hardness test is decisive and, where possible, a load of 30HV should be applied.

If Brinell and Rockwell tests are used, conversion tables should be used.

Vickers hardness test - according to GOST 2999.

Brinell hardness test - according to GOST 9012.

Rockwell hardness test - according to GOST 9013.

Marking of stainless steel elements

Separately, it should be said about the fasteners made of stainless steel. It has a special marking. For example, A2-70, where A-2 is the steel grade, 70 is the tensile strength. To calculate the tensile strength, you need to multiply the indicated value by 10: we get 700 MPa (which corresponds to the strength class of carbon steel fasteners 5.6).

We hope that this article will be useful when choosing fasteners for a specific type of work. You will be able to determine if a metric fastener is suitable for the load and type of construction. You can order bolts, screws, studs, nuts and washers in our online store. It’s easy to select suitable elements - the product cards provide detailed information about each of them.

9.1 Notation

Markings are given in tables 12 and 13.

Table 12 - Markings of nuts by strength classes in accordance with 3.1

| Strength class | 4 | 5 | 6 | |

| Alternative markings | or designation symbol | 4 | 5 | 6 |

| or code symbol (dial system) | ||||

End of

table 12

| Strength class | 8 | 9 | 10 | 121) | |

| Alternative markings | or designation symbol | 8 | 9 | 10 | 12 |

| or code symbol (dial system) | |||||

| 1) At the 12 o'clock position, the marking dot cannot be replaced by the manufacturer's mark. | |||||

Table 13 - Marking of nuts by strength classes in accordance with 3.2

| Strength class | 04 | 05 |

| Marking |

Specifications for bolts, screws, studs and nuts

STRENGTH CLASSES OF BOLTS, SCREWS AND STUDS (GOST 1759.4-87, ISO 898/1-78)

The standard applies to bolts, screws and studs made of carbon unalloyed or alloyed steels with metric threads in accordance with GOST 24705-2004 with a diameter of 1 to 48 mm.

| Mechanical properties | Strength class 1 | ||||||||||||

| 3.6 | 4.6 | 4.8 | 5.6 | 5.8 | 6.6 | 6.8 | 8.8 | 9.8 2 | 10.9 | 12.9 | |||

| d<16 mm | d>16 mm | ||||||||||||

| Temporary tensile strength σв, MPa | nom. | 300 | 400 | 500 | 600 | 800 | 800 | 900 | 1000 | 1200 | |||

| max. | 330 | 400 | 420 | 500 | 520 | 600 | 800 | 830 | 900 | 1040 | 1220 | ||

| Brinell hardness HB | name | 90 | 114 | 124 | 147 | 152 | 181 | 238 | 242 | 276 | 304 | 366 | |

| max. | 238 | 304 | 318 | 342 | 361 | 414 | |||||||

| Rockwell hardness HRB | name | 52 | 67 | 71 | 79 | 82 | 89 | — | |||||

| max. | 99,5 | — | |||||||||||

| Rockwell hardness HRC | name | — | 22 | 23 | 28 | 32 | 39 | ||||||

| max. | — | 32 | 34 | 37 | 39 | 44 | |||||||

| Yield strength3 σt, MPa | nom. | 180 | 240 | 320 | 300 | 400 | 360 | 480 | — | ||||

| name | 190 | 240 | 340 | 300 | 420 | 360 | 480 | — | |||||

| Conditional yield strength σ0.2, MPa | nom. | — | 640 | 640 | 720 | 900 | 1080 | ||||||

| name | — | 640 | 660 | 720 | 940 | 1100 | |||||||

| 1 - designation of the strength class of bolts, screws and studs consists of two numbers: the first corresponds to 1/100 of the nominal value of tensile strength, MPa; the second corresponds to 1/10 of the ratio of the nominal value of the yield strength to the tensile strength, %. The product of the two indicated figures corresponds to 1/10 of the nominal value of the yield strength, MPa. 2 - applies only to thread diameters d < 16 mm. 3 - if the yield strength cannot be determined, find the conditional yield strength σ0.2. GOST 1759.4-87 provides other parameters, as well as the chemical composition of steels for the manufacture of bolts, screws, studs, recommended steel grades, as well as instructions for their heat treatment. | |||||||||||||

STRENGTH CLASSES OF NUTS (GOST 1759.5-87)

In the table, hardness values are given only for nuts with a large thread pitch. Minimum hardness values are only required for heat-treated nuts and nuts that cannot be proof-load tested. For other nuts, the minimum hardness value is for reference only.

For strength classes 04, 4, 5, 6, 9, the lower limit of hardness HRC is not regulated, the upper limit is no more than HRC 30.

The strength classes of nuts with a nominal height equal to or greater than 0.8d (effective thread length equal to or greater than 0.6d) are designated by a number indicating the highest strength class of bolts with which they can be mated in a connection and corresponding to 1/100 of the nominal stress of test load in the test mandrel.

The strength classes of nuts with a nominal height equal to or more than 0.5d and less than 0.8d (effective thread length equal to or more than 0.4d and less than 0.6d) are indicated by a combination of two numbers: the second number corresponds to 1/100 of the nominal tension of the proof load in the hardened test mandrel, and the first indicates that.

that the load capacity of the connection of this nut with a bolt is lower than with a hardened mandrel and lower than that of nuts with a height equal to or greater than 0.8d. EXAMPLES OF SYMBOLS FOR FASTENING PRODUCTS

Screw according to GOST 17473-80, accuracy class A, version 2, thread diameter d = 12 mm with fine thread pitch, with thread tolerance range 6e, length l = 60 mm, strength class 5.8, made of mild steel , with a zinc coating 9 microns thick, chromated:

Screw A2M12 x 1.25-6e x b0.58.S.019 GOST 17473-80

Nut according to GOST 5916-70 version 2, thread diameter d = 12 mm, with fine thread pitch , with a left-hand thread, with a tolerance range of 6H, strength class 05, made of steel grade 40X, with a zinc coating 6 microns thick, chromated:

Nut 2M12 x 1.25-LH-6H.05.40Х.016 GOST 5916-70

Bolt version 1 , thread diameter d - 12 mm.

with spanner size S = 18 mm, length l = 60 mm with large thread pitch, tolerance range 6g, strength class 5.8, uncoated: Bolt M12-6g x 60.58 (S18) GOST 7805-70

Same version 3, with fine thread pitch, tolerance range 6g, strength class 10.9, made of steel 40X, with coating 01 6 microns thick:

Bolt ZM12 x 1.25 - 6g x 60.109.40Х.016 GOST 7808-70

Notes:

1. The symbol does not indicate: version 1, large thread pitch, right-hand thread, lack of coating, as well as parameters uniquely defined by product standards, accuracy class B, if the standard for a specific fastener provides for two accuracy classes (A and B) . 2. If a coating not provided for by the standard is used, its designation is indicated in accordance with GOST 9306-85.

Recommended symbol scheme for bolts, screws, studs and nuts:

Where, 1

- product name;

2

— accuracy class;

3

- execution;

4

- nominal thread diameter;

5

— thread pitch;

6

- thread direction;

LH - left; 7

— thread tolerance field;

8

— product length (except nuts);

9

- strength class or material group;

10

- indication and use of quiet (C) or automatic (A) steel;

11

- grade of material for products of strength classes 05;

8; 8.8 and above, groups 21-26 and 31-35; 12

— type and thickness (total) of the coating;

13

- product standard number.

With the introduction of new GOSTs

ov for fasteners that comply with

ISO

, a new form of symbol has appeared.

Bolt according to GOST R ISO 4014-2013:

Bolt with hex head GOST R ISO 4014 - M12 x 120 - 12.9 - B5R

Nut according to GOST R ISO 7042-2011:

Hex nut GOST R ISO 7042 - M12 - 12

Screw according to GOST R ISO 12474 -2012:

Screw with a cylindrical head and a hexagonal socket for a key GOST R ISO 12474 - M12 x 1.25 x 20 - 12.9 - B7R

Such GOSTs also have corresponding technical requirements - ISO.

TYPES AND SYMBOLS OF COATINGS OF BOLTS, SCREWS, STUDS AND NUTS (GOST 1759.0-87)

| Type of coverage | Coverage designation | |

| according to GOST 9.306-85 | digital | |

| Zinc, chromated Cadmium, chromated Multilayer: copper-nickel Multilayer: copper-nickel-chrome Oxide, oil-impregnated Phosphate, oil-impregnated Tin Copper Zinc Oxide, filled with chromates Oxide from acidic solutions Silver Nickel | c. hr Kd. hr M. N. M. N. X. 6 Chem. Oks. prm Chem. Phos. prm O M Ts An. Oks. NHR Chem. Pass Wed n | 01 02 03 04 05 06 07 08 09 10 11 12 13 |

Bolts, screws, studs and nuts are manufactured with one of the types of coatings indicated in the table, or without coatings. It is allowed to use other types of coatings - in accordance with GOST 9.303-84. The choice of coating thickness is in accordance with GOST 9.303-84. Technical requirements - according to GOST 9.301-86.

The main thread deviations should be assigned according to GOST 16093-2004 depending on the required coating thickness. Thread tolerance fields are indicated for uncoated products. After coating, the requirements for the thread are in accordance with GOST 16093-2004.

The design, dimensions and surface roughness of bolts, screws, studs and nuts are established in product standards.

Tolerances for the dimensions, shape and location of the surfaces of bolts, screws, studs and nuts are in accordance with GOST 1759.1. Recommended technological processes for the manufacture of bolts, screws and studs from non-alloy and alloy steels and steel grades

| Strength class | Technological processes | steel grade | Standard |

| 3.6 | Hot stamping Cold stamping followed by softening heat treatment | 10, 10kp | GOST 10702 |

| 4.6 | Hot stamping Cold stamping followed by softening heat treatment | 20 | GOST 1050 |

| 4.8 | Cold stamping | 10, 10kp | GOCT 10702 |

| 5.6 | Hot stamping Cold stamping followed by softening heat treatment | 30,35 | GOSG 1050 GOST 4543 GOST 10702 |

| 5.8 | Cold stamping | 10, 10kp, 20, 20kp | |

| 6.6 | Hot stamping followed by quenching and tempering Cold stamping followed by quenching and tempering | 35 | GOST 1050 GOST 4543 GOST 5663 GOST 10702 |

| Hot stamping | 45, 40G | ||

| 6.8 | Cold stamping | 20, 20kp | GOSG 1050 GOST 5663 GOST 10702 |

| 8.8 — 12.9 | Hot stamping followed by quenching and tempering Cold stamping followed by quenching and tempering Cutting followed by quenching and tempering Cold stamping of heat-strengthened metal | 35, 35X, 38XA, 45G, 40G2, 40X, 30KhGSA, 35KhGSA, 16KhSN, 20G2R | GOST 4543 GOST 10702 |

Mechanical properties of bolts, screws and studs made of corrosion-resistant, heat-resistant, heat-resistant and heat-resistant steels at normal temperature

| Conventional designation groups | Tensile strength σв, N/mm² | Yield strength σт, N/mm² | Relative elongation δ, % | Steel | |

| no less | Brand | Standard | |||

| 21 | 510 | 195 | 35 | 12X18H10T 12X18H9T 10X17H13M2T 10X17H13M3T 06ХН28МДТ | GOST 5632 |

| 22 | 590 | 345 | 20 | 12X13 08X21H6M2T | |

| 23 | 690 | 540 | 12 | 20X13 14X17H2 | |

| 24 | 880 | 540 | 8 | 10X11H23T3MP | |

| 25 | 880 | 735 | 10 | 13X11H2B2MF 25Х1МФ 25Х2М1Ф 20Х1М1Ф1ТР | GOST 5632 GOST 20072 |

| 26 | 1080 | 835 | 10 | 07Х16Н6 | GOST 5632 |

Mechanical properties of nuts made of corrosion-resistant, heat-resistant, heat-resistant and heat-resistant steels at normal temperature

| Group symbol | Test load stress σ, N/mm² | Steel | |

| no less | Brand | Standard | |

| 21 | 510 | 12X18H10T 12X18H9T 10X17H13M2T 10X17H13M3T 06ХН28МДТ | GOST 5632 |

| 22 | 590 | 12X13 08X21H6M2T | |

| 23 | 690 | 20X13 14X17H2 | |

| 24 | 880 | 10X11H23T3MP | |

| 25 | 880 | 13X11H2B2MF 25Х1МФ 25Х2М1Ф 20Х1М1Ф1ТР | GOST 5632 GOST 20072 |

| 26 | 1080 | 07Х16Н6 | GOST 5632 |

Mechanical properties of bolts, screws and studs made of non-ferrous alloys at normal temperature

| Conventional designation groups | Tensile strength σв, N/mm² | Yield strength σт, N/mm² | Relative elongation δ, % | Material | |

| no less | Brand | Standard | |||

| 31 | 260 | 120 | 15 | AMg5P, AMg5 | GOST 4784 |

| 32 | 310 | — | 12 | Brass L63 Brass LS59-1 | GOST 15527 GOST 12920 |

| 33 | 310 | — | 12 | Brass LS59-1 antimagnetic Brass L63 antimagnetic | GOST 15527 GOST 12920 |

| 34 | 490 | — | 12 | Bronze Br. AMts9-2 | GOST 18175 |

| 35 | 370 | 195 | 10 | D1, D1P, D16, D16P | GOST 4784 |

The nuts have corresponding groups; only the voltage from the test load is regulated.

Table in GOST 1759.0-87. MARKING

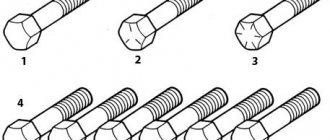

Bolts with a hexagonal head, screws with a cylindrical head and a hexagonal socket, studs and hexagonal nuts are marked with a sign of the strength class (or material group) and a mark (trademark) of the manufacturer, and products with a left-hand thread are additionally marked with a sign of a left-hand thread (arrow ).

The left-hand thread mark for bolts and nuts can be replaced by cuts on the edges of hexagons.

The following are subject to mandatory marking: - hex head bolts of strength class 4.6. 5.6, 6.6, 8.8, 9.8, 10.9, 12.9; — cylindrical head screws with hexagonal socket and studs of strength classes 8.8, 9.8, 10.9, 12.9; — nuts of strength classes 05, 8, 9, 10, 12.

Products not listed above and of unspecified strength classes, as well as products made by cutting, are marked by agreement between the manufacturer and the consumer.

Marking marks can be convex or recessed.

When marking strength classes, it is allowed not to put a dot separating the first and second numbers of the strength class sign.

When low-carbon martensitic steels are used for products of strength class 10.9, the strength class sign must be underlined: 10.9 or 109.

Bolts and screws with a diameter of 6 mm or more must be marked.

Studs with a thread diameter of 12 mm or more are subject to marking. It is allowed to mark studs with a thread diameter of 8 mm or more using substitute marks:

In GOST 1759.0-87 in Appendix 2

Minimum breaking loads are given for bolts, screws and studs with coarse and fine thread pitches depending on the diameter and material group.

GOST 7798-70 are no longer relevant

— Bolts with hexagonal head of accuracy class B. Design and dimensions — lost force in the Russian Federation from

07/01/2014

.

By order No. 318-st dated May 5, 2015, GOST 7798-70 was restored on the territory of the Russian Federation only in relation to products supplied under the State Defense Order; - for bolts with a large thread pitch and threads not along the entire length of the rod, use GOST R ISO 4014-2013

;

— for bolts with a large thread pitch and threads up to the head, use GOST R ISO 4017-2013

;

— for bolts with a fine thread pitch and threads up to the head, use GOST R ISO 8676-2013

;

- for bolts with a fine thread pitch and threads not along the entire length of the rod, use GOST R ISO 8765-2013

.

GOST 7805-70

— Hex head bolts of accuracy class A — lost force in the Russian Federation from

07/01/2014

.

By order No. 316-st dated May 5, 2015, GOST 7798-70 was restored on the territory of the Russian Federation only in relation to products supplied under the State Defense Order; - for bolts with a large thread pitch and threads not along the entire length of the rod, use GOST R ISO 4014-2013

;

— for bolts with a large thread pitch and threads up to the head, use GOST R ISO 4017-2013

;

— for bolts with a fine thread pitch and threads up to the head, use GOST R ISO 8676-2013

;

- for bolts with a fine thread pitch and threads not along the entire length of the rod, use GOST R ISO 8765-2013

.

GOST 11738-84

— Screws with a cylindrical head and a hexagonal socket for a key, accuracy class A. — lost force in the Russian Federation from

07/01/2014

.

By order No. 320-st dated May 5, 2015, GOST 7798-70 was restored on the territory of the Russian Federation only in relation to products supplied under the State Defense Order; — for screws with large thread pitches, use GOST R ISO 4762-2012

;

— for screws with fine thread pitch, use GOST R ISO 12474-2012

.

GOST 15589-70

— Hex head bolts of accuracy class C. — lost force in the Russian Federation from

07/01/2014

.

By order No. 317-st dated May 5, 2015, GOST 7798-70 was restored on the territory of the Russian Federation only in relation to products supplied under the State Defense Order; - for bolts with threads not along the entire length of the rod, use GOST R ISO 4016-2013

;

— for bolts with threads up to the head, use GOST R ISO 4018-2013

.

GOST 22353-77

— High-strength bolts of accuracy class V. — lost force on the territory of the Russian Federation;

- use GOST R 52644-2006

.

GOST 22354-77

— High-strength nuts of accuracy class B. — no longer valid on the territory of the Russian Federation;

- use GOST R 52645-2006

.

GOST 22355-77

— Washers of class C accuracy for high-strength bolts.

— lost force on the territory of the Russian Federation; — use GOST 32484.5-2013

.

Related documents:

GOST 1759.0-87 - Bolts, screws, studs and nuts. Technical specifications GOST 1759.1-82 - Bolts, screws, studs, nuts and screws. Tolerances. Methods for monitoring dimensions and deviations in shape and arrangement of surfaces GOST 1759.2-82 - Bolts, screws and studs. Surface defects and control methods GOST 1759.3-83 - Nuts. Surface defects and control methods GOST 1759.4-87 - Bolts, screws and studs. Mechanical properties and test methods GOST 1759.5-87 - Nuts. Mechanical properties and test methods GOST R ISO 4014-2013 - Hex head bolts. Accuracy classes A and B. GOST R ISO 4017-2013 - Hex head screws. Accuracy classes A and B. GOST R ISO 8676-2013 - Hex head screws with fine thread pitch. Accuracy classes A and B. GOST R ISO 8765-2013 - Hex head bolts with fine thread pitch. Accuracy classes A and B.

https://www.volat-spb.ru/

What is important to know?

When designing and installing prefabricated structures, it is necessary to use fasteners that can withstand a load equal to 2-3 times the maximum load for this structure. That is, if, when designing a structure, the calculated loads on a threaded connection are about 400 MPa, then it is necessary to use high-strength bolts of class 8.8 and higher.

You can purchase both regular bolts of classes 4.6-5.8 and high-strength bolts of classes 8.8-12.9. In addition, for installation in aggressive environments there are bolts and nuts made of A2 and A4 stainless steel. All products are certified and comply with GOST and DIN standards. Don't test your luck - use fasteners of appropriate strength!

Cold die forging

Long-length hardware, called wire rod, is used as the starting material for the production of the most common types of nuts. Standardized similar products are made from alloys that do not contain alloying additives - these are carbon steels. But the current regulatory documents also allow the use for this purpose not only of “stainless steel”, but also of non-ferrous metals, as well as their alloys. The selection of material should be approached taking into account the scope of application of the connecting parts, as well as the requirements for their strength properties.

The production of nuts using cold die forging technology is carried out on special units. They are called cold heading machines.

Modern examples of such equipment demonstrate high productivity: per minute they, as they say, “produce up to 400 fasteners.” Compliance of the parameters of the final product with the requirements of the standards is ensured by a high level of processing accuracy of each workpiece.

Sequence of stages

The technological process of cold die forging includes a number of stages. Below is their sequence.

- Preliminary preparation of the surface of long metal hardware: cleaning from iron oxides (element Fe) - rust and scale, as well as from other contaminants; washing; applying a thin phosphate layer.

- Unwinding and straightening the wire. This is done by pulling it through a special device.

- Feeding wire into the cutting unit. There it is cut into blanks with the required dimensions. This operation is carried out using a movable knife together with a cutting sleeve.

- Actually, stamping. Provides for repeated processing of the workpiece with high pressure. As a result, it acquires the given 6-sided configuration.

- Preparing a hole of the required diameter.

- Applying chamfers.

- Formation of internal thread knurling. For this purpose, a special nut thread-cutting machine equipped with taps is used.

At the request of the customer, a coating resistant to the negative effects of corrosion is applied to the surface of products manufactured according to the scheme described above. Most often, it represents a protective layer of zinc (element Zn). The service life of galvanized fasteners is significantly longer than that of conventional connecting parts.

Steel grades

For the production of nuts by cold die forging, it is recommended to use the following alloys:

hard steel, characterized by increased resistance to deformation, grades

- ШХ15 – structural bearing alloyed with chromium;

- U10A, U10, U8 – unalloyed instrumental;

- 40XH, 40X, 35X, 30X – chromium alloy structural;

- 30G – manganese alloy structural;

- steel 45, 40, 35, 30 – high-quality carbon structural steel;

steel, characterized by medium hardness and the same level of resistance to deformation, of the following grades:

- 18ХГT – heat-strengthened chromium-manganese alloy structural;

- steel 20 – high-quality structural steel enriched with carbon;

- 12ХНЗ, 20ХН – chromium-nickel alloy structural;

- 20XG – chromium-manganese alloy structural;

- 20G, 15G – manganese alloy structural;

- 20X. 15Х – chromium alloy structural;

- 15XF – chrome vanadium alloyed structural;

soft steel, characterized by a low level of resistance to deformation, grades:

- 15kp, 10kp, 08kp – high-quality boiling carbon structural;

- steel 15, 10, 08 – high-quality carbon structural steel.

Features of cold die forging of nuts

The features of this technology are associated precisely with the type of raw materials used for the manufacture of fasteners of this type. In particular, it is recommended to stamp nuts from alloyed and high-carbon alloys by preheating the workpiece so that it becomes warm or semi-hot. In addition, it is necessary to ensure that the lubricant operates effectively.

In order to improve the metal formability, both preliminary and intermediate heat treatment should be specified in the technological map. When choosing the mode of this operation, the structure and chemical composition of the alloy must be taken into account. For example, when the workpiece is made of low-alloy or carbon steel, the cold pressing procedure is preceded by phosphating followed by washing. Phosphating is the heat treatment of intermediate production products in the following substances: Cd3(PO4)2, FePO4, Mn3(PO4)2, Zn3(PO4)2. These are phosphate salts of the metals cadmium, iron, manganese and zinc, respectively. Good results in terms of reducing specific forces, the degree of wear and the amount of friction are ensured by the use of coatings based on zinc phosphate (Zn3(PO4)2▪2Н2О).

Bolt accuracy

Another important property is accuracy. Manufacturers produce products in two accuracy classes. Class A - implies that the rod fits into the hole with minimal clearance. The diameter of the mounting hole cannot be 0.3 mm greater than the thickness of the bolt. This kind of precision is quite easy to achieve on a production floor, but almost impossible on a construction site. Class B and C fasteners can be installed in mounting holes larger than the product rod by 2 - 3 mm.

The precision of a bolted connection has a significant impact on its strength and load resistance. In particular, the more accurately the mounting hole is made, the less will be the impact of loads arising perpendicular to the axis of the rod.

Fastening elements, presented in a wide variety on the modern market, are used both for simple connection of elements of various structures, and for increasing their reliability and ability to withstand significant loads. The strength class of the bolts that need to be selected depends on the purposes for which these elements are planned to be used.

Galvanized hex bolt with nut

Fastener properties

Hardware produced by various enterprises differ from each other in geometric parameters, shape, material, and purpose. In addition, they can be distinguished by the type of coating and a number of others. In addition to the mentioned properties, bolts of the same type differ in strength parameters.

For example, an M16 bolt can be used to fasten parts of a fence or fence, and the same bolt can be used to assemble a bridge or crane structure. Accordingly, for the first option, a bolt with lower strength parameters can be used than for the second application option. Bolts used to assemble cranes and similar equipment are called crane bolts. They are distinguished by higher strength and especially strong steels are used for their manufacture. In the Russian Federation, GOST 7817-70 is in force, which normalizes the requirements for fasteners used in particularly critical structures.

Hardware has several forms - bolts, nuts, screws, etc. Each of these products is used to solve specific problems. Various steels and different technologies are used for their manufacture. The marking that will be applied to the surface of the fastener also depends on this.