For reference, table 10 (coarse thread pitch) and table 11 (fine thread pitch) show the breaking loads for nuts and bolts of various strength classes. For bolts of low strength classes, the expected failure will be stripping of the bolt threads, while for bolts of high strength classes, stripping of the nut threads can be expected.

Table 10 - Breaking loads for nuts with a nominal height of 0.5 d

up to 0.8

d

(large thread pitch)

| Nut strength class | Test load voltage nuts, N/mm2 | Minimum stress in the bolt shaft when the thread breaks, N/mm2, for bolts of strength class | |||

| 6.8 | 8.8 | 10.9 | 12.9 | ||

| 04 | 380 | 260 | 300 | 330 | 350 |

| 05 | 500 | 290 | 370 | 410 | 480 |

Table 11 - Breaking loads for nuts with a nominal height of 0.5 d

up to 0.8

d

(fine thread pitch)

| Nut strength class | Minimum stress in the bolt shaft when the thread is broken, %, stress from the test load of bolts of strength class | |||

| 6.8 | 8.8 | 10.9 | 12.9 | |

| 04 | 85 | 65 | 45 | 40 |

| 05 | 100 | 85 | 60 | 50 |

4.2. Assembling connections with high-strength bolts if complete disassembly of connections is necessary

If it is necessary to completely disassemble the connections, the design load should be removed according to a specially developed project and the assembly should be restored using the following technology:

4.2.1. The technological process for assembling connections includes:

— inspection of structures and verification of their compliance with the requirements of the project and Chapter SNiP III-18-75 (regarding the accuracy of manufacturing of structures);

— alignment of holes and fixation of elements and connection parts in the design position using mounting plugs (10% of the number of holes, but not less than 2 pcs.);

— installation of high-strength bolts in holes free from plugs;

— checking the geometric dimensions of assembled structures;

- tight seal of the package;

— tensioning the supplied high-strength bolts to the force specified in the project;

- removing the plugs, placing high-strength bolts in the vacated holes and tensioning them to the design force.

4.2.2. The difference in thickness of the elements covered by the overlays, determined before installing the overlays using a ruler and feeler gauge, should not exceed 0.5 mm.

4.2.3. If the difference between the planes of the parts being connected is from 0.5 to 3 mm, in order to ensure a smooth bend of the lining, the edge of the protruding part must be smoothed with an emery stone at a distance of up to 30 mm from the edge of the part with a slope no steeper than 1:10. If the difference between the planes is more than 3 mm, spacers should be used. The use of gaskets must be agreed with the design organization.

4.2.4. The lengths of the bolts used are selected depending on the thickness of the package ().

4.2.5. When drilling holes in elements with machined surfaces, coolants containing oil should not be used.

4.2.6. The connections should be assembled immediately using high-strength bolts and plugs. The use of other bolts as assembly bolts is prohibited.

4.2.7. Each bolt is installed in connection with two high-strength washers (one is placed under the bolt head, the other under the nut).

4.2.8. Nuts tightened to the design torque are not secured with anything additional.

4.2.9. When installing high-strength bolts, the nuts must be screwed freely (by hand) along the threads. Otherwise, the nut or bolt should be replaced and the rejected bolts and nuts sent for reprocessing.

Types of bolt fastening

Threaded connections are structurally different from each other.

Bolted

A bolt is a part equipped with a head and threads at different ends. The thread is necessary to screw on the nut. The head is picked up from the outside with a wrench.

To install hardware, holes of larger diameter are drilled on the surfaces to be joined. The end side is chamfered.

The bolted fastening is easy to replace if broken.

The disadvantage of the connection is that it requires a lot of space, which leads to an increase in the size and weight of the structure.

Advantage: easy replacement if broken.

Screw

The screw is screwed into the housing using a special end tool. The head comes in different shapes, including 6-sided. The main difference is the small installation area.

Negative point: during installation, the thread is often damaged, and it is difficult to remove part of the fastener. Therefore, screw connections are not used for repeated installation/disassembly.

Using studs

A stud is a cylindrical fastener without a head, the ends of which have threads of the same diameter. There is a tight cut on one side. The other end is needed to install the nut.

Fastening with studs is required for frequent assembly of the structure.

The element is in demand for frequent assembly/disassembly of the structure and installation in hard-to-reach places. The stud may bend and lose strength. The thread often breaks due to heavy loads.

How to decipher steel markings?

To make deciphering the designations of different types of steels easy, you should know well what they are. Certain categories of steel have special markings. They are usually designated by certain letters, which allows you to immediately understand both the purpose of the metal in question and its approximate composition. Let's look at some of these brands and understand their designation.

Properties and purpose of structural alloy steels

Structural steels specially intended for the manufacture of bearings can be recognized by the letter “Ш”; this letter is placed at the very beginning of their marking. After it in the brand name there is a letter designation of the corresponding alloying additives, as well as numbers by which the quantitative content of these additives is determined. Thus, steel grades ShKh4 and ShKh15, in addition to iron and carbon, contain chromium in amounts of 0.4 and 1.5%, respectively.

The letter “K”, which appears after the first digits in the brand name, indicating the quantitative carbon content, denotes structural non-alloy steels used for the production of vessels and steam boilers operating under high pressure (20K, 22K, etc.).

High-quality alloy steels, which have improved casting properties, can be recognized by the letter “L” at the very end of the marking (35ХМЛ, 40ХЛ, etc.).

Deciphering the grades of construction steel can cause some difficulty if you do not know the specifics of the markings. Alloys of this category are designated by the letter “C”, which is placed at the very beginning. The numbers following it indicate the minimum yield strength. These brands also use additional letter designations:

- letter T – heat-strengthened rolled products;

- letter K – steel, characterized by increased corrosion resistance;

- letter D is an alloy characterized by a high copper content (S345T, S390K, etc.).

Unalloyed steels belonging to the tool category are designated by the letter “U”; it is affixed at the beginning of their marking. The number following this letter expresses the quantitative carbon content in the alloy in question. Steels of this category can be high-quality and high-quality (they can be identified by the letter “A”, it is placed at the end of the brand name). Their marking may contain the letter “G”, which means a high content of manganese (U7, U8, U8A, U8GA, etc.).

, containing alloying elements in their composition, are marked similarly to alloyed structural ones (KhVG, 9KhVG, etc.).

Composition of alloy tool steels (%)

The marking of those steels that are included in the high-speed cutting category begins with the letter “P”, followed by numbers indicating the quantitative content of tungsten. Otherwise, brands of such alloys are named according to the standard principle: letters denoting the element, and, accordingly, numbers reflecting its quantitative content. The designation of such steels does not indicate chromium, since its standard content in them is about 4%, as well as carbon, the amount of which is proportional to the vanadium content. If the amount of vanadium exceeds 2.5%, then its letter designation and quantitative content are affixed at the very end of the marking (З9, Р18, Р6М5Ф3, etc.).

The influence of some additives on the properties of steel

Unalloyed steels belonging to the electrical category are marked in a special way (they are also often called pure technical iron). The low electrical resistance of such metals is ensured due to the fact that their composition is characterized by a minimum carbon content - less than 0.04%. There are no letters in the designation of grades of such steels, only numbers: 10880, 20880, etc. The first digit indicates the classification by type of processing: hot-rolled or forged - 1, calibrated - 2. The second digit is associated with the category of the aging coefficient: 0 - non-standardized, 1 - normalized The third digit indicates the group to which this steel belongs according to the standardized characteristic taken as the main one. The value of the standardized characteristic itself is determined from the fourth and fifth digits.

The principles by which the designation of steel alloys is carried out were developed back in the Soviet period, but to this day they are successfully used not only in Russia, but also in the CIS countries. Having information about a particular grade of steel, you can not only determine its chemical composition, but also effectively select metals with the required characteristics.

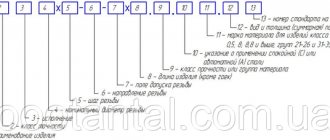

Symbols and markings

All nuts have a symbol; it shows specialists basic information about the products. They are also marked with markings that contain information about the parameters and properties of the hardware.

The symbol is divided into three types:

- complete – all parameters are indicated;

- brief – not very significant characteristics are described;

- simplified - only the most important information.

The designations include the following information:

- type of fastener;

- accuracy and strength class;

- view;

- step;

- thread diameter;

- coating thickness;

- designation of the standard according to which the product was produced.

In addition, the nut is marked to help identify the fastener. It is applied to the end face and, in some cases, to the side face. It contains information about the strength class and the manufacturer's mark.

The inscription is applied by deepening into the surface using a special machine. Information about the manufacturer is indicated in any case, even if there is no strength class. Complete data can be obtained by studying relevant sources. For example, information for high-strength nuts can be found in GOST R 52645-2006. Or in GOST 5927-70 for ordinary ones.

8.2 Hardness test

When inspecting nuts, the hardness test is carried out on one of the supporting surfaces of the nut at three points shifted relative to each other by 120°, and the hardness values are determined as the arithmetic mean of three measurements.

In controversial cases, hardness is checked on a longitudinal section passing through the axis of the nut, at points located as close as possible to the outer diameter of the nut thread.

The Vickers hardness test is decisive and, where possible, a load of 30HV should be applied.

If Brinell and Rockwell tests are used, conversion tables should be used.

Vickers hardness test - according to GOST 2999.

Brinell hardness test - according to GOST 9012.

Rockwell hardness test - according to GOST 9013.

By purpose

Based on their purpose, the following types of bolts can be distinguished:

- Ploughshare – designed for fastening heavy suspended structures. Based on the name, you can understand that it is widely used in agriculture, usually for attaching shares to tillage equipment.

- Furniture - differs from other types in that the thread is not cut along the entire length of the rod. The third part remains the usual integral part. The head of such fasteners is usually smooth, which is necessary so that the bolt does not protrude above the surface of the furniture. Despite the names, such elements are also used in other areas, especially often in construction.

- Road – widely used when installing fences. It is distinguished by a semicircular head, under which there is a square headrest. This design allows the fencing elements to be firmly fixed to the posts. It is used in all areas where there is a need to fix thin sheets of metal, wood, plastic and other materials.

- Mechanical bolts are the most common type of bolts used in mechanical engineering. It is characterized by increased strength properties and resistance to aggressive external environments.

- Track - used in the railway sector, most often for connecting individual parts of the rails. They differ in that the thread can be less than half the length of the rod.

You can understand what type of hardware it is based on the symbol of the bolts.

Modern marking of bolts by strength

The new GOST has changed little both in the arrangement of symbols and in their semantic meaning. At the top we can still see the maker's mark. Next comes the swim number.

The strength class of the hardware is indicated below according to the new GOST. Here you can also find the letter S, which says that we have a high-strength bolt with a hex head with an increased size. The designation of the class of resistance to harmful atmospheric influences also remains. It comes last.

Strength classes

GOST 1759.4−87, depending on the mechanical characteristics of parts, involves dividing these products into eleven categories. The rules for deciphering their designations should not cause serious problems - multiplying the number located in front of the point by 100 allows you to determine such an indicator as the tensile strength of the bolt material. The unit used to measure it is N/mm 2. For example, designation 4.6 assumes that the product has a tensile strength parameter equal to 400 N/mm 2.

Multiplying the second digit by 10 allows you to find out the yield strength parameter (the stress at which the alloy becomes susceptible to plastic deformation). For example, for category 3.6 it will be 60%.

When calculating loads in threaded connections, it is customary to include a certain margin of safety in terms of the yield strength.

Bolts belonging to the group of high-strength products must have a tensile strength of at least 800 MPa. They have found wide application in those industries in which strict reliability requirements are imposed on structures. This group includes all parts starting from category 8.8. High-strength nuts, in turn, should be considered products of class no less than 8.0.

It should be noted that the strength category of threaded parts depends not only on their material, but also on the manufacturing technology. Almost all bolts included in the group of high-strength products are produced by the upsetting method, and special semi-automatic rolling machines are used to form threads. After mechanical processing, the products undergo appropriate heat treatment. The final stage in the production of high-strength bolts is coating.

The technological equipment used to produce parts using the upsetting method is very diverse. There are models capable of producing about 200 units of product in one minute. The main material for their production is low-carbon and alloy steel alloys. The main requirement for them is the amount of carbon. According to the documentation, this parameter should not exceed 40%.

An excellent example of such materials can be steel 20KP, 40Kh, 20G2R and others. Thanks to the use of various types of heat treatment, it is possible to produce parts belonging to different strength categories from one material. As an example, it is worth considering steel 35, from which the following products can be made:

- 5.6 - achieved by processing the product on lathes and milling machines.

- 6.6, 6.8 - volumetric stamping.

- 8.8 - after machining, the product is subjected to hardening.

The classification of high-strength bolts involves the presence of highly specialized products used in certain industries. All their characteristics are described in special regulatory documentation. And also highly specialized bolts may differ in design options, which are designated by letters:

- U - indicates the possibility of using the fastening element at temperatures down to -40 °C. It is worth noting that the letter is most often not indicated in the designation.

- HL - temperature conditions are more stringent, and this product can be used at -65 °C.

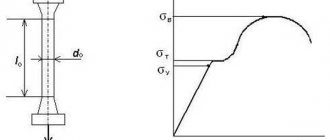

What is yield strength and how to determine it

The yield strength σт is the critical load on a detachable connection, at which an irreversible process of destruction of the structure occurs without increasing the acting force.

The parameter is affected by temperature. As it increases, σt decreases.

There are 2 formulas to calculate the indicator:

- For temporary tensile strength: the 1st digit in the designation of the strength class is multiplied by 100, then multiplied by the 2nd digit, the result is divided by 10. So, for hardware of group 5.8 σt=400 MPa (5x100x8:10=400).

- By strength class: the 1st and 2nd digits are multiplied by each other, then by 10. For category 5.8: σt=400 MPa (5x8x10=400).

The yield strength is the critical load on a detachable joint.

The higher the yield strength, the longer the part is able to remain in a state of tension and resist dynamic and stationary forces. When selecting fasteners, a 2- or 3-fold safety factor is taken into account.

What classes are there?

Strength classes for nuts are approved in GOST 1759.5-87, which is currently not relevant. But its analogue is the international standard ISO 898-2-80, which is what manufacturers all over the world are guided by. This document applies to all nuts with metric threads, except fasteners:

- with special parameters (work in conditions of extreme temperatures - 50 and +300 degrees Celsius, with high resistance to corrosion processes);

- self-locking and locking type.

In accordance with this standard, nuts are divided into two groups.

- With a diameter of 0.5 to 0.8 mm. Such products are called “low” and are used in places where high loads are not expected. Basically, they protect nuts with a height of more than 0.8 diameters from unwinding. Therefore, they are made from low-quality low-carbon steel. For such products there are only two strength classes (04 and 05), and they are designated by a two-digit number. Where the first says that this product does not support a force load, and the second shows one hundredth of the force at which the thread can break.

- With a diameter of 0.8 or more. They can be of normal height, high and especially high (H≈0.8d; 1.2d and 1.5d, respectively). Fasteners above 0.8 diameter are designated by a single number, which indicates the highest degree of reliability of the bolts with which the nut can be connected. There are seven strength classes in total for nuts of the high group – that’s 4; 5; 6; 8; 9; 10 and 12.

The regulatory document specifies the rules for selecting nuts to bolts according to strength level. For example, with a class 5 nut, it is recommended to use a bolt cross-section less than or equal to M16 (4.6; 3.6; 4.8), less than or equal to M48 (5.8 and 5.6). But in practice, it is advised to replace products with a low level of strength with a higher one.

8.1 Proof load test

A proof load test should be carried out whenever the testing equipment used allows, and this test is decisive for nuts with a thread diameter of M5 and larger.

The nut is screwed onto a hardened mandrel, as shown in Figures 1 and 2. In cases of dispute, the tensile test is decisive (see Figure 1).

1) D11 - according to GOST

25346

Figure 1 - Axial tensile test

Figure 2 - Axial compression test

The test load is applied to the nut in the axial direction and held for 15 s. The nut must withstand the load without breaking or stripping the thread and can be unscrewed by hand after the load is removed. If the thread of the mandrel is damaged during the test, the test is considered invalid. When unscrewing a nut, it is permissible to use a wrench to turn the nut 1/2 turn, and then it must be unscrewed by hand.

The hardness of the test mandrel must be at least 45 HRC.

The tolerance field of the mandrel thread is 5h6g, with the exception of the tolerance of the outer diameter of the thread, which should be 1/4 of the tolerance field 6g in its lower part.

Manufacturing technology

In the modern world, several technologies are used to make nuts. Some of them are used to produce large quantities of fasteners with a minimum amount of scrap and optimal consumption of materials. The process occurs virtually without human intervention, automatically. The main methods for producing nuts in large volumes are cold stamping technology and hot forging.

Cold stamping

It is a fairly progressive technology that allows the mass production of fasteners with small losses of no more than 7% of the total number of products. Special automated machines allow you to produce up to 400 products within a minute.

Stages of manufacturing fasteners using cold technology.

- Rods are prepared from the required type of steel. Before processing, they are cleaned of rust or foreign deposits. Phosphates and a special lubricant are then applied to them.

- Slicing. Metal blanks are placed in a special mechanism and cut into pieces.

- The nut blanks are cut off using a movable cutting mechanism.

- Stamping. After all the previous manipulations, the blanks are sent to a hydraulic stamping press, where they are shaped and a hole is punched.

- The final stage. Cutting threads inside parts. This operation is carried out on a special nut-threading machine.

After completing the work, some nuts from the batch must be checked for compliance with the parameters specified in advance. These are the dimensions, thread and maximum load that the product can withstand. To produce hardware using this technology, a certain steel intended for cold stamping is used.

Hot forging

The hot technology for producing nuts is also very common. The raw materials for the production of hardware using this method are also metal rods, cut into pieces of the required length.

The main stages of production are as follows.

- Heat. Cleaned and prepared rods are heated to a temperature of 1200 degrees Celsius so that they become plastic.

- Stamping. A special hydraulic press forms hexagonal blanks and punches a hole inside them.

- Thread cutting. The products are cooled and threads are applied inside the holes. For this, rotating rods resembling taps are used. To facilitate the process and prevent rapid wear during cutting, machine oil is supplied to the parts.

- Hardening. If products require increased strength, they are hardened. To do this, they are heated again to a temperature of 870 degrees Celsius, cooled at high speed and immersed in oil for about five minutes. These actions harden the steel, but it becomes brittle. To get rid of fragility while maintaining strength, hardware is kept in an oven at high temperature (800-870 degrees) for about an hour.

After all processes are completed, the nuts are checked on a special stand to ensure they meet the strength requirements. After inspection, if the hardware passes it, they are packaged and sent to the warehouse. The production facilities still have outdated equipment in need of repair and maintenance work. To produce fasteners for such equipment, lathes and milling machines are used. However, such work is characterized by very low productivity and huge consumption of materials. But they are needed in any case, and therefore for small batches of fasteners this technology still remains relevant.

See the following video for the process of making nuts and other hardware.

Connecting bolts using threads

Thread classification:

- metric;

- inch;

- cylindrical pipe;

- conical;

- rectangular;

- trapezoidal;

- persistent;

- standardized round.

Metric thread is the main type of threaded connection. Its parameters are the nominal diameter and thread pitch in millimeters, established by GOST 8724-81.

Connecting bolts using threads is reliable and technologically advanced.

Advantages:

- reliability;

- multifunctionality;

- manufacturability;

- the ability to adjust the compression force;

- availability of a wide range of products.

Disadvantage: tendency to self-unscrew.

Material

The strength of the fastening element is one of the most important parameters characterizing hardware. The strength of the fastening directly depends on the type of material from which it is made. Depending on the strength characteristics, the metal for production and the mode of its heat treatment are selected.

Most often, standard bolts are made of alloy and non-alloy steel. But in some cases they can be made of other metals, such as copper, aluminum, which are used in cases where there is no need to achieve high fastener strength. For jewelry making, fasteners can be made from precious metals such as gold, silver and others.

Very often, to improve the technical characteristics of hardware, a special coating is used that protects the fastening element from environmental influences (humidity, water, temperature range, chemicals).

Among the most common coatings are the following varieties:

- Zinc. The thickness of the zinc coating can vary depending on the requirements. For bolts used in household appliances, the thickness is usually small. But for industrial fasteners it is usually up to 25 microns.

- Cadmium-plated. Not a very common type of bolt, due to the toxic properties of cadmium. Therefore, they are used in rare cases when coatings made of other materials do not allow achieving the desired performance characteristics.

- Nickel. Typically used for fasteners used in furniture production. Nickel only improves decorative characteristics and practically does not change operational characteristics.

- Phosphating and oxidation. They are used to create a protective layer on the surface of bolts due to oxidation of the base metal.

- Zinc lamellar. They are becoming widespread because they can increase the service life of fasteners several times.

Application depending on coating and materials of bolts DIN 933

Bolts are made primarily from 20 and 35 steel, as are many other metal fasteners.

The galvanized bolt DIN 933 is widely used as it has a sufficient anti-corrosion protective layer. In conditions of high humidity or special operating conditions, appropriate fasteners should be used.

Galvanized Bolts

| High strength bolts | ⇒ | bridge and metro construction, road structures, high-rise construction |

| Stainless steel bolts | ⇒ | A2: coastal structures; A4: acidic environments (food industry, medical facilities) |

| Galvanized Bolts | ⇒ | cadmium at high humidity “sea, river” |

| ⇒ | brass plumbing, electrical structures; requirements for decorative qualities | |

| ⇒ | chrome requirements for decorative qualities | |

| ⇒ | copper any heating devices (tanks, boilers) | |

| Hot-dip galvanized bolts | ⇒ | for internal and external construction work |

| Bolts with thermal diffusion zinc coating | ⇒ | operation of industrial facilities |

According to the shape of the heads

Given the variety of bolts and their designs, there is an additional classification. Depending on the shape of the head, the following are distinguished:

- Universal (hex head) is the most common type and can be tightened using regular wrenches. It is used in almost all areas; most often this type can be found in mechanical engineering and construction.

- Anchor - a special type that is used for fastening heavy elements. These bolts come in a wide variety of shapes and sizes. Typically used in construction for the installation of window frames, doorways, suspended ceilings and lamps.

- An eye bolt is a high-strength fastener that has a fastening ring instead of a head. This design allows you to lift large loads. Some models provide a hinged ring, which allows it to rotate freely on the base.

- With a semicircular head - often used in the production of furniture and installation of fences.

- With a countersunk head - usually used in radio engineering and electrical engineering. After tightening, the bolt head does not protrude above the surface; the bolt head is completely flat and has internal slots for tightening with a screwdriver. The diameter of the head is not much larger than the diameter of the rod.

- Headless Bolt - This type does not have a part called the head, the drive slots are cut directly into the shank.

Similarities and differences between DIN 931 and DIN933 standards

Standards DIN 931 and DIN 933 are the closest analogues of GOST 7805 and GOST 7798, respectively. However, there is one important aspect here. As you know, each domestic standard normalizes the production of bolts of only one precision level. So, the first of the above is valid for class “A” fasteners, and the second is for fasteners made with accuracy corresponding to class “B”. In German regulatory documents the situation in this regard is somewhat different.

- The requirement to produce bolts with accuracy class “A” applies to products with threads up to M24 and a length not exceeding 150 mm.

- The dimensional characteristics of such fasteners must meet the requirements of class “B” if their thread diameter is greater than M24 and their length exceeds 150 mm.

There are also differences in the limit values of the thread diameter. It was said above that GOST 7805 has more nomenclature items compared to GOST 7798 due to the addition of seven diameters, the size of which is less than 6 mm (minimum -1.6 mm). And the upper values of this indicator are identical – M48.

In German standards, everything looks exactly the opposite. That is, the minimum thread there is the same - M1.6, but the maximum is different. In DIN 931 it is M39, and in DIN 933 it is M52. Accordingly, all maximum values of other parameters, starting from the height of the head and ending with the holes in the rod, also differ.